Professional Documents

Culture Documents

7-Mbe900-04a Inyector

Uploaded by

Gerson AquinoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7-Mbe900-04a Inyector

Uploaded by

Gerson AquinoCopyright:

Available Formats

MBE 900 SERVICE MANUAL

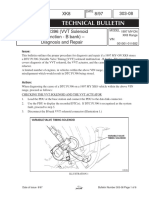

5. Attach the adapter J 46384 and impact extractor J 46375. Thread the narrow end of the

adaptor onto the internal threading in the head of the nozzle holder. Thread the impact

extractor onto the wide end of the adaptor. See Figure 2-8.

NOTE:

Do not attempt to take apart the nozzle holder. If there is a problem, replace the nozzle

holder.

6. Using the impact extractor, pull out the nozzle holder.

7. Remove the impact extractor and adaptor from the nozzle holder.

8. Take the heat isolator off the nozzle holder. See Figure 2-9. Discard the old O-ring.

1. Nozzle Holder 4. Transfer Tube

2. Heat Isolator 5. Thrust Bolt

3. O-ring

Figure 2-9 Heat Isolator Removal

All information subject to change without notice. (Rev. 2004)

6SE414 0404 Copyright © 2004 DETROIT DIESEL CORPORATION From Bulletin 7-MBE900-04 2-15

2.3 NOZZLE HOLDER

2.3.2 Nozzle Holder Installation

Install the nozzle holder as follows:

1. Lubricate the new O-ring with a light coat of grease and install it on the nozzle holder.

2. Using the heat isolator installer J 46393, press the new heat isolator onto the nozzle.

[a] Position the new heat isolator over the nozzle.

[b] Place the receptacle from the heat isolator installer over the head of the nozzle holder

and the pressure-fit cap over the heat isolator. See Figure 2-10 and see Figure 2-11.

Figure 2-10 Heat Isolator Installer Components (J 46393)

(Rev. 2004) All information subject to change without notice.

2-16 From Bulletin 7-MBE900-04 6SE414 0404 Copyright © 2004 DETROIT DIESEL CORPORATION

MBE 900 SERVICE MANUAL

[c] Place this entire assembly in a vise and close the vise enough to pressure-fit the heat

isolator around the nozzle. See Figure 2-11.

1. Nozzle 3. Nozzle Holder

2. Heat Isolator 4. Vise

Figure 2-11 Pressure-Fitting the Heat Isolator onto the Nozzle

[d] Open the vise and remove the two parts of the heat isolator installer from the nozzle

holder. Check that the heat isolator is firmly pressed onto the nozzle.

NOTE:

Take care that the nozzle holder is installed correctly and is aligned properly with respect

to the transfer tube.

All information subject to change without notice. (Rev. 2004)

6SE414 0404 Copyright © 2004 DETROIT DIESEL CORPORATION From Bulletin 7-MBE900-04 2-17

2.3 NOZZLE HOLDER

3. Install the nozzle holder. See Figure 2-12.

1. Nozzle Holder 4. Retaining Bolt

2. Tensioning Arm 5. Interference-Fit Ball

3. End Cover (constant throttle valve)

Figure 2-12 Nozzle Holder Installation

[a] Use the tensioning arm to turn the nozzle holder until the interference-fit ball in the

tensioning arm lines up with the locating element in the end cover of the constant

throttle valve.

[b] Tighten the retaining bolt on the tensioning arm 30 N·m (22 lb·ft) for the recessed

hex head bolt and 35 N·m (26 lb·ft) for the 12-point bolt with the spherical collar.

4. Lubricate the new O-ring with a light coat of grease and install it on the transfer tube.

NOTE:

Take care that the interference-fit ball on the transfer tube fits into the slot in the cylinder

head.

(Rev. 2004) All information subject to change without notice.

2-18 From Bulletin 7-MBE900-04 6SE414 0404 Copyright © 2004 DETROIT DIESEL CORPORATION

You might also like

- MBE900 Nozzle Holder PDFDocument5 pagesMBE900 Nozzle Holder PDFJosue Alvarez VegaNo ratings yet

- (Rev. A) Hot Injection Adapter KitDocument8 pages(Rev. A) Hot Injection Adapter KitLost LionNo ratings yet

- 303-08 P1396 RepairDocument6 pages303-08 P1396 Repairmarcelo ustarezNo ratings yet

- Cylinder Head: SpecificationsDocument5 pagesCylinder Head: SpecificationsFares100% (1)

- 2008-10-13 115103 91 CamryDocument5 pages2008-10-13 115103 91 CamryWilmer PerezNo ratings yet

- Epa07 Mbe 900 Workshop Manual (Ddc-Svc-Man-0034)Document155 pagesEpa07 Mbe 900 Workshop Manual (Ddc-Svc-Man-0034)Jose Amador Guardado100% (3)

- Heater Replacement Instructions For Point Gate and Thru Hole TipsDocument2 pagesHeater Replacement Instructions For Point Gate and Thru Hole TipsEsteban Vanegas AlvarezNo ratings yet

- Overhaul: Heater & Air ConditionerDocument4 pagesOverhaul: Heater & Air ConditionerIcaro FerreiraNo ratings yet

- Overhaul: Heater & Air ConditionerDocument4 pagesOverhaul: Heater & Air ConditionerCoco LinoNo ratings yet

- Boletim Tecnico - JF016 - Re0f10dDocument9 pagesBoletim Tecnico - JF016 - Re0f10dautomaticosbrasilNo ratings yet

- Instructions: Headlamp Visor KitDocument2 pagesInstructions: Headlamp Visor KitPaco JonesNo ratings yet

- Ss AFFECTED PRODUCT 3508BDocument13 pagesSs AFFECTED PRODUCT 3508Bjoalca31No ratings yet

- Culata Motor 3406Document3 pagesCulata Motor 3406Julio GuillenNo ratings yet

- Cylinder Head InstallDocument6 pagesCylinder Head Installboosterdaily16No ratings yet

- InstallationDocument4 pagesInstallationEdson CRNo ratings yet

- Cylinder Head Gasket - Installation (08 - 2013 - ) (Cylinder Head Assembly) - Toyota Sienna 3.5ltsDocument8 pagesCylinder Head Gasket - Installation (08 - 2013 - ) (Cylinder Head Assembly) - Toyota Sienna 3.5ltsFran SanchezNo ratings yet

- Engine Disassembly Assembly 1Document9 pagesEngine Disassembly Assembly 1Moaed KanbarNo ratings yet

- Cuidados Instalacion Bobina Motor EcotecDocument2 pagesCuidados Instalacion Bobina Motor Ecotecflash_24014910No ratings yet

- M - Fi - 0025 Fuel InjectorDocument2 pagesM - Fi - 0025 Fuel InjectorhugocarbouNo ratings yet

- Patg Pamg Turbo PartsDocument12 pagesPatg Pamg Turbo Parts1luckywolf0% (1)

- ConrodDocument4 pagesConrodIrwanto ManafNo ratings yet

- Pistons and Connecting RodsDocument6 pagesPistons and Connecting Rodsma.powersourceNo ratings yet

- 777D Liner Projection UpdateDocument4 pages777D Liner Projection UpdateAplesNo ratings yet

- Engine Cooling Upgrade Kit RIVA RACINGDocument11 pagesEngine Cooling Upgrade Kit RIVA RACINGMaxence De FilippiNo ratings yet

- Item Standard Value Limit Value Valve Sinkage - 0.1 To 0.1 MM (-0.004 To 0.004 In.) 0.5 MM (0.020 In.)Document11 pagesItem Standard Value Limit Value Valve Sinkage - 0.1 To 0.1 MM (-0.004 To 0.004 In.) 0.5 MM (0.020 In.)pearl nojokeNo ratings yet

- Sis 2.0Document3 pagesSis 2.0Rui ArezesNo ratings yet

- Cylinder Head Assembly: Service and Repair Removal and InstallationDocument2 pagesCylinder Head Assembly: Service and Repair Removal and InstallationJose Pichinte100% (1)

- Installation Procedure: NoticeDocument5 pagesInstallation Procedure: Noticerakhikishore143No ratings yet

- Valvulas 02Document7 pagesValvulas 02Janderson LacerdaNo ratings yet

- InstallationDocument2 pagesInstallationEdson CRNo ratings yet

- Service Buletin 07-2965DDocument29 pagesService Buletin 07-2965DAgustinus KNo ratings yet

- Tier 4 I E E A I Manual C4.4 To C 7.1 Industrial Products TPD1726E1Document29 pagesTier 4 I E E A I Manual C4.4 To C 7.1 Industrial Products TPD1726E1EduardoCastilloNo ratings yet

- Torque Converter - Install (RENR3366-07)Document5 pagesTorque Converter - Install (RENR3366-07)connor.millsNo ratings yet

- VW 3VWLN6161CM082257 AllSystemDTC 20221028150536Document9 pagesVW 3VWLN6161CM082257 AllSystemDTC 20221028150536hitecNo ratings yet

- Engine Unit Reassembly-1Document33 pagesEngine Unit Reassembly-1Mr KayNo ratings yet

- RENR492704Document3 pagesRENR492704Victor NoschangNo ratings yet

- 1001 12 PDFDocument26 pages1001 12 PDFTuấn NeoNo ratings yet

- 12165-70 - 1 Sundry Instr.Document328 pages12165-70 - 1 Sundry Instr.kodrysNo ratings yet

- Installation: Using A Riveter, Install The Fuel Filler Opening Lid With The 2 Rivets To The BodyDocument3 pagesInstallation: Using A Riveter, Install The Fuel Filler Opening Lid With The 2 Rivets To The BodyMoh DeBrNo ratings yet

- Fitting Instructions: Anti-Condensation Heaters, HC 4, 5, 6 & P7Document4 pagesFitting Instructions: Anti-Condensation Heaters, HC 4, 5, 6 & P7HanNo ratings yet

- CylindersDocument9 pagesCylindersvencyNo ratings yet

- Specifications Culender Head 3512 CatDocument16 pagesSpecifications Culender Head 3512 CatAngel Theran Pardo75% (4)

- Instalasin Jacketed Tubing (MS-CRD-ITUB)Document7 pagesInstalasin Jacketed Tubing (MS-CRD-ITUB)herysyam1980No ratings yet

- Mecanismo de Valvulas D7EDocument7 pagesMecanismo de Valvulas D7ELizandro Brito100% (1)

- 819-6043 Jul 08Document4 pages819-6043 Jul 08kudatroya43No ratings yet

- Fuel SistemDocument55 pagesFuel SistemRodolfo AlbertoNo ratings yet

- ENGINE Timing 4ZZ-FEDocument31 pagesENGINE Timing 4ZZ-FEAriel100% (1)

- 3Document6 pages3George GuerreroNo ratings yet

- Struers Prestopress3 Embedded PressDocument23 pagesStruers Prestopress3 Embedded PressnarutomovieNo ratings yet

- Pistons and Connecting Rod AssembliesDocument7 pagesPistons and Connecting Rod AssembliesnobodymagdesignNo ratings yet

- Cold Start BlockDocument3 pagesCold Start BlockPurga GTNo ratings yet

- 19d Impeller SpacingDocument9 pages19d Impeller Spacingbtgottlieb100% (1)

- Tc920 ManualDocument3 pagesTc920 ManualJuliao MatosNo ratings yet

- MBE4000 EGR Connector Pipe InstallationDocument6 pagesMBE4000 EGR Connector Pipe InstallationАндрейNo ratings yet

- Kit de Instalación 1250RO-4 para OL500 SeriesDocument1 pageKit de Instalación 1250RO-4 para OL500 SeriesHarold VasquezNo ratings yet

- 2100103-Tilt CylindersDocument17 pages2100103-Tilt CylindersFrancisco DiazNo ratings yet

- Toyota Hilux 2019Document10 pagesToyota Hilux 2019mauricio9378No ratings yet

- Enp JW11-72.5-300Document14 pagesEnp JW11-72.5-300chengkkNo ratings yet

- Engine SystemsDocument197 pagesEngine Systems0128 Nguyễn Thanh BìnhNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- MBE CodesDocument9 pagesMBE CodesPedro AparicioNo ratings yet

- Detroit Diesel Guia Del Tecnico MBE EGR 900 920 y 4000 PDFDocument122 pagesDetroit Diesel Guia Del Tecnico MBE EGR 900 920 y 4000 PDFGerson AquinoNo ratings yet

- Mercedes Benz Brocure Mb900Document16 pagesMercedes Benz Brocure Mb900ramsi17No ratings yet

- Pro-Shift™ 7-Speed Transmissions ModelsDocument2 pagesPro-Shift™ 7-Speed Transmissions ModelsGerson AquinoNo ratings yet

- Mb900 Trouble GuideDocument427 pagesMb900 Trouble GuideCarlos Chzs100% (10)

- 8-Mbe900-05a Rociadores de AceiteDocument4 pages8-Mbe900-05a Rociadores de AceiteGerson AquinoNo ratings yet

- 7.1 Exhaust Manifold: The Following Procedures Describe The Removal and Installation of The Exhaust ManifoldDocument6 pages7.1 Exhaust Manifold: The Following Procedures Describe The Removal and Installation of The Exhaust ManifoldGerson AquinoNo ratings yet

- Mb900 Trouble GuideDocument427 pagesMb900 Trouble GuideCarlos Chzs100% (10)

- Detroit Diesel, Guía Del Técnico, MBE EGR 900, 920 y 4000Document122 pagesDetroit Diesel, Guía Del Técnico, MBE EGR 900, 920 y 4000Dino Martin Mercado Quispe100% (18)

- 3 MBE900 04aDocument10 pages3 MBE900 04aJorge A Salinas100% (1)

- 4-MBE900-04a Compresor EgrDocument36 pages4-MBE900-04a Compresor EgrGerson AquinoNo ratings yet

- 2-MBE900-04a (1) Sistema de Lubricaciode AceiteDocument30 pages2-MBE900-04a (1) Sistema de Lubricaciode AceiteGerson AquinoNo ratings yet

- MBE4000 Serv ManDocument587 pagesMBE4000 Serv ManRicardo Diaz95% (20)

- 5 MBE900 04aDocument36 pages5 MBE900 04aRoger Lechado Garcia100% (1)

- 3 MBE900 04aDocument10 pages3 MBE900 04aJorge A Salinas100% (1)

- Arnes m2 106 ELECTRICODocument8 pagesArnes m2 106 ELECTRICOGerson Aquino100% (1)

- Detroit Diesel, Guía Del Técnico, MBE EGR 900, 920 y 4000Document122 pagesDetroit Diesel, Guía Del Técnico, MBE EGR 900, 920 y 4000Dino Martin Mercado Quispe100% (18)

- Ajuste Valvulas e Inyectores DetroitDocument6 pagesAjuste Valvulas e Inyectores DetroitGabriel Duarte100% (19)

- 4-MBE900-04a Compresor EgrDocument36 pages4-MBE900-04a Compresor EgrGerson AquinoNo ratings yet

- 1 Mbe900 05aDocument166 pages1 Mbe900 05aAlex Robledo Olarte100% (2)

- DDC SVC BRO 0001 - 2014r1Document35 pagesDDC SVC BRO 0001 - 2014r1Gerson AquinoNo ratings yet

- 5 MBE900 04aDocument36 pages5 MBE900 04aRoger Lechado Garcia100% (1)

- Bulkheat Modulos m2 106Document30 pagesBulkheat Modulos m2 106Gerson Aquino67% (3)

- AXOR - Specifications PDFDocument18 pagesAXOR - Specifications PDFenzo7259No ratings yet

- Softwar Del DDC Vcu Freihliner 2005Document84 pagesSoftwar Del DDC Vcu Freihliner 2005Gerson AquinoNo ratings yet

- 2007 MBE900 SpecsDocument2 pages2007 MBE900 SpecsGerson AquinoNo ratings yet

- m2 Business Class LightsDocument43 pagesm2 Business Class LightsNadie EN AbsolutoNo ratings yet

- In Truth To Mollusca According To New Studies by J RutherfordDocument4 pagesIn Truth To Mollusca According To New Studies by J RutherfordbalaiNo ratings yet

- The Explanation of The Fundamentals of Islamic BeliefDocument95 pagesThe Explanation of The Fundamentals of Islamic BeliefbooksofthesalafNo ratings yet

- Catalogue: Packer SystemDocument56 pagesCatalogue: Packer SystemChinmoyee Sharma100% (1)

- Food Poisoning: VocabularyDocument9 pagesFood Poisoning: VocabularyHANG WEI MENG MoeNo ratings yet

- MX 400Document231 pagesMX 400Percy JimenezNo ratings yet

- Mechanical Advantage HomeworkDocument8 pagesMechanical Advantage Homeworkafeurbmvo100% (1)

- Leaflet CycleManager Ep CycleManager ErDocument7 pagesLeaflet CycleManager Ep CycleManager ErValeska ArdilesNo ratings yet

- Organic Chemistry (Some Basic Principles and TechniquesDocument30 pagesOrganic Chemistry (Some Basic Principles and TechniquesNaveen SharmaNo ratings yet

- Movimiento Circular, Momentun Lineal y EnergíaDocument92 pagesMovimiento Circular, Momentun Lineal y EnergíaJulio César Macías ZamoraNo ratings yet

- Monk - Way of The Elements RevisedDocument3 pagesMonk - Way of The Elements Revisedluigipokeboy0% (1)

- Genie Z45/22Document58 pagesGenie Z45/22jonny david martinez perezNo ratings yet

- Visedo FPC-2016Document13 pagesVisedo FPC-2016Probonogoya Erawan SastroredjoNo ratings yet

- Menstrupedia Comic: The Friendly Guide To Periods For Girls (2014), by Aditi Gupta, Tuhin Paul, and Rajat MittalDocument4 pagesMenstrupedia Comic: The Friendly Guide To Periods For Girls (2014), by Aditi Gupta, Tuhin Paul, and Rajat MittalMy Home KaviNo ratings yet

- Advanced Steel Structure Concepts: 2 MonthsDocument4 pagesAdvanced Steel Structure Concepts: 2 MonthsAnkit SoniNo ratings yet

- Daphne Alpha Cleaner Series: Lubricant Product InformationDocument2 pagesDaphne Alpha Cleaner Series: Lubricant Product InformationChart ChNo ratings yet

- Deva Surya - 19MF02Document30 pagesDeva Surya - 19MF02SaravananNo ratings yet

- Smart Locker - A Sustainable Urban Last-Mile Delivery Solution: Benefits and Challenges in Implementing in VietnamDocument14 pagesSmart Locker - A Sustainable Urban Last-Mile Delivery Solution: Benefits and Challenges in Implementing in VietnamQuynh LeNo ratings yet

- Icpc11 - Thermodynamics and Fluid MechanicsDocument22 pagesIcpc11 - Thermodynamics and Fluid MechanicsAPARNANo ratings yet

- Metageographies of Coastal Management: Negotiating Spaces of Nature and Culture at The Wadden SeaDocument8 pagesMetageographies of Coastal Management: Negotiating Spaces of Nature and Culture at The Wadden Seadwi kurniawatiNo ratings yet

- Into The Unknown 21 Doc PDFDocument9 pagesInto The Unknown 21 Doc PDFFernando AlbuquerqueNo ratings yet

- Model: P660 Series: Differential Pressure Gauge With Diaphragm ElementDocument6 pagesModel: P660 Series: Differential Pressure Gauge With Diaphragm ElementTÀi VÕNo ratings yet

- Smart Watch User Manual: Please Read The Manual Before UseDocument9 pagesSmart Watch User Manual: Please Read The Manual Before Useeliaszarmi100% (3)

- Sams Practical Transistor Theory 1964Document132 pagesSams Practical Transistor Theory 1964BillNo ratings yet

- Working at Heights GuidelineDocument15 pagesWorking at Heights Guidelinechanks498No ratings yet

- Coca ColaDocument50 pagesCoca Colamariyha PalangganaNo ratings yet

- Digital Trail Camera: Instruction ManualDocument20 pagesDigital Trail Camera: Instruction Manualdavid churaNo ratings yet

- Nammiaca 000032Document5,323 pagesNammiaca 000032gangadhark196No ratings yet

- Master Key Utbk Saintek 2022 (Paket 3) Bahasa InggrisDocument5 pagesMaster Key Utbk Saintek 2022 (Paket 3) Bahasa InggrisRina SetiawatiNo ratings yet

- XC24M MG DatasheetDocument3 pagesXC24M MG DatasheetAbdulJawad Ibrahim ElmezoghiNo ratings yet

- Art and Geography: Patterns in The HimalayaDocument30 pagesArt and Geography: Patterns in The HimalayaBen WilliamsNo ratings yet