Professional Documents

Culture Documents

VP:::, VP:::,: 140 Depth in Pavement 1 in

Uploaded by

bartkkkkkkkkkkkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VP:::, VP:::,: 140 Depth in Pavement 1 in

Uploaded by

bartkkkkkkkkkkkCopyright:

Available Formats

76 TRANSPORTATION RESEARCH RECORD 1355

The composite modulus of an n-layer pavement system is

140

Depth In pavement 1 In. calculated with the following equation (1, Appendix PP).

2 In.

o~120

"']-100

4 ln.

E. = [~ ~ x 3 E;(l - µ~)] J

0

0

n-1 h, (1 - µn (1)

~ BO

For a three-layer system, (AC bound layer, non-AC bound

~ 60

layer, and subgrade), Equation 1 may be written as

,_~ 40

20 J E1 (1 - µ,2)

3 E1(1 - µ,; ) 1 Z e

O""""z::J...~-'-------'~-'-~.L---'-~-'---''----'-~-'---'-~-'----' - - -- +-

0 20 40 60 80 100 120 140 160 180 200 220 240 260 (1 - µT) x (1 - µ,D

Pa11ement Surface Temperature Plus 5-0ay Mean Air Temperature ( F)

0

Ee = (2)

FIGURE I Variation of pavement temperature with depth

and surface temperature plus 5-day mean air temperature

(1, Appendix L).

where

µ1 = Poisson's ratio of AC bound layer,

o"- µ2 =Poisson's ratio of non-AC bound layer ,

• 110

~ µ, = Poisson's ratio of the equivalent (or composite) layer,

.z 100

£ 1 = Young's modulus of AC bound layer,

!'.

~ 90 x = ratio of AC bound layer thickness to non-AC bound

E

~ 80 layer thickness (h/h 2 ), and

15 70 z = ratio of Young's modulus of the AC bound layer

E to Young's modulus of the non-AC bound layer

~ 60

0

CL 50 (E/£2).

c:

0

"

::E 40 Several functions have been developed to estimate the var-

30 '---'-~'---'-~.L..--L-~.W...-'-""-"'...._---'-'...._~..._.._~_,_, iation of the modulus of AC concrete with temperature. An

a.a a.2 a.4 a.6 a.a 1.a 1 .2 1.4 1.6 1 .s 2.a 2.2 2.4

Temperature Adjustment Factor

approximation taken from the Asphalt Institute (3) and rec-

ommended for correction of NDT results (4) is

(/~)'

Base Material Curve (Base Thicknesa)

Asphalt (Full Depth) A (All thicknesBes) LogE,,d = logEne1d + 0.028829?200 [ - (;)']

A:iphalt (Deep Strength) B (4" of granular .:iubba s e)'

Portla nd Cement Concrete

Granular (Non-Stabilized) C (6") ; D (12"); E (20") ; F (25")

+ 0.000005 vP:::, [(t 0 )'

0

- (t)']

Cement Treated Base

Sound

Cracked

D t4 • ) 1 E (0 '" )

C 14'") I D t 8 • )

0.00189 vP:::,

(1 0 ) '" (1)'

[ (fo) l.I - (j) LI

J

' It more than 4" of granular material present u~e "Granular (Non-Stabilized)"

base material category .

FIGURE 2 AASHTO recommended temperature adjustment

factors (J, Appendix L).

+ 0.931757 [(/~)" - (;),,] (3)

where

ALTERNATIVE TEMPERATURE

>-. = 0.17033,

CORRECTION METHOD

n = 0.02774,

t = test temperature (degrees Fahrenheit),

It is important to note that Figure 2 does not differentiate

f = loading frequency (hertz),

between pavements with different AC bound layer thick-

t = standard temperature,

0

nesses. For instance, if a pavement has 2 in. of AC concrete

over a 6 in. granular base or 8 in. of AC concrete over a 6

f = standard frequency,

0

Pac = percent AC by weight of the mix,

in. granular base, Curve Con Figure 2 is the recommended

£field = AC concrete modulus at the standard temperature

correction curve. To improve the AASHTO procedure an

and frequency,

adjustment factor was developed that estimates the change

r = 1.3 + 0.49825 log(/

0 0

),

in the overall pavement stiffness from the change in the AC

r = 1.3 + 0.49825 log(f), and

bound layer stiffness and the geometry of the pavement. To

P200 = percent aggregate passing the No. 200 sieve.

calculate this factor the average pavement temperature, the

ratio of AC bound layer thickness to non-AC bound thickness, Equation 3 may be simplified. A value of P.c = 5.7 percent

and the modular ratio of AC bound to non-AC bound layers was selected as typical (5). Typical FWD load duration is

are used. approximately 30 to 40 msec (6). Using the approximation

You might also like

- A of A Solid: New Fomulation Skin-Effect Resistance Internal Inductance Frequency-Dependent Cylindrical ConductorDocument6 pagesA of A Solid: New Fomulation Skin-Effect Resistance Internal Inductance Frequency-Dependent Cylindrical Conductorpomon666No ratings yet

- 3 Impatt DiodesDocument5 pages3 Impatt DiodesEduardo FuentesNo ratings yet

- Experiment - : OBJ CtiveDocument11 pagesExperiment - : OBJ CtiveBreaking DieNo ratings yet

- A Robustly Stable Output Feedback Saturated Controller For The BDocument6 pagesA Robustly Stable Output Feedback Saturated Controller For The BAMIR SOHAILNo ratings yet

- Finite Difference Method... Dr. Hatem MOKHTARIDocument3 pagesFinite Difference Method... Dr. Hatem MOKHTARIDr. Hatem MOKHTARI100% (2)

- Simple and Accurate Formula For Calculating The Conduction Angle of Single Phase RectifierDocument3 pagesSimple and Accurate Formula For Calculating The Conduction Angle of Single Phase RectifierMichele Oconnor0% (1)

- Bandpass Filters Using Parallel Coupled Stripline Stepped ImpedaDocument3 pagesBandpass Filters Using Parallel Coupled Stripline Stepped Impedasrividhya ganesanNo ratings yet

- Hamilton 1966Document6 pagesHamilton 1966alex thomasNo ratings yet

- PML Berenger1996 PDFDocument8 pagesPML Berenger1996 PDFCíntia ArantesNo ratings yet

- Applications - Transmission Line CalculatorDocument6 pagesApplications - Transmission Line CalculatorAliOucharNo ratings yet

- EEE209 Online2Document28 pagesEEE209 Online2MeowNo ratings yet

- Cruz MaltaDocument18 pagesCruz MaltaYamith GomezNo ratings yet

- Ieee Perdidas en El Nucleo Usando Metodo NumericoDocument4 pagesIeee Perdidas en El Nucleo Usando Metodo NumericoYesenia Valencia RodriguezNo ratings yet

- Twisted Pair Transmission Line Distributed Parametrs PDFDocument8 pagesTwisted Pair Transmission Line Distributed Parametrs PDF임광식0% (1)

- 4761-Article Text-8519-1-10-20130718 PDFDocument15 pages4761-Article Text-8519-1-10-20130718 PDFik43207No ratings yet

- Bond Deterioration Between Reinforcing Bars and Concrete Subject To Cyclic Loads and CracksDocument8 pagesBond Deterioration Between Reinforcing Bars and Concrete Subject To Cyclic Loads and CracksPPPNo ratings yet

- State Standards: - 2 - H V V LDocument3 pagesState Standards: - 2 - H V V LMihai TataroiNo ratings yet

- Charge InjectDocument7 pagesCharge InjectPritamNo ratings yet

- Coupling Coefficient For Trapezoidal GratingDocument3 pagesCoupling Coefficient For Trapezoidal GratingTuhin Mishuk PaulNo ratings yet

- General Design Method For Bolted Connections - Soeren Stephan Et AlDocument17 pagesGeneral Design Method For Bolted Connections - Soeren Stephan Et AlSoeren StephanNo ratings yet

- On The Phase Transition: Additional Information On J. Chem. PhysDocument3 pagesOn The Phase Transition: Additional Information On J. Chem. PhysArchana SNo ratings yet

- Ferroresonance CalculationDocument8 pagesFerroresonance Calculationwildtrek0% (1)

- Stern 1972Document9 pagesStern 1972abdulbabulNo ratings yet

- Naca Tech - Criticalstressof PlatecolumnsDocument17 pagesNaca Tech - Criticalstressof PlatecolumnsPedro GalvaniNo ratings yet

- Brown 1978Document14 pagesBrown 1978Cerduardo Chanchisco Roga RojasNo ratings yet

- Jefimenko's Wedge CircuitDocument9 pagesJefimenko's Wedge CircuitPat Tab3No ratings yet

- Microstrip Discontinuity Capacitances For Right-An81e Bends, T Junctions, and CrossingsDocument6 pagesMicrostrip Discontinuity Capacitances For Right-An81e Bends, T Junctions, and CrossingsElectronic BoyNo ratings yet

- Giacoletto 1996Document10 pagesGiacoletto 1996Alexandre HenriquesNo ratings yet

- The TransmissionLine Equations For TwoConductor LinesDocument18 pagesThe TransmissionLine Equations For TwoConductor Linesdooman2012No ratings yet

- Article: Stepped Hss T-And Cross - Connections Under Branch In-Plane and Out - Of-Plane BendingDocument5 pagesArticle: Stepped Hss T-And Cross - Connections Under Branch In-Plane and Out - Of-Plane Bendinggv Sathishkumar KumarNo ratings yet

- Iterative Solution of Waveguide Discontinuity Problems: (Manuscript Received November 25, 1966)Document24 pagesIterative Solution of Waveguide Discontinuity Problems: (Manuscript Received November 25, 1966)Shl MasNo ratings yet

- CAPE Physics 2012 U2 P2Document22 pagesCAPE Physics 2012 U2 P2Braeylnn RobinsonNo ratings yet

- Pub 400Document5 pagesPub 400ingenvictorNo ratings yet

- SLT-B QuestionsDocument6 pagesSLT-B QuestionsrhythmNo ratings yet

- Poon1974 ADocument3 pagesPoon1974 AGeorge AcostaNo ratings yet

- Chapter 4 Steady StateDocument72 pagesChapter 4 Steady StateGemechis AsfawNo ratings yet

- Statistical Mechanics of Anyons: CompleteDocument17 pagesStatistical Mechanics of Anyons: CompleteLeôncioNo ratings yet

- Novel Phase Reconfigurable Synthesized Transmission Line and Its Application To Reconfigurable Hybrid CouplerDocument4 pagesNovel Phase Reconfigurable Synthesized Transmission Line and Its Application To Reconfigurable Hybrid CouplerGurulakshmi A BNo ratings yet

- Surface Displacement of An Elastic Layer Under Uniformly Distributed LoadsDocument10 pagesSurface Displacement of An Elastic Layer Under Uniformly Distributed LoadsMohamad ZNo ratings yet

- A Simple Approach For Determining Core-Loss of Magnetic MaterialsDocument3 pagesA Simple Approach For Determining Core-Loss of Magnetic MaterialsHoàng Tâm LêNo ratings yet

- Voltage Across The Terminals of A Receiving AntennaDocument10 pagesVoltage Across The Terminals of A Receiving Antennadtvt2006No ratings yet

- Transient Analysis of Microstrip-Like Interconnections Guarded by Ground TracksDocument14 pagesTransient Analysis of Microstrip-Like Interconnections Guarded by Ground TracksSaranya KalaichelvanNo ratings yet

- Snoek Effect PDFDocument5 pagesSnoek Effect PDFhamed soleymaniNo ratings yet

- Exp 2 Metre BridgeDocument6 pagesExp 2 Metre Bridgehyn xeNo ratings yet

- Esnel Equations PDFDocument18 pagesEsnel Equations PDFneomindxNo ratings yet

- Module2 15EC71Document23 pagesModule2 15EC71Priyanka PrakashNo ratings yet

- Applications - Transmission Line CalculatorDocument5 pagesApplications - Transmission Line CalculatorŽeljkoMarkovićNo ratings yet

- Newton Kantorovitch TheoremDocument7 pagesNewton Kantorovitch TheoremHwi KimNo ratings yet

- An Alternative Approach To Analyze Unsymmetrical Faults in Power SystemDocument6 pagesAn Alternative Approach To Analyze Unsymmetrical Faults in Power SystemAbcdNo ratings yet

- Influence of Mutual Coupling Between Parallel Circuits On The Setting of Distance ProtectionDocument7 pagesInfluence of Mutual Coupling Between Parallel Circuits On The Setting of Distance Protectioncarlos patrickNo ratings yet

- Molecular Spectroscopy: Nu El ElDocument23 pagesMolecular Spectroscopy: Nu El ElAbd El-Fattah Mohamed OufNo ratings yet

- Part One Waveguides and CavitiesDocument9 pagesPart One Waveguides and CavitiesnananghadisodikinNo ratings yet

- Optical Properties of A Uniaxial LayerDocument17 pagesOptical Properties of A Uniaxial Layerymakhlouka001No ratings yet

- 1502957604lectrure 11 12 13 KUETDocument35 pages1502957604lectrure 11 12 13 KUETAnikaNo ratings yet

- BF 01040819Document4 pagesBF 01040819gabrieltamas7890No ratings yet

- 004 - Medan Listrik Wangsness C3Document11 pages004 - Medan Listrik Wangsness C3Sisda FerliantiNo ratings yet

- Fresnel Formulæ: 1 Single InterfaceDocument5 pagesFresnel Formulæ: 1 Single InterfaceDer Untiringe KäferNo ratings yet

- Jamel - EUROCORR 2008Document10 pagesJamel - EUROCORR 2008Ricardo NogueiraNo ratings yet

- EMTP Modelling of Grounding Electrodes PDFDocument4 pagesEMTP Modelling of Grounding Electrodes PDFCesar ZamudioNo ratings yet

- Johnson and Baus: ProposedDocument1 pageJohnson and Baus: ProposedbartkkkkkkkkkkkNo ratings yet

- Road Accident Cost Prediction Model Using Systems Dynamics ApproachDocument8 pagesRoad Accident Cost Prediction Model Using Systems Dynamics ApproachbartkkkkkkkkkkkNo ratings yet

- Johnson and Baus: Efl.wDocument1 pageJohnson and Baus: Efl.wbartkkkkkkkkkkkNo ratings yet

- D-11 Basketball Goal Post Footing and Goal Assembly Details - 201407301802167813 PDFDocument1 pageD-11 Basketball Goal Post Footing and Goal Assembly Details - 201407301802167813 PDFbartkkkkkkkkkkkNo ratings yet

- Site StructureDocument1 pageSite StructurebartkkkkkkkkkkkNo ratings yet

- Basketball Goal Post Footing and Goal Assembly Details PDFDocument1 pageBasketball Goal Post Footing and Goal Assembly Details PDFbartkkkkkkkkkkk100% (1)

- Typical Deflection-UnboundDocument1 pageTypical Deflection-UnboundbartkkkkkkkkkkkNo ratings yet

- FIG. 5 Adjustment of Number of Deduct ValuesDocument1 pageFIG. 5 Adjustment of Number of Deduct ValuesbartkkkkkkkkkkkNo ratings yet

- Mean JointDocument1 pageMean JointbartkkkkkkkkkkkNo ratings yet

- Typical DeflectionDocument2 pagesTypical DeflectionbartkkkkkkkkkkkNo ratings yet

- Asphalt Correction FactorDocument1 pageAsphalt Correction FactorbartkkkkkkkkkkkNo ratings yet

- Deflection Bowls+2 PDFDocument1 pageDeflection Bowls+2 PDFbartkkkkkkkkkkkNo ratings yet

- Deflection TemperatureDocument1 pageDeflection TemperaturebartkkkkkkkkkkkNo ratings yet

- Typical Deflection-Full DepthDocument1 pageTypical Deflection-Full DepthbartkkkkkkkkkkkNo ratings yet

- N 355 Samples, N 15 Samples andDocument1 pageN 355 Samples, N 15 Samples andbartkkkkkkkkkkkNo ratings yet

- D900 Vs CBR PDFDocument1 pageD900 Vs CBR PDFbartkkkkkkkkkkkNo ratings yet

- D900 Vs CBR PDFDocument1 pageD900 Vs CBR PDFbartkkkkkkkkkkkNo ratings yet

- ASTM-D6433-11-Roads-and-parking-lots-PCI-surveys 44Document1 pageASTM-D6433-11-Roads-and-parking-lots-PCI-surveys 44bartkkkkkkkkkkkNo ratings yet

- ASTM-D6433-11-Roads-and-parking-lots-PCI-surveys 45Document1 pageASTM-D6433-11-Roads-and-parking-lots-PCI-surveys 45bartkkkkkkkkkkkNo ratings yet

- ASTM-D6433-11-Roads-and-parking-lots-PCI-surveys 46Document1 pageASTM-D6433-11-Roads-and-parking-lots-PCI-surveys 46bartkkkkkkkkkkkNo ratings yet

- Detail - IRC SP 84Document2 pagesDetail - IRC SP 84bartkkkkkkkkkkkNo ratings yet

- Beam TestDocument1 pageBeam TestbartkkkkkkkkkkkNo ratings yet

- ASTM-D6433-11-Roads-and-parking-lots-PCI-surveys 43Document1 pageASTM-D6433-11-Roads-and-parking-lots-PCI-surveys 43bartkkkkkkkkkkkNo ratings yet

- Basketball Goal Post FootingDocument1 pageBasketball Goal Post FootingbartkkkkkkkkkkkNo ratings yet

- Deflection Bowls+2Document1 pageDeflection Bowls+2bartkkkkkkkkkkkNo ratings yet

- Deflection BowlsDocument1 pageDeflection BowlsbartkkkkkkkkkkkNo ratings yet

- Detalji Kanalete I TrotoariDocument1 pageDetalji Kanalete I TrotoaribartkkkkkkkkkkkNo ratings yet

- Geografski Koordinati Na Krajnite To Ki Na Republika MakedonijaDocument1 pageGeografski Koordinati Na Krajnite To Ki Na Republika MakedonijabartkkkkkkkkkkkNo ratings yet

- Povr (Ina 25 713 KM Glaven Grad Skopje Broj Na Op (Tini 84 Broj Na Naseleni Mesta 1 767Document1 pagePovr (Ina 25 713 KM Glaven Grad Skopje Broj Na Op (Tini 84 Broj Na Naseleni Mesta 1 767bartkkkkkkkkkkkNo ratings yet

- BMC-4.Basics of Building ComponentsDocument20 pagesBMC-4.Basics of Building ComponentsMeenu Priya100% (1)

- Profile - Kamal Realtor WWW - Kamalrealtors.com +91 973878774Document5 pagesProfile - Kamal Realtor WWW - Kamalrealtors.com +91 973878774Aditya BhandariNo ratings yet

- Overhead Cranes-Safety&InspectorDocument214 pagesOverhead Cranes-Safety&InspectorMohamed Adel100% (6)

- Sheet LaminationDocument13 pagesSheet LaminationRishika JaiswalNo ratings yet

- SVW 12 1000kW 41000 To 3412000 BtuhDocument2 pagesSVW 12 1000kW 41000 To 3412000 BtuhAmber ChavezNo ratings yet

- Rate Analysis Multi - Drift 30-05-2022 - R2Document8 pagesRate Analysis Multi - Drift 30-05-2022 - R2Rajat SharmaNo ratings yet

- Nova ABS Plastic Formwork by Sandeep NaikwadeDocument11 pagesNova ABS Plastic Formwork by Sandeep NaikwadeNovaFormworkNo ratings yet

- Rheomac® 707Document4 pagesRheomac® 707M HAFEEZ RAJANo ratings yet

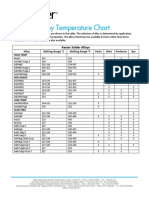

- Alloy Temperature ChartDocument2 pagesAlloy Temperature ChartDaymer AularNo ratings yet

- Ex ArisuDocument12 pagesEx ArisuJeiner Leyva BernalNo ratings yet

- Silt TrapDocument5 pagesSilt TrapasyreenhaikalNo ratings yet

- Concrete Cube Report - Parapets 21 August 2021 28 Day TestDocument1 pageConcrete Cube Report - Parapets 21 August 2021 28 Day Testakakak01No ratings yet

- Casing Centralizer Series - 1 - Types of Centralizers - Pegasus Vertex, Inc. - BlogDocument3 pagesCasing Centralizer Series - 1 - Types of Centralizers - Pegasus Vertex, Inc. - BlogNihad PaşazadəNo ratings yet

- IM Trampa Flotador FTB125Document4 pagesIM Trampa Flotador FTB125ltorrNo ratings yet

- Efficiency and Application of Alternative Low Cost Construction Technologies in BuildingDocument133 pagesEfficiency and Application of Alternative Low Cost Construction Technologies in BuildingkidusNo ratings yet

- Feasibility OutlineDocument20 pagesFeasibility OutlineAlyyssa Julfa ArcenoNo ratings yet

- Dale Sinclair (Author) - Guide To Using The RIBA Plan of Work 2013-RIBA Publishing (2019) PDFDocument121 pagesDale Sinclair (Author) - Guide To Using The RIBA Plan of Work 2013-RIBA Publishing (2019) PDFPalaNo ratings yet

- 5-Fita de Cobre X Superficie de ConduçãoDocument3 pages5-Fita de Cobre X Superficie de Conduçãomt6760No ratings yet

- Guidelines Using Thermal Mass Concrete BuildingsDocument12 pagesGuidelines Using Thermal Mass Concrete Buildingsnatalia_campelo100% (1)

- Waterproofing ApplicationsDocument16 pagesWaterproofing ApplicationsTansel YılmazNo ratings yet

- Transmital Letter of Core Samples - JDT (South)Document1 pageTransmital Letter of Core Samples - JDT (South)Nscr GpiNo ratings yet

- Facility Condition Assessment: GuidebookDocument54 pagesFacility Condition Assessment: GuidebookMaxmore KarumamupiyoNo ratings yet

- Quikrete Concrete Product GuideDocument28 pagesQuikrete Concrete Product GuideBurak Yanar100% (1)

- HVAC Load CalculationDocument5 pagesHVAC Load Calculationthanh_79No ratings yet

- Excavator Maintenance ChartDocument2 pagesExcavator Maintenance ChartAnandkumar Pokala89% (9)

- 5 Asme Viii A 24 Clamp ConnectionDocument6 pages5 Asme Viii A 24 Clamp ConnectionIrvansyah RazadinNo ratings yet

- Annexure - B Safety SOP ChecklistDocument4 pagesAnnexure - B Safety SOP ChecklistANUJ SHAHNo ratings yet

- Brich HansenDocument5 pagesBrich HansenHUGINo ratings yet

- Muhammad Atif KhanDocument6 pagesMuhammad Atif KhanKQ House of DesignNo ratings yet

- Sprinkler Cabinets 3, 6, & 12 Sprinklers, 1/2 or 3/4 Inch NPT 6 ESFR Sprinklers, 3/4 or 1 Inch NPT General Description Technical DataDocument4 pagesSprinkler Cabinets 3, 6, & 12 Sprinklers, 1/2 or 3/4 Inch NPT 6 ESFR Sprinklers, 3/4 or 1 Inch NPT General Description Technical Datacarlos vegaNo ratings yet