Professional Documents

Culture Documents

PRCI Hot Tap Analysis Input Report: Joint Details Pipe Sleeve

PRCI Hot Tap Analysis Input Report: Joint Details Pipe Sleeve

Uploaded by

Maulana Hendra0 ratings0% found this document useful (0 votes)

13 views1 pageThe document provides details for analyzing a hot tap on a low carbon steel pipe with an outer diameter of 16 inches and thickness of 0.2 inches. The pipe contains methane gas flowing at 10 feet per second at 80 degrees Fahrenheit and 600 psi pressure. A low carbon steel sleeve with thickness of 0.25 inches and gap of 0.05 inches from the pipe is to be used. Welding will be done with an EXX18 electrode under low, medium, and high heat input conditions.

Original Description:

PRCI HOT TAP

Original Title

trial PRCI

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides details for analyzing a hot tap on a low carbon steel pipe with an outer diameter of 16 inches and thickness of 0.2 inches. The pipe contains methane gas flowing at 10 feet per second at 80 degrees Fahrenheit and 600 psi pressure. A low carbon steel sleeve with thickness of 0.25 inches and gap of 0.05 inches from the pipe is to be used. Welding will be done with an EXX18 electrode under low, medium, and high heat input conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pagePRCI Hot Tap Analysis Input Report: Joint Details Pipe Sleeve

PRCI Hot Tap Analysis Input Report: Joint Details Pipe Sleeve

Uploaded by

Maulana HendraThe document provides details for analyzing a hot tap on a low carbon steel pipe with an outer diameter of 16 inches and thickness of 0.2 inches. The pipe contains methane gas flowing at 10 feet per second at 80 degrees Fahrenheit and 600 psi pressure. A low carbon steel sleeve with thickness of 0.25 inches and gap of 0.05 inches from the pipe is to be used. Welding will be done with an EXX18 electrode under low, medium, and high heat input conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

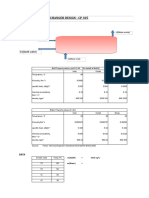

PRCI Hot Tap Analysis Input Report 4/13/2020 7:59:35AM

userex01 User Example 01 - Sleeve/Gas

Joint Details

Pipe Sleeve

Material = Low Carbon Steel Material = Low Carbon Steel

Thickness = 0.2000 in Thickness = 0.2500 in

Temperature = 80.00 F Temperature = 80.00 F

Outer Diameter = 16.0000 in Gap between Pipe / Sleeve = 0.0500 in

Base Metal Chemistry

Carbon: 0.22 Maganese: 1.20 Silicon: 0.00

Nickel: 0.00 Chrome: 0.00 Molybdenum: 0.00

Copper: 0.00 Vanadium: 0.00 Niobium: 0.00

Nitrogen: 0.00 (ppm) Boron: 0.00 (ppm) Ce(IIW) = 0.42

Pipe Contents

Content = Methane

Linear Flow Rate = 10.00 ft/sec Volume Flow Rate = mmscfd

Temperature = 80.00 F

Pressure = 600.00 Psig

Welding Conditions

Case: Low HI

Electrode Type = EXX18 Heat Input = 15.00 kJ/in

Electrode Diameter = 0.1250 in

Current = Voltage = Welding Speed =

Case: Medium HI

Electrode Type = EXX18 Heat Input = 25.00 kJ/in

Electrode Diameter = 0.1250 in

Current = Voltage = Welding Speed =

Case: High HI

Electrode Type = EXX18 Heat Input = 40.00 kJ/in

Electrode Diameter = 0.1250 in

Current = Voltage = Welding Speed =

You might also like

- Data Sheet Indirect Fired Heater NapkjsDocument12 pagesData Sheet Indirect Fired Heater Napkjsahmad santosoNo ratings yet

- Final SizingDocument14 pagesFinal SizingAnand BhiseNo ratings yet

- Assignment 3 ShazmirDocument10 pagesAssignment 3 ShazmirVedarajan ArmugamNo ratings yet

- Astm A350 LF2 PDFDocument1 pageAstm A350 LF2 PDFAna Raquel SantosNo ratings yet

- ASME Venting Calculation FB-2007 - PDFDocument3 pagesASME Venting Calculation FB-2007 - PDFjaganNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- Ned-1501 Finian C02Document3 pagesNed-1501 Finian C02Am ENo ratings yet

- Ned-1501 Finian C01 PDFDocument3 pagesNed-1501 Finian C01 PDFAm ENo ratings yet

- Ned-1501 Finian C01 (BT) PDFDocument3 pagesNed-1501 Finian C01 (BT) PDFAm ENo ratings yet

- Nickel-Chromium:: Heating Element & Resistance AlloysDocument2 pagesNickel-Chromium:: Heating Element & Resistance Alloysajaya biswalNo ratings yet

- NIC Components NRSX SeriesDocument9 pagesNIC Components NRSX SeriesNICCompNo ratings yet

- Modicon TM3 - TM3TI4Document9 pagesModicon TM3 - TM3TI4kpeNo ratings yet

- Certificado Pipeliner 6P+Document2 pagesCertificado Pipeliner 6P+Eric RamirezNo ratings yet

- Home enDocument3 pagesHome enpm9286vNo ratings yet

- Heat Transfer Area For Fin Tube Heat Exchanger For FBDDocument8 pagesHeat Transfer Area For Fin Tube Heat Exchanger For FBDPrathmesh GujaratiNo ratings yet

- #2. 열교환기 Design sheetDocument5 pages#2. 열교환기 Design sheet배광득0% (1)

- Danfoss - Design Report - Siddique - Ice - FactoryDocument17 pagesDanfoss - Design Report - Siddique - Ice - FactoryNaqqash SajidNo ratings yet

- Pr-2 Teknik Produksi I: Catur Kristiawan 124.16.021Document8 pagesPr-2 Teknik Produksi I: Catur Kristiawan 124.16.021Reynold AvgNo ratings yet

- NIC Components NRSG SeriesDocument8 pagesNIC Components NRSG SeriesNICCompNo ratings yet

- Data Sheet For SINAMICS G120 Power Module PM240: Rated Data General Tech. SpecificationsDocument2 pagesData Sheet For SINAMICS G120 Power Module PM240: Rated Data General Tech. SpecificationstrynoskNo ratings yet

- NIC Components NRSZC SeriesDocument7 pagesNIC Components NRSZC SeriesNICCompNo ratings yet

- Hydro-Test Calculation ZafarDocument3 pagesHydro-Test Calculation ZafarKaushar JamalNo ratings yet

- Compare S235JR, E250BRDocument6 pagesCompare S235JR, E250BRGANESHNo ratings yet

- G42Crmo4+Qt Cast Steel (1.7231) : Standard: Chemical Composition Min. % Max. %Document2 pagesG42Crmo4+Qt Cast Steel (1.7231) : Standard: Chemical Composition Min. % Max. %bhavin178No ratings yet

- Jobnumber: 0001 Job Name: BKT Wheel End Mount: Parameter Value Parameter ValueDocument22 pagesJobnumber: 0001 Job Name: BKT Wheel End Mount: Parameter Value Parameter ValueAkash PathadeNo ratings yet

- Double - Pipe - Exchanger (Para o Lado Ar)Document4 pagesDouble - Pipe - Exchanger (Para o Lado Ar)gabrieltravassosNo ratings yet

- 7112.a Data SheetsDocument7 pages7112.a Data SheetsAlexis PradoNo ratings yet

- Sup St500 Temperature Transmitter User ManualDocument2 pagesSup St500 Temperature Transmitter User ManualWolf BlackNo ratings yet

- WFI Plant Cooling Water Exchanger PHEDocument2 pagesWFI Plant Cooling Water Exchanger PHEdaniyalahmad119No ratings yet

- Liquid Service Line SizingDocument7 pagesLiquid Service Line SizingTilak AvNo ratings yet

- Modicon TM3 - TM3TI4Document9 pagesModicon TM3 - TM3TI4Fuad JahićNo ratings yet

- Tops 050TB2Document7 pagesTops 050TB2Faifai ChulanitaNo ratings yet

- Product Characteristics: Pressure SensorsDocument3 pagesProduct Characteristics: Pressure SensorsfadhlidzilNo ratings yet

- Application Note: Temperature Measurement With ThermocouplesDocument12 pagesApplication Note: Temperature Measurement With ThermocouplesMartinNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data SheetBoberNo ratings yet

- A 350 Grade LF2 ASTM A350 (USA) : StandardsDocument1 pageA 350 Grade LF2 ASTM A350 (USA) : StandardsMartin AndradeNo ratings yet

- Temperature Measurement Lab Report PDFDocument13 pagesTemperature Measurement Lab Report PDFSyafiiqahNo ratings yet

- 2N3440 STM TransistorDocument4 pages2N3440 STM TransistortotaliseNo ratings yet

- Quality According To Standard Number X20Cr13 EN 10088-3:2008 1.4021Document1 pageQuality According To Standard Number X20Cr13 EN 10088-3:2008 1.4021Krishna LavangamNo ratings yet

- Electrical and Thermal Performance: Ceramic Plate Series Thermoelectric Cooler Features ApplicationsDocument4 pagesElectrical and Thermal Performance: Ceramic Plate Series Thermoelectric Cooler Features Applicationsابكر ابو ميلادNo ratings yet

- PHE DesignDocument53 pagesPHE Designchgourishankar2000100% (1)

- PWR220/PWR221 S Series Shunt Resistor: Features ApplicationsDocument4 pagesPWR220/PWR221 S Series Shunt Resistor: Features ApplicationsGermanilloZetaNo ratings yet

- STE NTC ThermistorDocument9 pagesSTE NTC ThermistorEdson RibeiroNo ratings yet

- V.4 - Wall Thickness & Bend Thin 6 InchDocument15 pagesV.4 - Wall Thickness & Bend Thin 6 InchSuaib VCSNo ratings yet

- Seamless Pipes - API 5L Grade X65 PSL 2Document2 pagesSeamless Pipes - API 5L Grade X65 PSL 2isan.structural TjsvgalavanNo ratings yet

- Aluminum 1050-H14 (Soportes)Document2 pagesAluminum 1050-H14 (Soportes)Carlos Andres Garcia MuñozNo ratings yet

- 28-Technical Data Dearator DesignDocument3 pages28-Technical Data Dearator DesignFazri CMENo ratings yet

- ClimaSys CC - NSYCCOTHCDocument2 pagesClimaSys CC - NSYCCOTHCcauvongkhongmauNo ratings yet

- China Starwin Battery Pack Datasheet - RDocument9 pagesChina Starwin Battery Pack Datasheet - Rmiguel barreraNo ratings yet

- Dual Fuel HCCI Combustion - High Octane and High Cetane Number FuelsDocument22 pagesDual Fuel HCCI Combustion - High Octane and High Cetane Number Fuelsali reza ShakooriNo ratings yet

- Tops 030TB2Document6 pagesTops 030TB2Faifai ChulanitaNo ratings yet

- G120G220Document8 pagesG120G220nattapongthiangdeeNo ratings yet

- Heat Exchanger DesignDocument8 pagesHeat Exchanger Designkikokiko KarimNo ratings yet

- Exapmle 2-Gas Well PDFDocument3 pagesExapmle 2-Gas Well PDFSazzadul HossainNo ratings yet

- 5SDD 0120C0200: Rectifier DiodeDocument4 pages5SDD 0120C0200: Rectifier DiodeRajiv ChaudhariNo ratings yet

- Thermocouple: Common SpecificationsDocument6 pagesThermocouple: Common Specificationsmertel_26No ratings yet

- Insulation Thickness Calculation of Pipe: T T T T Input RequiredDocument3 pagesInsulation Thickness Calculation of Pipe: T T T T Input RequiredEddie FongNo ratings yet

- CMT Aluminum Tubing 2023 June 30Document36 pagesCMT Aluminum Tubing 2023 June 30Abraham BolañosNo ratings yet

- PINCH ANALYSIS Part 4 - Pinch Design Method-Maximum Energy Recovery Networks PDFDocument34 pagesPINCH ANALYSIS Part 4 - Pinch Design Method-Maximum Energy Recovery Networks PDFCaioPaesNo ratings yet

- COM-EF-844-1: Coatings Inspection Report FormDocument9 pagesCOM-EF-844-1: Coatings Inspection Report FormMaulana Hendra100% (1)

- Mech & Chem Pipe X52 PDFDocument4 pagesMech & Chem Pipe X52 PDFMaulana HendraNo ratings yet

- Grove Rough Terrain Cranes Spec 4ecb98 PDFDocument5 pagesGrove Rough Terrain Cranes Spec 4ecb98 PDFMaulana HendraNo ratings yet

- Features: Measurement of Residual Stresses in Uoe-Saw Line PipesDocument5 pagesFeatures: Measurement of Residual Stresses in Uoe-Saw Line PipesMaulana HendraNo ratings yet