Professional Documents

Culture Documents

SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21

Uploaded by

SRIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21

Uploaded by

SRICopyright:

Available Formats

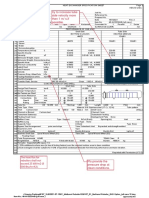

1 HEAT EXCHANGER SPECIFICATION SHEET Page 1

2 HES-SI Units

3

4 Job No.

5 Customer Reference No.

6 Address Proposal No.

7 Plant Location Date 5/8/2021 Rev

8 Service of Unit Column Feed Bottoms Exchanger Item No. alt case

9 Size 800 x 5900 mm Type BEM Horizontal Connected In 1 Parallel 1 Series

10 Surf/Unit (Gross/Eff) / m2 Shell/Unit 1 Surf/Shell (Gross/Eff) / m2

11 PERFORMANCE OF ONE UNIT

12 Fluid Allocation Shell Side Tube Side

13 Fluid Name water with 100 ppm of methanol rich methanol

14 Fluid Quantity, Total kg/hr 31356 34423

15 Vapor (In/Out) 1.0327 72.819

16 Liquid 31356 31356 34422 34350

17 Steam

18 Water

19 Noncondensables

20 Temperature (In/Out) C 134.70 57.96 38.51 110.00

21 Specific Gravity 0.9319 0.9844 0.9782 0.9337

22 Viscosity cP 0.2021 0.4911 0.0130 V/L 0.8090 0.0180 V/L 0.2867

23 Molecular Weight, Vapor

24 Molecular Weight, Noncondensables

25 Specific Heat kJ/kg-C 4.2799 4.1100 1.4000 V/L 4.0400 1.1808 V/L 4.1513

26 Thermal Conductivity W/m-C 0.6860 0.6459 0.0220 V/L 0.5550 0.0260 V/L 0.5921

27 Latent Heat kJ/kg 889.76 756.03

28 Inlet Pressure barG 12.100 9.550

29 Velocity m/s 0.10 5.74e-2

30 Pressure Drop, Allow/Calc kPa 35.000 4.348 35.000 1.381

31 Fouling Resistance (min) m2-K/W 0.000000 0.000000

32 Heat Exchanged 2792. kW MTD (Corrected) 21.2 C

33 Transfer Rate, Service 407.34 W/m2-K Clean 553.21 W/m2-K Actual 553.21 W/m2-K

34 CONSTRUCTION OF ONE SHELL Sketch (Bundle/Nozzle Orientation)

35 Shell Side Tube Side

36 Design/Test Pressure barG 16.000 / 14.000 /

37 Design Temperature C 170.00 170.00

38 No Passes per Shell 1 1

39 Corrosion Allowance mm 3.000 0.000

40 Connections In mm 1 @ 102.26 1 @ 102.26

41 Size & Out mm 1 @ 102.26 1 @ 102.26

42 Rating Intermediate @ @

43 Tube No. OD 19.050 mm Thk(Avg) 1.651 mm Length 5.900 m Pitch mm

44 Tube Type Plain Material 316 Stainless steel (17 Cr, 12 Ni) Tube pattern

45 Shell Carbon steel ID 800.00 OD 822.23 mm Shell Cover

46 Channel or Bonnet 316 Stainless steel (17 Cr, 12 Ni) Channel Cover

47 Tubesheet-Stationary 316 Stainless steel (17 Cr, 12 Ni) Tubesheet-Floating

48 Floating Head Cover Impingement Plate None

49 Baffles-Cross Type Single-Seg. %Cut (Diam) Spacing(c/c) Inlet mm

50 Baffles-Long Seal Type None

51 Supports-Tube U-Bend Type None

52 Bypass Seal Arrangement pairs seal strips Tube-Tubesheet Joint Expanded and strength welded

53 Expansion Joint Type

54 Rho-V2-Inlet Nozzle kg/m-s2 Bundle Entrance 226.65 Bundle Exit 214.57 kg/m-s2

55 Gaskets-Shell Side Spiral Wound Metal (SS) Tube Side Spiral Wound Metal (SS)

56 - Floating Head

57 Code Requirements ASME TEMA Class R

58 Weight/Shell 6392.3 kg Filled with Water 9450.9 kg Bundle 4380.9 kg

59 Remarks:

60 1. 35% additional surface area (in lieu of fouling factors) over the required surface area in clean condition

61 2.heat exchagner shall be suitable for 110% of specified condensate flowrate from thermal performance and tube vibration.

62

63 Reprinted with Permission (v7.3.2)

J:\Inquiry-Panfeng\8167_SLB\2021-07-28\02_Column Feed Bottoms Exchanger\SQ8167_02_Column Feed Bottoms Exchanger Process

Item No.: alt case DS Rev B (alt case 10 deg approach).htri

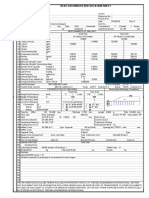

Vibration Analysis Page 2

Released to the following HTRI Member Company:

HES

HES

Xist 7.3.2 5/8/2021 11:46 SN: 00371-53375827 HES-SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

1 Shellside condition Sens. Liquid (Level 2.3000)

2 Axial stress loading (MPa) 0.000 Added mass factor 1.718

3 Beta 4.118

4 Position In The Bundle Inlet Center Outlet

5 Length for natural frequency (m) 0.772 0.772 0.772

6 Length/TEMA maximum span (--) 0.507 0.507 0.507

7 Number of spans (--) 8 8 8

8 Tube natural frequency (Hz) 59.9 59.5 59.3 +

9 Shell acoustic frequency (Hz) 0.0 0.0 0.0

10 Flow Velocities Inlet Center Outlet

11 Window parallel velocity (m/s) 0.20 0.20 0.19

12 Bundle crossflow velocity (m/s) 0.10 0.10 9.76e-2

13 Bundle/shell velocity (m/s) 7.20e-2 6.98e-2 6.68e-2

14 Fluidelastic Instability Check Inlet Center Outlet

15 Log decrement HTRI 0.076 0.080 0.084

16 Critical velocity (m/s) 2.56 2.59 2.64

17 Baffle tip cross velocity ratio (--) 0.0453 0.0443 0.0416

18 Average crossflow velocity ratio (--) 0.0402 0.0393 0.0370

19 Acoustic Vibration Check Inlet Center Outlet

20 Vortex shedding ratio (--) 0.000 0.000 0.000

21 Chen number (--) 0 0 0

22 Turbulent buffeting ratio (--) 0.000 0.000 0.000

23 Tube Vibration Check Inlet Center Outlet

24 Vortex shedding ratio (--) 0.017 0.017 0.016

25 Parallel flow amplitude (mm) 0.000 0.000 0.000

26 Crossflow amplitude (mm) 0.001 0.001 0.001

27 Tube gap (mm) 4.950 4.950 4.950

28 Crossflow RHO-V-SQ (kg/m-s2) 9.90 10.00 9.37

29 Bundle Entrance/Exit

30 (analysis at first tube row) Entrance Exit

31 Fluidelastic instability ratio (--) 0.048 0.044

32 Vortex shedding ratio (--) 0.083 0.078

33 Crossflow amplitude (mm) 0.00097 0.00092

34 Crossflow velocity (m/s) 0.49 0.47

35 Tubesheet to inlet/outlet support (mm) None None

36 Shell Entrance/Exit Parameters Entrance Exit

37 Impingement device None --

38 Flow area (m2) 6.42e-3 6.42e-3

39 Velocity (m/s) 1.46 1.38

40 RHO-V-SQ (kg/m-s2) 1975.8 1870.5

41 Shell type BEM Baffle type Single-Seg.

42 Tube type Plain Baffle layout Perpend.

43 Pitch ratio 1.2598 Tube diameter, (mm) 19.050

44 Layout angle 30 Tube material 316 Stainless steel (17 Cr, 12 Ni)

45 Number U-Bend supports Elastic modulus, (MPa) 187194

46 Use deresonating baffles No Supports/baffle space 0

47 Program Messages

48 + Frequency ratios are based upon lowest natural or acoustic frequency

49 * Items with asterisk exceed a conservative lower limit for vibration-free design. Review your case

50 using the procedure described in Online Help; You may find that a vibration problem is unlikely.

51

52

53

54

J:\Inquiry-Panfeng\8167_SLB\2021-07-28\02_Column Feed Bottoms Exchanger\SQ8167_02_Column Feed Bottoms Exchanger Process

Item No.: alt case DS Rev B (alt case 10 deg approach).htri

Drawings Page 5

Released to the following HTRI Member Company:

HES

HES

Xist 7.3.2 5/8/2021 11:46 SN: 00371-53375827 HES-SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

1

2 6978

3 mm

4 314 383 5515 383

5 mm mm mm mm

6

S1 T2

7

8

9

10

11

822

12 mm

13

14

15

16

17 T1 S2 Fixed Slotted

18 1381 3531

19 mm mm

20

21 S1 T2

22

23

634 634

24 mm mm

25

26

27

28 634 634 654

mm mm mm

29

30

31 T1 S2

32

33 Front Channel Shell Rear Channel

34

35 Nozzles OD, mm Rating Design Shell Tube W eight kg Company HES

36 S1 Inlet 114.3 Pres (barG) 16 14 Bundle 4381 Customer Ref

S2 Outlet 114.3 Temp (C) 170 170 Dry 6392 Item alt case

37 T1 Inlet 114.3 Passes 1 1 W et 9451 Service Column Feed Bottoms Exchanger

38 T2 Outlet 114.3 Thick (mm) 11.113 1.651 TEMA BEM Setting Plan

39 Date 5/8/2021 By

Diagram Rev

40

41

42

Item No.: alt case J:\Inquiry-Panfeng\8167_SLB\2021-07-28\02_Column Feed Bottoms Exchanger\SQ8167_02_Column Feed Bottoms Exchanger Process DS Rev B (alt case 10 deg approach).htri

You might also like

- 0132497468-Ch11 ISMDocument27 pages0132497468-Ch11 ISMJeison Rincón Garzón89% (9)

- Blank Tema SheetDocument1 pageBlank Tema SheetYosua ChangNo ratings yet

- Heat Exchanger Specification SheetDocument1 pageHeat Exchanger Specification SheetRizal NajibNo ratings yet

- 2019-12-20 Reboiler - Spec. SheetDocument1 page2019-12-20 Reboiler - Spec. SheetVasiljka Đordan JelacaNo ratings yet

- TEMA Sheet Heat Exchanger Specification SheetDocument3 pagesTEMA Sheet Heat Exchanger Specification SheetSonNguyenNo ratings yet

- TEMA Spec SheetDocument1 pageTEMA Spec SheetvikzefgNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- Tema SheetDocument1 pageTema SheetMayank AgrawalNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Condenser 7.5 (RATING)Document1 pageCondenser 7.5 (RATING)Madelyn BelbesNo ratings yet

- Heat Exchanger Rev - 02Document1 pageHeat Exchanger Rev - 02TKT ConsultantNo ratings yet

- Shell&Tube TEMAsheet 1Document1 pageShell&Tube TEMAsheet 1Rikiya FebriyanNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10Document1 pageAspen Exchanger Design and Rating Shell & Tube V10MAYANK AGRAWALNo ratings yet

- Consub TemaDocument1 pageConsub TemaMAYANK AGRAWALNo ratings yet

- Case 3Document1 pageCase 3nirajkulkarni09No ratings yet

- Case 4Document1 pageCase 4nirajkulkarni09No ratings yet

- Case 5Document1 pageCase 5nirajkulkarni09No ratings yet

- Case 2Document1 pageCase 2nirajkulkarni09No ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 1/31/2023 at 3:41:24 PM TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 1/31/2023 at 3:41:24 PM TEMA Sheetvaratharajan g rNo ratings yet

- E-200 TEMA SheetDocument1 pageE-200 TEMA Sheetuse for school google drive storageNo ratings yet

- 1Document1 page1kkkprotNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11anggun 119280087No ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12Document1 pageAspen Exchanger Design and Rating Shell & Tube V12TIPAZONo ratings yet

- Case 6Document1 pageCase 6nirajkulkarni09No ratings yet

- Soal A CS Suhu 35 TSDocument1 pageSoal A CS Suhu 35 TSanggun 119280087No ratings yet

- E-100 TEMA SheetDocument1 pageE-100 TEMA Sheetuse for school google drive storageNo ratings yet

- BB 1Document1 pageBB 1SaidFerdjallahNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11anggun 119280087No ratings yet

- Shell&TubeResults 215E009Document5 pagesShell&TubeResults 215E009ganis supriadiNo ratings yet

- Steam Liquid Ex With Steam Flow of 0.224 KgpersecDocument5 pagesSteam Liquid Ex With Steam Flow of 0.224 Kgpersecchemical509No ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V8.8Document3 pagesAspen Exchanger Design and Rating Shell & Tube V8.8Camila Florencia ScarlatoNo ratings yet

- Heat Exchanger Specification SheetDocument2 pagesHeat Exchanger Specification SheetDycka Anugerah PuryantoroNo ratings yet

- Overall SummaryDocument1 pageOverall SummaryMayank AgrawalNo ratings yet

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDocument1 pageHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgNo ratings yet

- Heat Exchanger Rating Data Sheet Eslam Shebl Units: D:/general/PHPC/htri/new Preheater Proposal - HtriDocument1 pageHeat Exchanger Rating Data Sheet Eslam Shebl Units: D:/general/PHPC/htri/new Preheater Proposal - HtriEslam ShiblNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9Document1 pageAspen Exchanger Design and Rating Shell & Tube V9MAYANK AGRAWALNo ratings yet

- 240-05-DTS-009 V-501 Air ReceiverDocument20 pages240-05-DTS-009 V-501 Air ReceiverEmran NazirNo ratings yet

- 240-05-DTS-010 V-400 Regenaration Gas SeperatorDocument20 pages240-05-DTS-010 V-400 Regenaration Gas SeperatorEmran NazirNo ratings yet

- Gas-Gas Exchanger DatasheetDocument3 pagesGas-Gas Exchanger DatasheetidilfitriNo ratings yet

- Shell & Tube Heat ExchangerDocument3 pagesShell & Tube Heat ExchangerBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Process Design Report SummaryDocument3 pagesProcess Design Report Summarymuhd.qasimNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9: Tema SheetDocument7 pagesAspen Exchanger Design and Rating Shell & Tube V9: Tema SheetTuấn VũNo ratings yet

- Intercambiador de Calor: Heat Exchanger Data SheetDocument6 pagesIntercambiador de Calor: Heat Exchanger Data SheetBRENDA VIVIANA ARANDA JURADONo ratings yet

- Tubos y Coraza PDFDocument2 pagesTubos y Coraza PDFsamara navasNo ratings yet

- Tubos y Coraza PDFDocument2 pagesTubos y Coraza PDFsamara navasNo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- Data Sheet Gas Scrubber 42 InchDocument32 pagesData Sheet Gas Scrubber 42 InchWijayantoNo ratings yet

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- Gas Chiller DatasheetDocument2 pagesGas Chiller DatasheetidilfitriNo ratings yet

- Gas Chiller Datasheet PDFDocument2 pagesGas Chiller Datasheet PDFidilfitriNo ratings yet

- E-101, Precalentador de PropanoDocument1 pageE-101, Precalentador de PropanoIsaac RodriguezNo ratings yet

- CH-RA3 Page 2Document1 pageCH-RA3 Page 2Sonya LoveraNo ratings yet

- Heat Exchanger Specification Sheet SI UnitsDocument1 pageHeat Exchanger Specification Sheet SI UnitsdhaNo ratings yet

- Htri PDFDocument1 pageHtri PDFLuigy L-aNo ratings yet

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- CCT ShellAndTubeReportDocument2 pagesCCT ShellAndTubeReportLuthfi LegooNo ratings yet

- Heat Exchanger Specification Sheet SI-BARG UnitsDocument2 pagesHeat Exchanger Specification Sheet SI-BARG Unitsshahbaz akramNo ratings yet

- MECH3030 01 Intro Spr2015Document59 pagesMECH3030 01 Intro Spr2015BillyNo ratings yet

- MSC Fastener Modeling For Joining Composite Parts 06-SpiritAero - BoshersDocument22 pagesMSC Fastener Modeling For Joining Composite Parts 06-SpiritAero - BoshersSergey Fedorinov100% (1)

- Ce2201 QB2Document15 pagesCe2201 QB2Balaji KumarNo ratings yet

- Weld Strength Calculator 12Document5 pagesWeld Strength Calculator 12NATC LLP0% (1)

- Assignment 1Document3 pagesAssignment 1vysrilekhaNo ratings yet

- Lagrangian & Eularian Frames DescriptionDocument2 pagesLagrangian & Eularian Frames DescriptionAwadh KapoorNo ratings yet

- Work WsDocument5 pagesWork Wsapi-261954479No ratings yet

- Down-Hole Test ProcedureDocument5 pagesDown-Hole Test ProcedureAngela BriggsNo ratings yet

- X vs. T 2: 1) Tablas de Tiempo Al Cuadrado Tabla 1 0 0,22 0,43 0,62 0,825 M 0 0,8336 1,685 2,471 3,323329 S 2Document6 pagesX vs. T 2: 1) Tablas de Tiempo Al Cuadrado Tabla 1 0 0,22 0,43 0,62 0,825 M 0 0,8336 1,685 2,471 3,323329 S 2kustNo ratings yet

- Soil-Foundation-Superstructure Interaction For The Tallest Tower in The World The Kingdom TowerDocument14 pagesSoil-Foundation-Superstructure Interaction For The Tallest Tower in The World The Kingdom TowerZakaria MahmudNo ratings yet

- Warner R.F. - Simplified Analysis of Creep in Prestressed Concrete BeamsDocument9 pagesWarner R.F. - Simplified Analysis of Creep in Prestressed Concrete BeamsCristóbal BerríosNo ratings yet

- LAB 10 - SHEAR BOX TEST (Level 1)Document5 pagesLAB 10 - SHEAR BOX TEST (Level 1)Doris AsmaniNo ratings yet

- Formula SheetDocument7 pagesFormula SheetCarlos GómezNo ratings yet

- Mechanical Behaviour and Deformation Mechanisms of Zn-Al-Cu-Mg AlloysDocument146 pagesMechanical Behaviour and Deformation Mechanisms of Zn-Al-Cu-Mg Alloysshahin azNo ratings yet

- PHS 212 - Spring 2017 - Syllabus (A & B)Document2 pagesPHS 212 - Spring 2017 - Syllabus (A & B)Fares FadlallahNo ratings yet

- Physicsws AllenDocument5 pagesPhysicsws AllenBenin J RobiNo ratings yet

- Motion in One Dimension: Your Answer by Giving Two Examples EachDocument32 pagesMotion in One Dimension: Your Answer by Giving Two Examples Eachnaresh kumarNo ratings yet

- Chapter 21 Practice Problems Review and Assessment PDFDocument15 pagesChapter 21 Practice Problems Review and Assessment PDFrenz harvey mabezaNo ratings yet

- Aircraft: 1. Design ConditionsDocument16 pagesAircraft: 1. Design ConditionsCarlos HenriqueNo ratings yet

- 2 Cell Box CulvertDocument22 pages2 Cell Box Culvertabhijeet sahuNo ratings yet

- Flow Over Ogee Spillway: Physical and Numerical Model Case StudyDocument14 pagesFlow Over Ogee Spillway: Physical and Numerical Model Case StudyAkash KaleNo ratings yet

- MathematicsDocument4 pagesMathematicsdkorean493No ratings yet

- Midterm Exam Statics of Rigid BodiesDocument7 pagesMidterm Exam Statics of Rigid Bodiestone100% (1)

- June 2019 (9-1) QP - Paper 2 CIE Physics IGCSEDocument16 pagesJune 2019 (9-1) QP - Paper 2 CIE Physics IGCSEiman hafizNo ratings yet

- Drilling Hydraulics ADocument63 pagesDrilling Hydraulics Asryn89100% (3)

- Ph3151 All 5 Chapter NotesDocument108 pagesPh3151 All 5 Chapter NotesGowtham KumarasamyNo ratings yet

- 6.tutorial Exercises C.5 C.6 With Summary Answers (V 15.3.2018)Document11 pages6.tutorial Exercises C.5 C.6 With Summary Answers (V 15.3.2018)Chungyin YuNo ratings yet

- Dragster CarDocument159 pagesDragster CarMuhammad Asyraf100% (1)