Professional Documents

Culture Documents

CHAPTER II Thesis

Uploaded by

Rara GarciaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CHAPTER II Thesis

Uploaded by

Rara GarciaCopyright:

Available Formats

METHODOLOGY

Conceptualize framework of the Study

The study was conceptualized from the eagerness of coping up in modern and

advanced technology from other countries. Philippines is under in developing country, in

other side it is facing problems on its way to modernization especially in agricultural

sector. Agriculture has a huge impact to the economy and it is appropriate for us to

welcome new ideas and knowledge on how to advance our techniques in farming.

Aeroponics is known globally and it can be seen from the feedbacks of the people from

different countries all over the world who adapted the concept says that it was effective in

farming.

The researchers then came up with an idea to adapt the concept to create a study

for actual acclimation of the technology as first move to introduce the system in our

community.

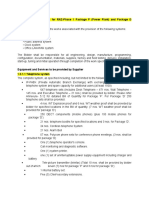

INPUT PROCESS OUTPUT

Conducting Outlining Detailed

research by paper and paper and

accessing in world designing the design of the

wide web related system system

to the study

Detailed paper and Fabrication of Fabricated

system design the system aeroponic

system

Fabricated Preliminary Functional

aeroponic system testing and and modified

Modification system

Functional and Performance Field

modified system Evaluation performance

Functional and Cost Analysis

modified system

Equipment and Instrument

Materials

Items Purpose

PVC Pipes ( 6” ) It serves as the holder of the crops and as a chamber for the

sprayer of water solution

PVC cup ( 6’’ ) It covers the PVC pipes in both sides

PVC Pipes ( 1 ¼ “ ) It will serves as passage of water solution

Elbow ( 1 ¼ “ ) It connects the pipes

Angle Bar ( 1” ) It serves as the frame of the system

Submersible Pump It is to regulate the circulation or flow of the water solution

Spray nozzles Use as the outlet of the water solution delivered to the crop

Vulcaseal It will seal all the connections of the pipes to avoid leaks

pH meter To measure the pH level of the water solution

Welding Rod Connects the angle bars

Bolts and Nuts Secure the PVC pipes to the angle bar

Tools

Items Purpose

Electric Drill Use to drill holes for the holder of the crop, for the connections

of the pipes and for the installation of the spray nozzles.

Welding Machine Use for welding

Cutter Use to cut the materials into specified measurements

Fabrication

The following are the activities to be undertaken in the construction of aeroponics

system:

Measuring. The pipes will be measured according to the desired length based on

the design. Adjustments will be considered.

Cutting. This process will be undertaken using a cutter. Pipes and angle bars will

be cut according to their specified measurements.

Drilling. This process requires electric drill to make a hole in the container for the

holder of the crops and pipes placement.

Welding. The angle bars will be connected to construct the frame of the system

using welding rod and welding machine.

Attaching. In this process, the spray nozzles will be attached to their

corresponding places. The pipes will be connected using the elbows. The vulcaseal will

be used for securing the pipes from leaks.

Assembling. This process will be assembling the components or parts of the

system. This will be; pipes to the container, pipe to the submersible pump, and pump to

the container will be connected respectively as well as the spray nozzles. The crop holder

will be placed on its corresponding places.

Evaluation

Preliminary Testing

Preliminary testing will be performed for adjustments and modification of the

design before the final evaluation.

Final Evaluation

After performing the preliminary testing and upon the adjustments and

modification of the design, final evaluation will be done for the performance of the

system.

Data to be Gathered

The following parameters will be gathered to determine the responses of the

different nutrient water solution under aeroponic system;

Height. The height of the crop will be taken a month after planting from the base

to the tip of the longest leaf.

Number of leaves. The number of well-developed leaves of the sample plant will

be counted and recorded at harvest.

Leaf Area per plant (LA/Plant). The leaf area per plant will be determined by

the ratio between the total leaf weight per plant and the mean leaf weight per sq. cm.

from five sample plants per treatment.

total leaf weight per plant

Leaf Area per Plant =

mean leaf wt . per sq .cm of leaf

Percent of survival. The percent of the survival will be determined by the ratio

between remaining plants and the total number of plants.

Remaining Plants

Percent of Survival= ×100

total number of plants

The data to be gathered will be arranged, tabulated, and statistically analyzed

using Analysis of Variance (ANOVA). Significant findings will be further tested using

Turkey-Kramer post hoc test for the mean comparison.

Profitability Analysis. All the materials and labor inputs in the study will be

recorded for the computation of the return on investment (ROI) where:

Net Income

ROI= ×100

total production costs

Economic Analysis using payback period to determine the feasibility of utilizing

the system.

total production costs

Payback= ×100

Net Income

Statistical Design of the Study

The completely Randomized Design (CRD) will be employed in the test using

spinach. The commodity will be tested five times using the facility. The following

treatments will be used in the study are:

Treatment 1 =

Treatment 2 =

Treatment 3 =

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Rachel Ann G. Garcia Ma. Nessalyn U. Peralta Aldrin P. Sagao Lherisse Joy B. Valdez Bachelor of Science in Agricultural EngineeringDocument2 pagesRachel Ann G. Garcia Ma. Nessalyn U. Peralta Aldrin P. Sagao Lherisse Joy B. Valdez Bachelor of Science in Agricultural EngineeringRara GarciaNo ratings yet

- Conducted Seminar in Brgy. Sabangan, San Juan, Ilocos Sur: (Aeroponics System For Onion Production)Document8 pagesConducted Seminar in Brgy. Sabangan, San Juan, Ilocos Sur: (Aeroponics System For Onion Production)Rara GarciaNo ratings yet

- Review of Related LiteratureDocument4 pagesReview of Related LiteratureRara Garcia100% (1)

- Ilocos Sur Polytechnic State College 1Document18 pagesIlocos Sur Polytechnic State College 1Rara GarciaNo ratings yet

- Aeroponics System for Onion Leeks ProductionDocument24 pagesAeroponics System for Onion Leeks ProductionRara Garcia100% (1)

- Generating Power Using Dynomo With Rotating EquipmentDocument18 pagesGenerating Power Using Dynomo With Rotating EquipmentRara GarciaNo ratings yet

- Ilocos Sur Polytechnic State College: Vlog101 - Don'T Waste Your Waste: An EvaluationDocument54 pagesIlocos Sur Polytechnic State College: Vlog101 - Don'T Waste Your Waste: An EvaluationRara GarciaNo ratings yet

- Aeroponics System For Onion Production: - Ma. Nessalyn U. Peralta - Aldrin P. Sagao - Lherisse Joy B. ValdezDocument5 pagesAeroponics System For Onion Production: - Ma. Nessalyn U. Peralta - Aldrin P. Sagao - Lherisse Joy B. ValdezRara GarciaNo ratings yet

- Solar-Powered Seed Sowing MachineDocument7 pagesSolar-Powered Seed Sowing MachineRara Garcia100% (1)

- Generating Power Using Dynomo With Rotating EquipmentDocument18 pagesGenerating Power Using Dynomo With Rotating EquipmentRara GarciaNo ratings yet

- Chapter 1 and 2-Jcklrd PDFDocument39 pagesChapter 1 and 2-Jcklrd PDFRara GarciaNo ratings yet

- Solar Food DehydatorDocument41 pagesSolar Food DehydatorRara GarciaNo ratings yet

- Solar Food DehydatorDocument41 pagesSolar Food DehydatorRara GarciaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 909design of High Efficiency Pelton Turbine For Micro-HydropowerDocument13 pages909design of High Efficiency Pelton Turbine For Micro-HydropowerrachidtuNo ratings yet

- Mitch Fryling and Linda Hayes - Motivation in Behavior Analysis A Critique PDFDocument9 pagesMitch Fryling and Linda Hayes - Motivation in Behavior Analysis A Critique PDFIrving Pérez Méndez0% (1)

- Smart CityDocument4 pagesSmart CityRendi NafiahNo ratings yet

- Risktec Drilling Soc 0.3 PDFDocument16 pagesRisktec Drilling Soc 0.3 PDF1sNo ratings yet

- Frontal - Cortex Assess Battery FAB - ScaleDocument2 pagesFrontal - Cortex Assess Battery FAB - Scalewilliamsa01No ratings yet

- Introduction to Oil & Gas Drilling and Well OperationsDocument22 pagesIntroduction to Oil & Gas Drilling and Well OperationsMohammed Abdul SamiNo ratings yet

- Human Rights Law IntroductionDocument8 pagesHuman Rights Law IntroductionXander ZingapanNo ratings yet

- Training Catalog Piovan AcademyDocument24 pagesTraining Catalog Piovan AcademyKlein Louse AvelaNo ratings yet

- CorrectDocument45 pagesCorrectaskerman 3No ratings yet

- Consumer Behavior Quiz (01-16-21)Document3 pagesConsumer Behavior Quiz (01-16-21)litNo ratings yet

- LCD LG (M17,1917S-BNN E)Document34 pagesLCD LG (M17,1917S-BNN E)Ion IonutNo ratings yet

- Pytania Do Obrony Spoza Pracy Dyplomowej Filologia Angielska Studia I StopniaDocument5 pagesPytania Do Obrony Spoza Pracy Dyplomowej Filologia Angielska Studia I StopniabartNo ratings yet

- Advances in Littorinid BiologyDocument193 pagesAdvances in Littorinid Biologyasaad lahmarNo ratings yet

- Nozomi Networks Smart Polling Data SheetDocument4 pagesNozomi Networks Smart Polling Data SheetFlávio Camilo CruzNo ratings yet

- 1.finite Impulse Response (FIR) FiltersDocument16 pages1.finite Impulse Response (FIR) FiltersSamet YılmazNo ratings yet

- Alumni Speaks... : Axay GandhiDocument4 pagesAlumni Speaks... : Axay GandhiSajal MorchhaleNo ratings yet

- Human Persons Are Oriented Toward Their Impending DeathDocument40 pagesHuman Persons Are Oriented Toward Their Impending DeathNaddy Retxed100% (1)

- Distributed Tic-Tac-Toe: Requirements, Design & AnalysisDocument8 pagesDistributed Tic-Tac-Toe: Requirements, Design & AnalysisRitika AgnihotriNo ratings yet

- Fines Tcs198 2x36wDocument8 pagesFines Tcs198 2x36wwilber ticonaNo ratings yet

- ECSS E ST 32 10C - Rev.1 (6march2009) PDFDocument24 pagesECSS E ST 32 10C - Rev.1 (6march2009) PDFTomaspockNo ratings yet

- Candidate Workshop ManualDocument45 pagesCandidate Workshop ManualMark Brewer100% (1)

- Scope of WorkDocument4 pagesScope of WorkMathivanan AnbazhaganNo ratings yet

- A Treatise On Physical GeographyDocument441 pagesA Treatise On Physical Geographyramosbrunoo8933No ratings yet

- The Origins Development and Possible Decline of The Modern StateDocument65 pagesThe Origins Development and Possible Decline of The Modern StateJasper Jade MartinNo ratings yet

- Standards and Their ClassificationsDocument3 pagesStandards and Their ClassificationsJoecelle AbleginaNo ratings yet

- Handbook Valve Technology 03.04.2020Document132 pagesHandbook Valve Technology 03.04.2020Ramazan YaşarNo ratings yet

- Overhead Management through Template ConfigurationDocument5 pagesOverhead Management through Template ConfigurationBalanathan VirupasanNo ratings yet

- Challenges of Deep Excavation for KVMRT StationsDocument85 pagesChallenges of Deep Excavation for KVMRT StationsAlwin AntonyNo ratings yet

- Extending NAS Web App MobileDocument2 pagesExtending NAS Web App MobileD2VNo ratings yet

- BJT AmplifiersDocument21 pagesBJT AmplifiersAligato John RayNo ratings yet