Professional Documents

Culture Documents

Design of Double Composite Bridges Using High Strength Steel PDF

Uploaded by

Krisna SetiawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Double Composite Bridges Using High Strength Steel PDF

Uploaded by

Krisna SetiawanCopyright:

Available Formats

Available online at www.sciencedirect.

com

Available online at www.sciencedirect.com

Procedia

Engineering

Procedia Engineering 00 (2011) 000–000

Procedia Engineering 14 (2011) 1825–1829

www.elsevier.com/locate/procedia

The Twelfth East Asia-Pacific Conference on Structural Engineering and Construction

Design of Double Composite Bridges using High Strength

Steel

CS Shim1a, JW Whang2, CH Chung3, PG Lee4

1

Department of Civil and Env. Engineering, Chung-Ang University (csshim@cau.ac.kr)

2

IDM Engineering(jwhwang@idm3d.co.kr) (chchung5@dankook.ac.kr)

3

Department of Civil Engineering, Dankook University

4

Steel Structure Research Laboratory, Research Institute of Industrial Science & Technology (pg289@rist.re.kr)

Abstract

High performance steel for bridges (HSB) which has higher performance in tensile, yield strength,

toughness, weldability than common steels has been developed in Korea. HSB800 has a minimum tensile

strength of 800MPa. However, design of long-span steel bridges with high strength steels is limited

because of buckling and fatigue. In this paper, two concepts of composite and hybrid were utilized to

solve the obstacles. Double-composite action in negative moment region was adopted to increase flexural

stiffness of composite sections and to enhance buckling problems of steel plates. Combination of steel

box girders and double-composite truss girders along the length of the bridges was also utilized to enable

the design of longer span bridges. New continuous bridges with more than 100m span length were

designed using the proposed concept and HSB. Effectiveness of each combination was discussed to

suggest recommendations for the design of composite bridges with high performance steels.

© 2011 Published by Elsevier Ltd.

KEYWORDS: high performance steel, double composite action, hybrid, box girder, truss girder

1. INTRODUCTION

High performance steel for bridges (HSB) is a new material for bridge design. Steel box girder bridges

are common types for medium span bridges and concrete box girders or cable supported bridges are used

a

Corresponding author: Email: csshim@cau.ac.kr

a

Presenter: Email: csshim@cau.ac.kr

1877–7058 © 2011 Published by Elsevier Ltd.

doi:10.1016/j.proeng.2011.07.229

1826 CS Shim et al. / Procedia Engineering 14 (2011) 1825–1829

2 Author name / Procedia Engineering 00 (2011) 000–000

for longer span bridges. Even though HSB has higher strength, there are many obstacles to utilize the

strength because of buckling, fatigue, connection and deflection. Double composite action is one of the

solutions for the problems (Kim & Shim 2009, Shim 2005, Shim et al. 2006).

In this paper, a new mixed bridge concept is proposed to lengthen the span length of steel bridges and

to utilize the high strength steel. As shown in Figure 1, a double composite steel truss for negative

moment region and a normal steel box girder for positive moment region are combined. Composite slab

between lower chords enhances the stability of thin plate and deflection of the bridge. Mixed connection

with vertical and horizontal shear studs is designed to obtain composite action between steel members and

concrete slab.

Figure 1: Long-span double composite hybrid truss bridge

2. HIGH STRENGTH STEEL FOR BRIDGES

There were remarkable improvements of steel production which brought developments of high

performance steel for bridges (HPS) in US, Japan, Europe and Korea. HPS has similar improved strength,

weldability, higher toughness, and better weathering and fabrication characteristics. High strength steel

for bridges (HSB) in Korea is produced by applying thermo-mechanical control process (TMCP) and

optimizing chemical compositions resulted higher tensile strength and no reduction of strength for thick

plate as shown in Figure 2. High toughness of 47J at -20℃ reduces occurrence of brittle fracture at low

temperature and improves cold-formability. In addition, the low Pcm and Ceq of HSB enhance weldability,

that is, reduce cold cracking and lower preheating temperature.

HSB500 (tensile strength of 500MPa), HSB600 (tensile strength of 600MPa), and HSB800 (tensile

strength of 800MPa) were successfully developed and registered in Korean Industrial Standards (KS D

3868) and added to the new Korean roadway bridge design code as summarized in Table 1. Typical

stress-strain curves for HSB are presented in Figure 3.

(a) Strength (b) Toughness (c) Weldability

Figure 2: Performance of HSB

CS Shim et al. / Procedia Engineering 14 (2011) 1825–1829 1827

Author name / Procedia Engineering 00 (2011) 000–000 3

1000

HSB500

900

HSB600

800

HSB800

Stress (MPa) 700

600

500

400

300

200

100

0

0 0.05 0.1 0.15 0.2 0.25 0.3

Strain

Figure 3: Stress-strain curves for HSB

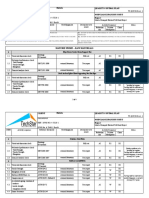

Table 1: Design specification on HSB steel

Yield Tensile Maximum Allowable Allowable shear Allowable bearing

Symbol

strength strength thickness stress stress stress

HSB500 380 MPa 500 MPa 100 mm 230 MPa 135 MPa 345 MPa

HSB600 450 MPa 600 MPa 100 mm 270 MPa 155 MPa 405 MPa

HSB800 690 MPa 800 MPa 80 mm 380 MPa 220 MPa 570 MPa

3. DESIGN OF DOUBLE COMPOSITE BRIDGES

3.1 Conceptual design

Concept two-span continuous hybrid bridges with span length of 100m, 120m and 150m were designed

according to allowable stress design. HSB was utilized for some parts of the bridge which are subject to

high stress. Steel bridges with high strength steel may have difficulty to satisfy the deflection limit. In

negative moment region, composite slab was designed to connect two lower chords by mixed stud shear

connection. Figure 4 shows the typical sections of upper and lower chord of the truss section.

Relatively low allowable stress of concrete can limit the usage of high strength steel for steel-concrete

composite structures. High strength concrete with more than 40MPa was used for the design. Details of

composite slab were designed according to “Composite Plates in bridges” in Eurocode 4 (EN 1994-2).

Deflection limit of the steel plate for concrete casting is 0.05hc. Through the conceptual design, hybrid

combinations of different strength of HSB were investigated. Design issues for the experimental

verification were also suggested from the design.

3.2 Connection details

Steel plates in composite slabs between lower chords need to be designed according to Table 2 (EN

1994-2). Instead of stiffeners, shear studs are placed on the steel plates to prevent local buckling as shown

in Figure 5. Where headed stud connectors of diameter d are arranged in such a way that splitting forces

1828 CS Shim et al. / Procedia Engineering 14 (2011) 1825–1829

4 Author name / Procedia Engineering 00 (2011) 000–000

can occur in the direction of the slab thickness, transverse reinforcement should be provided, as shown in

Figure 5, such that the distance ev ≥ 6d (EN 1994-2). For connectors with shear resistance PRd at

longitudinal spacing s, the cross sectional area of reinforcement per unit length should

satisfy Asv ≥ PRd /(3 f sd s ) .

Static and fatigue design of mixed stud shear connection with vertical and horizontal connectors as

shown in Figure 5 was executed according to the previous experimental research by Kim and Shim

(2009). However, it is necessary to verify the empirical equation for high strength steel and high strength

concrete.

Concrete slab width

(a) Upper chord section

(b) Low chord section

Figure 4: Truss section

Table 2: Upper limits to spacings of shear connectors in a composite plate in compression

Class 2 Class 3

Outstand flange: 14 tε 20 tε

Transverse to the direction of compressive stress

Interior flange: 45 tε 50 tε

In the direction of compressive stress All composite plates: 22 tε 25 tε

(b) Connection detail

(a) Details of Nantenhach bridge

Figure 5: Details of composite slab between lower chords

CS Shim et al. / Procedia Engineering 14 (2011) 1825–1829 1829

Author name / Procedia Engineering 00 (2011) 000–000 5

4. CONCLUSIONS

For the new high performance steel in Korea, a new bridge concept was proposed and several design

examples of hybrid double composite truss bridges were developed. In order to maximize the

effectiveness of HSB, double composite truss in negative moment regions is connected to normal steel

box girders of mid-span and end span.

Details of steel plate to enhance the stability were investigated and hybrid stud shear connection was

adopted for the connection. Requirements for stud spacings, transverse reinforcement and minimum

reinforcement ratio to control cracking were considered in the design. Currently, an experimental program

is performed to verify the design concepts and basic requirements of long span bridges with HSB800.

Acknowledgements

This research was supported by POSCO and the support is gratefully acknowledged.

References

[1] Eurocode 4 (1994). Design of composite steel and concrete structures. Part 1, General rules and rules for buildings, ENV

1994-2. CEN.

[2] Eurocode 4 (2005). Design of composite steel and concrete structures. Part 2, General rules and rules for bridges, EN 1994-2.

CEN.

[3] Kim HH, Shim CS (2009). Experimental investigation of double composite twin-girder railway bridges. Journal of

Constructional Steel Research, 65(6), June, pp.1355-1366.\

[4] Shim CS (2005). Research on the Double Composite Twin-Girder Railway Bridges. Proc. of the 8th Korea-China-Japan

Symposium on Structural Steel Construction, 10.13, pp. 49-58.

[5] Shim CS, Kim HH, Lee PG (2006). Design of Continuous Double Composite High-speed Railway Bridges. Proceedings of

7th International Conference on Short & Medium Bridges, August 22~25, Montreal, Canada, pp. ID-043-1~11.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Tensa Modular Type LR: Expansion JointsDocument12 pagesTensa Modular Type LR: Expansion JointsKrisna SetiawanNo ratings yet

- Loading AssesmentDocument7 pagesLoading AssesmentKrisna SetiawanNo ratings yet

- Seismic Isolation VibrateDocument15 pagesSeismic Isolation VibrateAdet WildanNo ratings yet

- Wrana 2015 4 PDFDocument11 pagesWrana 2015 4 PDFarslanpasaNo ratings yet

- ITP TS-QCP-018 r1Document4 pagesITP TS-QCP-018 r1Krisna SetiawanNo ratings yet

- 107KLAPISPX2018 - Spesifikasi Teknis LRB Portal Ramp CikunirDocument2 pages107KLAPISPX2018 - Spesifikasi Teknis LRB Portal Ramp CikunirKrisna SetiawanNo ratings yet

- Method Statement - Bearing-Top Structural Steel Bridge - Pendulum BearingDocument4 pagesMethod Statement - Bearing-Top Structural Steel Bridge - Pendulum BearingKrisna SetiawanNo ratings yet

- Fatigue Test MBJSDocument50 pagesFatigue Test MBJSKrisna SetiawanNo ratings yet

- Flow Chart Japek Highway ConstructionDocument3 pagesFlow Chart Japek Highway ConstructionKrisna Setiawan0% (1)

- Structural Stell FabricationDocument24 pagesStructural Stell FabricationLiyakathalikhan Shahjahan100% (1)

- Bms Bridge Loading CodeDocument26 pagesBms Bridge Loading CodeKrisna SetiawanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- M4-Kinematics in One-DimensionDocument14 pagesM4-Kinematics in One-Dimensionggt9zfhsjvNo ratings yet

- DPP No. 41: PhysicsDocument6 pagesDPP No. 41: PhysicsGajanan PurudNo ratings yet

- Industrial N3G WZElectronicsDocument102 pagesIndustrial N3G WZElectronicsLogan JesseNo ratings yet

- HighDynamicPerformance Motors - 2210 NEW - LowresDocument56 pagesHighDynamicPerformance Motors - 2210 NEW - LowresMohamed MOUCHRIFNo ratings yet

- Lab Details - 3 BranchDocument10 pagesLab Details - 3 BranchDevdoot SahuNo ratings yet

- Biomechanics of Knee Joint - A ReviewDocument11 pagesBiomechanics of Knee Joint - A ReviewMat MarinhoNo ratings yet

- 444 PDFDocument45 pages444 PDFfacedoneNo ratings yet

- Log 92 Tip Conductivity SalinityDocument1 pageLog 92 Tip Conductivity SalinityJUAN RAMIREZ MARTINEZNo ratings yet

- Lecture Notes On Distributions: Hasse CarlssonDocument83 pagesLecture Notes On Distributions: Hasse CarlssonRajesh MondalNo ratings yet

- MECH 211 Module 9 Distributed Loads and Hydrostatic Forces CablesDocument18 pagesMECH 211 Module 9 Distributed Loads and Hydrostatic Forces CablesFirst name Last nameNo ratings yet

- Revised PM Is 12786 August 2020Document8 pagesRevised PM Is 12786 August 2020Mahesh YadavNo ratings yet

- MA8402 Probability and Queueing MCQDocument18 pagesMA8402 Probability and Queueing MCQ4038 Ramajayam.UNo ratings yet

- AP CALCULUS - Optimization Problems SolutionsDocument1 pageAP CALCULUS - Optimization Problems SolutionsVehid.KurticNo ratings yet

- Design Strength of Screw AAMA TIR-A9Document1 pageDesign Strength of Screw AAMA TIR-A9Giri DharanNo ratings yet

- FprCEN - TS 12390-9 - 2015 (Marked)Document31 pagesFprCEN - TS 12390-9 - 2015 (Marked)Cristina StancuNo ratings yet

- Riemann IntegrationDocument25 pagesRiemann IntegrationJayaratneNo ratings yet

- Ammann Asphalt Mixing-Plant Brochure enDocument90 pagesAmmann Asphalt Mixing-Plant Brochure enMihai Popescu100% (4)

- Altair Flux 2019.1 User Guide: New FeaturesDocument74 pagesAltair Flux 2019.1 User Guide: New FeaturesrobschaelNo ratings yet

- Tutorial 3 RemakeDocument8 pagesTutorial 3 RemakeMatataTomato M30No ratings yet

- Cylindrical Pressure VesselDocument10 pagesCylindrical Pressure VesselHenry Ovedje WanoghoNo ratings yet

- Vibration Motor CatalogueDocument36 pagesVibration Motor Cataloguevivek dongareNo ratings yet

- Sample Design Calculation Using Hardy Cross MethodDocument13 pagesSample Design Calculation Using Hardy Cross MethodZol HasNo ratings yet

- #160 Lifting Fixture 38tons 020807Document14 pages#160 Lifting Fixture 38tons 020807halder_kalyan9216No ratings yet

- Shell Gadus S2 V100 2Document2 pagesShell Gadus S2 V100 2Muhammad SaputraNo ratings yet

- Applications of SuperconductivityDocument45 pagesApplications of SuperconductivityElif SoyluNo ratings yet

- Rig Servo - en PDFDocument16 pagesRig Servo - en PDFJavier MiramontesNo ratings yet

- ASSIGNMENT-GRADE 9 MATH MELCs VIDEO LESSONSDocument5 pagesASSIGNMENT-GRADE 9 MATH MELCs VIDEO LESSONSJoey Abang Oco100% (1)

- Designing and Analysis of Cryogenic Storage Vessels: January 2016Document13 pagesDesigning and Analysis of Cryogenic Storage Vessels: January 2016Hassan HabibNo ratings yet

- 15-10-2022 - JR - Super60-STERLING BT - Jee-Main - UTM-07 - Key & Sol'sDocument12 pages15-10-2022 - JR - Super60-STERLING BT - Jee-Main - UTM-07 - Key & Sol'sPrabhakar BandaruNo ratings yet

- ASCE 7-16 Ground-Motion Scaling Procedure For Nonlinear Analysis of Buildings in Comparison With ASCE 7-10 and ASCE 7-05Document33 pagesASCE 7-16 Ground-Motion Scaling Procedure For Nonlinear Analysis of Buildings in Comparison With ASCE 7-10 and ASCE 7-05sunaifctmNo ratings yet