Professional Documents

Culture Documents

Manual Feeding Into Bins: Tri-Pack Films Limited

Uploaded by

hunain zafarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Feeding Into Bins: Tri-Pack Films Limited

Uploaded by

hunain zafarCopyright:

Available Formats

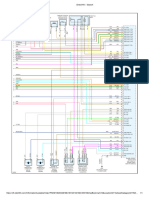

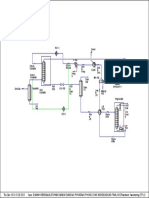

M-1131 M-1121 BLEND A BLEND B BLEND FOR S-1232 / 1231

MAIN FEEDING TURBO BLOWER MAIN FEEDING ROTARY FEEDER GRAVIMETERIC MIXING UNIT GRAVIMETERIC MIXING UNIT GRAVIMETERIC MIXING UNIT

CAPACITY : 15000 Kg/Hr CAPACITY : 15000 Kg/Hr FOR EXTRUDER A FOR EXTRUDER B FOR SILO 1232 / 1231

POWER : 34 KW POWER : 0.75 KW CAPACITY : 250 Kg/Hr CAPACITY : 350 Kg/Hr CAPACITY : XXX Kg/Hr

POWER : XXX KW POWER : XXX KW POWER : XXX KW

Manual Feeding into Bins

M-1131

Homopolymer &

Blend A Blend B Blend for Additive to S-1232

S-1232 / From Sheet 2 of 5

1231

M-1121 Coopolymer & Additive to

4 Hopper 165 B

From Sheet 2 of 5

Coopolymer & Additive to

3 Hopper 165 A

From Sheet 2 of 5

Homopolymer to S-1211, S-

2 1212, S-1221, S-1231

From Sheet 2 of 5

Stream Number Sr. No Date of Rev Prep'd By App'd By

Parameter 1 2 3 4 1 16-Mar-20 Omer HOM

Flowrate (kg/hr) 15000 15000 250 350

Temp ('C) 25-35 25-35 25-35 25-35

Pressure (Mpa) - - - -

Notes:

1 - Process data for streams is based on process conditions of producing Plain 30 (O/W) film.

TRI-PACK FILMS LIMITED

2 - Equipment specifications are taken from plant OEM Manuals. PROCESS FLOW DIAGRAM

FILM LINE 3

FEEDING AREA

Rev Document Number Page

1 1 of 6

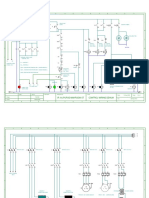

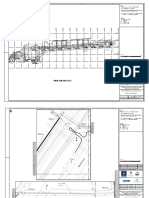

M-1410 S-1211 S-1212 S-1221 S-1231 S-1232

MAIN FEEDING BLOWER STORAGE SILO STORAGE SILO STORAGE SILO STORAGE SILO STORAGE SILO

CAPACITY : XXX Kg/Hr TOTAL CAPACITY : 50 m3 TOTAL CAPACITY : 50 m3 TOTAL CAPACITY : 50 m3 CAPACITY : 18m3 CAPACITY : 18m3

POWER : XXX KW TOTAL CAPACITY : 28000 kg TOTAL CAPACITY : 28000 kg TOTAL CAPACITY : 28000 kg CAPACITY : 10000 kg CAPACITY : 10000 kg

CAPACITY AT LOW LEVEL : 2750 kg CAPACITY AT LOW LEVEL : 2750 kg CAPACITY AT LOW LEVEL : 2750 kg CAPACITY AT LOW LEVEL : 400 Kg CAPACITY AT LOW LEVEL : 400 Kg

M-1311 M-1312 M-1313 M-1321 M-1342

ROTARY FEEDER ROTARY FEEDER ROTARY FEEDER ROTARY FEEDER ROTARY FEEDER

CAPACITY : 3765 Kg/Hr CAPACITY : 2580 Kg/Hr CAPACITY : 2600 Kg/Hr CAPACITY : 400 Kg/Hr CAPACITY : 600 Kg/Hr

DRY-1391 DRY-1392 DRY-1393 DRY-1394 DRY-1395

ELECTRIC HEATER ELECTRIC HEATER ELECTRIC HEATER ELECTRIC HEATER ELECTRIC HEATER

POWER : XXX KW POWER : XXX KW POWER : XXX KW POWER : XXX KW POWER : XXX KW

M-1392 M-1393 M-1394

M-1395

HEATING AIR BLOWER HEATING AIR BLOWER HEATING AIR BLOWER

HEATING AIR BLOWER

CAPACITY : XXX Kg/Hr CAPACITY : XXX Kg/Hr CAPACITY : XXX Kg/Hr

CAPACITY : XXX Kg/Hr

POWER : XXX KW POWER : XXX KW POWER : XXX KW

Homopolymer & Additives

from Blender 124

From Sheet 1 of 5

Homopolymer from

blower M1121

From Sheet 1 of 5

Air to dust

collection silo

Air to dust

collection silo

Fluff from Crusher S-1212 S-1221 S-1231 S-1232

M-1541

From Sheet 5 of 6

DRY-1391 DRY-1392 DRY-1393 DRY-1394 DRY-1395

7 8 9 10 11

12 Homopolymer Feed to

M-1392 M-1393 M-1394 M-1395 Main Hopper

6

To Sheet 3 of 5

M-1410 M-1311 M-1312 M-1313 M-1321 M-1342 Metal

Detector

Stream Number Sr. No Date of Rev Prep'd By App'd By

Parameter 5 6 7 8 9 10 11 12 1 16-Mar-20 Omer HOM

Flowrate (kg/hr) 84.2743 1920.274 1432.8 - - 360 43.2 1920.274

Temp ('C) - - - - - - - -

Pressure (Mpa) - - - - - - - -

Notes:

1 - Process data for streams is based on process conditions of producing Plain 30 (O/W) film.

TRI-PACK FILMS LIMITED

2 - Equipment specifications are taken from plant OEM Manuals. PROCESS FLOW DIAGRAM

FILM LINE 3

SILO AREA

Rev Document Number Page

0 2 of 6

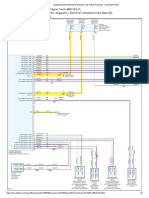

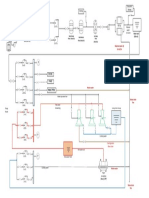

Extruder 1 Extruder 2 Extruder A Extruder B Filter Casting Machine Cast WP-2 Cast WP-3 C-Frame

PRIMARY EXTRUDER SECONDARY EXTRUDER SATELLITE EXTRUDER SATELLITE EXTRUDER Disc Type Filter CAPACITY : 3150 kg/Hr Cast -2 Water Circulation Pump Cast -3 Water Circulation Pump NDC Thickness

CAPACITY : 3200 kg/hr CAPACITY : 3200 kg/hr CAPACITY : 150 kg/hr CAPACITY : 320 kg/hr CAPACITY : 3200 kg/Hr SPEED : 7-70 m/min CAPACITY : 32.4 m3/Hr CAPACITY : 27 m3/Hr Scanner

SCREW DIA : 175 mm SCREW DIA : 220 mm SCREW DIA : 90 mm SCREW DIA : 115 mm MAX PRESSURE DROP : 12.5 Mpa TEMP. OF CHILL ROLL : 15-60 C POWER : 22 KW POWER : 11 KW

SPEED : 16-235 rpm SPEED : 9-115 rpm SPEED : 14-183 rpm SPEED : 8.7-114 rpm MAX PRESSURE ALLOWED : 30 MPA CHILL ROLL DIA : 2200 mm

L/D Ratio : 20 L/D Ratio : 20 L/D Ratio : 29 L/D Ratio : 33 FILTERATION AREA : 4 sq.m CHILL ROLL WIDTH : 1300mm

MOTOR POWER : 800 KW MOTOR POWER : 350 KW MOTOR POWER : 75 KW MOTOR POWER : 132 KW HEATER POWER : 63.5 KW HEAT DUTY : 600,000 KCal/hr

HEATING LOAD CYLINDER: 92 KW HEATING LOAD CYLINDER: 157 KW HEATING LOAD CYLINDER: 32 KW HEATING LOAD CYLINDER: 70 KW

HEATING LOAD FLANGE: 26 KW HEATING LOAD FLANGE: 9 KW

HEATING LOAD CON PIPE: 20 KW

Ext 1 OP Ext 2 OP Ext A OP Die AK - BL Cast HX-2 Cast HX-3

Ext B OP

Extruder 1 Lube Oil Pump Extruder 1 Lube Oil Pump Extruder A Lube Oil Pump Three Cavity T-Die Air Knife Blower Cast -2 Cooling Water / Chilled Cast -3 Cooling Water / Chilled

Homopolymer Feed Ext 1 WP Ext 2 WP Ext A WP Ext B WP Width of Lip : 980 mm CAPACITY : 11.5 m3/min Water Heat Exchanger Water Heat Exchanger

Gap of Lip : 2.4±0.7 mm PRESSURE DIFF. : 2100 mm AQ

from blower M-1410 Extruder 1 Water Pump Extruder 1 Water Pump Extruder B Water Pump Extruder 1 Water Pump

HEATER POWER : 58 KW POWER : 11 KW

From Sheet 2 of 5 EX - BL DIE Wiper - BL Cast 2 TK Cast 3 TK

FUMES EXHAUST BLOWER Wiper Air Blower Cast-2 Tank Cast-3 Tank

CAPACITY : 150 m3/min CAPACITY : XXX m3/Hr

POWER : 3.7 KW POWER : XXX KW

Fumes Exhausted

CL-1 CL-2 CL-3 CL-4 CL-5

CL-1 CL-2 CL-3 CL-4 CL-5

through blower

Filter

Extruder 1 AK - BL Wiper BL

Ext 1 WP Extruder 2 Ext 2 WP 13 EX - BL DIE

Ext 1 OP Ext 2 OP

Feed from blower Die 1 Die 2 Film Sheet to

Blend A Die 3 Die 4 17 MDO

From Sheet 1 of 5

CL-1 CL-2 CL-3 CL-4 CL-5 CL-6 14 Die 5 Die 6

16 To Sheet 4 of 5

Die 7 Die 8

Die 9 Die 10

Chill Roll

Water Level

Extruder A Ext B WP Die

Feed from blower C-Frame

Blend B Bath for Bath for

Ext A OP Warm Water Chilled Casting Roll Guide Roll

From Sheet 1 of 5 to Water from

CL-1 CL-2 CL-3 CL-4 CL-5 CL-6 CL-7 CL-8 15 Cast HX-2 Cast HX-3

18 Warm Water

Chilled Warm Water Chilled

Water from to Water from to

Chiller Chiller Chiller Chiller

Extruder B Ext B WP

Ext B OP

Cast WP-2 Cast WP-3

Cast - 2 TK Cast - 3 TK

Stream Number Sr. No Date of Rev Prep'd By App'd By

Parameter 13 14 15 16 17 18 1 16-Mar-20 Omer HOM

Flowrate (kg/hr) 1920.27 43.4 87.1 2050 2050 -

Temp ('C) 261.2 240 210 242 35 10

Pressure (Mpa) 7.2 10.4 11.2 - - -

Notes:

1 - Process data for streams is based on process conditions of producing Plain 30 (O/W) film.

TRI-PACK FILMS LIMITED

2 - Equipment specifications are taken from plant OEM Manuals. PROCESS FLOW DIAGRAM

FILM LINE 3

EXTRUSION & CASTING AREA

Rev Document Number Page

1 3 of 6

MDL-1 Pump MDL-3 Pump MDL-6 Pump MDL-9 Pump MDM-1 Pump MDH-1 Pump MDO TDO TD EX BL-7 TD EX BL-8

CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr CAPACITY : 3150 kg/Hr CAPACITY : 3150 kg/Hr CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr

POWER : XXX KW POWER : XXX KW POWER : XXX KW POWER : XXX KW POWER : XXX KW POWER : XXX KW SPEED : 7-70 m/min SPEED : 32-320 m/min POWER : XXX KW POWER : XXX KW

MDL-2 Pump MDL-4 Pump MDL-10 Pump MDM-2 Pump MDH-2 Pump 32-320 m/min RAIL LENGTH : 59500 mm TD EX BL-9 TD EX BL-10

MDL-7 Pump

CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr 32-320 m/min WORKING WIDTH IN : 600 - 1100 mm

CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr

POWER : XXX KW POWER : XXX KW POWER : XXX KW POWER : XXX KW POWER : XXX KW Roll Temp. Range : 80-150 C WORKING WIDTH OUT : 6400 mm - 7100 mm POWER : XXX KW POWER : XXX KW

POWER : XXX KW

Roll Width : 1300 mm POWER : 45 KW X 2

MDL-5 Pump MDL-8 Pump MDL-11 Pump MDM-3 Pump

MDL MOTOR POWER : 15 KW

To Main Oil Return CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr

MDM MOTOR POWER : 45 KW Fumes to Atmosphere Fumes to Atmosphere Fumes to Atmosphere Fumes to Atmosphere

POWER : XXX KW POWER : XXX KW POWER : XXX KW POWER : XXX KW

Header through Duct through Duct through Duct through Duct

Film Sheet from Cast TD EX BL7 TD EX BL8 TD EX BL9 TD EX BL10

Unit

To Sheet 3 of 5

TDO To Main Oil Return Header

MDO 19

21

TD 11L

TD 10L

TD 15L

TD 17L

TD 13L

TD 14L

TD 16L

TD 12L

TD 9L

TD 8L

TD 1L

TD 2L

TD 3L

TD 4L

TD 5L

TD 6L

TD 7L

MDH-2 OP

Film Sheet to Winder

Air Supply MDL-1 OP

To Sheet 5 of 5

TD 1R

TD 3R

TD 3R

TD 4R

TD 5R

TD 6R

TD 7R

TD 11R

20

TD 15R

TD 18R

TD 10R

TD 13R

TD 14R

TD 16R

TD 12R

TD 9R

TD 8R

MDH-1 OP

MDL-2 OP

MDM-3 OP Air Supply

MDL-3 OP

MDM-2 OP

MDL-4 OP

MDM-1 OP

MDL-5 OP MDL-11 OP

MDL-10 OP

MDL-6 OP

MDL-9 OP

From Main Oil Supply MDL-7 OP

Header MDL-8 OP

22

Main Oil Header 23

Stream Number Sr. No Date of Rev Prep'd By App'd By

Parameter 19 20 21 22 23 1 16-Mar-20 Omer HOM

Flowrate (kg/hr) 2050 2050 -

Temp ('C) 85 39.4 - 180 250

Pressure (Mpa) 0.6

Notes:

1 - Process data for streams is based on process conditions of producing Plain 30 (O/W) film.

TRI-PACK FILMS LIMITED

2 - Equipment specifications are taken from plant OEM Manuals. PROCESS FLOW DIAGRAM

FILM LINE 3

MDO & TDO AREA

Rev Document Number Page

1 4 of 6

Pull WP-1 M1510 M1551 M1541 Winder OZ BL-1 OZ BL-3 Winder Overhead Crane Aging Rack

CAPACITY : XXX m3/Hr Ejector Blower Trim Blower Trim Crusher SPEED : 32-320 m/min Ozone Blower Ozone Blower LIFTING CAPACITY : 10 Ton STORAGE CAPACITY : 30 Ton

POWER : XXX KW CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr CAPACITY : XXX kg/Hr ROLL WIDTH : 7000 mm CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr Number of Cores : 60

Pull WP-2 POWER : XXX KW POWER : XXX KW POWER : XXX KW CORE : 550mm(D) X 7400 mm (L) POWER : XXX KW POWER : XXX KW

CAPACITY : XXX m3/Hr MAX WINDING DIAMETER : 1400 mm

POWER : XXX KW HFG POWER : 200 KW OZ BL-2 OZ BL-4

DRIVE POWER : 112 KW Ozone Blower Ozone Blower

CAPACITY : XXX m3/Hr CAPACITY : XXX m3/Hr

Ozone to Atmosphere POWER : XXX KW POWER : XXX KW

through Duct

OZ BL1 OZ BL2 OZ BL3 OZ BL4

Film Sheet from TDO Semi FInished Good to

O-Frame

24 A B 25 PS-3

To Sheet 5 of 5

To Sheet 6 of 6

WINDER

AGING RACK

PULL WP1 PULL WP2

Chilled Water Suppy

from Chiller

WINDER

OVERHEAD

CRANE

M1510

M M1541

Fluff to Feeding

Hopper

26 To Sheet 2 of 6

M1551

Stream Number Sr. No Date of Rev Prep'd By App'd By

Parameter 24 25 26 1 16-Mar-20 Omer HOM

Flowrate (kg/hr) 2050 2050 84.27

Temp ('C) 34 30-35 34

Pressure (Mpa)

Notes:

1 - Process data for streams is based on process conditions of producing Plain 30 (O/W) film.

TRI-PACK FILMS LIMITED

2 - Equipment specifications are taken from plant OEM Manuals. PROCESS FLOW DIAGRAM

FILM LINE 3

WINDER & AGING RACK

Rev Document Number Page

1 5 of 6

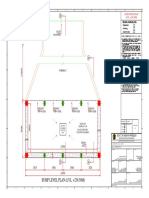

PS-3 Overhead Crane Primary Slitter 3 Packing Crane 1 Packing Crane 2

LIFTING CAPACITY : 10 Ton Maximum Speed : XXX m/min Lifting Capacity : 1 ton Lifting Capacity : 1 ton

POWER : XXX KW

Trim for Recycling

Paper Cores from Core

Cutting Machine 28

(Operation Side)

Trim Winder

Rewinding Stations (Front Side)

Rewinding Stations (Rear Side)

Unwind Section

Packing Station

Pull Section

Web Guide

Semi FInished Good to FG TO

PS-3 DISPATCH HALL

To Sheet 6 of 6

27

Trim Winder

(Drive Side)

PS-3 PACKING PACKING

OVERHEAD CRANE 1 CRANE 2

Finished Good to Packing

29 Station

Air Supply

30

Semi Finished Good to

Secondary Slitters

Stream Number Sr. No Date of Rev Prep'd By App'd By

Parameter 27 28 29 30 1 16-Mar-20 Omer HOM

Flowrate (kg/hr) 2500 56 - 2444

Temp ('C) - - - -

Pressure (Mpa) - - 0.6 -

Notes:

1 - Process data for streams is based on process conditions of producing Plain 30 (O/W) film.

TRI-PACK FILMS LIMITED

2 - Equipment specifications are taken from plant OEM Manuals. PROCESS FLOW DIAGRAM

FILM LINE 3

PRIMARY SLITTER 3 & PACKING HALL

Rev Document Number Page

1 6 of 6

You might also like

- Wiring Diagram: BlackDocument1 pageWiring Diagram: BlackPanos karydisNo ratings yet

- EWD Vehicle Exterior Back-Up LightDocument1 pageEWD Vehicle Exterior Back-Up LightVôĐốiNo ratings yet

- Introduction to PHE-WMO Gas Processing SystemsDocument30 pagesIntroduction to PHE-WMO Gas Processing SystemsHendri Anur100% (2)

- Window StickerDocument1 pageWindow Stickerjimmy ochoaNo ratings yet

- Automatic Transaxle Control SystemDocument2 pagesAutomatic Transaxle Control SystemMohamed AdelNo ratings yet

- G4a ElDocument6 pagesG4a ElEvan Valentine CalderwoodNo ratings yet

- Corolla 2016diagrama completo-1ZR-TDocument29 pagesCorolla 2016diagrama completo-1ZR-TJose david Martinez apazaNo ratings yet

- Cat C18 With Emcp 4Document4 pagesCat C18 With Emcp 4Abdul Khaliq67% (3)

- LMCPDocument1 pageLMCPhr KingsViewNo ratings yet

- Ac Power E A-412-461 Ac Power E A-412-461 Ac Power E A-412-461Document17 pagesAc Power E A-412-461 Ac Power E A-412-461 Ac Power E A-412-461Luis Enrique De los Santos FarfánNo ratings yet

- Engine Control System 3UR FEDocument20 pagesEngine Control System 3UR FEalejandro chavezNo ratings yet

- SITES Model PDFDocument1 pageSITES Model PDFismail khalilNo ratings yet

- 1.9 l/66 KW Turbo-Diesel Engine, Engine Codes AGR 1.9 l/66 KW Turbo-Diesel Engine, Engine Codes ALH 1.9 l/81 KW Turbo-Diesel Engine, Engine Codes AHFDocument14 pages1.9 l/66 KW Turbo-Diesel Engine, Engine Codes AGR 1.9 l/66 KW Turbo-Diesel Engine, Engine Codes ALH 1.9 l/81 KW Turbo-Diesel Engine, Engine Codes AHFEUROSERVNo ratings yet

- WM Porsche 928 Wiring Diagram - 1986Document20 pagesWM Porsche 928 Wiring Diagram - 19869TECHNIK50% (2)

- SC-2100 Feed Gas Slug Catcher V-2401 Inlet Gas SeparatorDocument2 pagesSC-2100 Feed Gas Slug Catcher V-2401 Inlet Gas SeparatorMidha NeerNo ratings yet

- Ford AODDocument10 pagesFord AODMohammed MochrifNo ratings yet

- Fuel System Wiring Schematic For 2007-2008 Chevrolet SilveradoDocument11 pagesFuel System Wiring Schematic For 2007-2008 Chevrolet SilveradoCmo100% (3)

- Supreme Cable SpecificationDocument34 pagesSupreme Cable SpecificationAri AriNo ratings yet

- Golf/Bora No. 53 / 1: 2.0 l/88 KW Motronic, Engine Code ATF 2.0 l/85 KW Motronic, Engine Code AZHDocument26 pagesGolf/Bora No. 53 / 1: 2.0 l/88 KW Motronic, Engine Code ATF 2.0 l/85 KW Motronic, Engine Code AZHskupowskijNo ratings yet

- $RJX76N7Document1 page$RJX76N7franklinNo ratings yet

- 252en Uml51f Ac2 110v Set 221008Document8 pages252en Uml51f Ac2 110v Set 221008Sinuhe LopezNo ratings yet

- M CH Đèn Lùi. Backup Lamp2Document1 pageM CH Đèn Lùi. Backup Lamp2Trần Ngọc CựuNo ratings yet

- Chemical Compatibility ChartDocument6 pagesChemical Compatibility ChartCecep AtmegaNo ratings yet

- TANK-1 TANK-2: P-3 FM-1 FM-2 P-4 FM-3 Panel Control F-2Document1 pageTANK-1 TANK-2: P-3 FM-1 FM-2 P-4 FM-3 Panel Control F-2Ris Dendy Pratama Trust Tandung MayangNo ratings yet

- CaptivaDocument7 pagesCaptivaJulio LeijaNo ratings yet

- AvionDocument1 pageAvionADRIAN MARQUEZNo ratings yet

- 1,6l Simos (AEH+AKL)Document11 pages1,6l Simos (AEH+AKL)Tremalone SemionelaNo ratings yet

- Honda 5speedDocument11 pagesHonda 5speedAllen Clayton100% (1)

- ALCO Loco Auto Flasher Light - 0Document6 pagesALCO Loco Auto Flasher Light - 0majjisatNo ratings yet

- TURN SIGNALDocument2 pagesTURN SIGNALOliver leal100% (1)

- Microsoft PowerPoint - BLCP Training Cource F Turbine 1Document54 pagesMicrosoft PowerPoint - BLCP Training Cource F Turbine 1Natthaphon NaosookNo ratings yet

- Porsche 928 1985 Wire DiagramDocument18 pagesPorsche 928 1985 Wire DiagramOscar HamerNo ratings yet

- Ir .HJ - Pupud Mahpudin ST Control Wiring Dehum: A B C D E F G HDocument6 pagesIr .HJ - Pupud Mahpudin ST Control Wiring Dehum: A B C D E F G HindraNo ratings yet

- Control Wiring DEHUM Dan AhuDocument7 pagesControl Wiring DEHUM Dan AhuindraNo ratings yet

- Ir .HJ - Pupud Mahpudin ST Control Wiring Dehum: A B C D E F G HDocument5 pagesIr .HJ - Pupud Mahpudin ST Control Wiring Dehum: A B C D E F G HindraNo ratings yet

- C18 Generator Set Electrical System With EMCP3: Harness and Wire Electrical Schematic SymbolsDocument4 pagesC18 Generator Set Electrical System With EMCP3: Harness and Wire Electrical Schematic SymbolsImtiaz AhmedNo ratings yet

- PlantPAx Sample AppDocument2 pagesPlantPAx Sample AppisraelalmaguerNo ratings yet

- 13.8V 40A Power Supply Schematic PrintsDocument1 page13.8V 40A Power Supply Schematic PrintsRafael FersacaNo ratings yet

- Supplemental Restraints (Restraints and Safety Systems) - ALLDATA RepairDocument3 pagesSupplemental Restraints (Restraints and Safety Systems) - ALLDATA Repairkar fxinNo ratings yet

- Harness - Tail Lamp K068-6997 A 01Document1 pageHarness - Tail Lamp K068-6997 A 01Daniel RobichaudNo ratings yet

- T4 Base Wiring From May 1999 OnDocument23 pagesT4 Base Wiring From May 1999 OnOHW SERNo ratings yet

- Sump Level PlanDocument14 pagesSump Level PlanvishalNo ratings yet

- For Approval: Ceiling Space To Be Airtight by OthersDocument1 pageFor Approval: Ceiling Space To Be Airtight by Othersavinash3479No ratings yet

- Electrical Wiring Z13585 - 2 4012-46Document1 pageElectrical Wiring Z13585 - 2 4012-46mohamed100% (1)

- Existing Road: Tracking Rout To Bagmati RiverDocument1 pageExisting Road: Tracking Rout To Bagmati RiverKishore PradhanNo ratings yet

- Ignition Switch and Helm System Wiring DiagramDocument1 pageIgnition Switch and Helm System Wiring DiagramluvepeboNo ratings yet

- 48v-wiring-diagramDocument1 page48v-wiring-diagramKammoeNo ratings yet

- Thu Dec 19 21:51:28 2013 Case: D:/Minh Hien/Simulation/Bksim/Bai Giang Mo Phong/Mo Phong Cong Nghe/Lng/Lng-Final - Hscflowsheet: Sweetening (Tpl1)Document1 pageThu Dec 19 21:51:28 2013 Case: D:/Minh Hien/Simulation/Bksim/Bai Giang Mo Phong/Mo Phong Cong Nghe/Lng/Lng-Final - Hscflowsheet: Sweetening (Tpl1)KutiNo ratings yet

- Overall Electrical Wiring DiagramDocument144 pagesOverall Electrical Wiring DiagramArnuphap SudwaiyonNo ratings yet

- AC#BA.1 Air Compressor With TankDocument1 pageAC#BA.1 Air Compressor With TankMinh NguyễnNo ratings yet

- Chpp4 - Treated Water Piping Layout General Arrangement: Drawing NumberDocument9 pagesChpp4 - Treated Water Piping Layout General Arrangement: Drawing Numbermansoor2182No ratings yet

- Nal-19302405 SNDocument2 pagesNal-19302405 SNImacAlotta HoesNo ratings yet

- Engine management system, 8-Cyl-02-01Document1 pageEngine management system, 8-Cyl-02-01oretuertoyanapaNo ratings yet

- Preliminary document for total power and automation solutionsDocument7 pagesPreliminary document for total power and automation solutionsTien LamNo ratings yet

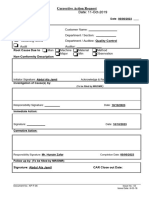

- CAR Form EmptyDocument1 pageCAR Form Emptyhunain zafarNo ratings yet

- Agenda OMSP Train The Trainer - 2016Document3 pagesAgenda OMSP Train The Trainer - 2016hunain zafarNo ratings yet

- gd2024Document255 pagesgd2024hunain zafarNo ratings yet

- C610h Auto Tensile Tester Product BrochureDocument3 pagesC610h Auto Tensile Tester Product BrochureNirmala SNo ratings yet

- Sampling and Testing Plan For Raw MaterialDocument3 pagesSampling and Testing Plan For Raw Materialhunain zafarNo ratings yet

- Letter of MotivationDocument1 pageLetter of Motivationhunain zafarNo ratings yet

- Vendor Audit Questionnaire ReviewDocument5 pagesVendor Audit Questionnaire Reviewhunain zafarNo ratings yet

- 4.1.2a Supplier Questionnaire Template PDFDocument5 pages4.1.2a Supplier Questionnaire Template PDFhunain zafarNo ratings yet

- Simplexity Thinking Program BrochureDocument7 pagesSimplexity Thinking Program Brochurehunain zafarNo ratings yet

- Core ResultsDocument4 pagesCore Resultshunain zafarNo ratings yet

- Hazardous Substances Rules 2003 - Category I Chemical Usage at Tri-Pack Films Limited V1Document18 pagesHazardous Substances Rules 2003 - Category I Chemical Usage at Tri-Pack Films Limited V1hunain zafarNo ratings yet

- Database 4-1Document7 pagesDatabase 4-1hunain zafarNo ratings yet

- Contractors DataDocument9 pagesContractors Datahunain zafarNo ratings yet

- Environmental Aspects Register (Iso 14001)Document11 pagesEnvironmental Aspects Register (Iso 14001)hunain zafarNo ratings yet

- Benefits of Internal AuditorsDocument1 pageBenefits of Internal Auditorshunain zafarNo ratings yet

- Calibration Master Data BaseDocument60 pagesCalibration Master Data Basehunain zafarNo ratings yet

- Training CalculatorDocument3 pagesTraining Calculatorhunain zafarNo ratings yet

- Tri-Pack Films Limited - WWF Green Office Implementation PlanDocument2 pagesTri-Pack Films Limited - WWF Green Office Implementation Planhunain zafarNo ratings yet

- Sr. # Date / Week No. of Visitors Visitor's Company TPFL Host DeptDocument4 pagesSr. # Date / Week No. of Visitors Visitor's Company TPFL Host Depthunain zafarNo ratings yet

- Visitors Records (00000002)Document12 pagesVisitors Records (00000002)hunain zafarNo ratings yet

- Contractors + Visitors DataDocument9 pagesContractors + Visitors Datahunain zafarNo ratings yet

- RO-1 Water Diagram PDFDocument1 pageRO-1 Water Diagram PDFhunain zafarNo ratings yet

- Contractors + Visitors DataDocument9 pagesContractors + Visitors Datahunain zafarNo ratings yet

- Training ProgramsDocument1 pageTraining Programshunain zafarNo ratings yet

- GP 4100 Food QuestionnaireDocument10 pagesGP 4100 Food Questionnairehunain zafarNo ratings yet

- Calibration Master Data BaseDocument60 pagesCalibration Master Data Basehunain zafarNo ratings yet

- # of Contractors Employees April May Contractor Apr Wk1 Apr Wk2 Apr Wk3 Apr Wk4 May Wk1 May Wk2 TotalDocument9 pages# of Contractors Employees April May Contractor Apr Wk1 Apr Wk2 Apr Wk3 Apr Wk4 May Wk1 May Wk2 Totalhunain zafarNo ratings yet

- Ro-1 Water Circuit Layout PDFDocument1 pageRo-1 Water Circuit Layout PDFhunain zafarNo ratings yet

- Ro-1 Water Circuit Layout PDFDocument1 pageRo-1 Water Circuit Layout PDFhunain zafarNo ratings yet

- BRCGS Standard Clarifies Food Defence and FraudDocument6 pagesBRCGS Standard Clarifies Food Defence and Fraudhunain zafarNo ratings yet

- Fleet Tracking & Ride Management AppsDocument15 pagesFleet Tracking & Ride Management AppsAbnan YazdaniNo ratings yet

- I. Bejtka - Cross (CLT) and Diagonal (DLT) Laminated Timber As InnovativeDocument144 pagesI. Bejtka - Cross (CLT) and Diagonal (DLT) Laminated Timber As InnovativeFredNo ratings yet

- AlienVault Getting Started Guide v47Document18 pagesAlienVault Getting Started Guide v47fortinet123No ratings yet

- Email Marketing CourseDocument18 pagesEmail Marketing CourseChaand TaraNo ratings yet

- Network AnalysisDocument71 pagesNetwork AnalysisJayNo ratings yet

- Audit Harley DavidsonDocument2 pagesAudit Harley DavidsonAbdul Hafizh100% (1)

- National Certificate in Business (First Line Management) (Level 3) Level 3 Credits 45 PurposeDocument6 pagesNational Certificate in Business (First Line Management) (Level 3) Level 3 Credits 45 PurposeyolandasrpNo ratings yet

- Electromagnetic Radiation Applications in Food ProcessingDocument34 pagesElectromagnetic Radiation Applications in Food ProcessingMichaela ZacharovovaNo ratings yet

- Acoplamentos de Lamela de Aço ROBA-DSDocument72 pagesAcoplamentos de Lamela de Aço ROBA-DSFernando KonitzNo ratings yet

- Legends of SkyloftDocument30 pagesLegends of SkyloftAnonymous WaLbdWNo ratings yet

- cRIO 9073Document28 pagescRIO 9073Emanuel GabrielNo ratings yet

- WS.1933.31JAN24 - Annual InspectionDocument3 pagesWS.1933.31JAN24 - Annual InspectionpauucoxNo ratings yet

- Finger-Vein Based Biometric Security SystemDocument4 pagesFinger-Vein Based Biometric Security SystemInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Innovation Challenge 1383801939799 1410445682820Document4 pagesInnovation Challenge 1383801939799 1410445682820Athif Khan100% (1)

- Moscow's iconic Narkomfin commune houseDocument4 pagesMoscow's iconic Narkomfin commune housebamca123No ratings yet

- Formula Renault 1.6 NEC JuniorDocument13 pagesFormula Renault 1.6 NEC JuniorRick LangedijkNo ratings yet

- Cyanate Ester Resin5Document26 pagesCyanate Ester Resin5rkkumarcpriNo ratings yet

- Exploration 4 EWAN Chapter 1Document9 pagesExploration 4 EWAN Chapter 1leinad71No ratings yet

- DVPF 7 eDocument123 pagesDVPF 7 eעליזה שדמיNo ratings yet

- Invoice 168714Document1 pageInvoice 168714Subham MukherjeeNo ratings yet

- Carbonite Portal v8.84 - Release NotesDocument14 pagesCarbonite Portal v8.84 - Release NotesAlbertoDanielRodriguezSandovalNo ratings yet

- TerminologyDocument77 pagesTerminologyBianca Emanuela LazarNo ratings yet

- Marketing Management: Marketing Audit Report: Sony CorporationDocument24 pagesMarketing Management: Marketing Audit Report: Sony CorporationJahanzaib ShahzadNo ratings yet

- Golf/Tennis Resort Development Impacts OperationsDocument21 pagesGolf/Tennis Resort Development Impacts OperationsTheamicable Firstlady Mar100% (1)

- Work Boats Waflaf 665 - 1963 PDFDocument8 pagesWork Boats Waflaf 665 - 1963 PDFJUAN GONZALEZ NUNEZ100% (1)

- Pressure ControlDocument12 pagesPressure ControlMohamed RashedNo ratings yet

- AEROI - 0930 311200 Easy Cover Parts ListDocument42 pagesAEROI - 0930 311200 Easy Cover Parts ListJonah RagleNo ratings yet

- SpeakmanDocument2 pagesSpeakmanpoladwipaNo ratings yet

- Rose Petal Paper ProductsDocument3 pagesRose Petal Paper ProductsHardesh Kumar HiraNo ratings yet

- Additive Manufacturing in DentistryDocument8 pagesAdditive Manufacturing in DentistryRushabh ZambadNo ratings yet