Professional Documents

Culture Documents

Technical Data Sheet - Logiclave™ LAB: Design

Uploaded by

harishupretiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data Sheet - Logiclave™ LAB: Design

Uploaded by

harishupretiCopyright:

Available Formats

Technical Data Sheet— Logiclave™ LAB

Freestanding range of autoclaves available in standard cylindrical and rectangular chamber sizes from 100 to 300

litres capacity.

• Mounted on swivel castors for easy transportation and positioning

• Designed to fit through standard width doorways

• Hygienic stainless steel fascia panels throughout entire range

• Single and double entry variants available

• Logiclave™ control system

• High efficiency integral steam generator option

Design

Suitable for fully automatic operation up to 138°C / 2.2Bar,

the Logiclave™ LAB autoclave is based on the key

requirements of the following standards and references:

• PD5500

• BS EN285

• BS 2646

• BS 3970 Pt1

• BS EN 61010

• HTM 2010

• C14 NHS Model engineering specifications

• HSE Guidance Note PM73

In addition, the equipment complies fully with the

appropriate requirements of the Pressure Equipment

Regulations 1999 (SI 1999 No. 2001) and is CE marked

accordingly.

Typical Applications

• Porous / Fabrics

• Equipment & Utensils

• Empty Glassware

• Culture Media

• Plastic Discard

• Mixed Discard

• Fluid Discard

Control System

The Logiclave™ type controller is based on a rugged industrial type full colour touch screen display with all

necessary functionality to easily operate the autoclave. The screen with its intuitive large buttons and display

layout provides the means of easily opening and closing the door and selecting and starting process cycles.

During normal operation all critical process temperatures and pressures are displayed along with current stage

and elapsed times etc. Password protected advanced functions and features.

Installation Services Required

Persons responsible for selecting and purchasing a Logiclave™ LAB autoclave should consider the provision of

the following utilities and connections:

• Steam – From site supply or integral steam generator?

• Water – Softened water is recommended.

• Compressed Air – From site supply or on board compressor?

• Power Supply – Availability of suitably rated 3 Phase supply?

• Drainage Connection – Proximity of floor drain?

• Safety Valve Vents – Ideally piped to outside of the building.

• CAT5 Ethernet Network Access Point – Only required with remote data archiving option.

All mechanical services are to be located within 2 metres pipe run of the rear of the autoclave and terminated

with suitable hand operated isolation valves. Please contact our technical department for recommendations and

assistance with installation planning.

4 Bentley Court, Finedon Rd Ind Estate, Wellingborough, Northants, NN8 4BQ

Tel: 01933 270999 Fax: 0870 803 4760

Email: info@autoclave.uk.com Web: www.autoclave.uk.com

Data Sheet Issue: August 2013

1

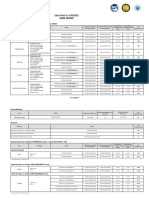

Technical Specifications — Logiclave™ LAB with Rectangular Chambers

Model LAB150V LAB225V LAB300V

Design Code PD5500 Cat 3, BS2646, PED 97/23/EC Mod B1+F & G

Chamber Material 316L Stainless Steel

Jacket Material 316L Stainless Steel

Chamber Design Pressure 2.62 Bar / Full Vacuum

Jacket Design Pressure 2.62 Bar

Design Temp 140°C

Working Pressure 2.2 Bar / Full Vacuum

Working Temp 138°C

Dimensions

600x500x500mm 600x500x750mm 600x500x1000mm

Chamber Dimensions (HWD) (HWD) (HWD)

Nominal Chamber Capacity 150 Litres 225 Litres 300 Litres

External Dimensions (Single Entry) 1900x730x1350mm (HWD)

1900x730x1310mm

External Dimensions (Double Entry) N/A N/A (HWD)

Loading Height 875mm

Approx Dry Weight 650kg 700kg 750kg

Internal Water Tank Capacity 23 Litres

Typical Utility Requirements

Power Supply (External Steam) 20A 3PH,N+E 50Hz 400/230VAC

Power Supply (ISG) 63A 3PH,N+E 50Hz 400/230VAC

External Steam Connection (No ISG) 0.5" BSP

Steam Supply Pressure 4.0 - 5.0 Bar

Water Supply Connection 22mm O/D Copper

Water Supply Pressure 1.5 - 3.0 Bar <60CaCo3

Compressed Air Supply Connection 0.5" BSP

Compressed Air Supply Pressure 6.0 - 8.0 Bar

Drain Outlet 35mm O/D Copper

Drain Temp ≤90°C

Chamber Safety Valve Outlet 22mm O/D Copper

Jacket Safety Valve Outlet 22mm O/D Copper

Water Tank Overflow 28mm O/D Copper

Heat Gain ≈3Kw

Typical utility usage per cycle (including steam generation)

Water: 63.6Litres (Porous cycles) / 297Litres (Fluids Cycles)

Electricity: 10KwH

Note: Utility consumption will vary depending on the size and nature of the load. These figures are based on typical

loads with the equipment under normal operating conditions and are provided for indication only.

4 Bentley Court, Finedon Rd Ind Estate, Wellingborough, Northants, NN8 4BQ

Tel: 01933 270999 Fax: 0870 803 4760

Email: info@autoclave.uk.com Web: www.autoclave.uk.com

Data Sheet Issue: August 2013

2

Features — Logiclave™ LAB with Rectangular Chambers

Model LAB150V LAB225V LAB300V

External Steam Supply Yes

Integral Steam Generation Optional

Integral Air Compressor Optional

Double Door Option No No Yes

Controller Logiclave™ With Full Colour Touch Screen HMI

Data Printer Yes

Paperless Graphical Recorder Optional

Independent Chart Recorder Optional

Ethernet Connectivity Yes

Vacuum Assisted Air Removal Optional

Power Operated Vertical Door Yes

Pressure Gauges Yes

Stainless Steel Piping Yes

Stainless Steel Process Valves Yes

Stainless Steel Enclosure Yes

Emergency Stop / Door Interlocks Yes

Multi Program Yes

Data Archiving Yes

Vented Cooling Yes

Thermal Door Interlock Yes

Water Cooled Jacket Optional

CAT 3 Effluent Retention Optional

SPF Fascia (Bio-seal) N/A N/A Optional

Crevice Free Pipework Optional

Passivation (Chamber & Piping) Optional

Remote Data Archiving Optional

Exhaust Filtration Optional

RO Water Treatment Plant Optional

Polished Chamber Optional

Removable Side Panels Yes

Drain Condenser Unit Optional

Internal Shelves Maximum 4

4 Bentley Court, Finedon Rd Ind Estate, Wellingborough, Northants, NN8 4BQ

Tel: 01933 270999 Fax: 0870 803 4760

Email: info@autoclave.uk.com Web: www.autoclave.uk.com

Data Sheet Issue: August 2013

3

Technical Specifications — Logiclave™ LAB with Cylindrical Chambers

Model LAB100V LAB145V LAB200V

Design Code PD5500 Cat 3, BS2646, PED 97/23/EC Mod B1+F & G

Chamber Material 316L Stainless Steel

Jacket Material 316L Stainless Steel

Chamber Design Pressure 2.62 Bar / Full Vacuum

Jacket Design Pressure 2.62 Bar

Design Temp 140°C

Working Pressure 2.2 Bar / Full Vacuum

Working Temp 138°C

Dimensions

500mm Dia x 500mm 500mm Dia x 750mm 500mm Dia x 1000mm

Chamber Dimensions Deep Deep Deep

Nominal Chamber Capacity 100 Litres 145 Litres 200 Litres

External Dimensions (Single Entry) 1900x730x1350mm (HWD)

External Dimensions (Double Entry) N/A

Loading Height 875mm

Approx Dry Weight 500kg 550kg 600kg

Internal Water Tank Capacity 23 Litres

Typical Utility Requirements

Power Supply (External Steam) 20A 3PH,N+E 50Hz 400/230VAC

Power Supply (ISG) 63A 3PH,N+E 50Hz 400/230VAC

External Steam Connection (No ISG) 0.5" BSP

Steam Supply Pressure 4.0 - 5.0 Bar

Water Supply Connection 22mm O/D Copper

Water Supply Pressure 1.5 - 3.0 Bar <60CaCo3

Compressed Air Supply Connection 0.5" BSP

Compressed Air Supply Pressure 6.0 - 8.0 Bar

Drain Outlet 35mm O/D Copper

Drain Temp ≤90°C

Chamber Safety Valve Outlet 22mm O/D Copper

Jacket Safety Valve Outlet 22mm O/D Copper

Water Tank Overflow 28mm O/D Copper

Heat Gain ≈3Kw

Typical utility usage per cycle (including steam generation)

Water: 63.6Litres (Porous cycles) / 297Litres (Fluids Cycles)

Electricity: 10KwH

Note: Utility consumption will vary depending on the size and nature of the load. These figures are based on typical

loads with the equipment under normal operating conditions and are provided for indication only.

4 Bentley Court, Finedon Rd Ind Estate, Wellingborough, Northants, NN8 4BQ

Tel: 01933 270999 Fax: 0870 803 4760

Email: info@autoclave.uk.com Web: www.autoclave.uk.com

Data Sheet Issue: August 2013

4

Features — Logiclave™ LAB with Cylindrical Chambers

Model LAB100V LAB145V LAB200V

External Steam Supply Yes

Integral Steam Generation Optional

Integral Air Compressor Optional

Double Door Option No No No

Controller Logiclave™ With Full Colour Touch Screen HMI

Data Printer Yes

Paperless Graphical Recorder Optional

Independent Chart Recorder Optional

Ethernet Connectivity Yes

Vacuum Assisted Air Removal Optional

Power Operated Vertical Door Yes

Pressure Gauges Yes

Stainless Steel Piping Yes

Stainless Steel Process Valves Yes

Stainless Steel Enclosure Yes

Emergency Stop / Door Interlocks Yes

Multi Program Yes

Data Archiving Yes

Vented Cooling Yes

Thermal Door Interlock Yes

Water Cooled Jacket Optional

CAT 3 Effluent Retention Optional

SPF Fascia (Bio-seal) N/A N/A N/A

Crevice Free Pipework Optional

Passivation (Chamber & Piping) Optional

Remote Data Archiving Optional

Exhaust Filtration Optional

RO Water Treatment Plant Optional

Polished Chamber Optional

Removable Side Panels Yes

Drain Condenser Unit Optional

Internal Shelves Maximum 3

4 Bentley Court, Finedon Rd Ind Estate, Wellingborough, Northants, NN8 4BQ

Tel: 01933 270999 Fax: 0870 803 4760

Email: info@autoclave.uk.com Web: www.autoclave.uk.com

Data Sheet Issue: August 2013

5

Logiclave™ LAB - Typical Dimensions

FRONT VIEW LH SIDE VIEW REAR VIEW

Notes:

1. Fits through standard width doorway

2. All utility connections made to rear of

Logiclave™ LAB

3. Side panels removable for maintenance

access. Ensure adequate clearance for

panel removal.

4. Machine levelled in final position with

adjustable feet.

5. Weights and dimensions do not include all

options.

ISOMETRIC

Specifications and dimensions subject to change without notice

RH SIDE VIEW (COVERS REMOVED)

4 Bentley Court, Finedon Rd Ind Estate, Wellingborough, Northants, NN8 4BQ

Tel: 01933 270999 Fax: 0870 803 4760

Email: info@autoclave.uk.com Web: www.autoclave.uk.com

Data Sheet Issue: August 2013

6

Logiclave™ LAB – Ordering Information

Option Code Example

Model No. X Where X = Model No. e.g. LAB150V

Double Entry DE Yes / No

Polished Chamber POL Yes / No

Integral Steam Generator ISG Yes / No

Integral Air Compressor AC Yes / No

Paperless Graphical Recorder GR Yes / No

Independent Chart Recorder CH Yes / No

Vacuum Assisted Air Removal VAC Yes / No

Preinstalled Programs NP Where N = Number of preinstalled programs (1-6)

Water Cooled Jacket WAT Yes / No

CAT 3 Effluent Retention CAT Yes / No

SPF Fascia (Bio-seal) SPF Yes / No

Crevice Free Pipework CFP Yes / No

Remote Data Archiving RDA Yes / No

Exhaust Filtration EXH Yes / No

RO Water Treatment Plant RO Yes / No

Where N = Number of removable shelves (Max 3

No. of Shelves N Cylindrical or 4 Rectangular)

Drain Condenser Unit DCU Yes / No

Example - To order a 300 Litre Logiclave™ LAB autoclave with integral steam generator, a graphical recorder and

suitable for processing CAT3 contaminated waste the product code would be constructed as follows:

LAB300V+ISG+GR+VAC+CAT+EXH

4 Bentley Court, Finedon Rd Ind Estate, Wellingborough, Northants, NN8 4BQ

Tel: 01933 270999 Fax: 0870 803 4760

Email: info@autoclave.uk.com Web: www.autoclave.uk.com

Data Sheet Issue: August 2013

7

▪ Laboratory Autoclaves ▪ Steam Sterilizers ▪

▪ Washer Disinfectors ▪ Endoscope Washer Driers ▪

Sales

Service

Validation

Testing

Refurbishments

Accessories

4 Bentley Court, Finedon Rd Ind Estate, Wellingborough, Northants, NN8 4BQ

Tel: 01933 270999 Fax: 0870 803 4760

Email: info@autoclave.uk.com Web: www.autoclave.uk.com

Data Sheet Issue: August 2013

8

You might also like

- Beginning Digital Electronics through ProjectsFrom EverandBeginning Digital Electronics through ProjectsRating: 5 out of 5 stars5/5 (1)

- Sanyo Mco 17aic Co2 Incubator Service Manual 4154392Document17 pagesSanyo Mco 17aic Co2 Incubator Service Manual 4154392Diego CompairedNo ratings yet

- Catalog SJ-MLDocument3 pagesCatalog SJ-MLVật Tư Lab Đức Dương Như Nguyễn (AS ONE JAPAN)No ratings yet

- Esab Origo Mig 510Document2 pagesEsab Origo Mig 510Khaled MekhamerNo ratings yet

- Indirect Heater 5 k Technical Data SheetDocument2 pagesIndirect Heater 5 k Technical Data Sheetshakouri1370_8902064No ratings yet

- Array Box: Protect and Enhance The Performance of Your Photovoltaic InstallationDocument2 pagesArray Box: Protect and Enhance The Performance of Your Photovoltaic InstallationudaynandhanNo ratings yet

- Coolcabinet Precision Precision Air Conditioner Air ConditionerDocument5 pagesCoolcabinet Precision Precision Air Conditioner Air Conditioneryusuf mohd sallehNo ratings yet

- Technical Data 3870Document18 pagesTechnical Data 3870fqalvesNo ratings yet

- Cryo Bath Low - 80Document7 pagesCryo Bath Low - 80vijay.victorysolutions01No ratings yet

- CR 9 KCDocument4 pagesCR 9 KCLiviu ToaderNo ratings yet

- PRIMOTIG - AC - DC - New Tig MachineDocument2 pagesPRIMOTIG - AC - DC - New Tig MachineYm PrathishNo ratings yet

- BE44-118 Tuffy T3Document12 pagesBE44-118 Tuffy T3Ali Abdul MannanNo ratings yet

- MovinCool Spot Cooling CatalogueDocument16 pagesMovinCool Spot Cooling CatalogueKhizerNo ratings yet

- Data Sheet Daniel Series 700 Model v788 en 6385002Document10 pagesData Sheet Daniel Series 700 Model v788 en 6385002Marcelo PinheiroNo ratings yet

- Cca-1112a-Ce BrochureDocument6 pagesCca-1112a-Ce BrochuretswNo ratings yet

- Innovair PEK 60Hz R410a Commercial Package Brochure EnglishDocument12 pagesInnovair PEK 60Hz R410a Commercial Package Brochure Englishcris melos100% (1)

- Autoklaf Page 3.bin PDFDocument16 pagesAutoklaf Page 3.bin PDFNadya Rizky SNo ratings yet

- FD TCR Industrial 1Document8 pagesFD TCR Industrial 1HemonNo ratings yet

- SD Series: Medical & Laboratory AutoclavesDocument5 pagesSD Series: Medical & Laboratory AutoclavesTan Hung LuuNo ratings yet

- Process Measurement and Control: Enraf Small Volume Prover Specifications Worksheet Rev VDocument6 pagesProcess Measurement and Control: Enraf Small Volume Prover Specifications Worksheet Rev VadjiNo ratings yet

- Dental AutoclaveDocument5 pagesDental Autoclavehasanosamah12No ratings yet

- Zuec Ventilation SolutionsDocument8 pagesZuec Ventilation SolutionsAllen EspeletaNo ratings yet

- Boiler Data Sheet PDFDocument1 pageBoiler Data Sheet PDFpeter mackey mamani mamanchuraNo ratings yet

- Easy to install 2/2 motorised valves for on/off controlDocument4 pagesEasy to install 2/2 motorised valves for on/off controlARUN VISHWAKARMANo ratings yet

- Environmentally Friendly Cooling With Heat: Ecoo 2.0: The Classic of Adsorption RefrigerationDocument3 pagesEnvironmentally Friendly Cooling With Heat: Ecoo 2.0: The Classic of Adsorption RefrigerationGokulSubramanianNo ratings yet

- BOX_BD_1010_M4_059kWDocument4 pagesBOX_BD_1010_M4_059kWAiman AliNo ratings yet

- Vacuum Regeneration Dryer AdvantagesDocument4 pagesVacuum Regeneration Dryer AdvantagesAcika PeleNo ratings yet

- Lyovapor l-300Document17 pagesLyovapor l-300ionelianosNo ratings yet

- DHM 6 Set: Mini Instantaneous Water Heater PRODUCT-NO.: 236452Document4 pagesDHM 6 Set: Mini Instantaneous Water Heater PRODUCT-NO.: 236452Cire Lop CastroNo ratings yet

- ARC-77 Datasheet - Bosch - Tronic - 4000cDocument2 pagesARC-77 Datasheet - Bosch - Tronic - 4000ctlp-bearNo ratings yet

- FD - Industrial DehumidifierDocument8 pagesFD - Industrial DehumidifierAntoniaNo ratings yet

- MovinCool Climate Pro K60 CatalogDocument4 pagesMovinCool Climate Pro K60 CatalogMiguel VieiraNo ratings yet

- Single Stage Configuration: Water Evaporation CapacityDocument4 pagesSingle Stage Configuration: Water Evaporation CapacityugandaNo ratings yet

- Manual de Instalacion Osko XR5 - Rayos X Convencional Analogico Data SheetDocument6 pagesManual de Instalacion Osko XR5 - Rayos X Convencional Analogico Data SheetLeandro Pabon Villarreal100% (1)

- H 07 Specsheet v3.1 2015 01 07Document2 pagesH 07 Specsheet v3.1 2015 01 07murtada gubaNo ratings yet

- Component List Efficent InsulationDocument5 pagesComponent List Efficent Insulationnikesh moreNo ratings yet

- Rotary Evaporators Evaporation SolutionsDocument8 pagesRotary Evaporators Evaporation SolutionsFungusface PathogenNo ratings yet

- Steam Sterilizer GuideDocument6 pagesSteam Sterilizer GuideYana LesmanaNo ratings yet

- Familyoverview LBR-SicWave g505156 enDocument4 pagesFamilyoverview LBR-SicWave g505156 enTien LoiNo ratings yet

- Technical Specification Combo HC1008CDNC2D-PDocument5 pagesTechnical Specification Combo HC1008CDNC2D-PManuela AsmatNo ratings yet

- Datasheet - NZMN3-AE630: Part No. Article No. Catalog NoDocument12 pagesDatasheet - NZMN3-AE630: Part No. Article No. Catalog NoConstantin UdreaNo ratings yet

- Overnight Thaw Technical Datasheet: S1Ot-Ss Overnight Thaw S2Ot-Ss Overnight ThawDocument2 pagesOvernight Thaw Technical Datasheet: S1Ot-Ss Overnight Thaw S2Ot-Ss Overnight ThawKuljinder VirdiNo ratings yet

- Water Testing1802Document15 pagesWater Testing1802Umesh MishraNo ratings yet

- 5SL41047 Datasheet enDocument5 pages5SL41047 Datasheet enkavireeshgh_007No ratings yet

- MotorDocument2 pagesMotorKeLvinLazyBoyNo ratings yet

- Hisense Corporation: AS-09UR4SVNVG1 AS-12UR4SVNVG1 As-12Ur4Svgvg As-18Ur4Stvvg As-24Ur4SqjvgDocument34 pagesHisense Corporation: AS-09UR4SVNVG1 AS-12UR4SVNVG1 As-12Ur4Svgvg As-18Ur4Stvvg As-24Ur4SqjvgRajesh SoniNo ratings yet

- Reguladore SENSUS para Gas CombustibleDocument20 pagesReguladore SENSUS para Gas CombustibleJorge BaronNo ratings yet

- Wascomat Crossover Dryer OPL Specifications DAWF0GNM Non Meteres Card Ready GasDocument2 pagesWascomat Crossover Dryer OPL Specifications DAWF0GNM Non Meteres Card Ready Gasmairimsp2003No ratings yet

- Contura - Wall TypeDocument4 pagesContura - Wall TypeMohamed ImranNo ratings yet

- Data Sheet FD1200-2000-3000Document6 pagesData Sheet FD1200-2000-3000ManojNo ratings yet

- BRVA00100Document2 pagesBRVA00100iram2005No ratings yet

- Krohne OPTIFLUX 2000Document16 pagesKrohne OPTIFLUX 2000Anonymous 1LgoS05gvlNo ratings yet

- TX Thermal Dispersion Switch Data SheetDocument5 pagesTX Thermal Dispersion Switch Data SheetROGELIO QUIJANONo ratings yet

- Pump Cable 300mDocument2 pagesPump Cable 300mheri fauziNo ratings yet

- Compact FliyerDocument1 pageCompact FliyerFlavio Miranda GonzalezNo ratings yet

- Air - Water Heat ExchangersDocument4 pagesAir - Water Heat ExchangersLOI HONo ratings yet

- TS Sterling Sterlco TC110 Series - Rev09.13.2018Document2 pagesTS Sterling Sterlco TC110 Series - Rev09.13.2018Omar A. HernandezNo ratings yet

- Inverter Heat Pump Outdoor Units up to 18 kWDocument3 pagesInverter Heat Pump Outdoor Units up to 18 kWVlad PandichiNo ratings yet

- CenTraVac Centrifugal Chiller Product Report - Cap.450TRDocument2 pagesCenTraVac Centrifugal Chiller Product Report - Cap.450TRWahyu HarisantoNo ratings yet

- Flygt PumpsDocument56 pagesFlygt PumpsThe_RainmakerNo ratings yet

- Level TransmitterDocument2 pagesLevel TransmitterharishupretiNo ratings yet

- RGCB Kerela InsulationDocument1 pageRGCB Kerela InsulationharishupretiNo ratings yet

- How to Optimize Your Website for Search EnginesDocument3 pagesHow to Optimize Your Website for Search EnginesharishupretiNo ratings yet

- Differential Pressure Sensor FilterDocument10 pagesDifferential Pressure Sensor FilterharishupretiNo ratings yet

- Analog Continuous Liquid Level TransmitterDocument1 pageAnalog Continuous Liquid Level TransmitterharishupretiNo ratings yet

- Offer of Clean Room Display - Biosafe Lab India Pvt. LTD PDFDocument4 pagesOffer of Clean Room Display - Biosafe Lab India Pvt. LTD PDFharishupretiNo ratings yet

- Cable Catalogue-2016 PDFDocument64 pagesCable Catalogue-2016 PDFSuman Mandal100% (1)

- Super Universal Modules TXM1.8X PDFDocument10 pagesSuper Universal Modules TXM1.8X PDFharishupretiNo ratings yet

- TX-I/O™: Building TechnologiesDocument10 pagesTX-I/O™: Building TechnologiesNur Kholis MasjidNo ratings yet

- Level Switches-CatalougeDocument4 pagesLevel Switches-CatalougeharishupretiNo ratings yet

- 2009 National Standard Plumbing CodeDocument332 pages2009 National Standard Plumbing Codemelvin_parilla7774100% (1)

- Level Switches-CatalougeDocument4 pagesLevel Switches-CatalougeharishupretiNo ratings yet

- BIM IntroductionDocument104 pagesBIM Introductionharishupreti50% (2)

- TX Open RS232 - 485 Module (TXI2.OPEN)Document8 pagesTX Open RS232 - 485 Module (TXI2.OPEN)harishupretiNo ratings yet

- Trane - Coil Sizing Guide PDFDocument42 pagesTrane - Coil Sizing Guide PDFyousuffNo ratings yet

- TXM1.8D y 1.16DDocument8 pagesTXM1.8D y 1.16DMiguel Angel Mentado ManzanaresNo ratings yet

- Catalogue - CoilsDocument12 pagesCatalogue - CoilsblindjaxxNo ratings yet

- Carrier Coil SelectionDocument86 pagesCarrier Coil SelectionharishupretiNo ratings yet

- SALDocument12 pagesSALharishupretiNo ratings yet

- Total Load in Cooling CoilDocument60 pagesTotal Load in Cooling CoilharishupretiNo ratings yet

- M9116, M9124, and M9132 Series Electric Non-Spring-Return ActuatorsDocument4 pagesM9116, M9124, and M9132 Series Electric Non-Spring-Return ActuatorsharishupretiNo ratings yet

- AHUDocument37 pagesAHUharishupretiNo ratings yet

- NB AhuDocument48 pagesNB AhuSMBEAUTYNo ratings yet

- MODUBUSDocument46 pagesMODUBUSharishupretiNo ratings yet

- LonWorks in BriefDocument73 pagesLonWorks in BriefPaulo MuñozNo ratings yet

- BMS Intergration PDFDocument16 pagesBMS Intergration PDFsyedpandtNo ratings yet

- Three-Port Slipper Valves for Closed-Circuit Heating SystemsDocument6 pagesThree-Port Slipper Valves for Closed-Circuit Heating SystemsharishupretiNo ratings yet

- Siemens Building ManagementDocument266 pagesSiemens Building ManagementGirish Jha100% (2)

- DDC Networks and Protocols GuideDocument122 pagesDDC Networks and Protocols Guideharishupreti100% (1)

- LP nr3 RY2022 Gree MonoDocument3 pagesLP nr3 RY2022 Gree MonoBogdan IstrateNo ratings yet

- Automatic Weather StationDocument8 pagesAutomatic Weather StationMyat Tun OoNo ratings yet

- M61250EFPDocument50 pagesM61250EFPJesus SilvaNo ratings yet

- Service Bulletin: PurposeDocument3 pagesService Bulletin: PurposejussmeeeNo ratings yet

- 5 Collaborative ProjectDocument26 pages5 Collaborative ProjectCabagnot Piolo JuliusNo ratings yet

- Silcostart: Static Motor Softstarter Solving Starting ProblemsDocument4 pagesSilcostart: Static Motor Softstarter Solving Starting ProblemsMohamed AlkharashyNo ratings yet

- Chapter 1 - Julia Case Bradley Programming in Visual Basic 6.0Document5 pagesChapter 1 - Julia Case Bradley Programming in Visual Basic 6.0Vishal Rane100% (1)

- How To Submit To D2LDocument1 pageHow To Submit To D2LArtem GovorovNo ratings yet

- Loan Prediction SystemDocument31 pagesLoan Prediction SystemFakorede Akinwande alexNo ratings yet

- K-MCD200R SMDocument66 pagesK-MCD200R SMAurelio Gómez aguilarNo ratings yet

- ServiceNow Sample Resume 3Document7 pagesServiceNow Sample Resume 3Chiranjeevi ChNo ratings yet

- ZXA10 C610 Product Description - V1.1.0 - 20190411Document64 pagesZXA10 C610 Product Description - V1.1.0 - 20190411Edson Lira100% (2)

- Karthik ResumeDocument3 pagesKarthik Resumekarthik_04652No ratings yet

- Multiple Vacancies With MENAISCO in Jazan - Saudi ArabiaDocument5 pagesMultiple Vacancies With MENAISCO in Jazan - Saudi ArabiaViiq Corpse GrinderNo ratings yet

- Baffle Jig Not A SilencerDocument10 pagesBaffle Jig Not A SilencerAmmoLand Shooting Sports NewsNo ratings yet

- R&S Nrq6 Aclr 100 MHZ (Using FFT Filtering) Application SheetDocument5 pagesR&S Nrq6 Aclr 100 MHZ (Using FFT Filtering) Application SheetfriedmanNo ratings yet

- Project Synopsis on Software Quality AssuranceDocument11 pagesProject Synopsis on Software Quality AssuranceYajnaseni Neelabh0% (1)

- DX 5000 Plus User Manual NewDocument17 pagesDX 5000 Plus User Manual NewclaudiodelbiancoNo ratings yet

- QSB6.7 Series: Diesel Generator SetDocument4 pagesQSB6.7 Series: Diesel Generator SetVIET TRIEU HUYNHNo ratings yet

- Cisco System Managing de Supply ChainDocument7 pagesCisco System Managing de Supply ChainNorberto VarasNo ratings yet

- M650. User Manual. 2009, Carmanah Technologies Corporation. Revised June - M650 - UserManual - RevADocument76 pagesM650. User Manual. 2009, Carmanah Technologies Corporation. Revised June - M650 - UserManual - RevAPaul PerazaNo ratings yet

- Hi 8596 - V Rev L PDFDocument12 pagesHi 8596 - V Rev L PDFVarshaNo ratings yet

- First American Grand Prix - The Savannah Auto Races, 1908-1911, The - Tanya A. BaileyDocument239 pagesFirst American Grand Prix - The Savannah Auto Races, 1908-1911, The - Tanya A. BaileyFilipeBouraNo ratings yet

- VMware Compatibility Guide Servidores DELL R720 - Vmware 6.5Document2 pagesVMware Compatibility Guide Servidores DELL R720 - Vmware 6.5Emanuel TavaresNo ratings yet

- Configure a L2TPDocument3 pagesConfigure a L2TPVentas Nature PrimeNo ratings yet

- 02 5G Xhaul Transport - BRKSPM-2012 BRKSPG-2680Document98 pages02 5G Xhaul Transport - BRKSPM-2012 BRKSPG-2680MakusNo ratings yet

- L828/L829 Ferroresonant Constant Current RegulatorDocument1 pageL828/L829 Ferroresonant Constant Current RegulatorSantiagoNo ratings yet

- CIS RAM For IG1 Workbook v21.10.25Document144 pagesCIS RAM For IG1 Workbook v21.10.25pikanteNo ratings yet

- Anomaly Detection Using A Self-Sufficient Ad Hoc Electrical Impedance Tomography Sensor Deployed Within Imaged SpaceDocument5 pagesAnomaly Detection Using A Self-Sufficient Ad Hoc Electrical Impedance Tomography Sensor Deployed Within Imaged Spaceaibramai3No ratings yet

- AocvDocument5 pagesAocvgowripNo ratings yet