Professional Documents

Culture Documents

Caracteristicas Del Tubo PDF

Uploaded by

Abelino Vargas TenjoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caracteristicas Del Tubo PDF

Uploaded by

Abelino Vargas TenjoCopyright:

Available Formats

Technical Data Sheet TA2100 A Page 1 of 3

Tubing

Stock codes A010xx (x: see below) 9 Apr 2010

Stock O.D. t Mass Length

Tube material* and type Inside bead:

code [mm] [mm] (kg/m) [mm]

A01000 1.4404 EN 10217-7 welded tube 8,0 1,0 0,17 6000 max. 0,2 mm

A01005 1.4404 EN 10217-7 welded tube 12,0 1,2 0,32 5800 max. 0,2 mm

A01015 1.4404 EN 10217-7 welded tube 16,0 1,5 0,54 5800 max. 0,2 mm

A01020 1.4404 EN 10217-7 welded tube 20,0 2,0 0,89 6000 max. 0,2 mm

A01025 1.4404 EN 10217-7 welded tube 25,0 2,0 1,13 5800 max. 0,2 mm

A01030 1.4404 EN 10217-7 welded tube 30,0 2,5 1,69 5800 max. 0,2 mm

A01035 1.4404 EN 10217-7 welded tube 38,0 3,0 2,59 5800 max. 0,2 mm

A01060 1.4404 EN 10217-7 welded tube 60,3 3,91 5,45 5800 removed

O.D.

Max. working pressure defined by Marioff:

200 bar for tube Ø 8 - 20 mm

140 bar for tube Ø 25 - 60,3 mm

t

O.D.= tube outer diameter Ø

t = wall thickness

Tube manufacturing specification

Tolerance classes EN 10217-7/EN ISO 1127: D4/T3, except for O.D. 60,3 mm D3/T3

Surface finishing Outside bead removed by grinding. No weld undercut allowed.

Roundness to be ensured.

Yield point RP 0,2 min.240 N/mm2 50°C

Heat treatment Annealed

Hardness HRB 72 - 82 / HV1 130 - 160 for Ø < 38

Product marking “HI-FOG sprinkler system” & manufacturer’s markings (with charge number)

Testing 100% eddy current testing

Tube cleaning Pickled or cleaned inside by other means. No loose particles allowed.

Delivery state Cleaned inside, sealed at both ends

Material certificate 3.1 (EN 10204)

Packing In wooden package

Design specification EN13480-3 and DNV Rules for classification of ships, Part 4, Chapter 1

Welding factor Z=1

Corrosion allowance c0 = 0

Bending allowance According to DNV Rules for ships, Part 4 and EN 13480-3

Bending radius R/D > 2,5

Marioff Corporation Oy • Virnatie 3 / P.O.Box 86, FI-01301 Vantaa, Finland

Tel. +358 (0)9 870 851 • Fax +358 (0)9 8708 5399 • www.marioff.com

© Marioff Corporation Oy 2010.

Marioff is part of UTC Fire & Security, which provides fire safety and security solutions to more than one million customers around the world. Headquartered in Connecticut, UTC Fire &

Security is a business unit of United Technologies Corp., which provides high technology products and services to the building and aerospace industries worldwide. More information can

be found at www.utcfireandsecurity.com.

Technical Data Sheet TA2100 A Page 2 of 3

Tubing

Stock codes A01xxx (x: see below) 9 Apr 2010

Stock O.D. t Mass Length

Tube material* and type Inside bead:

code [mm] [mm] (kg/m) [mm]

A01080 1.4404 EN 10217-7 welded tube 76,1 5,00 8,93 12000 max. 0,5 mm

A01090 1.4404 EN 10217-7 welded tube 88,9 5,00 10,54 12000 max. 0,5 mm

A01110 1.4404 EN 10217-7 welded tube 101,6 6,00 14,41 12000 max. 0,5 mm

A01130 1.4404 EN 10217-7 welded tube 114,3 7,00 18,87 12000 max. 0,5 mm

O.D.

Max. working pressure defined by Marioff:

140 bar for tube Ø 76,1 - 114,3 mm

O.D.= tube outer diameter Ø

t = wall thickness

Tube manufacturing specification

Tolerance classes EN 10217-7/EN ISO 1227: D3/T3

Surface finishing Outside bead removed by grinding. No weld undercut allowed.

Roundness to be ensured.

Yield point 240 N/mm2 50°C

Heat treatment Annealed

Product marking “HI-FOG sprinkler system” & manufacturer’s markings (with charge number)

Testing 100% eddy current testing

Tube cleaning Pickled or cleaned inside by other means. No loose particles allowed.

Delivery state Cleaned inside, sealed at both ends

Material certificate 3.1 (EN 10204)

Packing In wooden package

Design specification EN 13480-3:2002 Issue 2 (2005-08)

Welding factor Z=1

Corrosion allowance c0 = 0

Bending allowance According to EN 13480-3

Bending radius see page 3

Marioff Corporation Oy • Virnatie 3 / P.O.Box 86, FI-01301 Vantaa, Finland

Tel. +358 (0)9 870 851 • Fax +358 (0)9 8708 5399 • www.marioff.com

© Marioff Corporation Oy 2010.

Marioff is part of UTC Fire & Security, which provides fire safety and security solutions to more than one million customers around the world. Headquartered in Connecticut, UTC Fire &

Security is a business unit of United Technologies Corp., which provides high technology products and services to the building and aerospace industries worldwide. More information can

be found at www.utcfireandsecurity.com.

Technical Data Sheet TA2100 A Page 3 of 3

Tubing

9 Apr 2010

Bending radius

Mimimun bending radius for tubes is calculated according to EN 13480-3:2002 Issue 2 (2005-08).

O.D [mm] min bending radius [mm]

D76,1 210

D88,9 270

D101,6 300

D114,3 350

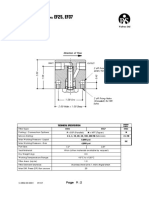

See also figure below (source: SFS-EN 13480-4 (2002-09-09)).

Optimal range for the longitudinal weld seam at bend; recommendation:

Marioff Corporation Oy • Virnatie 3 / P.O.Box 86, FI-01301 Vantaa, Finland

Tel. +358 (0)9 870 851 • Fax +358 (0)9 8708 5399 • www.marioff.com

© Marioff Corporation Oy 2010.

Marioff is part of UTC Fire & Security, which provides fire safety and security solutions to more than one million customers around the world. Headquartered in Connecticut, UTC Fire &

Security is a business unit of United Technologies Corp., which provides high technology products and services to the building and aerospace industries worldwide. More information can

be found at www.utcfireandsecurity.com.

You might also like

- Tpmcsteel: Welded Pipe For Pressure PurposeDocument2 pagesTpmcsteel: Welded Pipe For Pressure Purpose兆緯No ratings yet

- BoM Old ShanghaiDocument1 pageBoM Old ShanghaiMuhammad IrsyadNo ratings yet

- Tubular Hot Finished Structural Hollow SectionsDocument12 pagesTubular Hot Finished Structural Hollow SectionsVinit AhluwaliaNo ratings yet

- D05 07108 SKN4K-04 YtDocument1 pageD05 07108 SKN4K-04 YtEhsan PoravarNo ratings yet

- High Strength Steel Tubes For Structural and Engineering ApplicationsDocument12 pagesHigh Strength Steel Tubes For Structural and Engineering ApplicationsA LettristeNo ratings yet

- Technical Specification: DescriptionDocument2 pagesTechnical Specification: DescriptionAnonymous RcxX0FcNo ratings yet

- Revisar CMV 273mmDocument1 pageRevisar CMV 273mmGuadalupe Beltrán PacíficoNo ratings yet

- Certif Tu InDocument18 pagesCertif Tu InSri GangaNo ratings yet

- ASTM A 269 Standar Spec. For Seamless and Welded Autenitic SS TubingDocument6 pagesASTM A 269 Standar Spec. For Seamless and Welded Autenitic SS TubingJose TorresNo ratings yet

- Tech Spec Spiral Pipe For Faide Project.r1Document5 pagesTech Spec Spiral Pipe For Faide Project.r1Delshad DuhokiNo ratings yet

- technical_datasheet_3_pieces_ball_valve_adler_fp3_stainless_steel_fire_safeDocument12 pagestechnical_datasheet_3_pieces_ball_valve_adler_fp3_stainless_steel_fire_safeBenny 37No ratings yet

- Flow Meter Data SheetDocument8 pagesFlow Meter Data SheethilmiNo ratings yet

- Submittal Asset Doc Loc 5695806 (Hst3 2021)Document17 pagesSubmittal Asset Doc Loc 5695806 (Hst3 2021)Luen HopNo ratings yet

- AEGNEP Compressed AirDocument42 pagesAEGNEP Compressed AirDavid HayesNo ratings yet

- 1.4003 (3Cr12)Document11 pages1.4003 (3Cr12)celalkeskiner94No ratings yet

- Microcor Erosion ProbesDocument3 pagesMicrocor Erosion ProbesYordan PerdomoNo ratings yet

- Ds100-5-Eng (Mut2200el)Document12 pagesDs100-5-Eng (Mut2200el)JAIME HERNANDEZ HERNANDEZNo ratings yet

- API ballot changes elevator bore wear limitsDocument2 pagesAPI ballot changes elevator bore wear limitsIngenius TeamNo ratings yet

- ASTM A312 2014 Specification For Seamless and Welded Austenitic Stainless Steel Pipe PDFDocument4 pagesASTM A312 2014 Specification For Seamless and Welded Austenitic Stainless Steel Pipe PDFanon_295291420No ratings yet

- Robust Stainless Steel Pressure Transmitters for Harsh EnvironmentsDocument4 pagesRobust Stainless Steel Pressure Transmitters for Harsh EnvironmentsRodica PuscauNo ratings yet

- Submittal-ASSET-DOC-LOC-5695806 (HST3)Document16 pagesSubmittal-ASSET-DOC-LOC-5695806 (HST3)Luen HopNo ratings yet

- Ventile Electromagnetice Ev220b 15-50Document13 pagesVentile Electromagnetice Ev220b 15-50John BarrowNo ratings yet

- Product Information: These Values Are Valid With Hatko Applicators and CrimpersDocument1 pageProduct Information: These Values Are Valid With Hatko Applicators and CrimpersEhsan PoravarNo ratings yet

- Bahra WiresDocument12 pagesBahra WiresJoseph JoeNo ratings yet

- Terminals Datasheet D05.07024: Product InformationDocument2 pagesTerminals Datasheet D05.07024: Product InformationEhsan PoravarNo ratings yet

- Hilti HST3Document18 pagesHilti HST3Victor Tai100% (2)

- Dockweiler BPE SpecDocument1 pageDockweiler BPE SpecRey LieNo ratings yet

- Wise A600Document2 pagesWise A600naser712No ratings yet

- Baumer CombiTemp-TCR6 DS en 1907Document7 pagesBaumer CombiTemp-TCR6 DS en 1907Hữu NghịNo ratings yet

- EGT346Document3 pagesEGT346ghared salehNo ratings yet

- AMBICA 40mm Rod SS316L MTCDocument2 pagesAMBICA 40mm Rod SS316L MTCmetalexinNo ratings yet

- Bill of Materials: BQMFC015150 BQMFC016200 BQMFC017250 BQMFC018300 BQMFC019350Document1 pageBill of Materials: BQMFC015150 BQMFC016200 BQMFC017250 BQMFC018300 BQMFC019350Muhammad IrsyadNo ratings yet

- Item 4 Datasheet (1) 159001279Document1 pageItem 4 Datasheet (1) 159001279Luis Breña DiazNo ratings yet

- Cable Glands and Accessories - UpdatedDocument18 pagesCable Glands and Accessories - UpdatedAlfonsus W.M.No ratings yet

- Self-regulating heating cable guideDocument2 pagesSelf-regulating heating cable guideagdagdsNo ratings yet

- Cold Drawn Seamless Steel Tubes For Hydraulic CylindersDocument8 pagesCold Drawn Seamless Steel Tubes For Hydraulic Cylindersvijayasarathy2013No ratings yet

- Electrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetDocument4 pagesElectrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetEvka AkováNo ratings yet

- Tube HydraulicsDocument8 pagesTube HydraulicsrijalharunNo ratings yet

- DIN 1628 ST 52.4Document2 pagesDIN 1628 ST 52.4Anonymous m1cSnEavoNo ratings yet

- Raxton Breather Drains: Technical SpecificationDocument1 pageRaxton Breather Drains: Technical SpecificationElliza IshakNo ratings yet

- Dunaferr Cold Rolled Product catalogueDocument12 pagesDunaferr Cold Rolled Product catalogueMihály PálffyNo ratings yet

- Seamless Precision Steel Tubes For Hydraulic Cylinders - TN 008-00Document8 pagesSeamless Precision Steel Tubes For Hydraulic Cylinders - TN 008-00refeiNo ratings yet

- CBH-22-296 DIN 931 HB HT M10 X 70 SELF 8.8Document2 pagesCBH-22-296 DIN 931 HB HT M10 X 70 SELF 8.8qualityNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Engineering Data Sheet: Ci Discharge HosesDocument1 pageEngineering Data Sheet: Ci Discharge HosesIskandar HasibuanNo ratings yet

- Hardox 450: General Product DescriptionDocument2 pagesHardox 450: General Product DescriptionTeodor EzaruNo ratings yet

- MT 14 465 T1 Report Supplier 1 48.3mm TubeDocument1 pageMT 14 465 T1 Report Supplier 1 48.3mm TubeHaseeb KhanNo ratings yet

- Strenx 700 MC: Advanced High Strength SteelDocument2 pagesStrenx 700 MC: Advanced High Strength SteeldbaNo ratings yet

- Datasheet - Live: Capacitors With Screw Terminals 105 C B 43 650 B 43 670Document7 pagesDatasheet - Live: Capacitors With Screw Terminals 105 C B 43 650 B 43 670Blendwerk AntikunstNo ratings yet

- Product Range - Pipes - : Load and Service Years Can Be Seen atDocument4 pagesProduct Range - Pipes - : Load and Service Years Can Be Seen atConstantin CilibiuNo ratings yet

- Part list for cross over platform materialDocument1 pagePart list for cross over platform materialMaria MarcanoNo ratings yet

- Terminal Blcok Ex e Increased SafetyDocument2 pagesTerminal Blcok Ex e Increased SafetyEmmanuelPETITNo ratings yet

- 14 C.0802.00.0001 (Cat)Document1 page14 C.0802.00.0001 (Cat)Marwen GataaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Articulo 1Document8 pagesArticulo 1Abelino Vargas TenjoNo ratings yet

- Inf Ensayos de Comprésion Mes de Febrero de 2020Document8 pagesInf Ensayos de Comprésion Mes de Febrero de 2020Abelino Vargas TenjoNo ratings yet

- Datasheet - Alcaldía Bogotá - Imprenta Distrital - 0513-2020 - Bogotá D.C. - On PDFDocument5 pagesDatasheet - Alcaldía Bogotá - Imprenta Distrital - 0513-2020 - Bogotá D.C. - On PDFAbelino Vargas TenjoNo ratings yet

- Datasheet - Alcaldía Bogotá - Imprenta Distrital - 0513-2020 - Bogotá D.C. - On PDFDocument5 pagesDatasheet - Alcaldía Bogotá - Imprenta Distrital - 0513-2020 - Bogotá D.C. - On PDFAbelino Vargas TenjoNo ratings yet

- Distribution Blocks PDFDocument3 pagesDistribution Blocks PDFAbelino Vargas TenjoNo ratings yet

- Caracteristicas Del Tubo PDFDocument3 pagesCaracteristicas Del Tubo PDFAbelino Vargas Tenjo100% (1)

- Mounting Adapter XCN711K5T10D12S20: Stock Code 2000091663Document3 pagesMounting Adapter XCN711K5T10D12S20: Stock Code 2000091663Abelino Vargas TenjoNo ratings yet

- Income Tax Raids: Procedures and RightsDocument4 pagesIncome Tax Raids: Procedures and RightsshanikaNo ratings yet

- 5197-Car Hire 04 Dates-Ltr 157 DT 23.04.19Document1 page5197-Car Hire 04 Dates-Ltr 157 DT 23.04.19arpannathNo ratings yet

- Phillips Curve and Okun's LawDocument3 pagesPhillips Curve and Okun's LawSheldon JosephNo ratings yet

- Decoled FR Sas: Account MovementsDocument1 pageDecoled FR Sas: Account Movementsnatali vasylNo ratings yet

- BN68-13792A-01 - Leaflet-Remote - QLED LS03 - MENA - L02 - 220304.0Document2 pagesBN68-13792A-01 - Leaflet-Remote - QLED LS03 - MENA - L02 - 220304.0Bikram TiwariNo ratings yet

- OM-Module-5 (PM)Document25 pagesOM-Module-5 (PM)Absar SiddiquiNo ratings yet

- 5TH International Conference BrochureDocument5 pages5TH International Conference Brochureanup patwalNo ratings yet

- ICE Export Catalog 2011Document72 pagesICE Export Catalog 2011Thien BinhNo ratings yet

- Datasheet Hitec HS-311 ServoDocument1 pageDatasheet Hitec HS-311 ServoMilo LatinoNo ratings yet

- Dan Fue Leung v. IACDocument2 pagesDan Fue Leung v. IACCedricNo ratings yet

- 36 Writing Craft Essays by Chuck PalahniukDocument16 pages36 Writing Craft Essays by Chuck PalahniukAndy Ochumba0% (10)

- Alrehman Pirani Resume LMCDocument1 pageAlrehman Pirani Resume LMCapi-307195944No ratings yet

- 04 IPHS Primary Health CentreDocument20 pages04 IPHS Primary Health CentreKailash NagarNo ratings yet

- What Is Automation: Delegation of Human Control Functions To Technical Equipment Aimed Towards AchievingDocument26 pagesWhat Is Automation: Delegation of Human Control Functions To Technical Equipment Aimed Towards AchievingVeeraperumal ArumugamNo ratings yet

- Section 1 Quiz: Reduced Maintenance Real-World Modeling Both ( ) NoneDocument50 pagesSection 1 Quiz: Reduced Maintenance Real-World Modeling Both ( ) NoneNikolay100% (2)

- Kamor Ul Islam Jakoan Kobir Riad Omar Faruk Iqramul Hasan MD Abdur Rahman MD Kamrul Hasan FahimDocument16 pagesKamor Ul Islam Jakoan Kobir Riad Omar Faruk Iqramul Hasan MD Abdur Rahman MD Kamrul Hasan FahimRezoan FarhanNo ratings yet

- Sdoc 09 13 SiDocument70 pagesSdoc 09 13 SiJhojo Tesiorna FalcutilaNo ratings yet

- Appropriation For Annual Budget Year 2022Document5 pagesAppropriation For Annual Budget Year 2022Rafael FerolinoNo ratings yet

- An 124Document4 pagesAn 124Ank Electro FuzzNo ratings yet

- Tony'sDocument11 pagesTony'sanna sanaeiNo ratings yet

- Breast Problems After DeviveryDocument19 pagesBreast Problems After DeviverySanthosh.S.UNo ratings yet

- Indonesia Trade Report Highlights Recovery & OutlookDocument27 pagesIndonesia Trade Report Highlights Recovery & OutlookkennydoggyuNo ratings yet

- Principles of BioenergyDocument25 pagesPrinciples of BioenergyNazAsyrafNo ratings yet

- Group Assignment 1 - FinalDocument13 pagesGroup Assignment 1 - FinalWanteen LeeNo ratings yet

- Communication Barriers - Effects On Employees EfficiencyDocument27 pagesCommunication Barriers - Effects On Employees Efficiencyvanquish lassNo ratings yet

- Introduction of Hris Chapter No.1: Tayyaba IqbalDocument16 pagesIntroduction of Hris Chapter No.1: Tayyaba IqbalmahnooorNo ratings yet

- Marquez Vs Comelec GR 112889Document1 pageMarquez Vs Comelec GR 112889JFA100% (1)

- Turbo Charger and GasketDocument2 pagesTurbo Charger and GasketDavid NguyenNo ratings yet

- Charter OCAP 4-Device Remote Control: Manufacturer'S CodesDocument2 pagesCharter OCAP 4-Device Remote Control: Manufacturer'S CodesDerek WebsterNo ratings yet