Professional Documents

Culture Documents

7112.a Data Sheets

Uploaded by

Alexis PradoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7112.a Data Sheets

Uploaded by

Alexis PradoCopyright:

Available Formats

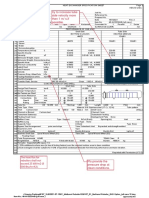

Technical Specification

Plate Heat Exchanger SIGMA M 18 NBL

Customer : Metalinox Group

Your inquiry | Item : Rum PHE’s | cold filtration - regeneration

Quote No. | Item : 7112.A | Pos.: 1

Technical Calculation Cold side Warm side

Section: exchanger Rum Rum

Flow rate 6,000.0 l/h 6,000.0 l/h

Mass flow 5,666.1 kg/h 5,615.0 kg/h

Heat load kW 136.73

Temperature in out °C -4.0 18.0 30.0 8.2

Media type liquid gaseous liquid gaseous

Density t/m³ 0.944 0.936

Specific Heat kJ/kgK 3.945 4.021

Thermal conductivity W/mK 0.356 0.361

Dynamic viscosity cP 5.208 3.030

Latent heat kJ/kg 0.000 0.000

Surface m² 7.5

K-Value W/m²K 1,515.6

Excess surface | Fouling % | cm²K/W 5.90 | 0.3680

Oper. pressure (min|max) | Test pressure bar 0.00 | 10.00 | 12.50 0.00 | 10.00 | 12.50

Gasket material EPDM EPDM

Plate material | Fixing AISI 316L | mechanically fixed

No. of plates | Sheet thickness No. | mm 43 | 0.50 / 0.50

Pressure loss bar | bar 0.290 0.230

Hold-up volume (water) l 13.568 13.568

No. of passes | Plate arrangement countercurrent 3 | 3 x 7 SH 3 | 3 x 7 SW

Frame design Carbon steel - primer and coating in color RAL 7001

Rules | Fluid group | Category 2014/68/EU / AD2000 | 2 | Art. 4 Paragraph 3

Intermediate Plate | Intermediate Frame No. 0 | 0

Oper. pressure (min|max) | Test pressure bar 0.00 | 10.00 | 14.30

Design temperature min | max -10.0 °C | 95.0 °C

Maximum fitting no. of plates 83

Cold side Connections Warm side

Pos. Type | Size | Material Pos. Type | Size | Material

In H Clamp connection ISO DN-50 - 60,3x2 AISI In C Clamp connection ISO DN-50 - 60,3x2 AISI

316Ti 316Ti

Out B Clamp connection ISO DN-50 - 60,3x2 AISI Out E Clamp connection ISO DN-50 - 60,3x2 AISI

316Ti 316Ti

Accessories No. Description

Sketch (Subject to technical changes upon placing the order !)

Dimensions (mm)

length (L) : 860.00

width (B) : 340.00

height (H) : 1,026.00

measure (n) : 165.00

measure (o) : 150.50

measure (p) : 900.50

Net weight (kg) 208

The thermal resistance of the platepack materials is up to max. 95.0 °C .

ANG_EN 3.0 – PG3.6.28-M0-DB 2.1015 24-APR-2023

Technical Specification

Plate Heat Exchanger SIGMA M 18 NBL

Customer : Metalinox Group

Your inquiry | Item : Rum PHE’s | cold filtration - reheating

Quote No. | Item : 7112.A | Pos.: 2

Technical Calculation Cold side Warm side

Section: exchanger Rum Warm water

Flow rate 6,000.0 l/h 12,000.0 l/h

Mass flow 5,632.3 kg/h 11,962.0 kg/h

Heat load kW 187.46

Temperature in out °C 0.0 30.0 32.0 18.5

Media type liquid gaseous liquid gaseous

Density t/m³ 0.939 0.997

Specific Heat kJ/kgK 3.995 4.183

Thermal conductivity W/mK 0.359 0.607

Dynamic viscosity cP 3.640 0.889

Latent heat kJ/kg 0.000 0.000

Surface m² 10.2

K-Value W/m²K 2,479.1

Excess surface | Fouling % | cm²K/W 5.10 | 0.1960

Oper. pressure (min|max) | Test pressure bar 0.00 | 10.00 | 12.50 0.00 | 10.00 | 12.50

Gasket material EPDM EPDM

Plate material | Fixing AISI 316L | mechanically fixed

No. of plates | Sheet thickness No. | mm 58 | 0.50 / 0.50

Pressure loss bar | bar 0.300 0.760

Hold-up volume (water) l 17.824 18.432

No. of passes | Plate arrangement countercurrent 4 | 4 x 7 SW 4 | 1 x 8 SH + 3 x 7 SH

Frame design Carbon steel - primer and coating in color RAL 7001

Rules | Fluid group | Category 2014/68/EU / AD2000 | 2 | Art. 4 Paragraph 3

Intermediate Plate | Intermediate Frame No. 0 | 0

Oper. pressure (min|max) | Test pressure bar 0.00 | 10.00 | 14.30

Design temperature min | max -10.0 °C | 95.0 °C

Maximum fitting no. of plates 83

Cold side Connections Warm side

Pos. Type | Size | Material Pos. Type | Size | Material

In H Clamp connection ISO DN-50 - 60,3x2 AISI In D Clamp connection ISO DN-50 - 60,3x2 AISI

316Ti 316Ti

Out A Clamp connection ISO DN-50 - 60,3x2 AISI Out E Clamp connection ISO DN-50 - 60,3x2 AISI

316Ti 316Ti

Accessories No. Description

Sketch (Subject to technical changes upon placing the order !)

Dimensions (mm)

length (L) : 860.00

width (B) : 340.00

height (H) : 1,026.00

measure (n) : 165.00

measure (o) : 150.50

measure (p) : 900.50

Net weight (kg) 226

The thermal resistance of the platepack materials is up to max. 95.0 °C .

ANG_EN 3.0 – PG3.6.28-M0-DB 2.1015 24-APR-2023

Technical Specification

Plate Heat Exchanger SIGMA M 18

Customer : Metalinox Group

Your inquiry | Item : Rum PHE’s | cold filtration – reheating with regen

Quote No. | Item : 7112.A | Pos.: 2a

Technical Calculation Cold side Warm side

Section: exchanger Rum Warm water

Flow rate 6,000.0 l/h 12,000.0 l/h

Mass flow 5,672.0 kg/h 11,950.3 kg/h

Heat load kW 82.73

Temperature in out °C 17.0 30.0 32.0 26.0

Media type liquid gaseous liquid gaseous

Density t/m³ 0.945 0.996

Specific Heat kJ/kgK 4.039 4.183

Thermal conductivity W/mK 0.362 0.614

Dynamic viscosity cP 2.606 0.816

Latent heat kJ/kg 0.000 0.000

Surface m² 10.2

K-Value W/m²K 1,738.7

Excess surface | Fouling % | cm²K/W 50.50 | 1.9300

Oper. pressure (min|max) | Test pressure bar 0.00 | 10.00 | 12.50 0.00 | 10.00 | 12.50

Gasket material EPDM EPDM

Plate material | Fixing AISI 316L | mechanically fixed

No. of plates | Sheet thickness No. | mm 58 | 0.50 / 0.50

Pressure loss bar | bar 0.280 0.750

No. of passes | Plate arrangement countercurrent 4 | 4 x 7 SW 4 | 1 x 8 SH + 3 x 7 SH

Accessories No. Description

Sketch (Subject to technical changes upon placing the order !)

Dimensions ()

length (L) :

width (B) :

height (H) :

measure (n) :

measure (o) :

measure (p) :

Net weight (kg) 71

The thermal resistance of the platepack materials is up to max. 95.0 °C .

ANG_EN 3.0 – PG3.6.28-M0-DB 2.1015 24-APR-2023

Technical Specification

Plate Heat Exchanger SIGMA M 18 NBL

Customer : Metalinox Group

Your inquiry | Item : Rum PHE’s | cold filtration - cooling

Quote No. | Item : 7112.A | Pos.: 3

Technical Calculation Cold side Warm side

Section: cooler propylene glycol 30% Rum

Flow rate 32,500.0 l/h 6,000.0 l/h

Mass flow 33,757.7 kg/h 5,635.5 kg/h

Heat load kW 196.77

Temperature in out °C -6.7 -1.2 30.0 -1.5

Media type liquid gaseous liquid gaseous

Density t/m³ 1.039 0.939

Specific Heat kJ/kgK 3.785 3.990

Thermal conductivity W/mK 0.417 0.359

Dynamic viscosity cP 8.621 3.765

Latent heat kJ/kg 0.000 0.000

Surface m² 7.6

K-Value W/m²K 1,775.3

Excess surface | Fouling % | cm²K/W 4.90 | 0.2630

Oper. pressure (min|max) | Test pressure bar 0.00 | 10.00 | 12.50 0.00 | 10.00 | 12.50

Gasket material EPDM EPDM

Plate material | Fixing AISI 316L | mechanically fixed

No. of plates | Sheet thickness No. | mm 44 | 0.50 / 0.50

Pressure loss bar | bar 0.380 0.250

Hold-up volume (water) l 14.176 13.568

No. of passes | Plate arrangement countercurrent 1 | 1 x 22 SH 3 | 3 x 7 SW

Frame design Carbon steel - primer and coating in color RAL 7001

Rules | Fluid group | Category 2014/68/EU / AD2000 | 2 | Art. 4 Paragraph 3

Intermediate Plate | Intermediate Frame No. 0 | 0

Oper. pressure (min|max) | Test pressure bar 0.00 | 10.00 | 14.30

Design temperature min | max -10.0 °C | 95.0 °C

Maximum fitting no. of plates 83

Cold side Connections Warm side

Pos. Type | Size | Material Pos. Type | Size | Material

In B Clamp connection ISO DN-50 - 60,3x2 AISI In E Clamp connection ISO DN-50 - 60,3x2 AISI

316Ti 316Ti

Out A Clamp connection ISO DN-50 - 60,3x2 AISI Out C Clamp connection ISO DN-50 - 60,3x2 AISI

316Ti 316Ti

Accessories No. Description

Sketch (Subject to technical changes upon placing the order !)

The linked image cannot be display ed. The file may hav e been mov ed, renamed, or deleted. V erify that the link points to the correct file and location.

Dimensions (mm)

length (L) : 860.00

width (B) : 340.00

height (H) : 1,026.00

measure (n) : 165.00

measure (o) : 150.50

measure (p) : 900.50

Net weight (kg) 209

The thermal resistance of the platepack materials is up to max. 95.0 °C .

ANG_EN 3.0 – PG3.6.28-M0-DB 2.1015 24-APR-2023

Technical Specification

Plate Heat Exchanger SIGMA M 18

Customer : Metalinox Group

Your inquiry | Item : Rum PHE’s | cold filtration – cooling with regen

Quote No. | Item : 7112.A | Pos.: 3a

Technical Calculation Cold side Warm side

Section: cooler propylene glycol 30% Rum

Flow rate 32,500.0 l/h 6,000.0 l/h

Mass flow 33,775.3 kg/h 5,686.9 kg/h

Heat load kW 75.42

Temperature in out °C -6.7 -4.6 8.2 -4.0

Media type liquid gaseous liquid gaseous

Density t/m³ 1.039 0.948

Specific Heat kJ/kgK 3.780 3.913

Thermal conductivity W/mK 0.415 0.354

Dynamic viscosity cP 9.404 6.490

Latent heat kJ/kg 0.000 0.000

Surface m² 7.6

K-Value W/m²K 1,521.9

Excess surface | Fouling % | cm²K/W 9.50 | 0.5700

Oper. pressure (min|max) | Test pressure bar 0.00 | 10.00 | 12.50 0.00 | 10.00 | 12.50

Gasket material EPDM EPDM

Plate material | Fixing AISI 316L | mechanically fixed

No. of plates | Sheet thickness No. | mm 44 | 0.50 / 0.50

Pressure loss bar | bar 0.390 0.310

No. of passes | Plate arrangement countercurrent 1 | 1 x 22 SH 3 | 3 x 7 SW

Accessories No. Description

Sketch (Subject to technical changes upon placing the order !)

Fehler! Es wurde kein Dateiname angegeben.

Dimensions ()

length (L) :

width (B) :

height (H) :

measure (n) :

measure (o) :

measure (p) :

Net weight (kg) 54

The thermal resistance of the platepack materials is up to max. 95.0 °C .

ANG_EN 3.0 – PG3.6.28-M0-DB 2.1015 24-APR-2023

Technical Specification

Plate Heat Exchanger SIGMA M 18 TBL

Customer : Metalinox Group

Your inquiry | Item : Rum PHE’s | cold filtration - 3 stage design

Quote No. | Item : 7112.A | Pos.: 4

Technical Calculation Cold side Warm side

Section: heating Rum Warm water

Flow rate 6,000.0 l/h 12,000.0 l/h

Mass flow 5,632.3 kg/h 11,962.0 kg/h

Heat load kW 187.46

Temperature in out °C 0.0 30.0 32.0 18.5

Media type liquid gaseous liquid gaseous

Density t/m³ 0.939 0.997

Specific Heat kJ/kgK 3.995 4.183

Thermal conductivity W/mK 0.359 0.607

Dynamic viscosity cP 3.640 0.889

Latent heat kJ/kg 0.000 0.000

Surface m² 10.2

K-Value W/m²K 2,479.1

Excess surface | Fouling % | cm²K/W 5.10 | 0.1960

Oper. pressure (min|max) | Test pressure bar 0.00 | 10.00 | 12.50 0.00 | 10.00 | 12.50

Gasket material EPDM EPDM

Plate material | Fixing AISI 316L | mechanically fixed

No. of plates | Sheet thickness No. | mm 58 | 0.50 / 0.50

Pressure loss bar | bar 0.300 0.760

Hold-up volume (water) l 18.124 18.732

No. of passes | Plate arrangement countercurrent 4 | 4 x 7 SW 4 | 1 x 8 SH + 3 x 7 SH

Technical Calculation Cold side Warm side

Section: exchanger Rum Rum

Flow rate 6,000.0 l/h 6,000.0 l/h

Mass flow 5,666.1 kg/h 5,615.0 kg/h

Heat load kW 136.73

Temperature in out °C -4.0 18.0 30.0 8.2

Media type liquid gaseous liquid gaseous

Density t/m³ 0.944 0.936

Specific Heat kJ/kgK 3.945 4.021

Thermal conductivity W/mK 0.356 0.361

Dynamic viscosity cP 5.208 3.030

Latent heat kJ/kg 0.000 0.000

Surface m² 7.5

K-Value W/m²K 1,515.6

Excess surface | Fouling % | cm²K/W 5.90 | 0.3680

Oper. pressure (min|max) | Test pressure bar 0.00 | 10.00 | 12.50 0.00 | 10.00 | 12.50

Gasket material EPDM EPDM

Plate material | Fixing AISI 316L | mechanically fixed

No. of plates | Sheet thickness No. | mm 43 | 0.50 / 0.50

Pressure loss bar | bar 0.290 0.230

Hold-up volume (water) l 14.168 14.168

No. of passes | Plate arrangement countercurrent 3 | 3 x 7 SH 3 | 3 x 7 SW

Following section: cooling

ANG_EN 3.0 – PG3.6.28-M0-DB 2.1015 24-APR-2023

Technical Specification

Plate Heat Exchanger SIGMA M 18 TBL

Customer : Metalinox Group

Your inquiry | Item : Rum PHE’s | cold filtration - 3 stage design

Quote No. | Item : 7112.A | Pos.: 4

Technical Calculation Cold side Warm side

Section: cooling propylene glycol 30% Rum

Flow rate 32,500.0 l/h 6,000.0 l/h

Mass flow 33,757.7 kg/h 5,635.5 kg/h

Heat load kW 196.77

Temperature in out °C -6.7 -1.2 30.0 -1.5

Media type liquid gaseous liquid gaseous

Density t/m³ 1.039 0.939

Specific Heat kJ/kgK 3.785 3.990

Thermal conductivity W/mK 0.417 0.359

Dynamic viscosity cP 8.621 3.765

Latent heat kJ/kg 0.000 0.000

Surface m² 7.6

K-Value W/m²K 1,775.3

Excess surface | Fouling % | cm²K/W 4.90 | 0.2630

Oper. pressure (min|max) | Test pressure bar 0.00 | 10.00 | 12.50 0.00 | 10.00 | 12.50

Gasket material EPDM EPDM

Plate material | Fixing AISI 316L | mechanically fixed

No. of plates | Sheet thickness No. | mm 44 | 0.50 / 0.50

Pressure loss bar | bar 0.380 0.250

Hold-up volume (water) l 14.176 13.868

No. of passes | Plate arrangement countercurrent 1 | 1 x 22 SH 3 | 3 x 7 SW

Frame design Carbon steel - primer and coating in color RAL 7001

Rules | Fluid group | Category 2014/68/EU / AD2000 | 2 | Art. 4 Paragraph 3

Intermediate Plate | Intermediate Frame No. 0 | 2

Oper. pressure (min|max) | Test pressure bar 0.00 | 10.00 | 14.30

Design temperature min | max -10.0 °C | 95.0 °C

Maximum fitting no. of plates 148

Connections

Position No. Type | Size | Material

Frame head 2 Clamp connection ISO DN-50 - 60,3x2 AISI 316Ti

Movable Cover 3 Clamp connection ISO DN-50 - 60,3x2 AISI 316Ti

Intermediate Frame 7 i.f.-insert clamp connection straight DIN DN-50 - 53x1.5 AISI 36Ti

1 blind insert R 2" AISI 316TI

Accessories No. Description

Sketch (Subject to technical changes upon placing the order !)

Dimensions (mm)

length (L) : 1,695.00

width (B) : 340.00

height (H) : 1,150.00

measure (n) : 165.00

measure (o) : 275.00

measure (p) : 1,025.00

Net weight (kg) 489

The thermal resistance of the platepack materials is up to max. 95.0 °C .

The process calculation in particular the pressure loss calculation presumes equal operating pressures on both sides

of the unit.

ANG_EN 3.0 – PG3.6.28-M0-DB 2.1015 24-APR-2023

You might also like

- Plate Heat Exchanger Technical SpecificationDocument2 pagesPlate Heat Exchanger Technical SpecificationRaul SebastiamNo ratings yet

- Drum - Vertical Wire Mesh Mist EliminatorDocument8 pagesDrum - Vertical Wire Mesh Mist EliminatorAnonymous oVRvsdWzfBNo ratings yet

- PHE01 M6M 102P 1600kWDocument1 pagePHE01 M6M 102P 1600kWtsoomoo tsolmonNo ratings yet

- Dual Fuel Genset - Heat Recovery-1-2Document2 pagesDual Fuel Genset - Heat Recovery-1-2Ab Sami100% (1)

- BP6 Vapor X Água 20-65 10m3h FDDocument2 pagesBP6 Vapor X Água 20-65 10m3h FDAlexNo ratings yet

- 174-Fisa TehnicaDocument1 page174-Fisa TehnicaCosma loredanaNo ratings yet

- 600RT LMTD 2 T20Document1 page600RT LMTD 2 T20syahmi yacobNo ratings yet

- VG 320 Oil CoolerDocument32 pagesVG 320 Oil CoolergsdaundhNo ratings yet

- Process Design Report SummaryDocument3 pagesProcess Design Report Summarymuhd.qasimNo ratings yet

- Heat Exchanger Specification Sheet SI UnitsDocument1 pageHeat Exchanger Specification Sheet SI UnitsdhaNo ratings yet

- PHE SelectionsDocument67 pagesPHE SelectionsSelva Kumar Selva KumarNo ratings yet

- Heat Exchanger Rating Calc SheetDocument14 pagesHeat Exchanger Rating Calc SheetSatria 'igin' Girindra NugrahaNo ratings yet

- PHE - 4 Section For Ice Cream MixDocument9 pagesPHE - 4 Section For Ice Cream MixMuhammad JunaidNo ratings yet

- FD TC BERMO COPOLIMERO 3943 X ÁGUA Rev01Document2 pagesFD TC BERMO COPOLIMERO 3943 X ÁGUA Rev01Guilherme ZanotelliNo ratings yet

- CH 7 D 3.35.1-EDocument3 pagesCH 7 D 3.35.1-Eวงศกร สิงห์เอี่ยมNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- Double - Pipe - Exchanger (Para o Lado Ar)Document4 pagesDouble - Pipe - Exchanger (Para o Lado Ar)gabrieltravassosNo ratings yet

- Parametros Agua StripDocument1 pageParametros Agua StripJose CaminoNo ratings yet

- Plate Heat Exchanger Model M15-MFG - ASTM B265 Gr1 TitaniumDocument1 pagePlate Heat Exchanger Model M15-MFG - ASTM B265 Gr1 TitaniumCardoso MalacaoNo ratings yet

- Kelvion Plate Heat Exchanger: Thermal Data For: NT100X CDL-10Document2 pagesKelvion Plate Heat Exchanger: Thermal Data For: NT100X CDL-10JafarNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- Heat Exchanger Rating Data Sheet Eslam Shebl Units: D:/general/PHPC/htri/new Preheater Proposal - HtriDocument1 pageHeat Exchanger Rating Data Sheet Eslam Shebl Units: D:/general/PHPC/htri/new Preheater Proposal - HtriEslam ShiblNo ratings yet

- TL10PFM - 75P Dec182018Document1 pageTL10PFM - 75P Dec182018Anonymous pVoSWn8yh0No ratings yet

- CONDENSER - Performance Heat Exchanger: B10Tx20: SSP G7Document2 pagesCONDENSER - Performance Heat Exchanger: B10Tx20: SSP G7Goran PanticNo ratings yet

- Heat Exchanger Design for BreweryDocument14 pagesHeat Exchanger Design for BreweryAnand BhiseNo ratings yet

- T10-MFM Tech SpecDocument2 pagesT10-MFM Tech SpecMiltonNo ratings yet

- TECHNICAL DATASHEET FOR - For Supply of Amine - Plate & Frame ExchangerDocument4 pagesTECHNICAL DATASHEET FOR - For Supply of Amine - Plate & Frame Exchangerdilip matalNo ratings yet

- Heat Exchanger Specification SheetDocument4 pagesHeat Exchanger Specification SheetAnita PanthiNo ratings yet

- PSV Calculation Report - Gas / Vapor Relief Sizing Case: Const. VarDocument4 pagesPSV Calculation Report - Gas / Vapor Relief Sizing Case: Const. VarfarshadNo ratings yet

- WFI Plant Cooling Water Exchanger PHEDocument2 pagesWFI Plant Cooling Water Exchanger PHEdaniyalahmad119No ratings yet

- Techn Spec B01052211.WDocument1 pageTechn Spec B01052211.WJOSE GARCIANo ratings yet

- Weaver Heat Transfer Technologies DATA SHEET 1Document1 pageWeaver Heat Transfer Technologies DATA SHEET 1Bhavin PatelNo ratings yet

- MSS SP 58Document1 pageMSS SP 58octa aldyNo ratings yet

- F:/anni/contoh Htri/latihan 1.htriDocument1 pageF:/anni/contoh Htri/latihan 1.htriAnni RahmatNo ratings yet

- Heat exchanger specification sheet vibration analysisDocument3 pagesHeat exchanger specification sheet vibration analysisSRINo ratings yet

- GP04 2PHE 1M3H 98-40-10 FD Bermo TrocadorDocument5 pagesGP04 2PHE 1M3H 98-40-10 FD Bermo TrocadorWanner MartinsNo ratings yet

- Gas-Gas Exchanger DatasheetDocument3 pagesGas-Gas Exchanger DatasheetidilfitriNo ratings yet

- Kelvion Plate Heat Exchanger QuotationDocument2 pagesKelvion Plate Heat Exchanger QuotationJafarNo ratings yet

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- HE Can Warmer 3150313-173 english versionDocument2 pagesHE Can Warmer 3150313-173 english versiongrantday2000No ratings yet

- AQ10T-BFM, 363PL 2335kWDocument2 pagesAQ10T-BFM, 363PL 2335kWLiviu ConstantinNo ratings yet

- HE Rating Data Sheet v6Document1 pageHE Rating Data Sheet v6dhaNo ratings yet

- Gas Chiller Datasheet PDFDocument2 pagesGas Chiller Datasheet PDFidilfitriNo ratings yet

- Gas Chiller DatasheetDocument2 pagesGas Chiller DatasheetidilfitriNo ratings yet

- Hot Gas Recuperator Specification SheetDocument1 pageHot Gas Recuperator Specification Sheetmjaric81No ratings yet

- Calculation of Pipe Line Heat LossDocument9 pagesCalculation of Pipe Line Heat LossradanpetricaNo ratings yet

- Natural Gas Steam Heater SummaryDocument14 pagesNatural Gas Steam Heater SummarySivi NallamothuNo ratings yet

- Espec. Tecnica Ic Alfa LavalDocument1 pageEspec. Tecnica Ic Alfa LavalAlejandro Luis LandaNo ratings yet

- Chapter 1Document4 pagesChapter 1Aiman HazimNo ratings yet

- Heat Exchanger RatingDocument10 pagesHeat Exchanger RatinggabrieltravassosNo ratings yet

- Plate Heat Exchanger Technical SpecificationDocument1 pagePlate Heat Exchanger Technical SpecificationAsif Zahidul HaqNo ratings yet

- Heat Transfer Area For Fin Tube Heat Exchanger For FBDDocument8 pagesHeat Transfer Area For Fin Tube Heat Exchanger For FBDPrathmesh GujaratiNo ratings yet

- Tank Shell Calculation: Mechanical Calculations According To en 14015Document5 pagesTank Shell Calculation: Mechanical Calculations According To en 14015paeg651250% (4)

- Training Program On Basic Process Engineering Practices For Technip India Ltd. by The Technomanage GroupDocument68 pagesTraining Program On Basic Process Engineering Practices For Technip India Ltd. by The Technomanage GroupKrishanu SahaNo ratings yet

- Heat exchanger rating and specification dataDocument5 pagesHeat exchanger rating and specification datachemical509No ratings yet

- Tube Side Velocity CalculationDocument20 pagesTube Side Velocity CalculationNitin KurupNo ratings yet

- Pipe Fitting Losses: Chemical Engineer's GuideDocument8 pagesPipe Fitting Losses: Chemical Engineer's GuideEdu CordonNo ratings yet

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Curva Caracteristica Bomba Hotel Churum MeruDocument2 pagesCurva Caracteristica Bomba Hotel Churum MeruAlexis PradoNo ratings yet

- Especificaciones Equipos de Refrigeracion - Corporacion Dominguez (042123)Document5 pagesEspecificaciones Equipos de Refrigeracion - Corporacion Dominguez (042123)Alexis PradoNo ratings yet

- FP 1.0 Fire Pump Systems Engineering DataDocument1 pageFP 1.0 Fire Pump Systems Engineering DataAlexis PradoNo ratings yet

- Seleccion Bomba Sci Hotel Churum Meru 500VS165Document1 pageSeleccion Bomba Sci Hotel Churum Meru 500VS165Alexis PradoNo ratings yet

- Cuenta Rejillas EmergenciaDocument2 pagesCuenta Rejillas EmergenciaAlexis PradoNo ratings yet

- EGYS70HLP 115-127 V 60 HZ 1Document3 pagesEGYS70HLP 115-127 V 60 HZ 1Alexis PradoNo ratings yet

- ESCOUTCHEONSDocument8 pagesESCOUTCHEONSAlexis PradoNo ratings yet

- PENDENTDocument4 pagesPENDENTAlexis PradoNo ratings yet

- Seleccion Bomba Incendio Acar Motors IiDocument1 pageSeleccion Bomba Incendio Acar Motors IiAlexis PradoNo ratings yet

- Evaporadoras 3HpDocument44 pagesEvaporadoras 3HpAlexis PradoNo ratings yet

- Ficha Tecnica Trampa Termostatica Archive B PDFDocument2 pagesFicha Tecnica Trampa Termostatica Archive B PDFAlexis PradoNo ratings yet

- Ficha Tecnica Trampa Termostatica Archive A PDFDocument2 pagesFicha Tecnica Trampa Termostatica Archive A PDFAlexis PradoNo ratings yet

- Calculo Hidraulico Sci CoposaDocument3 pagesCalculo Hidraulico Sci CoposaAlexis PradoNo ratings yet

- KEH New “C” Generation Condensing UnitsDocument24 pagesKEH New “C” Generation Condensing UnitsAlexis PradoNo ratings yet

- Calculo de Carga Tunel KeepriteDocument2 pagesCalculo de Carga Tunel KeepriteAlexis PradoNo ratings yet

- Teachers' Perception of Their Initial Preparation in Teaching Senior High School PhysicsDocument11 pagesTeachers' Perception of Their Initial Preparation in Teaching Senior High School PhysicsFelipe López GarduzaNo ratings yet

- Orifice Plate Flow Calculator Pressure DropDocument6 pagesOrifice Plate Flow Calculator Pressure Droplutfi awnNo ratings yet

- Mix Design and Application of Porous Asphalt Pavement Using Japanese TechnologyDocument12 pagesMix Design and Application of Porous Asphalt Pavement Using Japanese TechnologyJelian GraceNo ratings yet

- EMM3302 Group ProjectDocument8 pagesEMM3302 Group ProjectNizar NanoNo ratings yet

- Fractional Dynamics and Control, DIMITRUDocument301 pagesFractional Dynamics and Control, DIMITRUWilson LawrenteNo ratings yet

- Fractured Water-Injection Wells: A Pressure Falloff Test For Determining Fracture DimensionsDocument11 pagesFractured Water-Injection Wells: A Pressure Falloff Test For Determining Fracture DimensionsMZNo ratings yet

- TexturingDocument25 pagesTexturingRtr Hasan MahmudNo ratings yet

- Phet Force and Newton's Laws ReviewDocument5 pagesPhet Force and Newton's Laws ReviewkhairatuddinariNo ratings yet

- QFT Lecture NotesDocument175 pagesQFT Lecture NotesRajneil100% (1)

- Quantum Chemistry Particle Probability WavefunctionsDocument3 pagesQuantum Chemistry Particle Probability Wavefunctionsanurag pandeyNo ratings yet

- Orifice Under Varying Head: Experiment No.: 5Document4 pagesOrifice Under Varying Head: Experiment No.: 5KshitizNo ratings yet

- Engineering Electromagnetics: The Steady Magnetic FieldDocument71 pagesEngineering Electromagnetics: The Steady Magnetic FieldSandeep RajputNo ratings yet

- Homework 3 FebDocument42 pagesHomework 3 FebEmmanuel Olowosulu100% (3)

- Open Circuit Test and Short Circuit Test of Synchronous GeneratorDocument22 pagesOpen Circuit Test and Short Circuit Test of Synchronous GeneratorSudip Mondal50% (2)

- Forces at Beams ShigleyDocument8 pagesForces at Beams ShigleyzohardvNo ratings yet

- Physics 71 2nd LE Reviewer IDocument2 pagesPhysics 71 2nd LE Reviewer IChristian GalopeNo ratings yet

- The Theory of EverythingDocument1 pageThe Theory of EverythingjoiannagcaoiliNo ratings yet

- Feyel 2003Document12 pagesFeyel 2003trung hiếu hoàngNo ratings yet

- Surface Chemistry of Solid Catalysts PDFDocument37 pagesSurface Chemistry of Solid Catalysts PDFCorby TranNo ratings yet

- Energy and Exergy Analyses of Cold Thermal Storage Systems: Int. J. Energy Res., 23, 1029) 1038 (1999)Document10 pagesEnergy and Exergy Analyses of Cold Thermal Storage Systems: Int. J. Energy Res., 23, 1029) 1038 (1999)Lia FitrianiNo ratings yet

- Chapter13 (Liquid and Solid)Document90 pagesChapter13 (Liquid and Solid)Cathy RavinaNo ratings yet

- Review of Propeller-Wing Aerodynamic InterferenceDocument21 pagesReview of Propeller-Wing Aerodynamic Interferencekrishnamoorthy_krishNo ratings yet

- DRAFT First Semester 2023 2024 Examination Timetable NewDocument16 pagesDRAFT First Semester 2023 2024 Examination Timetable NewpalngnenchikaNo ratings yet

- Acoustical Comparison of Bassoon CrooksDocument6 pagesAcoustical Comparison of Bassoon CrooksÀlber CatalàNo ratings yet

- Calculating CO2 compression factor & fugacity coefficient using equations of stateDocument20 pagesCalculating CO2 compression factor & fugacity coefficient using equations of statehamza A.laftaNo ratings yet

- Measure Temperature Remotely with a PyrometerDocument6 pagesMeasure Temperature Remotely with a PyrometerGhulam MurtazaNo ratings yet

- Game Sounds PhysicsDocument62 pagesGame Sounds PhysicsdanchristianoNo ratings yet

- Science Test - 1 QuarterDocument3 pagesScience Test - 1 QuarterCeeKay0% (1)

- GPSA - Gas Processors Suppliers Association, Engineering 12th Ed (Excel)Document19 pagesGPSA - Gas Processors Suppliers Association, Engineering 12th Ed (Excel)CHANADASNo ratings yet

- 1 s2.0 S0029801815005089 MainDocument7 pages1 s2.0 S0029801815005089 MainAhmad RidhoNo ratings yet