Professional Documents

Culture Documents

Sis 2.0

Uploaded by

Rui ArezesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sis 2.0

Uploaded by

Rui ArezesCopyright:

Available Formats

2001/06/01 Cylinder Head Assembly (SENR1029-01)

SMCS - SENR10290027

Remove Cylinder Head Assembly 1100-011

Start By:

PIP

a. remove rocker shaft assemblies and push rods

-10

202 858

b. remove water temperature regulator

2 5

c. remove aftercooler housing

d. remove fuel injection lines

04: /0 3 3 6

e. remove exhaust manifold

03: 30 /

SEN 39+

R 0

© 2 102 1:00

0 2 2C 9

Cat

ater

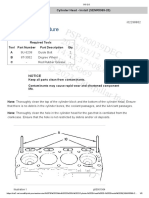

Typical Example

erp

1. Remove bolts (1) from the alternator bracket.

Con illa pill

2. Remove the bolts that hold plate (3) and remove the plate.

fide r: ar I

3. Disconnect water line (2) from the air compressor.

nc.

ntia

NOTE: Turn the water line tee toward the lifting bracket in order to provide clearance to remove the head bolt.

lG

ree

n

4. Remove bolts (4) and (5) that hold the cylinder head assembly to the cylinder block.

5. Fasten a hoist and remove the cylinder head assembly. The weight is approximately 135 kg (300 lb).

NOTICE

Do not put the cylinder head assembly down on a flat surface.

This can cause damage to the fuel injection valves.

6. Remove the gasket and seals from the spacer plate.

Install Cylinder Head Assembly 1100-012

NOTE: Be sure a new gasket has been installed between the spacer plate and the cylinder block. See the topic, "Remove &

Install Spacer Plate."

1. Thoroughly clean the spacer plate and the bottom surface of the cylinder head assembly. Install a new head gasket, new seals

(1) and two O-ring seals (2).

PIP

-10

2. Fasten a hoist and put the cylinder head assembly (3) in position on the cylinder block.

202 858

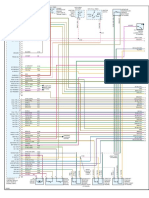

3. Tighten the bolts in sequence shown in illustration D11970.

04: 2 /0 5 3 6

03: 3 /3 0

SEN 39+

R 0

© 2 102 1:00

0 2 2C 9

Cat

erp ater

Con illa pill

(1) Large bolts (3/4 inch). Put 6V-4876 Molycoat Paste Lubricanton bolt threads and between washers and underside of bolt heads. (2) Small bolts (3/8 inch).

See Step 4h.

fide r: ar I

4. Install the cylinder head bolts and washers. Tighten the bolts in sequence shown.

ntia nc.

a. Tighten bolts 1 through 14 in number sequence to 270 ± 25 N·m (200 ± 20 lb ft).

b. Tighten bolts 1 through 14 in number sequence to 470 ± 20 N·m (345 ± 15 lb ft).

lG

ree

c. Tighten bolts 1 through 14 in number sequence again to 470 ± 20 N·m (345 ± 15 lb ft).

n

d. Install the rocker arm shafts for the engine valves and the remaining (3/4 in) bolts and/or compression brake studs.

e. Tighten bolts 15 through 26 in number sequence to 270 ± 25 N·m (200 ± 20 lb ft).

f. Tighten bolts 15 through 26 in number sequence to 450 ± 20 N·m (330 ± 15 lb ft).

g. Tighten bolts 15 through 26 in number sequence again to 450 ± 20 N·m (330 ± 15 lb ft).

h. Tighten the thirteen small bolts (2) to 45 ± 7 N·m (33 ± 5 lb ft).

4. Make an adjustment to the valves to have a clearance of 0.38 mm (.015 in)for intake and 0.76 mm (.030 in)for exhaust.

Tighten the locknuts for the valve adjustment screws to a torque of 28 ± 4 N·m (21 ± 3 lb ft).

Typical Example

5. Install plate (4).

6. Connect the water line to the air compressor.

7. Install bolts (5) for the alternator bracket.

End By:

a. install exhaust manifold

b. install fuel injection lines

c. install aftercooler housing.

d. Install water temperature regulator

PIP

e. install rocker shaft assemblies and push rods

-10

1DL1-UP, 2KR1-UP, 2SR1-UP, 2XS1-UP, 2YR1-UP, 3RR1-UP, 4SK1-UP, 4SN1-UP, 5EW1-UP, 5GR1-UP, 5JK1-UP, 5SG480-UP, 5ZS1-UP,

202 858

6BK1-UP, 6RN1-UP, 7FS1-UP, 7LN1-UP, 7XM1-UP, 8PL1-UP, 9CM1-UP, 9EM1-UP, 9LR1-UP, BXL1-UP, MEJ1-UP, RJM1-UP, T5X1-UP

PIP-10858536

04: 2 /0 5 3 6

2022/03/30

04:03:06+01:00

SENR10290027

03: 30 3 /

© 2022 Caterpillar Inc.

SEN 39+

0

Caterpillar:

Confidential Green

R

© 2 102 1:00

022 9

Cat

erp

illa

r In

c.

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Culata Motor 3406Document3 pagesCulata Motor 3406Julio GuillenNo ratings yet

- Torque Converter - Remove (RENR3366-07)Document5 pagesTorque Converter - Remove (RENR3366-07)connor.millsNo ratings yet

- Rocker Shaft Assembly and Push RodsDocument3 pagesRocker Shaft Assembly and Push Rodsma.powersourceNo ratings yet

- Cylinder Head InstallDocument6 pagesCylinder Head Installboosterdaily16No ratings yet

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulDocument26 pagesPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- Installation Procedure: NoticeDocument5 pagesInstallation Procedure: Noticerakhikishore143No ratings yet

- Ripper Tilt Cylinder - Remove and Install (RENR2054-04)Document8 pagesRipper Tilt Cylinder - Remove and Install (RENR2054-04)connor.millsNo ratings yet

- Transmission Valve Body Assy (Hilux (Tasa Made For Argentina) )Document5 pagesTransmission Valve Body Assy (Hilux (Tasa Made For Argentina) )Michael MarshallNo ratings yet

- Removal: CH-7 SR-24Document3 pagesRemoval: CH-7 SR-24Boncu BoncuNo ratings yet

- Transmission, Transfer Gears, and Differential - Remove (RENR3366-07)Document7 pagesTransmission, Transfer Gears, and Differential - Remove (RENR3366-07)connor.millsNo ratings yet

- Caterpillar Cat 330B L Excavator (Prefix 5LR) Service Repair Manual (5LR00001 and Up)Document27 pagesCaterpillar Cat 330B L Excavator (Prefix 5LR) Service Repair Manual (5LR00001 and Up)kfm8seuudu100% (1)

- Cylinder LinersDocument4 pagesCylinder Linersma.powersourceNo ratings yet

- Toyota Truck Pickup 2WD L4 2.4L SOHC 22R 1987Document8 pagesToyota Truck Pickup 2WD L4 2.4L SOHC 22R 1987Rick ZNo ratings yet

- Front Cover - Remove and Install (KENR6081-15)Document3 pagesFront Cover - Remove and Install (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- Caterpillar Cat 330 L EXCAVATOR (Prefix 2EL) Service Repair Manual (2EL00001 and Up)Document27 pagesCaterpillar Cat 330 L EXCAVATOR (Prefix 2EL) Service Repair Manual (2EL00001 and Up)kfm8seuudu100% (1)

- Convertidor de Torque D5BDocument13 pagesConvertidor de Torque D5BDeyner PerezNo ratings yet

- Sis 2.0 3Document1 pageSis 2.0 3kqgy9s6sgvNo ratings yet

- John Deere 450CLC Excavator Service Repair Technical Manual (TM1925)Document14 pagesJohn Deere 450CLC Excavator Service Repair Technical Manual (TM1925)laopaodunNo ratings yet

- Water PumpDocument7 pagesWater Pumpma.powersourceNo ratings yet

- Cyl Head c4Document5 pagesCyl Head c4lilikNo ratings yet

- Removal: CO-5 EM-34Document5 pagesRemoval: CO-5 EM-34marran almarranyNo ratings yet

- Remove Cylinder Head AssemblyDocument2 pagesRemove Cylinder Head AssemblyUriel MFNo ratings yet

- Toyota Prius Timing Chain Service GuideDocument13 pagesToyota Prius Timing Chain Service Guidefernando ortizNo ratings yet

- Philips N2213-00-15 SMDocument13 pagesPhilips N2213-00-15 SMFranco DurantNo ratings yet

- Remove & Install Cylinder Head AssemblyDocument2 pagesRemove & Install Cylinder Head AssemblyJuan LopezNo ratings yet

- Toyota Truck Tacoma 2002Document17 pagesToyota Truck Tacoma 2002FlorentinoChoquehuancaNo ratings yet

- Overhaul: Partial Engine Assy (1Gr Fe)Document50 pagesOverhaul: Partial Engine Assy (1Gr Fe)Islam AttiaNo ratings yet

- Remove 785 Damper SIS 2.0Document9 pagesRemove 785 Damper SIS 2.0isaac989No ratings yet

- Pistons and Connecting RodsDocument6 pagesPistons and Connecting Rodsma.powersourceNo ratings yet

- 3S-FE Distributor Removal, Installation, and Timing Adjustment GuideDocument5 pages3S-FE Distributor Removal, Installation, and Timing Adjustment GuideWilmer PerezNo ratings yet

- Armado de Transmision 924G - 101803Document30 pagesArmado de Transmision 924G - 101803linko estradaNo ratings yet

- Motor 1AZ-FE OverhaulDocument29 pagesMotor 1AZ-FE OverhaulfredhNo ratings yet

- Final Drive - Assemble (UENR4108-03)Document7 pagesFinal Drive - Assemble (UENR4108-03)ahmed mohamedNo ratings yet

- Sienna Timing Belt ReplacementDocument8 pagesSienna Timing Belt ReplacementGlenn MartinNo ratings yet

- Sis 2.0 2Document3 pagesSis 2.0 2Rui ArezesNo ratings yet

- Blade Lift Cyl AssemblyDocument4 pagesBlade Lift Cyl AssemblySHANENo ratings yet

- Crankshaft Front Seal and Wear SleeveDocument4 pagesCrankshaft Front Seal and Wear Sleevema.powersourceNo ratings yet

- Caterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)Document26 pagesCaterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)kfm8seuuduNo ratings yet

- Torque Converter - Install (RENR3366-07)Document5 pagesTorque Converter - Install (RENR3366-07)connor.millsNo ratings yet

- Install Cylinder Head on 3176C EngineDocument7 pagesInstall Cylinder Head on 3176C EngineCésar PérezNo ratings yet

- (TM) Toyota Manual de Motor Toyota Yaris Verso 2001 en InglesDocument11 pages(TM) Toyota Manual de Motor Toyota Yaris Verso 2001 en Inglesjonathan matusNo ratings yet

- Apollo Rack & Pinion Pneumatic ActuatorDocument10 pagesApollo Rack & Pinion Pneumatic ActuatorDelta ProductionNo ratings yet

- SB3-1-102Document6 pagesSB3-1-102jussmeeeNo ratings yet

- Toyota Matrix Timing Chain Removal and Installation GuideDocument16 pagesToyota Matrix Timing Chain Removal and Installation GuideGesco EscobarNo ratings yet

- RIO 16 TIEMPODocument13 pagesRIO 16 TIEMPOMarco ChanNo ratings yet

- 7-9 Arme y Desarme CilindrosDocument19 pages7-9 Arme y Desarme Cilindroslevinton jose tobias genesNo ratings yet

- Carburador Toyota 1991Document23 pagesCarburador Toyota 1991William Martínez B.No ratings yet

- Sis 2.0 5Document11 pagesSis 2.0 5michael.turner46tNo ratings yet

- Disassembly and Reassembly (Alternator)Document16 pagesDisassembly and Reassembly (Alternator)arstjunkNo ratings yet

- Disassembly Cylinder Head 920 Wheel LoaderDocument7 pagesDisassembly Cylinder Head 920 Wheel LoaderAmir Bambang YudhoyonoNo ratings yet

- Component Code AJ: Printed in Japan (02) 1Document5 pagesComponent Code AJ: Printed in Japan (02) 1PepeTRBKNo ratings yet

- Ripper lift R&IDocument8 pagesRipper lift R&Iconnor.millsNo ratings yet

- Final Drive - Disassemble (UENR4108-03)Document6 pagesFinal Drive - Disassemble (UENR4108-03)ahmed mohamedNo ratings yet

- Sis 2.0Document32 pagesSis 2.0Edgar Eli Carmona Zocón100% (1)

- TM 10-3930-669-34 Forklift Truck 6K Drexel MDL R60SL-DC Part 3Document65 pagesTM 10-3930-669-34 Forklift Truck 6K Drexel MDL R60SL-DC Part 3AdvocateNo ratings yet

- Caterpillar 3306 Gen Set Engine Service Repair Manual 85z03764-UpDocument3,964 pagesCaterpillar 3306 Gen Set Engine Service Repair Manual 85z03764-UpRaymond LimNo ratings yet

- Cylinder Blok c4Document7 pagesCylinder Blok c4lilikNo ratings yet

- Caterpillar Cat 120G MOTOR GRADER (Prefix 11W) Service Repair Manual (11W01019-01250)Document18 pagesCaterpillar Cat 120G MOTOR GRADER (Prefix 11W) Service Repair Manual (11W01019-01250)Arsel FirgiawanNo ratings yet

- Terberg Fifth Wheel Service ManualDocument11 pagesTerberg Fifth Wheel Service ManualSyed Danyal SalamNo ratings yet

- Install Cylinder Block Diesel EngineDocument11 pagesInstall Cylinder Block Diesel EngineCutiiVitezaNo ratings yet

- Manual de Yanmar Us45dDocument120 pagesManual de Yanmar Us45dcorlosNo ratings yet

- Hyundai 2015Document13 pagesHyundai 2015Aldo Omar50% (2)

- Volvo EW145B Service Repair ManualDocument19 pagesVolvo EW145B Service Repair ManualHai Van57% (21)

- Valve LashDocument1 pageValve LashJose Luis Poma MNo ratings yet

- 200AETDocument0 pages200AETJose Gregorio Aponte PerezNo ratings yet

- PACCAR PR engines detailsDocument4 pagesPACCAR PR engines detailsdzadza2No ratings yet

- Technical Service Information Engine CV Citra Sukses KamijayaDocument3 pagesTechnical Service Information Engine CV Citra Sukses KamijayaMonkey d LuffyNo ratings yet

- Amt 1201 - Prelim - Lab Module 2 - DelgadoDocument5 pagesAmt 1201 - Prelim - Lab Module 2 - DelgadoBrendan Lewis DelgadoNo ratings yet

- MR339 Laguna 1 - Engine & PeripheralsDocument311 pagesMR339 Laguna 1 - Engine & Peripheralssimon_rafferty_2100% (3)

- Citroen - Bosch Hdi Edc15c2 Injection System and Particle FilterDocument155 pagesCitroen - Bosch Hdi Edc15c2 Injection System and Particle FilterBenasaudio100% (7)

- Y00y4820-Vio25 Parts - 13.05.2014Document167 pagesY00y4820-Vio25 Parts - 13.05.2014Adil HanNo ratings yet

- Manual Montesa 4RT 05Document146 pagesManual Montesa 4RT 05jorgeNo ratings yet

- B30D 2Document150 pagesB30D 2Teknik MakinaNo ratings yet

- Manual Euro Weichai Full Data PDFDocument198 pagesManual Euro Weichai Full Data PDFMarco Soriano93% (14)

- Motorcycle Parts Catalog for SUZUKI UK125FS-I, FSC-I ModelsDocument74 pagesMotorcycle Parts Catalog for SUZUKI UK125FS-I, FSC-I ModelsChristian Labto Gatilogo77% (22)

- 06E Nomenclature ChartDocument1 page06E Nomenclature ChartDharani PathyNo ratings yet

- Specifications 3500 Cylinder Head Valves 2Document2 pagesSpecifications 3500 Cylinder Head Valves 2harikrishnanpd3327100% (1)

- SolexDocument3 pagesSolexBenedicto BeckerNo ratings yet

- Parts Catalog: 25, 30 HP (521cc) 2 Stroke ModelsDocument32 pagesParts Catalog: 25, 30 HP (521cc) 2 Stroke ModelsRonei MartinsNo ratings yet

- Airplane Engine Encyclopedia (En) Part 1Document282 pagesAirplane Engine Encyclopedia (En) Part 1Bea100% (1)

- MC 10163029 9999Document2 pagesMC 10163029 9999begueNo ratings yet

- Sensor Location DDC15 EP10Document15 pagesSensor Location DDC15 EP10Jose Alanis100% (1)

- Hot engine component diagramDocument6 pagesHot engine component diagramMartin SantoyoNo ratings yet

- Introduction To Ic EnginesDocument14 pagesIntroduction To Ic EnginesSai Sudheer100% (1)

- Enduro9 9HP-15HPDocument0 pagesEnduro9 9HP-15HPMohd Musa100% (1)

- Downloaded From Manuals Search EngineDocument10 pagesDownloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Bodybuilder Wiring Cummins IslDocument16 pagesBodybuilder Wiring Cummins IslHamilton MirandaNo ratings yet

- John Deere 4024TF281 Replacement Part GuideDocument2 pagesJohn Deere 4024TF281 Replacement Part GuideRamon Pujol PerramonNo ratings yet

- Manual Taller Suzuki SavageDocument3 pagesManual Taller Suzuki SavageELORIA ELORIA0% (1)