Professional Documents

Culture Documents

Mechanical Section Comments: Subject

Uploaded by

Ummair ChOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Section Comments: Subject

Uploaded by

Ummair ChCopyright:

Available Formats

Mechanical Section Comments

Subject: CCC "CONSTRUCTION COMPLETION CERTIFICATE" DOCUMENTATION –

OUTSTANDING ISSUE ITEM NO 25 -

DISCREPANCIES IN CCC DOCUMENTATION- MECHANICAL SECTION

Reference: Contractor’s email dated October 19, 2018

Review of scanned CCC (Construction Completion Certificate) documentation regarding

Mechanical Works provided by HEI-HRL JV up-till 19.10.2018, has revealed discrepancies

which are required to be addressed expeditiously as noted below:-

1- Firefighting System (CCC#1,CCC#2)

(1) RFI for painting on joints of steel structure columns and beams is required to be

provided.(RFI has not been raised by HEI)

(2) All Installation RFI,sand test reports of firefighting system i.e welding reports, hydro-

test reports of Admin Building, Hostels and Cafeteria are missing.(Uncommissioned

system)

(3) Installation RFI for one overhead refilling point of fire trucks is missing.(Need to

check with rehan)

(4) Installation RFI for placing of portable fire extinguishers at all plant site is missing.

(One RFI is already attached TEPC-HY-056 and O&M team also receive the fire

hydrant in presence of client ----Moreover, according to letter#1132 the comment#05

is in Progress-)

2- HVAC System (CCC#3):-

(1) RFIs for insulation and welding of chilled water supply and return piping need to

be provided.(RFIs are already been attached i.e. TU-370, TU-373)

(2) Installation RFI of VRF system in Admin Building, Hostels and Cafeteria is

missing. (Uncommissioned System)

(3) Approved MAS of HVAC Air Devices need to be provided.(Approved company is

YORK)

(4) Approved MAS of VRF System regarding Copper pipe and Insulation need to be

provided. (MAS is already provided to Nespak not returned to HEI)

(5) Installation RFI for Aluminum Louvers in Air compressor Building need to be

provided.

(6) RFIs for GI duct installation and GI duct alignment in Mechanical service building,

Chemical lab, CCB, Switchyard control building, Administration Building, Steam

Turbine, Gas turbine and Hostels available with HRL/HEI need to be

provided.(available and will be attached later)

(7) RFI for GI duct Light Test in Mechanical service building, Chemical lab, CCB,

Switchyard control building, Administration Building, Steam Turbine, Gas turbine

and Hostels available with HRL/HEI need to be provided. (available and will be

attached later)

(8) RFI for all air devices installed at GI ducts need to be provided. (available and

will be attached later)

(9) RFIs for installation of HVAC Equipments, all AHUs installed in plant and Chillers

need to be provided. (The point is similar to the point#02)

Mechanical Section Comments

3- Circulating water System (CCC1,CCC2,CCC#3):-

(1) RFI for painting on joints of steel structure columns and beams is required to be

provided. (RFI is attached with the reference of comment No.)

4- Closed Cooling Water System (CCC1,CCC2,CCC#3):

(1) RFI for painting on joints of steel structure columns and beams is required to be

provided. (RFI is attached with the reference of comment No.)

(2) HEI is required to submit rectified RFI for rejected Weld joint numbers 262,

264,269, 275, 23, 284, 312, 259, 09, 20 of CCCW system. TEPC Document: TEPC-

WE-111.

(3) HEI is required to submit rectified RFI for rejected Weld Joint Numbers 267, 313,

272 of CCCW system. TEPC Document: TEPC-WE-112.

5- Chlorination Plant (CCC#3):

(1) RFI for painting on joints of steel structure columns and beams is required to be

provided. (RFI is attached with the reference of comment No.)

(2) RFI for Piping Installation need to be provided.

6- Pipe Rack(CCC#1):-

(1) RFI for painting on joints of steel structure columns and beams is required to be

provided. (RFI is attached with the reference of comment No.)

7- Cranes (CCC#1,CCC#2,CCC#3):

(1) RFIs for installation of all cranes are not attached. (RFI is attached with the reference

of comment No.)

8- Oily Waste water Treatment System (CCC#1):

(1) RFI for Installation of Equipment is required to be provided. (RFI is attached with the

reference of comment No.)

(2) RFI for painting on joints of steel structure columns and beams is required to be

provided.

9- Fuel Gas system (CCC#1):

(1) In the provided folder of fuel system, Test reports and RFIs related to other systems i-

e EDG, HRSG, Nitrogen generation system, Compressed air system etc are

Attached. HEI is required to separate these reports and attach in the relevant file.

(RFI is attached with the reference of comment No.)

(2) RFI for Installation of Steel Structure in fuel gas station need to be provided.

(3) Welding Report for fuel gas piping system need to be submitted. (RFI is attached with

the reference of comment No.)

(4) Approved MS and ITP for the said system need to be provided. (RFI is attached with

the reference of comment No.)

Mechanical Section Comments

10-Nitrogen generation system (CCC#1)

(1) RFI for painting on joints of steel structure columns and beams is required to be

provided. (RFI is attached with the reference of comment No.)

(2) Welding joints inspection reports of nitrogen piping to be submitted.

(3) Air blowing inspection reports of nitrogen piping.

(4) Provide the hydro test inspection details and RFIs of nitrogen gas piping.

(5) Method statements of the nitrogen generation system need to be attached.

11-Compressed air system (CCC#1):

(1) RFI for painting on joints of steel structure columns and beams is required to be

provided. (RFI is attached with the reference of comment No.)

(2) According to approved ITP No HEI-Bhikki-QCP-C-ME-04 dated 26.08.2018, RFIs

related to hydro test packages, inspection prior to pressure testing, Restoration of

system after complete testing have not been attached.

12-Hydrogen Generation System (CCC#1, CCC#2):

(1) RFI for painting on joints of steel structure columns and beams is required to be

provided.

(2) RFIs for Welding joints of hydrogen generation system need to be provided.

(3) RFIs for supports and hangers of hydrogen piping need to be provided.

(4) Approved Method Statement for the said system need to be provided.

13-Chemical water Treatment System (CCC#1, CCC#2):

(1) RFI for installation of sanitary waste water and industrial waste water treatment

pumps need to be provided.

(2) Water Tight Test Reports shall be provided for Gates installed in Bio Ponds and

MBR tanks.

(3) Installation RFI for Removable Handrail in waste water lifting station need to be

provided.

(4) Installation RFI(s) need to be provided for Sludge feed pumps, sludge dehydrator&

Sludge mixers. (RFI is attached with the reference of comment No.)

(5) RFI for painting on joints of steel structure columns and beams is required to be

provided. (RFI is attached with the reference of comment No.)

(6) Approved ITP for chemical water treatment system is missing. (RFI is attached with

the reference of comment No.)

14-Fuel Oil System (CCC#1):

(1) RFI for painting on joints of steel structure columns and beams is required to be

provided. (RFI is attached with the reference of comment No.)

(2) Installation RFI for Oil Unloading Modification system is missing.

15-EDG (CCC#1):

(1) Installation RFI need to be provided.

(2) RFI for painting on joints of steel structure columns and beams is required to be

provided. (RFI is attached with the reference of comment No.)

17-Steam Turbine (CCC#3):

Mechanical Section Comments

1. RFI for painting on joints of steel structure columns and beams is required to be

provided.(RFI not found)

2. Approved ITP&MS shall be attached. (RFI is attached with the reference of

comment No.)

18-Gas Turbines (CCC#1, CCC#2):

(1) RFI for painting on joints of steel structure columns and beams is required to be

provided.(RFI not found)

(2) Approved ITP need to be provided. (RFI is attached with the reference of comment

No.)

19-HRSG (CCC#3):

(1) Method Statements TEPC-GL-A08-002, TEPC-GL-A08-003, and TEPC-GL-A08-004

are in Chinese language and without signature of NESPAK in the provided folder.

HEI to provide the same in English language bearing NESPAK signature. (This

document is HEI internal no need nespak to review )

(2) RFI for painting on joints of steel structure columns and beams is required to be

provided.(Refer to AN-425, AN-402, AN-514, AN-515)

(3) Hydro test Package of HRSG #2 is not provided and need to be submitted. Only

HRSG#1 is found.(Test Report is attached with reference of comment No.)

(4) Inspection Reports # TEPC-TU- 507/508 bearing Nespak signatures shall be

provided.(RFI is attached reference of comment No.)

(5) Approved Copies of WPS-PQR relating to HRSG welding is required. (Documents

are attached with reference of comment No.)

(6) Complete HRSG Stack Welding Record is to be provided. (Documents are attached

with reference of comment No.)

(7) Method Statement for Insulation of HRSG need to be provided. (Documents are

attached with reference of comment No.)

(8) Complete Insulation inspection record for HRSG Piping, Stack and ducts is required

to be provided. (Documents are attached with reference of comment No.)

(9) As per provision of ASME Code Section I, Master Data report and P3-P4 Forms

required. (Documents are attached with reference of comment No.)

(10) HRSG Name plate drawing indicating MWAP required to be provided.

(Documents are attached with reference of comment No.)

(11) NDT Procedures essentially required to be submitted prior to the following tests

shall be provided; (Documents are attached with reference of comment No.)

1-Radiographic testing 2- Ultrasonic testing 3- Magnetic testing4-Positive

material identification test/spectral analysis 5-Hardness testing

(12) HRSG safety Valves data sheet shall be provided. (Documents are attached with

reference of comment No.)

(13) Partial manufacturer data reports signed by ASME Inspector available with

HEI, are required. (Documents are attached with reference of comment No.)

(14) A complete Inspection record of Steam Blowing need to be provided.

(Documents are attached with reference of comment No.)

(15) HRSG Elevator's 3rd party inspection record is required.(RFI not found ---Need

to contact gulzar for RFIs)

Mechanical Section Comments

(16) Partial manufacturer reports for HRSG Safety valve are required to be provided.

(Documents are attached with reference of comment No.)

(17) Method statement and Complete Inspection record for Chemical Cleaning of

HRSG is required. (Documents are attached with reference of comment No.)

You might also like

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisFrom EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisRating: 5 out of 5 stars5/5 (1)

- 3.5 - Plumbing DC - 01Document93 pages3.5 - Plumbing DC - 01rkpatel40No ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- 1574 - 03 Vol 2B - DS Package PDFDocument69 pages1574 - 03 Vol 2B - DS Package PDFanjnaNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- MEP-R-ES-007-Flare Stack, Flare Tip and Flame Front GeneratorDocument10 pagesMEP-R-ES-007-Flare Stack, Flare Tip and Flame Front GeneratorimyourscinNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Etag 013Document136 pagesEtag 013sanh137No ratings yet

- 1574 03 Vol 2B DS PackageDocument69 pages1574 03 Vol 2B DS PackageZahoor AhmedNo ratings yet

- Challenges in Corrosion: Costs, Causes, Consequences, and ControlFrom EverandChallenges in Corrosion: Costs, Causes, Consequences, and ControlNo ratings yet

- Final TSDocument123 pagesFinal TSdebabratadas1234No ratings yet

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Optcl System in Orissa 400kv Bid DocumentDocument223 pagesOptcl System in Orissa 400kv Bid Documentranjish_007100% (1)

- CW9 Part 1Document9 pagesCW9 Part 1Steve CowanNo ratings yet

- VOL-IIA-Scope Details Package LAPANGA - 68-01Document38 pagesVOL-IIA-Scope Details Package LAPANGA - 68-01Sunil SinghNo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Vol IIDocument293 pagesVol IIscribd_rajaNo ratings yet

- 2010-Tindall Specification FinalDocument12 pages2010-Tindall Specification Finalshahhassa9No ratings yet

- CPWD Fire Hydrant DetailsDocument14 pagesCPWD Fire Hydrant DetailsAshwin SrikantaiahNo ratings yet

- 1665 03-Vol-Iib Ts HoistDocument15 pages1665 03-Vol-Iib Ts Hoistrvkumar3619690No ratings yet

- Technical SpecDocument298 pagesTechnical SpecMe100% (1)

- Technical Specification OF Tower Material For66Kvmulti Circuit-Panther Transmission LineDocument15 pagesTechnical Specification OF Tower Material For66Kvmulti Circuit-Panther Transmission Lineakhilesh205No ratings yet

- Appendix 13L-Storage TanksDocument103 pagesAppendix 13L-Storage TanksNitzOONo ratings yet

- UFC 48466108 Seismic Design For BuildingsDocument245 pagesUFC 48466108 Seismic Design For BuildingsDianna LambertNo ratings yet

- Power Cycle Piping ScopeDocument7 pagesPower Cycle Piping ScopeJackSparrow86No ratings yet

- 22 - Technical Specification Part VI-Civil & Structural WorksDocument32 pages22 - Technical Specification Part VI-Civil & Structural Worksah.bassioniNo ratings yet

- TI - SPC - OHE - Fittings - 0130 - With A - C - Slip - No - 1Document63 pagesTI - SPC - OHE - Fittings - 0130 - With A - C - Slip - No - 1Nawal RathoreNo ratings yet

- Tank Fabrication SpecsDocument21 pagesTank Fabrication Specsjlcheefei9258100% (1)

- Structural Steel: Technical Specifications For Repair Plan at The Coke Handling SystemDocument12 pagesStructural Steel: Technical Specifications For Repair Plan at The Coke Handling SystemAna RojasNo ratings yet

- 5.6 - Plumbig System - SCH - DBDocument23 pages5.6 - Plumbig System - SCH - DBrkpatel40No ratings yet

- Bsi 8010 Sec 2.1Document26 pagesBsi 8010 Sec 2.1José Roberto NicoletiNo ratings yet

- Government of India Technical Specification for Fittings for 25 kV a.c. OHEDocument50 pagesGovernment of India Technical Specification for Fittings for 25 kV a.c. OHEkhan11kNo ratings yet

- Technical Clarification-Seoul Machinery-1910-0318 OfferDocument4 pagesTechnical Clarification-Seoul Machinery-1910-0318 OfferAnaNo ratings yet

- BSR 2008Document65 pagesBSR 2008dxindraNo ratings yet

- BSR Notes IctadDocument14 pagesBSR Notes IctadDavid Web100% (4)

- Sandwich Bus Duct Specs for Power SystemDocument15 pagesSandwich Bus Duct Specs for Power SystemONILEDA1970No ratings yet

- Vol2 TL-S1-6 3626 PGCBDocument124 pagesVol2 TL-S1-6 3626 PGCBabhi120783No ratings yet

- Steam BoilerDocument134 pagesSteam Boilerchikukotwal0% (1)

- Updates To Api Standards: John M. Lieb, P.E. Tank Industry ConsultantsDocument8 pagesUpdates To Api Standards: John M. Lieb, P.E. Tank Industry ConsultantsOmar EzzatNo ratings yet

- 1488 2 Technical Specification ANNEXURE IIDocument3 pages1488 2 Technical Specification ANNEXURE IIsushant shirsatNo ratings yet

- 40MV Transformer TS 2791 FINALDocument12 pages40MV Transformer TS 2791 FINALRanchak KumarNo ratings yet

- 7-Annexure 21B To TS - Heating Ventilation and Air Conditioning WorksDocument15 pages7-Annexure 21B To TS - Heating Ventilation and Air Conditioning WorkscliffrajjoelNo ratings yet

- CODE-2 AND Code 3 ITRS Updated ListDocument40 pagesCODE-2 AND Code 3 ITRS Updated ListkyNo ratings yet

- 2519 Vol-2b Technical-SpecificationsDocument58 pages2519 Vol-2b Technical-SpecificationsAdityaNo ratings yet

- Modified STR - TMTDocument8 pagesModified STR - TMTnazi1945No ratings yet

- STR No. CORE-STR-01 For Fabricated & Galvanized Steel Structures For Ohe & Tss Effective From-21.05.2021Document79 pagesSTR No. CORE-STR-01 For Fabricated & Galvanized Steel Structures For Ohe & Tss Effective From-21.05.2021Sharad SinghNo ratings yet

- Mil B 24480a (SH)Document8 pagesMil B 24480a (SH)Jeff95TANo ratings yet

- Guidance For Propeller Repair IACSDocument26 pagesGuidance For Propeller Repair IACSDesmond Chin100% (1)

- Repsol Oil Operations: Nc-115 Field DevelopmentDocument11 pagesRepsol Oil Operations: Nc-115 Field DevelopmentYangui AliNo ratings yet

- C5000 16 G28 B V04 B02 PDFDocument321 pagesC5000 16 G28 B V04 B02 PDFAhmed OmarNo ratings yet

- Tender specification for crushers and associated worksDocument128 pagesTender specification for crushers and associated workszsmithNo ratings yet

- Civil and Mechanical Design Criteria for Beacon Solar ProjectDocument37 pagesCivil and Mechanical Design Criteria for Beacon Solar Projectrmm99rmm99No ratings yet

- Remaining DurationDocument12 pagesRemaining DurationKhan the GreatNo ratings yet

- Core Vendor GuidelinesDocument37 pagesCore Vendor GuidelinesGurdeep SinghNo ratings yet

- AC-VRF Statment MethodDocument4 pagesAC-VRF Statment MethodHassan ShamsNo ratings yet

- 1814 3) Design Criteria For Steel Structural WorksDocument18 pages1814 3) Design Criteria For Steel Structural WorksPrasadarao TalluriNo ratings yet

- Tech Specs of EOT CraneDocument42 pagesTech Specs of EOT CraneVicky GautamNo ratings yet

- MeezanDocument1 pageMeezanUmmair ChNo ratings yet

- Intro To MaintenanceDocument31 pagesIntro To Maintenancesharif339No ratings yet

- First Merit List: Fazaia Ruth Pfau Medical College, (FRPMC) PAF Base Faisal KarachiDocument4 pagesFirst Merit List: Fazaia Ruth Pfau Medical College, (FRPMC) PAF Base Faisal KarachiUmmair ChNo ratings yet

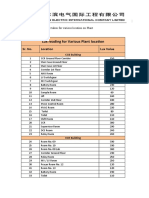

- Lux Reading For Various Plant LocationDocument2 pagesLux Reading For Various Plant LocationUmmair ChNo ratings yet

- Conversion FormulaDocument1 pageConversion FormulaUmmair ChNo ratings yet

- GuidelinesDocument23 pagesGuidelinespali khanNo ratings yet

- Authority Letter TemplateDocument1 pageAuthority Letter TemplateUmmair ChNo ratings yet

- Authority LetterDocument1 pageAuthority LetterUmmair ChNo ratings yet

- Malik Muhammad Aslam: Culinary Skills / KnowledgeDocument2 pagesMalik Muhammad Aslam: Culinary Skills / KnowledgeUmmair ChNo ratings yet

- I&C CCC Documentation DiscrepanciesDocument4 pagesI&C CCC Documentation DiscrepanciesUmmair ChNo ratings yet

- Authority Letter TemplateDocument1 pageAuthority Letter TemplateUmmair ChNo ratings yet

- Admin Building:-: Staff AccommodationDocument2 pagesAdmin Building:-: Staff AccommodationUmmair ChNo ratings yet

- Curriculum Vitae FormatDocument2 pagesCurriculum Vitae FormatUmmair ChNo ratings yet

- Leave & Over Time Application Form: Name M. Ummair Project 1180MW Bhikki Powerplant Duty Electrical EngineerDocument1 pageLeave & Over Time Application Form: Name M. Ummair Project 1180MW Bhikki Powerplant Duty Electrical EngineerUmmair ChNo ratings yet

- TEPC-I&C-0001 Chemical Building I&C Cabinets InstallationDocument2 pagesTEPC-I&C-0001 Chemical Building I&C Cabinets InstallationUmmair ChNo ratings yet

- Request For Inspection: Owner Nespak EPC ContractorDocument1 pageRequest For Inspection: Owner Nespak EPC ContractorUmmair ChNo ratings yet

- Space Shuttle Seminar ReportDocument32 pagesSpace Shuttle Seminar ReportVijay SinghNo ratings yet

- Requara. H. Wickens Fundamentals of Rail Vehicle Dynamics Guidance and StabiliteDocument42 pagesRequara. H. Wickens Fundamentals of Rail Vehicle Dynamics Guidance and Stabilitetesfaye awelNo ratings yet

- Guidance Note On WeldingDocument102 pagesGuidance Note On WeldingVishal SharmaNo ratings yet

- W 460 Rear Bearing ReplacementDocument5 pagesW 460 Rear Bearing Replacementhv4000No ratings yet

- Reliant Oven Promo Pack LowresDocument9 pagesReliant Oven Promo Pack LowresVictor RequenaNo ratings yet

- Government Industrial Training Institute exam on desktop publishingDocument3 pagesGovernment Industrial Training Institute exam on desktop publishingamerican_guy10No ratings yet

- HP Vertica 7.1.x GettingStartedDocument71 pagesHP Vertica 7.1.x GettingStartedRahul VishwakarmaNo ratings yet

- Electrical Installation Hand Book (ABB)Document241 pagesElectrical Installation Hand Book (ABB)Nguyen Van Truc100% (1)

- Using NodeMCU To Control An LED in LAN NetworkDocument3 pagesUsing NodeMCU To Control An LED in LAN Networkbayu prasetyoNo ratings yet

- RMFDocument245 pagesRMFsuryadiwaNo ratings yet

- Roof Mounted Fan Performance DataDocument14 pagesRoof Mounted Fan Performance DataCapserVNo ratings yet

- 5.2.0 (5.9) Line Model and PerformanceDocument23 pages5.2.0 (5.9) Line Model and PerformanceOMAR METRINo ratings yet

- Iec Standards For Variable Speed Drives and Motor Winding InsulationDocument4 pagesIec Standards For Variable Speed Drives and Motor Winding Insulationmani_208eeNo ratings yet

- l4 03 Measuring Purchasing PerformanceDocument150 pagesl4 03 Measuring Purchasing PerformanceMahendra Kumar Soni100% (3)

- (Original) Comprehensive Land Transport and Traffic Code of GSC RevisedDocument149 pages(Original) Comprehensive Land Transport and Traffic Code of GSC RevisedXIANo ratings yet

- 09c01 Fuel Injection Pump (Rotor)Document6 pages09c01 Fuel Injection Pump (Rotor)hbpate3No ratings yet

- Skoog Chapter 22 JawabanDocument11 pagesSkoog Chapter 22 JawabanmarisaaaNo ratings yet

- Jewellary Management SystemDocument2 pagesJewellary Management SystemsunnyNo ratings yet

- Imi 660 0707Document4 pagesImi 660 0707Tim StubbsNo ratings yet

- 100 Electronics Engineering Interview Questions and AnswersDocument15 pages100 Electronics Engineering Interview Questions and AnswersmanishNo ratings yet

- Renault Twingo (2000 - 2004) - Fuse Box DiagramDocument5 pagesRenault Twingo (2000 - 2004) - Fuse Box DiagramrafaelecNo ratings yet

- AABC ExtractDocument4 pagesAABC Extractanton7786No ratings yet

- Rick Thompson ResumeDocument2 pagesRick Thompson ResumeJohn AndersonNo ratings yet

- A400MDocument29 pagesA400MHikari Nazuha100% (1)

- Kouign Amann RecipeDocument59 pagesKouign Amann RecipeDanny DawsonNo ratings yet

- 4G13S1 Engine Service Manual (Easier Edition)Document28 pages4G13S1 Engine Service Manual (Easier Edition)River OzNo ratings yet

- Utilities EscalatorsDocument29 pagesUtilities EscalatorsCharles Joseph JacobNo ratings yet

- Geothermal Basics - Power Plant CostsDocument2 pagesGeothermal Basics - Power Plant Costssudhir_921995600No ratings yet

- Kamstrup Multical 602 - Installation and User GuideDocument28 pagesKamstrup Multical 602 - Installation and User GuideMarco RamosNo ratings yet

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftFrom EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftRating: 5 out of 5 stars5/5 (5)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!From EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No ratings yet

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsFrom EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNo ratings yet

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- How to Build a Tiny Portable House: With Plans and InstructionsFrom EverandHow to Build a Tiny Portable House: With Plans and InstructionsRating: 4 out of 5 stars4/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Grid-Scale Energy Storage Systems and ApplicationsFrom EverandGrid-Scale Energy Storage Systems and ApplicationsFu-Bao WuNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)