Professional Documents

Culture Documents

Training Calander IRWRI 2019-20 (Rev.)

Uploaded by

Akash kumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Training Calander IRWRI 2019-20 (Rev.)

Uploaded by

Akash kumarCopyright:

Available Formats

CONTACTS GLIMPSES OF IRWRI

Rly.

Name (S/Sri) Designation Mobile No.

Phone

Ramjanm Chaubey Principal 9794861403 42606

Dr. B.K.Srivastava AME/Trg. 9794861416 42690

Pawan Srivastava CWI/Weld 9794862439 44398

R.R.Mishra CWI/Weld 9794862525 42642 भारतीय रे ल

Ashok Kumar CWI/Weld 9794862513 42642 वे ं ग अनु संधान सं थान

e-mail : cwi.irwri@gmail.com

Indian Railways

Welding Research Institute

ADDRESS

Principal

Indian Railways Welding Research Institute

Diesel Locomotive Works

Varanasi – 221004 (UP), INDIA

Fax No.: 0542-2270184

Training Calendar 2019-20

िश ण िद िशका 2019-20

डीजल रे ल इं जन कारखाना

वाराणसी – 221004

LOCATION

Diesel Locomotive Works

IRWRI is located approx. 7 kms from Varanasi

Welding Training Varanasi – 221004

Junction. IRWRI is well connected with Rail and

road across India. Nearest railway station to Continuous improvement in quality (AN ISO 9001, 14001, 50001, OHSAS 18001 &

IRWRI is Manduadih (MUV). of our products and services ISO: 3834-2:2005 CERTIFIED ORGANISATION)

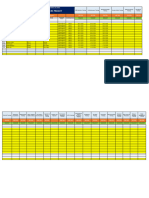

ABOUT IRWRI Training Calendar 2019-20

Training of DLW, NER, ECR, ER, CR &

NFR welding professionals & coordinate

Month /

between regional welding institutes and Module-I Module-II$ Module-III Module-IV$ Module-V Module-VI Module-VII

Module

function as Apex Body of Indian Railways Apr-19 08 – 27 22 – 27

for Welding training

May-19 06 – 25 13 - 25

Conducts Different modules of Welding

Courses Jun-19 03 – 29 17 – 29

Conducts Welder Qualification Test as Jul-19 08 – 27 22 – 27

per ISO:9606-1 for DLW Welders

Aug-19 26 – 31 19 - 31

Research & Quality Improvement

Sep-19 02 – 28 16 - 28

Activities

Welding related problems of DLW Oct-19 21 – 26* 14 – 26

Preparation of specification for latest Nov-19 04 – 30 18 – 23

welding equipments

Dec-19 02 – 21 09 – 21

FACILITIES AT IRWRI Jan-20 06 – 25 13 - 25

IN WELDING WORKSHOP: Feb-20 03 – 22 17 – 22

Shielded Metal Arc Welding

Mar-20 02 – 21 16 - 21

Gas Metal Arc Welding

Submerged Arc Welding Module Eligibility

Tungsten Inert Gas Welding I Newly Recruited/Promoted staff in welding trade.

Oxy-Acetylene Flame Cutting

II Regular Welder with minimum one year experience

Plasma Cutting

III Need based training for all mechanical staff. / * Maintenance of Welding Equipments

IN WELD TEST LAB:

Universal Tensile Tester IV Regular JE & SSE in Welding related area including CMT, inspection staff.

Micro Hardness Tester V Newly Recruited/Promoted JE & SSE in Welding related area.

Notch Abrasive Cutting Machine VI Training of Welding Instructor and Welding Supervisor from Welding Institute.

Micro Polisher / Grinding Machine Training of Jr. Scale & Sr. Scale officer of Mechanical Department including ACMT/CMT

VII

Optical Microscope from IR.

Bend & Fracture Test Machine Welder Qualification Test (as per ISO: 9606-1) is also being conducted by

Ultrasonic Flaw Detector Machine Indian Railways Welding Research Institute, DLW

Magnetic Particle Test Machine $ These courses covered under “PROJECT SAKSHAM” vide CRB’s letter no. E(MPP)/2017/3/25 dt.30.10.2017

You might also like

- WRI Course Brochure 2022 - 2023Document24 pagesWRI Course Brochure 2022 - 2023Srinivasan VairamanickamNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Railway Coach Factory, BhopalDocument22 pagesRailway Coach Factory, BhopalKanishkNo ratings yet

- CHAPTER 1 - MergedDocument25 pagesCHAPTER 1 - MergedHarshith Mn AcchuNo ratings yet

- Basic Welding CSCDocument1 pageBasic Welding CSCBobbyNo ratings yet

- Two Days Workshop On WPS/PQR/WPQDocument4 pagesTwo Days Workshop On WPS/PQR/WPQaadmaadmNo ratings yet

- Approved Suppliers List: SCM DepartmentDocument2 pagesApproved Suppliers List: SCM DepartmentAbdul MueedNo ratings yet

- Imran Final MprintDocument23 pagesImran Final Mprintvishal vallapureNo ratings yet

- FSW CDocument10 pagesFSW CCM Maheshwar ReddyNo ratings yet

- Regd No. Title CompanyDocument9 pagesRegd No. Title CompanykagnejukkeNo ratings yet

- CCRRDocument10 pagesCCRRSufiyan KhanNo ratings yet

- Iv File - FinalDocument6 pagesIv File - FinalKNCET EEENo ratings yet

- 2024 Zesa NTC Approved Training CalendersDocument8 pages2024 Zesa NTC Approved Training CalendershumphreyneketeNo ratings yet

- Training Calender 23-24 With Covering1Document2 pagesTraining Calender 23-24 With Covering1SureshNo ratings yet

- Internship2023Document13 pagesInternship2023thedevill421No ratings yet

- Course Calendar 2019-2020Document1 pageCourse Calendar 2019-2020venragNo ratings yet

- NilmaniDocument4 pagesNilmaniAbhishek PandeyNo ratings yet

- cv9497762 FileDocument2 pagescv9497762 Filehamid colonyNo ratings yet

- Naukri NavanathKashid (6y 6m)Document4 pagesNaukri NavanathKashid (6y 6m)3asNo ratings yet

- VEW ATE RMA RK: Prabhu SDocument4 pagesVEW ATE RMA RK: Prabhu SprabhutmuNo ratings yet

- Kadhirvel PQS CVDocument6 pagesKadhirvel PQS CVBaraneedharanNo ratings yet

- Niraj Updated CVDocument27 pagesNiraj Updated CVniraj kumarNo ratings yet

- Adobe Scan 05-Mar-2024Document3 pagesAdobe Scan 05-Mar-2024karthikkumarenNo ratings yet

- Me Cad 1 Lab Schedule 2023Document1 pageMe Cad 1 Lab Schedule 2023G.R.AzhaguvelSaranya Professor MechanicalNo ratings yet

- List of Rcy Registered Third Party Consultants For Water Quality Service - 02 January 2024Document3 pagesList of Rcy Registered Third Party Consultants For Water Quality Service - 02 January 2024Ashraf AliNo ratings yet

- Wtia Training Program 2014Document6 pagesWtia Training Program 2014Syed Mahmud Habibur RahmanNo ratings yet

- Hasimkhna Entrprses PDFDocument11 pagesHasimkhna Entrprses PDFRaj AryanNo ratings yet

- Welding Inspector May 2021Document8 pagesWelding Inspector May 2021SUNIL BABURAO GAVADENo ratings yet

- A Project Report On Cost Reduction in Melting - A SQC and Six Sigma ApproachDocument107 pagesA Project Report On Cost Reduction in Melting - A SQC and Six Sigma ApproachArun Prince100% (1)

- Miniproject 2022Document52 pagesMiniproject 2022Rahul N1MV19EE073No ratings yet

- L&T Construction Water & Effluent Treatment Ic Masterlist of Test Eqipments For CalibrationDocument3 pagesL&T Construction Water & Effluent Treatment Ic Masterlist of Test Eqipments For CalibrationFrancis DhanarajNo ratings yet

- CV - Service Engineer - RamkumarDocument4 pagesCV - Service Engineer - RamkumarRafeek AliNo ratings yet

- AWS Schedule 2022 - 0Document11 pagesAWS Schedule 2022 - 0Up WeldNo ratings yet

- Kirloskar Front Page1 HARSHITDocument2 pagesKirloskar Front Page1 HARSHITHarshith Mn AcchuNo ratings yet

- 016 Twi Me Montly Calendar Dec 2023Document1 page016 Twi Me Montly Calendar Dec 2023Manoj KumarNo ratings yet

- Project Approval 2Document6 pagesProject Approval 2mohamed abdulrahmanNo ratings yet

- RmcoDocument3 pagesRmcoQADEER SHANNo ratings yet

- 2023 - 01 - 19 10 - 35 Am Office LensDocument1 page2023 - 01 - 19 10 - 35 Am Office LensKARTHINo ratings yet

- Approved CV FormatDocument7 pagesApproved CV FormatEdison WalitNo ratings yet

- Put Schedule (I, Iii and Iv Yr)Document4 pagesPut Schedule (I, Iii and Iv Yr)DeePanshu GuPtaNo ratings yet

- Opening of Online Application Date and Time of Closing of Online ApplicationDocument27 pagesOpening of Online Application Date and Time of Closing of Online ApplicationSwapnil NachareNo ratings yet

- 01 Jan-2022 To 31 Dec-2022Document4 pages01 Jan-2022 To 31 Dec-2022tariqatsgNo ratings yet

- Corodur 4351 N OaDocument1 pageCorodur 4351 N OaMAHESH BELENo ratings yet

- Training & Industrial Safety Division, Ses & Pakistan Welding Institute (Pwi)Document3 pagesTraining & Industrial Safety Division, Ses & Pakistan Welding Institute (Pwi)ASAD RAHMANNo ratings yet

- Put Schedule (I, Iii and Iv Yr)Document4 pagesPut Schedule (I, Iii and Iv Yr)Nitin SinghNo ratings yet

- Submitted by Esampalli Ravi Kumar - 10521A0314 Musunuri Madhu Babu - 10521A0333 Gulipalli Ravi Teja - 10521A0317 Paruvu Venkata Rajendra - 10521A0339Document64 pagesSubmitted by Esampalli Ravi Kumar - 10521A0314 Musunuri Madhu Babu - 10521A0333 Gulipalli Ravi Teja - 10521A0317 Paruvu Venkata Rajendra - 10521A0339Manikanta Naidu100% (1)

- 344 PC 07 Arabtec SX MT 00061 - 03 Paint For Steel StructureDocument327 pages344 PC 07 Arabtec SX MT 00061 - 03 Paint For Steel Structurej f100% (1)

- M JNDocument254 pagesM JNShivangi MishraNo ratings yet

- Handbook On Welding TechniquesDocument89 pagesHandbook On Welding TechniquesPatrick J. Simunic100% (2)

- 2014 Welding School ScheduleDocument2 pages2014 Welding School SchedulehreerNo ratings yet

- CV Liu LeiDocument40 pagesCV Liu LeiMuthu SaravananNo ratings yet

- Academic Calendar For B.tech I Year2022 23Document1 pageAcademic Calendar For B.tech I Year2022 23KesavaNo ratings yet

- Apcs Data SheetDocument2 pagesApcs Data SheetRaja MuraliNo ratings yet

- 08-10-23 We MDPL GVNDRM 2nd Ra BillDocument220 pages08-10-23 We MDPL GVNDRM 2nd Ra BillLavanya vollalaNo ratings yet

- Railway NotificationDocument27 pagesRailway Notificationishare digital100% (2)

- Railway Recruitment 2022Document27 pagesRailway Recruitment 2022bna24 newsNo ratings yet

- Razali MohammedDocument4 pagesRazali Mohammedanon-853178No ratings yet

- Welder Qualification Follow ASME IX - Part 2 - Essential Variable For Welder Qualification! - AMARINEDocument14 pagesWelder Qualification Follow ASME IX - Part 2 - Essential Variable For Welder Qualification! - AMARINEtamizazaganNo ratings yet

- E3375 AP Lifting Ops Flyer (20th Run)Document6 pagesE3375 AP Lifting Ops Flyer (20th Run)alhad maNo ratings yet

- Fare Details: PNR No.: 2856757048 Transaction ID: 100002331947019Document4 pagesFare Details: PNR No.: 2856757048 Transaction ID: 100002331947019Akash kumarNo ratings yet

- Know Your PaymentDocument1 pageKnow Your PaymentAkash kumarNo ratings yet

- Optical Sources Part 2Document7 pagesOptical Sources Part 2Akash kumarNo ratings yet

- New Doc 2020-04-30 22.24.37 PDFDocument11 pagesNew Doc 2020-04-30 22.24.37 PDFAkash kumarNo ratings yet

- Solution Manual Digital Control and State Variable MethodsDocument128 pagesSolution Manual Digital Control and State Variable MethodsAkshat Gupta75% (16)

- Know Your PaymentDocument1 pageKnow Your PaymentAkash kumarNo ratings yet

- Delta Modulation: EE 442 - Spring SemesterDocument12 pagesDelta Modulation: EE 442 - Spring SemesterAkash kumarNo ratings yet

- Introduction To Power ScrewsDocument14 pagesIntroduction To Power Screwsاوبنتو العراقيNo ratings yet

- Topic-1 Thermodynamic WorkDocument5 pagesTopic-1 Thermodynamic WorkAlbert WangNo ratings yet

- Moments and Turning EffectsDocument3 pagesMoments and Turning EffectsMr.gamer play itNo ratings yet

- Solutions To Jaan Kalda's Problems in Thermodynamics: With Detailed Diagrams and Walkthroughs Edition 1.2.1Document76 pagesSolutions To Jaan Kalda's Problems in Thermodynamics: With Detailed Diagrams and Walkthroughs Edition 1.2.1Rahul GayenNo ratings yet

- Lab Services Materials CharacterizationDocument8 pagesLab Services Materials CharacterizationOwais MalikNo ratings yet

- Bearing Failure Analysis by Using 8 D ReportDocument7 pagesBearing Failure Analysis by Using 8 D Reportyash prajapatiNo ratings yet

- Model Complexity Reduction Using Laguerre FiltersDocument7 pagesModel Complexity Reduction Using Laguerre FiltersKais BouzraraNo ratings yet

- Linear and Quadratic Equations and Their Graphs (H) MSDocument2 pagesLinear and Quadratic Equations and Their Graphs (H) MSVindra Stacyann DhanrajNo ratings yet

- 2 Out 2 PDFDocument426 pages2 Out 2 PDFSwapnil MaladkarNo ratings yet

- Practice Paper For XII BDocument6 pagesPractice Paper For XII BvartikaagrawalaNo ratings yet

- Apa Sociology Research Paper ExampleDocument4 pagesApa Sociology Research Paper Exampleozbvtcvkg100% (1)

- Hob SelectionDocument4 pagesHob SelectionVikas ChauhanNo ratings yet

- Sample Paper 14: Class - X Exam 2021-22 (TERM - II) Mathematics StandardDocument3 pagesSample Paper 14: Class - X Exam 2021-22 (TERM - II) Mathematics StandardyeskolaNo ratings yet

- Problem SetDocument14 pagesProblem SetJr OlivarezNo ratings yet

- Aerodynamic AnalysisDocument8 pagesAerodynamic AnalysisezedinNo ratings yet

- 3-Laws of Chemical Thermodynamics-08!03!2022Document78 pages3-Laws of Chemical Thermodynamics-08!03!2022krishna sanapala2003100% (1)

- PASCO Chemistry Brochure INTDocument16 pagesPASCO Chemistry Brochure INTOleg GorincioiNo ratings yet

- Faculty of Economics and Business Universiti Malaysia Sarawak Business Mathematics EBQ1043 Tutorial 4Document2 pagesFaculty of Economics and Business Universiti Malaysia Sarawak Business Mathematics EBQ1043 Tutorial 4Li YuNo ratings yet

- Description of System: The Use of Hybrid Cars Is Becoming Increasingly Popular. A HybridDocument10 pagesDescription of System: The Use of Hybrid Cars Is Becoming Increasingly Popular. A HybridlauraximenauvaNo ratings yet

- Economy of Pakistan EssayDocument6 pagesEconomy of Pakistan Essayafhbgaohb100% (2)

- Dynamics Q1Document4 pagesDynamics Q1heheheNo ratings yet

- S&T Group 1 Mains AP & TSDocument30 pagesS&T Group 1 Mains AP & TSreddybhargav reddyNo ratings yet

- RBC Roller CamfollowersDocument56 pagesRBC Roller CamfollowersЮра ПименовNo ratings yet

- Math 9-Tos Diagnostic TestDocument5 pagesMath 9-Tos Diagnostic TestMyrna H. ConolNo ratings yet

- Highway Lab ReportDocument9 pagesHighway Lab Reportcarlton0878% (9)

- Lesson 5 Algebraic ExpressionsDocument9 pagesLesson 5 Algebraic ExpressionsLadina CristinaNo ratings yet

- Instrumentation Cable BSDocument42 pagesInstrumentation Cable BSShivaniNo ratings yet

- Four-Point Bending Test of Determining Stress-StrainDocument4 pagesFour-Point Bending Test of Determining Stress-StrainyasminaNo ratings yet

- Energy Skate StudentDocument3 pagesEnergy Skate StudentRosita Putri Rahmi HaeraniNo ratings yet

- Sustainable Issues in Infrastructure Engineering: Hany Shehata Sherif El-Badawy EditorsDocument231 pagesSustainable Issues in Infrastructure Engineering: Hany Shehata Sherif El-Badawy Editorsjhoward2012npNo ratings yet