Professional Documents

Culture Documents

Fabrication of Plastic

Uploaded by

Allan SsemujjuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabrication of Plastic

Uploaded by

Allan SsemujjuCopyright:

Available Formats

FABRICATION OF PLASTIC

Plastic fabrication is defined as any process which is used to design, manufacture, or assemble products

made from plastic or composites containing plastic. There are an extremely wide variety of plastic

fabrication methods available, each with their own unique advantages and disadvantages. Additionally,

certain methods are better suited for certain parts – fabricating small plastic kitchen containers will

likely not utilize the same method as fabricating large roofs or body panels for heavy trucks. Whatever

you wish to make from plastic, there is a fabrication method out there for you!

PLASTIC FABRICATION METHODS

Plastic fabrication methods can be widely divided into a number of categories depending on the

techniques used and the distinctive characteristics of the resulting products. Some of the most common

categories include:

Compounding, which is also referred to as blending, refers to any process in which two or more plastics

are combined into one

. Lamination is any method in which a plastic is used to form a barrier along the surface of another

material. It is frequently utilized to strengthen a product or increase its resistance to heat, electricity,

chemicals or other natural and artificial risks

. Plastic welding, similar to the more common metal welding, uses heat to melt pieces together. While

welding is still a process primarily associated with metal, it can be an effective process when working

with plastics that react poorly to other forms of adhesion.

Lastly, molding refers to any method which forms plastic into a shape by allowing it to harden within a

pre-formed mold. Molding is the most versatile of the plastic fabrication varieties, allowing for the

creation of everything from extremely large parts to extremely geometrically complex ones. Molding is

used to produce everything from household appliances to heavy machinery, toys to airplane parts. It has

become one of the most popular ways of fabricating plastic due to the time- and cost-efficiency of the

process and the strength, durability and stiffness of the completed parts.

There are a variety of sub-types of molding, which are traditionally separated according to:

Whether heat, pressure or a combination of both (such as an autoclave, a machine which applies both

heat and pressure simultaneously is used to cure the finished product

The method by which the plastic enters the mold

The presence or absence of reinforcing fibers such as glass, carbon or aramid (Kevlar)

You might also like

- What Is Plastic?: Manufacturing Processes For PlasticsDocument2 pagesWhat Is Plastic?: Manufacturing Processes For PlasticsJesse Jones SeraspeNo ratings yet

- Name Graham K Dengeza Reg Number R203579F Module Name Refractory Materials Assignment Number 1Document4 pagesName Graham K Dengeza Reg Number R203579F Module Name Refractory Materials Assignment Number 1GRAHAM KUNDAI DENGEZANo ratings yet

- PlasticsDocument7 pagesPlasticsAminaah AlhassanNo ratings yet

- MP-1 (10th Lecture) Polymers ManufacturingDocument19 pagesMP-1 (10th Lecture) Polymers Manufacturingmuhammad tariqNo ratings yet

- Specifically How To Win Customers and Impact Markets With Plastic ExtrusionoozoyDocument2 pagesSpecifically How To Win Customers and Impact Markets With Plastic Extrusionoozoyowlbadger5No ratings yet

- Adama University Faculty of Technology Construction Technology DepartmentDocument23 pagesAdama University Faculty of Technology Construction Technology Departmentsreedharreddy9710No ratings yet

- Joining Techniques For Thermoplastics MaterialsDocument4 pagesJoining Techniques For Thermoplastics MaterialskayodeNo ratings yet

- Every Little Thing You Need To Learn About Plastic ExtrusionqyeyzDocument2 pagesEvery Little Thing You Need To Learn About Plastic Extrusionqyeyzbankspot1No ratings yet

- 2017 57 YangDocument28 pages2017 57 YangErwin Jake CalivosoNo ratings yet

- Aircraft Materials, Construction and RepairDocument20 pagesAircraft Materials, Construction and RepairMark Jovince CardenasNo ratings yet

- Joining & Bonding of Composite Parts - The Structural Adhesive Advantage White PaperDocument13 pagesJoining & Bonding of Composite Parts - The Structural Adhesive Advantage White PaperSuresh DhanasekarNo ratings yet

- Group 4 LaboratoryDocument18 pagesGroup 4 LaboratoryJefrey M. ButilNo ratings yet

- Module 15 - UNIT III - PolymersDocument12 pagesModule 15 - UNIT III - PolymersJhess GaliciaNo ratings yet

- Laminates Versus Coextruded FilmsDocument12 pagesLaminates Versus Coextruded FilmsSagar BadnakheNo ratings yet

- Plastics: Mohammed Bilal 1 N S 1 9 AT 0 2 7 MMBC VDocument21 pagesPlastics: Mohammed Bilal 1 N S 1 9 AT 0 2 7 MMBC Vlalu mikeyNo ratings yet

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Molding: Molding or Moulding Is The Process ofDocument4 pagesMolding: Molding or Moulding Is The Process ofBilqis YusrinNo ratings yet

- The World of Plastics Engr. Lina D. Dela Cruz Chemical Engineering DepartmntDocument29 pagesThe World of Plastics Engr. Lina D. Dela Cruz Chemical Engineering DepartmntKristine Ann VillanuevaNo ratings yet

- Compression Molding AbstractDocument2 pagesCompression Molding AbstractFAIZ RASOOL100% (1)

- Investigatory Project ProposalDocument5 pagesInvestigatory Project ProposalJogie AradaNo ratings yet

- 5.2 Plastics: Called Thermo Sets: 5.2.1 Thermoplastics. Thermoplastics Become Soften When Heated and Hard When CooledDocument4 pages5.2 Plastics: Called Thermo Sets: 5.2.1 Thermoplastics. Thermoplastics Become Soften When Heated and Hard When CooledBereket BlessingNo ratings yet

- Manufacturing Processes AssignmentDocument23 pagesManufacturing Processes AssignmentAdarshAgrawalaNo ratings yet

- Plastic Application in BuildingDocument10 pagesPlastic Application in BuildingOlaniyan QozeemNo ratings yet

- The World of Plastics Engr. Lina D. Dela Cruz Chemical Engineering DepartmntDocument27 pagesThe World of Plastics Engr. Lina D. Dela Cruz Chemical Engineering DepartmntMarnel Roy MayorNo ratings yet

- MWP11A - Learning Unit 8 PlasticsDocument17 pagesMWP11A - Learning Unit 8 PlasticsThapelo MokoenaNo ratings yet

- Design For Plastics Unit 7Document10 pagesDesign For Plastics Unit 7Harinath GowdNo ratings yet

- Assign 2 Ishan SinglaDocument8 pagesAssign 2 Ishan SinglaishanNo ratings yet

- Advanced Building Material: Topic: PlasticDocument19 pagesAdvanced Building Material: Topic: PlasticSneha SahniNo ratings yet

- HCLDocument4 pagesHCLVinoth Vin GNo ratings yet

- Hold Molds Work in Extrusion Blow Molding TechnologyDocument7 pagesHold Molds Work in Extrusion Blow Molding TechnologyNormanBatesNo ratings yet

- Composites World Thermoformable Composite PanelsDocument26 pagesComposites World Thermoformable Composite PanelsSunilBhandariNo ratings yet

- Different Types of Moulding of ThermoplasticsDocument1 pageDifferent Types of Moulding of ThermoplasticsvijayakumarNo ratings yet

- Composition and Types of PlasticDocument1 pageComposition and Types of PlasticPamZie JOi UbaldoNo ratings yet

- Thermoforming of Single and Multilayer Laminates: Plastic Films Technologies, Testing, and ApplicationsFrom EverandThermoforming of Single and Multilayer Laminates: Plastic Films Technologies, Testing, and ApplicationsNo ratings yet

- Design & Development of Vaccum Forming Machine & DIE'Document5 pagesDesign & Development of Vaccum Forming Machine & DIE'ALAZAR MICHAELNo ratings yet

- Manufacturing Process - Module6.0Document13 pagesManufacturing Process - Module6.0Fiza KamaNo ratings yet

- Portfolio PlasticDocument5 pagesPortfolio PlasticGabrielaNo ratings yet

- PolymersDocument28 pagesPolymersarattayiljitheshNo ratings yet

- Plastics: ClassificationDocument6 pagesPlastics: ClassificationFortiter FysproNo ratings yet

- Study PlasticDocument15 pagesStudy PlasticfayaNo ratings yet

- Production of Plastic MaterialsDocument24 pagesProduction of Plastic Materialsfadhillah ivanNo ratings yet

- Injuction Moulding For Air Tigth CupDocument58 pagesInjuction Moulding For Air Tigth Cupajaysurya9245No ratings yet

- PlasticDocument2 pagesPlasticgenielizabeth0595No ratings yet

- Sintex Part 2Document29 pagesSintex Part 2payalmalayNo ratings yet

- Plastics Technology PracticeDocument35 pagesPlastics Technology Practicerizaazari4530100% (2)

- An Introduction To Single Screw Extrusion: Table of ContentsDocument6 pagesAn Introduction To Single Screw Extrusion: Table of ContentsKuzhaliNo ratings yet

- Classification On The Future Developments in Composite MaterialsDocument5 pagesClassification On The Future Developments in Composite MaterialsberhaneNo ratings yet

- Injection MoldingDocument33 pagesInjection MoldingDineshkumar RathinavelNo ratings yet

- Prepared By-Chaudhari M.M SVCP (Sinhgad), PUNE (INDIA) Dept. of Mech. EnggDocument39 pagesPrepared By-Chaudhari M.M SVCP (Sinhgad), PUNE (INDIA) Dept. of Mech. EnggMitul patelNo ratings yet

- Wear and Friction MaterialDocument24 pagesWear and Friction MaterialPrem Sankar100% (2)

- PolymersDocument14 pagesPolymersvanshpkotharistudyNo ratings yet

- What Is Injection Molding?: Thermosetting and ThermoplasticDocument3 pagesWhat Is Injection Molding?: Thermosetting and Thermoplasticretnadiah354No ratings yet

- Intro To Plastic Injection Molding EbookDocument43 pagesIntro To Plastic Injection Molding EbookJames Farrugia78% (9)

- Adhesive BondingDocument45 pagesAdhesive Bondingizantux100% (3)

- Plastic Injection Moulding: Guide Name: DR - PRASAD KDocument19 pagesPlastic Injection Moulding: Guide Name: DR - PRASAD Ktejas p nNo ratings yet

- BMC 4 Plastics-1Document18 pagesBMC 4 Plastics-1AzraNo ratings yet

- Presentation1 6.10.15Document31 pagesPresentation1 6.10.15Paramasivam VeerappanNo ratings yet

- AppliedDocument3 pagesAppliedYopiWindaSariNo ratings yet

- Advanced Processing and Manufacturing Technologies for Structural and Multifunctional Materials VIIFrom EverandAdvanced Processing and Manufacturing Technologies for Structural and Multifunctional Materials VIITatsuki OhjiNo ratings yet

- 8M Construction Digest February March 2023 Light VersionDocument48 pages8M Construction Digest February March 2023 Light VersionAllan SsemujjuNo ratings yet

- Legislation in Tilenga Oil ProjectDocument96 pagesLegislation in Tilenga Oil ProjectAllan SsemujjuNo ratings yet

- Tests On Aggregates MirriamDocument10 pagesTests On Aggregates MirriamAllan SsemujjuNo ratings yet

- Duties of DirectorsDocument3 pagesDuties of DirectorsAllan SsemujjuNo ratings yet

- Capital Expenditure AnalysisDocument5 pagesCapital Expenditure AnalysisAllan SsemujjuNo ratings yet

- Bible StudyDocument3 pagesBible StudyAllan SsemujjuNo ratings yet

- ApplicationDocument36 pagesApplicationAllan SsemujjuNo ratings yet

- Carpet Suppliers in UgandaDocument5 pagesCarpet Suppliers in UgandaAllan SsemujjuNo ratings yet

- Test On Durability of StoneDocument3 pagesTest On Durability of StoneAllan SsemujjuNo ratings yet

- TimberDocument3 pagesTimberAllan SsemujjuNo ratings yet

- Walling MaterialsDocument58 pagesWalling MaterialsAllan SsemujjuNo ratings yet

- WallsDocument8 pagesWallsAllan SsemujjuNo ratings yet

- Uses of Plastics in Building ConstructionDocument4 pagesUses of Plastics in Building ConstructionAllan SsemujjuNo ratings yet

- TimberDocument3 pagesTimberAllan SsemujjuNo ratings yet

- BondingDocument6 pagesBondingAllan SsemujjuNo ratings yet

- Cement and A Some ConcreteDocument7 pagesCement and A Some ConcreteAllan SsemujjuNo ratings yet

- Floor FinishesDocument35 pagesFloor FinishesAllan SsemujjuNo ratings yet

- C.wight MillsDocument8 pagesC.wight MillsAllan SsemujjuNo ratings yet

- Oyeet Eridadi 20/U/0578 (Quantity Surveying) Dressing of StonesDocument2 pagesOyeet Eridadi 20/U/0578 (Quantity Surveying) Dressing of StonesAllan SsemujjuNo ratings yet

- ConcreteDocument8 pagesConcreteAllan SsemujjuNo ratings yet

- Commerical Law CM QSDocument25 pagesCommerical Law CM QSAllan SsemujjuNo ratings yet

- Construction Materials GroupsDocument4 pagesConstruction Materials GroupsAllan SsemujjuNo ratings yet

- Advantage of Granite FlooringDocument1 pageAdvantage of Granite FlooringAllan SsemujjuNo ratings yet

- Makerere University: S/N Student Number Name Registration NumberDocument43 pagesMakerere University: S/N Student Number Name Registration NumberAllan SsemujjuNo ratings yet

- 2 Tort Negeligence-1Document26 pages2 Tort Negeligence-1Allan SsemujjuNo ratings yet

- Failure Modes of Retaining WallsDocument18 pagesFailure Modes of Retaining WallsAllan SsemujjuNo ratings yet

- R20 Advance Materials NotesDocument116 pagesR20 Advance Materials NotesPraveen 007No ratings yet

- Akshar Group Product List (Document2 pagesAkshar Group Product List (Gyanendra TripathiNo ratings yet

- Biochar Review Panahi2020Document29 pagesBiochar Review Panahi2020Khaled Abou AlfaNo ratings yet

- Eltra Cs 530Document122 pagesEltra Cs 530ahalonsoNo ratings yet

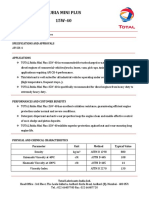

- Rubia Mini Plus 15w-40 Pds PDFDocument2 pagesRubia Mini Plus 15w-40 Pds PDFAmal AleyasNo ratings yet

- Self Assembled Nanoreactors PDFDocument46 pagesSelf Assembled Nanoreactors PDFandra mNo ratings yet

- Material P NumberDocument1 pageMaterial P Numberrameez khanNo ratings yet

- Acetic Acid CFQ 8Document6 pagesAcetic Acid CFQ 8Olivia Rae IrvingNo ratings yet

- Company Origin Products: X MET 8000 SeriesDocument4 pagesCompany Origin Products: X MET 8000 SeriesAhmed El MorsyNo ratings yet

- UTP A 6222 MoDocument1 pageUTP A 6222 MoKara WhiteNo ratings yet

- Lab 2. Lowry MethodDocument3 pagesLab 2. Lowry MethodDũng Nguyễn ViệtNo ratings yet

- Characterization of Domestic Wastewater at Bhubaneswar, Odisha, IndiaDocument11 pagesCharacterization of Domestic Wastewater at Bhubaneswar, Odisha, IndiaHamzaoui abd essalemNo ratings yet

- Tutorial Questions For CHME2201Document4 pagesTutorial Questions For CHME2201Peguy FotsoNo ratings yet

- Properties and Transformation of MatterDocument2 pagesProperties and Transformation of MatterRoseCamilleGuzmanNo ratings yet

- PP H040 GP/3: Product DescriptionDocument2 pagesPP H040 GP/3: Product DescriptionLukasz ZdunekNo ratings yet

- AQA A Level Chemistry Textbook AnswersDocument158 pagesAQA A Level Chemistry Textbook AnswersShilat BentataNo ratings yet

- Daftar Harga Merck 2016 - 1pr1Document250 pagesDaftar Harga Merck 2016 - 1pr1Haniif Prasetiawan67% (3)

- 02 - Chapter 1 With ReferencesDocument17 pages02 - Chapter 1 With ReferencesAKHTAR RAJANo ratings yet

- Low Density Polyethylene LD7000A: DescriptionDocument1 pageLow Density Polyethylene LD7000A: DescriptionJaime222No ratings yet

- AntacidsDocument16 pagesAntacidsPedroCordovageNo ratings yet

- First Summative Test in Science 7Document5 pagesFirst Summative Test in Science 7Monica P. RamosNo ratings yet

- Syrup & Elixir: Pharmaceutics Department Pharmacy Study Program Faculty of Medicine Brawijaya UniversityDocument33 pagesSyrup & Elixir: Pharmaceutics Department Pharmacy Study Program Faculty of Medicine Brawijaya UniversityHsn Tuyết HàNo ratings yet

- Assay of Magnesium HydroxideDocument8 pagesAssay of Magnesium HydroxiderahulNo ratings yet

- CHM 211Document19 pagesCHM 211Necherem MissionNo ratings yet

- Soap and Detergent ExperimentDocument12 pagesSoap and Detergent ExperimentAkmalhakim ZakariaNo ratings yet

- Lipids Function and StructureDocument58 pagesLipids Function and StructureTeddy K KunongNo ratings yet

- A 447Document4 pagesA 447william_m08No ratings yet

- Printing InkDocument23 pagesPrinting InkGema SukmaNo ratings yet

- Microstructure Study of Ferrous and Non Ferrous Alloys Under Various Compositions and Heat Treatment Conditions Lab ReportDocument7 pagesMicrostructure Study of Ferrous and Non Ferrous Alloys Under Various Compositions and Heat Treatment Conditions Lab Reportzrro50% (4)

- Low Cost Treatment To Automobile Waste Water Service CenterDocument3 pagesLow Cost Treatment To Automobile Waste Water Service CenterGRD JournalsNo ratings yet