Professional Documents

Culture Documents

Generator Item C-Inspections - 20

Uploaded by

Nuzul FurqonyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Generator Item C-Inspections - 20

Uploaded by

Nuzul FurqonyCopyright:

Available Formats

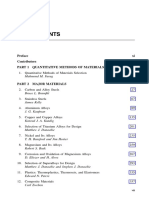

8 QUANTITATIVE METHODS OF MATERIALS SELECTION

tolerances, and surface finish. Whether or not the equipment or experience for

a given manufacturing process exist in a plant can also be considered as a hard

requirement in many cases. Compatibility between the manufacturing process

and the material is also an important screening parameter. For example, cast

irons are not compatible with sheet metal forming processes and steels are not

easy to process by die casting. In some cases, eliminating a group of materials

results in automatic elimination of some manufacturing processes. For example,

if plastics are eliminated because service temperature is too high, injection and

transfer molding should be eliminated as they are unsuitable for other materials.

Soft, or relative, requirements are subject to compromise and trade-offs. Ex-

amples of soft requirements include mechanical properties, specific gravity, and

cost. Soft requirements can be compared in terms of their relative importance,

which depends on the application under study.

Cost per Unit Property Method

The cost per unit property method is suitable for initial screening in applications

where one property stands out as the most critical service requirement.1 As an

example, consider the case of a bar of a given length (L) to support a tensile

force (F). The cross-sectional area (A) of the bar is given by

A ⫽ F/S (1)

where S ⫽ working stress of the material, which is related to its yield strength

by an appropriate factor of safety.

The cost of the bar (C⬘) is given by

C⬘ ⫽ C AL ⫽ (CFL)/S (2)

where C ⫽ cost of the material per unit mass

⫽ density of the material

Since F and L are constant for all materials, comparison can be based on the

cost of unit strength, which is the quantity:

[(C)/S] (3)

Materials with lower cost per unit strength are preferable. If an upper limit is

set for the quantity [(C)/S], then materials satisfying this condition can be

identified and used as possible candidates for more detailed analysis in the next

stage of selection.

The working stress of the material in Eqs. 1, 2, and 3 is related to the static

yield strength of the material since the applied load is static. If the applied load

is alternating, it is more appropriate to use the fatigue strength of the material.

Similarly, the creep strength should be used under loading conditions that cause

creep.

Equations similar to 2 and 3 can be used to compare materials on the basis

of cost per unit stiffness when the important design criterion is deflection in the

bar. In such cases, S is replaced by the elastic modulus of the material. The

You might also like

- Quantitative Methods of Materials Selection: Rigid Requirements AreDocument29 pagesQuantitative Methods of Materials Selection: Rigid Requirements AreDhananjay ShimpiNo ratings yet

- Presentation SobhyDocument23 pagesPresentation SobhySobhe ShoshaNo ratings yet

- Weight and Reliability Optimization of A Helicopter Composite Armor Using Dynamic ProgrammingDocument6 pagesWeight and Reliability Optimization of A Helicopter Composite Armor Using Dynamic ProgrammingHamed MemarianNo ratings yet

- Shear Strength Analysis of Dissimilar Materials Bolted JointDocument4 pagesShear Strength Analysis of Dissimilar Materials Bolted JointSufyan Berinyuy WiysahnyuyNo ratings yet

- CH 01Document10 pagesCH 01Ahmed M TNo ratings yet

- Modelo Johnson CookDocument10 pagesModelo Johnson CookCarlão VianaNo ratings yet

- Note On Light Weight StructureDocument3 pagesNote On Light Weight StructureAbhishek KumarNo ratings yet

- Johnson Cook DeterminationDocument25 pagesJohnson Cook DeterminationHourglass1100% (1)

- EMG 1204 Lecture 8Document55 pagesEMG 1204 Lecture 8James musambakiNo ratings yet

- Al Ramahi2019Document16 pagesAl Ramahi2019abdullahNo ratings yet

- Tensile Test ReportDocument4 pagesTensile Test ReportLaura JaimeNo ratings yet

- Designing Metal Building Roof Purlins for System ReliabilityDocument23 pagesDesigning Metal Building Roof Purlins for System Reliabilityardit bedhiaNo ratings yet

- Practical Compactness and Bracing Provisions For The Design of Single Angle BeamsDocument7 pagesPractical Compactness and Bracing Provisions For The Design of Single Angle Beamsbruno_alqNo ratings yet

- Materials Selection in Design GuideDocument40 pagesMaterials Selection in Design GuideAndres CarmonaNo ratings yet

- W6 Design Optimization Case Study Car StructuresDocument10 pagesW6 Design Optimization Case Study Car StructuresMartin PedrozaNo ratings yet

- Numerical Investigation of The Plastic Behaviour of Short Welded Aluminium Double-T Beams PDFDocument10 pagesNumerical Investigation of The Plastic Behaviour of Short Welded Aluminium Double-T Beams PDFdjordjeueNo ratings yet

- Material Selection in Gear DesignDocument6 pagesMaterial Selection in Gear DesignAndre Branco Gil0% (1)

- (Ebook) D Roylance - MIT - Mechanics of MaterialsDocument357 pages(Ebook) D Roylance - MIT - Mechanics of MaterialsmomenziNo ratings yet

- Reliability of Steel Frame Systems With Semi-Rigid ConnectionsDocument15 pagesReliability of Steel Frame Systems With Semi-Rigid ConnectionsJemy J FrancisNo ratings yet

- FinalDocument20 pagesFinalRajesh GamblerNo ratings yet

- Chap5 PDFDocument29 pagesChap5 PDFKaushik SenguptaNo ratings yet

- Chap5 PDFDocument29 pagesChap5 PDFKaushik SenguptaNo ratings yet

- Standard Test Method For Shear Properties Composites MaterialDocument13 pagesStandard Test Method For Shear Properties Composites MaterialJoaquín Olivares JerezNo ratings yet

- 2020-05 Design of Metal Building Roof Purlins Including System Reliability EffectsDocument22 pages2020-05 Design of Metal Building Roof Purlins Including System Reliability EffectspankajNo ratings yet

- Report Creep (Mme480)Document11 pagesReport Creep (Mme480)Esra TrokNo ratings yet

- Allowable Stress Design & Limit State DesignDocument42 pagesAllowable Stress Design & Limit State DesignIsmailNo ratings yet

- Aiaa 1652 532Document13 pagesAiaa 1652 532Junghyun AhnNo ratings yet

- Materials Selection For Hot Stamped Automotive Body Parts: An Application of The Ashby Approach Based On The Strain Hardening Exponent and Stacking Fault Energy of MaterialsDocument10 pagesMaterials Selection For Hot Stamped Automotive Body Parts: An Application of The Ashby Approach Based On The Strain Hardening Exponent and Stacking Fault Energy of MaterialsJaka Haris MustafaNo ratings yet

- The Time and Temperature Dependence of Fracture Toughness For ThermoplasticsDocument14 pagesThe Time and Temperature Dependence of Fracture Toughness For ThermoplasticslizixicNo ratings yet

- Fracture Toughness Testing Factors for Thin Sheet MaterialsDocument15 pagesFracture Toughness Testing Factors for Thin Sheet MaterialskarrarNo ratings yet

- Modeling Charpy Impact Test of Maraging SteelDocument13 pagesModeling Charpy Impact Test of Maraging SteelAYUSH KUMARNo ratings yet

- Experimental Analysis On Friction Materials For Supplemental Damping DevicesDocument33 pagesExperimental Analysis On Friction Materials For Supplemental Damping DevicesVincenzo PilusoNo ratings yet

- Deformation Behaviour of Spot-Welded High Strength Steels For Automotive ApplicationsDocument10 pagesDeformation Behaviour of Spot-Welded High Strength Steels For Automotive ApplicationsJose JuanNo ratings yet

- Design for Enhanced Material Damping: Ch 21Document8 pagesDesign for Enhanced Material Damping: Ch 21Khurram KirmaniNo ratings yet

- Ref 8 The Prediction of The Mechanical Properties ForDocument18 pagesRef 8 The Prediction of The Mechanical Properties Formohammadreza hajialiNo ratings yet

- Aeletters 2022 7 3 1Document11 pagesAeletters 2022 7 3 1miskoscribd2No ratings yet

- Analysis and Optimization of A Composite Leaf Spring: Mahmood M. Shokrieh, Davood RezaeiDocument9 pagesAnalysis and Optimization of A Composite Leaf Spring: Mahmood M. Shokrieh, Davood RezaeiVipin ShuklaNo ratings yet

- Materials 12 01726Document20 pagesMaterials 12 01726Gabriel JiménezNo ratings yet

- 1 s2.0 S092150931200010X MainDocument7 pages1 s2.0 S092150931200010X MainEduardo Atem De CarvalhoNo ratings yet

- Fatigue Material SelectionDocument6 pagesFatigue Material SelectionsubhaNo ratings yet

- Core Shear Properties of Sandwich Constructions by Beam FlexureDocument8 pagesCore Shear Properties of Sandwich Constructions by Beam FlexureBarang TeknikNo ratings yet

- Metodo Astm d1822Document10 pagesMetodo Astm d1822Ing Ipn VbaNo ratings yet

- Selection of Material Shape and Manufacturing Process For A Connecting RodDocument12 pagesSelection of Material Shape and Manufacturing Process For A Connecting RodNasr Cheaib0% (2)

- Galling Resistance and Wear Mechanisms - Cold Work Tool Materials Sliding Against Carbon Steel SheetsDocument6 pagesGalling Resistance and Wear Mechanisms - Cold Work Tool Materials Sliding Against Carbon Steel SheetsBert MiltonssonNo ratings yet

- سرمد صلاح - مشروعDocument1 pageسرمد صلاح - مشروعAhmed KhalidNo ratings yet

- Strength of Materials ReportDocument14 pagesStrength of Materials ReportRahul JohnsonNo ratings yet

- Mom ReportDocument8 pagesMom Reportm.sheraz malikNo ratings yet

- Effects of Microstructure On The Strain Rate Sensitivity of Advanced SteelsDocument9 pagesEffects of Microstructure On The Strain Rate Sensitivity of Advanced SteelsBalakrishnan RagothamanNo ratings yet

- Properties of Construction Materials and Their Stress/strain BehaviourDocument15 pagesProperties of Construction Materials and Their Stress/strain BehaviourOmokhiboria JoshuaNo ratings yet

- Materials: Fatigue Prediction of Aluminum Alloys Considering Critical Plane Orientation Under Complex Stress StatesDocument21 pagesMaterials: Fatigue Prediction of Aluminum Alloys Considering Critical Plane Orientation Under Complex Stress Statesadarshravindran1991No ratings yet

- J Matpr 2020 09 215Document5 pagesJ Matpr 2020 09 215assiallawi997No ratings yet

- Axial, Shear and Moment Interaction of Single Plate "Shear Tab" ConnectionsDocument16 pagesAxial, Shear and Moment Interaction of Single Plate "Shear Tab" ConnectionsAyman SedkyNo ratings yet

- Lumamba Chiyabi EM310 Assignment 1Document11 pagesLumamba Chiyabi EM310 Assignment 1Lumamba ChiyabiNo ratings yet

- A Method For Determining The Behaviour Factor of Moment-Resisting Steel Frames With SR ConnectionsDocument18 pagesA Method For Determining The Behaviour Factor of Moment-Resisting Steel Frames With SR ConnectionsMustafa LimdiwalaNo ratings yet

- Materials: Experimental and Numerical Investigations of High-Speed Projectile Impacts On 7075-T651 Aluminum PlatesDocument15 pagesMaterials: Experimental and Numerical Investigations of High-Speed Projectile Impacts On 7075-T651 Aluminum PlatesYousaf SaidalaviNo ratings yet

- SIA 3 Mechanical PropertiesDocument22 pagesSIA 3 Mechanical PropertiesSrinivas RallabandiNo ratings yet

- AAU Strength of Materials Lecture Notes 09-05-21Document66 pagesAAU Strength of Materials Lecture Notes 09-05-21Tahir Aed100% (7)

- Reliability of Engineering MaterialsFrom EverandReliability of Engineering MaterialsAlrick L SmithNo ratings yet

- Natural Gas Kiln Ceramic in - 10 PDFDocument1 pageNatural Gas Kiln Ceramic in - 10 PDFNuzul FurqonyNo ratings yet

- PGE - Piping Layout Separator Station - 1Document1 pagePGE - Piping Layout Separator Station - 1Nuzul FurqonyNo ratings yet

- Natural Gas Kiln Ceramic in - 11 PDFDocument1 pageNatural Gas Kiln Ceramic in - 11 PDFNuzul FurqonyNo ratings yet

- Natural Gas Kiln Ceramic in - 6 PDFDocument1 pageNatural Gas Kiln Ceramic in - 6 PDFNuzul FurqonyNo ratings yet

- Natural Gas Kiln Ceramic in - 8 PDFDocument1 pageNatural Gas Kiln Ceramic in - 8 PDFNuzul FurqonyNo ratings yet

- Momentums 37Document1 pageMomentums 37Nuzul FurqonyNo ratings yet

- Natural Gas Kiln Ceramic in - 5 PDFDocument1 pageNatural Gas Kiln Ceramic in - 5 PDFNuzul FurqonyNo ratings yet

- Natural Gas Kiln Ceramic in - 9 PDFDocument1 pageNatural Gas Kiln Ceramic in - 9 PDFNuzul FurqonyNo ratings yet

- Momentums 36Document1 pageMomentums 36Nuzul FurqonyNo ratings yet

- Natural Gas Kiln Ceramic in - 7 PDFDocument1 pageNatural Gas Kiln Ceramic in - 7 PDFNuzul FurqonyNo ratings yet

- Momentums 35Document1 pageMomentums 35Nuzul FurqonyNo ratings yet

- Generator Item C-Inspections - 14Document1 pageGenerator Item C-Inspections - 14Nuzul FurqonyNo ratings yet

- Momentums 34Document1 pageMomentums 34Nuzul FurqonyNo ratings yet

- Natural Gas Kiln Ceramic in - 1Document1 pageNatural Gas Kiln Ceramic in - 1Nuzul FurqonyNo ratings yet

- Ds DZ G Ds DV V Ds DP: Bernoulli's EquationDocument1 pageDs DZ G Ds DV V Ds DP: Bernoulli's EquationNuzul FurqonyNo ratings yet

- Generator Item C-Inspections - 18Document1 pageGenerator Item C-Inspections - 18Nuzul FurqonyNo ratings yet

- Momentums 33Document1 pageMomentums 33Nuzul FurqonyNo ratings yet

- Generator Item C-Inspections - 14Document1 pageGenerator Item C-Inspections - 14Nuzul FurqonyNo ratings yet

- Generator Item C-Inspections - 16Document1 pageGenerator Item C-Inspections - 16Nuzul FurqonyNo ratings yet

- Generator Item C-Inspections - 17Document1 pageGenerator Item C-Inspections - 17Nuzul FurqonyNo ratings yet

- Generator Item C-Inspections - 10Document1 pageGenerator Item C-Inspections - 10Nuzul FurqonyNo ratings yet

- Generator Item C-Inspections - 12Document1 pageGenerator Item C-Inspections - 12Nuzul FurqonyNo ratings yet

- Generator Item C-Inspections - 15Document1 pageGenerator Item C-Inspections - 15Nuzul FurqonyNo ratings yet

- Generator Item C-Inspections - 19Document1 pageGenerator Item C-Inspections - 19Nuzul FurqonyNo ratings yet

- Generator Item C-Inspections - 13Document1 pageGenerator Item C-Inspections - 13Nuzul FurqonyNo ratings yet

- Generator Item C-Inspections - 9Document1 pageGenerator Item C-Inspections - 9Nuzul FurqonyNo ratings yet

- Generator Item C-Inspections - 8Document1 pageGenerator Item C-Inspections - 8Nuzul FurqonyNo ratings yet

- Generator Item C-Inspections - 5Document1 pageGenerator Item C-Inspections - 5Nuzul FurqonyNo ratings yet

- Generator Item C-Inspections - 11Document1 pageGenerator Item C-Inspections - 11Nuzul FurqonyNo ratings yet

- ASTM D 638 - 14 Standard Test Method For Tensile Properties of PlasticsDocument1 pageASTM D 638 - 14 Standard Test Method For Tensile Properties of PlasticsGustavoNo ratings yet

- Replacement of AggregatesDocument9 pagesReplacement of AggregatesAbdullah Al-MamunNo ratings yet

- Catalog BravaDocument6 pagesCatalog BravaPerformance Lubricants, C.A.No ratings yet

- Tire Creep ManagementDocument2 pagesTire Creep ManagementhaziqNo ratings yet

- Petrochemical and Refinery Piping General Weld Inspection ReDocument6 pagesPetrochemical and Refinery Piping General Weld Inspection RealiNo ratings yet

- WFS 1001 HDocument2 pagesWFS 1001 Hsaravanan100% (1)

- CMV Fracture Toughness ArticleDocument10 pagesCMV Fracture Toughness ArticleFlo RenceNo ratings yet

- Aci 124 - 1994Document16 pagesAci 124 - 1994Bhavanishankar ShettyNo ratings yet

- Department of Public Works and Highways: DPWH Standard Specification For Carbon Fiber, Item 416Document8 pagesDepartment of Public Works and Highways: DPWH Standard Specification For Carbon Fiber, Item 416jay_medrano_1No ratings yet

- Analysis of Flange Transverse Bending of Corrugated Web I-Girders Under In-Plane LoadsDocument9 pagesAnalysis of Flange Transverse Bending of Corrugated Web I-Girders Under In-Plane LoadsAsr FlowerNo ratings yet

- Bromley CarpentryDocument3 pagesBromley Carpentrybromley-carpentryNo ratings yet

- Cable Correction FactorsDocument4 pagesCable Correction FactorspraveenniteenNo ratings yet

- Astm A479Document8 pagesAstm A479Orlando Rojas100% (3)

- Line Sizing Criteria PDFDocument8 pagesLine Sizing Criteria PDFwaelNo ratings yet

- Lecture 1. Shaft DesignDocument18 pagesLecture 1. Shaft DesignhasanNo ratings yet

- 3RD Term S2 Technical DrawingDocument30 pages3RD Term S2 Technical DrawingDada RasheedNo ratings yet

- Fabrication of PlasticDocument1 pageFabrication of PlasticAllan SsemujjuNo ratings yet

- CDB 4313 Heat Integration - Basic Heat IntegrationDocument25 pagesCDB 4313 Heat Integration - Basic Heat Integrationharvin raoNo ratings yet

- Roads Elemental CostingDocument47 pagesRoads Elemental Costingsarathirv6100% (2)

- High Strength SteelDocument19 pagesHigh Strength SteelBHARANINo ratings yet

- LG Inverter SCAC CatalogDocument20 pagesLG Inverter SCAC Catalogsk luko100% (1)

- METAL PUTTY TECHNICAL DATA SHEETDocument2 pagesMETAL PUTTY TECHNICAL DATA SHEETabdullahNo ratings yet

- Practical No 16 Software For Estimate of Septic TankDocument11 pagesPractical No 16 Software For Estimate of Septic TankAyushNo ratings yet

- Thixotropic Cleaning AgentDocument2 pagesThixotropic Cleaning AgentAlejandro NoviaNo ratings yet

- Brazing Copper To SteelDocument3 pagesBrazing Copper To SteelathulpcucekNo ratings yet

- OBO CatalogDocument5 pagesOBO CatalogDani Good VibeNo ratings yet

- Elastocrete P8J Waterproofing Kit Technical Data SheetDocument3 pagesElastocrete P8J Waterproofing Kit Technical Data SheetZèlia FláviaNo ratings yet

- A Comparison Between The Old and New Indian Codes For Concrete Mix DesignDocument10 pagesA Comparison Between The Old and New Indian Codes For Concrete Mix DesigntheijesNo ratings yet

- Method Statement For Installation of Strip Seal/ Modular Strip Seal Expansion Joints InstallationDocument2 pagesMethod Statement For Installation of Strip Seal/ Modular Strip Seal Expansion Joints Installationajit karandikarNo ratings yet

- Felker Piping Products: Stainless Steel Pipe, Tube & FittingsDocument58 pagesFelker Piping Products: Stainless Steel Pipe, Tube & FittingsFelipe Cruvinel DamascenoNo ratings yet