Professional Documents

Culture Documents

Plastic Roads PDF

Plastic Roads PDF

Uploaded by

ygcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plastic Roads PDF

Plastic Roads PDF

Uploaded by

ygcCopyright:

Available Formats

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 2, February 2017

A Survey on Cost Comparison of Sustainable

Plastic Road with Regular Bitumen Road

Ajay Dwivedi[1], Manik Mattoo[2], Jaideep Prabhu[3], Atul Dwivedi[4], Pankil Jain[5].

B.E Student, Department of Civil Engineering, Thakur College of Engineering and Technology, Mumbai,

Maharashtra, India1

B.E Student, Department of Civil Engineering, Thakur College of Engineering and Technology, Mumbai,

Maharashtra, India2

B.E Student, Department of Civil Engineering, Thakur College of Engineering and Technology, Mumbai,

Maharashtra, India3

B.E Student, Department of Civil Engineering, M.H Saboo Siddik College of Engineering, Mumbai,

Maharashtra, India4

B.E Student, Department of Civil Engineering, M.H Saboo Siddik College of Engineering, Mumbai,

Maharashtra, India5

ABSTRACT: The population growth, industrialization, consumerism and scientific development have led to the

uncontrollable accumulation of waste. Proper waste disposal is of great importance in both pastoral and metropolitan

areas. This study discussed the suitability of plastic waste materials for pavement construction.. The waste is mixed in

different proportions to the soil sample and their influences on geotechnical properties were studied. The results of the

tests indicated that plastic alone is not suitable for pavement subgrade. When quarry dust was added along with soil

plastic mix, it maintains the CBR value within the required range.

KEYWORDS: Plastic, Bitumen, Atterberg's limit, HRS Specification, CBR Value.

I. INTRODUCTION

The rate of production of waste has increased tremendously in almost all parts of the world in the past few decades. The

quantities of these waste that are accumulating, are causing serious disposal problems. The conservative methods of

disposal are found to be inadequate. Due to population growth, industrialization, consumerism and technological

development there has been a tremendous increase in the rate of production of waste. Every year, 7.2 million tons of

hazardous waste is produced and its disposal is becoming a major issue and about one km2 of additional landfill area is

needed every year. Indian government spends about Rs 1600 crore for treatment & disposal of these wastes. In addition

to this, industries release about 150 million tons of high volume low hazard waste every year, which is mostly dumped

on open low lying land areas. In this situation, the conventional waste disposal methods are found to be derisory.

Through this project, a small attempt has been made at deducing a new technique of waste disposal. This paper aims at

proposing a new method of disposal of plastic, quarry dust, and tyre waste by using them in the sub-grade soil of

pavement. The Main objective of this study are safe and prolific disposal of wastes - plastic, quarry dust, and tyre, the

study of index properties and CBR values of variable mixes of soil and waste and suitability of soil-waste mix in sub

grade.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0602011 1500

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 2, February 2017

II. RELATED WORK

Growth and Quality of infrastructure is one of the most important developing indication of any nation. Infrastructure

includes various sectors i.e Roads, Bridges, Dams, Tunnels, etc, Among all these different sectors, construction of

roads takes up the major part of all the infrastructure work in any nation, being it the most basic yet the most useful

mode of transport among all the others.

As the construction of roads plays such an important role in the development of any nation it is equally important to

assure that it doesn’t affect any other developing aspect of it.

The second most important point of concern after infrastructure for any country has to be its environment viz. to make

it a better place to live in for any living habitat.

We this research work we are trying to find a balance between these two factors which governs the progress of the

nation or any place and also reducing the overall cost of any road project. In the direction of finding this balance we've

tried to alter some of the materials and their quantities which are being used in the construction of regular roads. We've

tried to replace some amount of bitumen with the processed waste plastic and waste rubber tyres and have carried out

complete cost analysis of the same.

III. DEFINITION

A substance that contains one or more organic polymers of large molecular weight, solid in its finished state and at

some state while manufacturing or processing into finished articles, can be shaped by its flow.

IV. TYPES OF PLASTICS

1. Thermosets. 2. Elastomers.

3. Thermoplastics.

V. WHY USE OF PLASTIC?

Polymers have a number of essential properties, which exploited alone or together make a significant and expanding

contribution to construction needs.

1. Durable & corrosion resistant.

2. Good insulation for cold, heat & sound saving energy and dipping noise pollution.

3. It is economical and has a longer life.

4. Maintenance free.

5. Hygienic.

6. Ease of processing/ installation.

7. Lightweight.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0602011 1501

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 2, February 2017

VI. BASIC PROCESS

1. Segregation

2. Cleaning process

3. Shredding process

4. Collection process

VII. CO-PROCESSING OF PLASTIC WASTE MANAGEMENT

A. PLASTIC WASTE MANAGEMENT

1) Conventional Technology

• Recycling

• Incineration

• Land-filling

2) New Technology

• Plasma Pyrolysis Technology

• Liquid Fuel

• Polymer Blended Bitumen Roads

• Co-processing in Cement Kiln

B. PROCESS

1. Wet 2. Dry

i.Wet Process

1. Waste plastics by direct mixing with hot bitumen at 160°C.

2. The Mechanical agitator is needed.

3. The Addition of stabilizers and proper cooling.

4. Since the wet process requires a lot of investment and bigger plants.

5. Not commonly used.

ii.Dry Process

Mixing the appropriate quantity of dry shredded waste plastic with hot aggregate prior to production of bituminous

mixes at hot mix plant by varying percentage of plastic by weight of the mix.

(i) Various types of waste plastic are collected, analyzed as per their type and sent for storage.

(ii) These segregated wastes are then cleaned and dried to remove impurities from them. Then cut into a size of 1.18-

4.36 mm using shredding machine, (PVC waste should be eliminated).

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0602011 1502

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 2, February 2017

o

(iii) The aggregate mix is heated to 165 C (as per the HRS specification) and transferred to mixing chamber. Similarly,

the bitumen is to be heated up to a maximum of 160oC (HRS Specification) to have good binding and to prevent

weak bonding. (Monitoring the temperature is very important).

(iv) At the mixing chamber, the shredded plastics waste is to be added to the hot aggregate. It gets coated

homogeneously over the aggregate within 30 to 45 seconds, giving a look of oily coated aggregate.

(v) The plastics waste coated aggregate is mixed with hot bitumen at the temperature range between 150oC-165oC.

The resulted mix of temperature range 130oC-140oC is used for road construction. The road laying temperature is

between 110oC-120oC. Using the roller of 8 ton (min.) capacity.

VIII. COST ESTIMATION

The Cost of Waste Plastics: Rs.7 / Kg.

The Cost of Processing: Rs.5 / Kg.

The Total cost of Waste Plastics: Rs.12 / Kg.[5]

• Optimum percentage of plastic in the blend as per the test results is around 8% (% Wt. of bitumen)

• Generally roads in India are constructed in basic width of 3.0 m, 3.75 m. and 4.0 m.

• Consider 1 Km length road of width 3.75 m. it uses bitumen approx. 21300 Kg. For new work and 11925 Kg.

For Up-gradation.

The Cost of Bitumen: Rs.8400 / Drum (200 Kg.)[6]

The Cost of Bitumen: Rs.42 / Kg.

1. Cost of New Road / Km including BBM, Carpet, and Seal Coat: Rs. 18,95,000/-10

→ Bitumen required for work (approx.): 21,300 Kg. / Km

→ Cost of bitumen in new work: Rs.8,95,000 / Km.

→ Waste plastic, co-processed with bitumen for PMB (8% by Wt.): Rs.1,704 / Kg.

→ Cost of waste plastic used: Rs.20,450 / Kg.

→ Cost of Bitumen saved (1704Kg. equivalent to plastic used): Rs.71550

→ Total savings per Km.: Rs. 51,100

• Cost of Road (Up gradation)/km including Carpet and Seal Coat: Rs. 10, 80,000 [7]

→ Bitumen Required for work (approx.): 11925 Kg. / KM.

→ Cost of bitumen in repairs (Up gradation) per Km.: Rs. 5,01,000/-

→ Waste plastic, co processed with bitumen for PMB (8% by Wt.): 954 Kg.

→ Cost of waste plastic used: Rs. 11450

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0602011 1503

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 2, February 2017

→ Cost of Bitumen saved (954Kg. equivalent to plastic used): Rs.40,050

→ Total savings per Km.: Rs.28,600

• Optimum amount of waste plastic used in dry process: 10% (by Wt. of aggregates)

• The Amount of aggregates used in road construction (1 Km length x 3.75 m width):

3750 sqm x 12.5 Kg per sqm (Avg.) = 46875 Kg.

→ Therefore Amount of waste plastic used in the road (10% by Wt.): 4687.5 Kg.

2. Total Amount of waste plastic used in road construction using both the processes together (i.e. Combination of wet

process & dry process):1704 + 4687.5 = 6391.5 Kg

3. Total Cost of waste plastic used in road using mix process: Rs.76,700

4. Extra cost for construction of road (Cost of waste plastic used in road construction – Total savings using modified

bitumen): 76,700 – 51,100 = Rs.25,600 / Km

Table 1: Showing compressive & Bending strength

% of Plastic Compressive

Bending strength

coating over strength

(Mpa)

aggregate (Mpa)

10% 250 325

20% 270 335

30% 290 350

40% 320 390

According to the findings as the percentage of Plastic Coating over Aggregate increases the corresponding

Compressive and Bending Strength increases.

IX. ADVANTAGES

1. The Strength of the road increased.

2. Better resistance to water & water stagnation.

3. No stripping & have no potholes.

4. Increased binding & better bonding of the mix.

5. Better reliability property.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0602011 1504

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 2, February 2017

6. Maintenance cost of the road is almost zero.

7. No effect of radiation like UV rays.

X. DISADVANTAGES

1) Cleaning process -Toxic present in the co-mingled plastic waste start leaching.

2) During the road laying process- the presence of chlorine will definitely release lethal gas.

XI. COMPARISON

1) The durability of the roads laid out with shredded plastic waste is much more compared with roads with asphalt

with the ordinary mix.

2) While a normal 'highway quality' road lasts four to five years it is claimed that plastic-bitumen roads can last up to

10 years.

3) Rainwater will not leach through because of the plastic in the tar.

4) The cost of plastic road construction may be slightly higher compared to the conventional method.

5) The maintenance cost is low as compared to conventional method.

6) Its initial cost is slightly more as compared to conventional method.

REFERENCES

1. Prasad, Prasada Raju , Ramana Murthy,Use of Waste Plastic and Tyre in Pavement Systems‟, IE(I) Journal-CV, Vol.89, pp 31-35, 2008

2. Mercy Joseph Poweth, Solly George,Jessy Paul, the study of the use of plastic waste in road construction.

3. S. S. Varma, Roads from Plastic Waste, The Indian Concrete J. (2008) pp. 43-44.

4. N. R. R. D. A., Ministry of Rural Development, GOI, Guidelines for use of Plastic Waste in Rural Road Construction (2007).

5. M/S Sahu Polymers ,Akola ,Maharashtra, India.

6. Sales Officer, Hpcl , Akola, Maharashtra, India.

7. Chief Engineer, Pwd, Amravati, Maharashtra, Circular No Ce/Amt/Off.2(1) (1)/ Pri Rates /407/Dt25/01/11. For Amravati Division

8. Vasudevan .R, utilization of waste plastics for flexible pavement, Indian High Ways (Indian Road Congress), Vol.34, No.7. (July 2006).

9. Kajal , N K S Pundhir , Sangita and A Chandra(2007), Use of waste plastics and copper slag for low cost bituminous roads, Journal Of

Scientific and Industrial Research,Vol.66.pp.938-994

10. V. S. Punish and A. Veeraraghavan, Laboratory Fatigue Studies on Bituminous Concrete Mixed Utilizing Waster Shredded Plastic Modifier,

Proceedings of 21st ARRB Transport Research (ARRB) & 11th Road Engineering Association and Australia Conference, Claims, Australia

(2003) pp. 19-23.

11. C. S. Bindu, Int. J. Engg. & Technol., 2(6), 379-387 (2010).

12. Ministry of Road Transport and High Ways, Manual for construction and supervision of Bituminous works, New Delhi, November 2001.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0602011 1505

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Website: www.ijirset.com

Vol. 6, Issue 2, February 2017

BIOGRAPHY

1. Ajay Dwivedi Student of BE civil in Thakur College of Engineering and technology. He is

interested in pursuing a career in project management. Also a Masters aspirant in the field of

construction management. Being a civil engineer, author wants to bring in the best of

advancements in the field of civil engineering that will benefit the mankind and the human

race because "being a civil engineer is being a creator”.

2. Manik Mattoo

Student of Thakur college of engineering and technology. His interest is in pursuing a career

in Transportation Engineering. Also Preparing for GATE 2018 Exams and wishes to develop

new ideas and techniques in the field of civil engineering.

3. Jaideep Prabhu

Student of BE civil in Thakur College of Engineering and technology. He is interested in

pursuing a career in transportation engineering. Also preparing for higher studies in India and

abroad. Would like to work for the betterment in the field of civil engineering.

4. Atul Dwivedi

A Graduate of B.E.civil from M.H.Saboo Siddik college of engineering. He is interested in

making a career in construction management. Also, a masters aspirant in project management

has given various exams for higher studies.

5.Pankil Jain

A Graduate of B.E.civil from M.H.Saboo Siddik college of engineering. He is interested in

making a career in construction management. Also, a masters aspirant in project management

has qualified for various exams for higher studies.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2017.0602011 1506

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- LAB ACT 4 Elements, Compounds and MixturesDocument8 pagesLAB ACT 4 Elements, Compounds and MixturesJerome MosadaNo ratings yet

- Airfreshener Original FormulationDocument6 pagesAirfreshener Original FormulationRegs AccexNo ratings yet

- Membrane Separation Lab Report - 2018262532 PDFDocument4 pagesMembrane Separation Lab Report - 2018262532 PDFShida ShamNo ratings yet

- Road EstimateDocument49 pagesRoad EstimateNithin KhandeshNo ratings yet

- 600 M S G-Qty'sDocument1 page600 M S G-Qty'sNithin KhandeshNo ratings yet

- VastuDocument61 pagesVastuNithin KhandeshNo ratings yet

- Registration Plan Showing Layout Plot No: 4 in Survey No: 77/A Situated in Mamidipally Village of Armoor Mandal Dist: NizamabadDocument4 pagesRegistration Plan Showing Layout Plot No: 4 in Survey No: 77/A Situated in Mamidipally Village of Armoor Mandal Dist: NizamabadNithin KhandeshNo ratings yet

- Regode Bridge Revised ProgrammeDocument1 pageRegode Bridge Revised ProgrammeNithin KhandeshNo ratings yet

- Bujrampally Bridge Revised ProgrammeDocument1 pageBujrampally Bridge Revised ProgrammeNithin KhandeshNo ratings yet

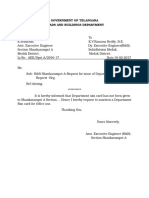

- Dept Sim Letter To DEEDocument1 pageDept Sim Letter To DEENithin KhandeshNo ratings yet

- Asst. Executive Engineer (R&B) Dy. Executive Engineer (R&B) Executive Engineer (R&B) Section Shankarampet A Subdivision Medak Division MedakDocument4 pagesAsst. Executive Engineer (R&B) Dy. Executive Engineer (R&B) Executive Engineer (R&B) Section Shankarampet A Subdivision Medak Division MedakNithin KhandeshNo ratings yet

- Aggregate Impact Value SheetDocument2 pagesAggregate Impact Value SheetNithin Khandesh100% (1)

- BC Gradation Test SheetDocument1 pageBC Gradation Test SheetNithin Khandesh0% (1)

- Work Details As On 26 Dec 2016Document2 pagesWork Details As On 26 Dec 2016Nithin KhandeshNo ratings yet

- Adwords Performance Report PDFDocument7 pagesAdwords Performance Report PDFNithin KhandeshNo ratings yet

- PC Strand PC Wire PC Bar Product Home PC Bar PC Bar PC Bar: (Next Topic) (Previous Topic)Document2 pagesPC Strand PC Wire PC Bar Product Home PC Bar PC Bar PC Bar: (Next Topic) (Previous Topic)Purnomo SetiadiNo ratings yet

- Metaladditivemanufacturinginaerospace AreviewDocument34 pagesMetaladditivemanufacturinginaerospace AreviewMac'Ann Ditshego MashaoNo ratings yet

- Timber BMCDocument11 pagesTimber BMCShubhrata SahareNo ratings yet

- TC WC W 37 Sept 23 7 Days.Document1 pageTC WC W 37 Sept 23 7 Days.Sabyasachi BangalNo ratings yet

- MP35N K Tube Technical Data SheetDocument2 pagesMP35N K Tube Technical Data Sheetstrip1No ratings yet

- SBD en Technical Data SheetDocument8 pagesSBD en Technical Data SheetJonathanFallasNo ratings yet

- 1.35046!CHRISGAS - Final Publishable Results - Web - November 2010Document33 pages1.35046!CHRISGAS - Final Publishable Results - Web - November 2010RicardoEscaladaCuadrado1301No ratings yet

- Low-Cost Sustainable Raw MaterialsDocument12 pagesLow-Cost Sustainable Raw MaterialsAdrian Tun PantiNo ratings yet

- Temperature of 17000C To Room Temperature of 250C. Take The Fusion Temperature From Any Reference BookDocument2 pagesTemperature of 17000C To Room Temperature of 250C. Take The Fusion Temperature From Any Reference BookAshok PradhanNo ratings yet

- Som Complete Marathon by Abhinav and Dheeraj Sir 13Document408 pagesSom Complete Marathon by Abhinav and Dheeraj Sir 13பிரதீப் சாமிநாதன்No ratings yet

- Final ExamDocument42 pagesFinal ExamEmerson HernandezNo ratings yet

- Surface Cleaning MethodsDocument4 pagesSurface Cleaning MethodsMAHESH CHANDNo ratings yet

- Using Chitosan To Extend Shelf Life Research Proposal Mantillas X-Faraday (Final)Document7 pagesUsing Chitosan To Extend Shelf Life Research Proposal Mantillas X-Faraday (Final)Tristan Jay AranasNo ratings yet

- Yff-Hc: SeriesDocument5 pagesYff-Hc: SeriesDhaval PatelNo ratings yet

- Cement - Part 1: Composition, Specifications and Conformity Criteria For Common CementsDocument25 pagesCement - Part 1: Composition, Specifications and Conformity Criteria For Common CementsAbey VettoorNo ratings yet

- This Chapter Will Discuss The Following Topics:: 5. Design of Reinforced Concrete SlabDocument45 pagesThis Chapter Will Discuss The Following Topics:: 5. Design of Reinforced Concrete SlabBatepola BacNo ratings yet

- Thevalakkara Thekkumbhagom BOQDocument31 pagesThevalakkara Thekkumbhagom BOQsmithNo ratings yet

- Toilet Plumbing SpecDocument6 pagesToilet Plumbing SpecdhanabalNo ratings yet

- Jurnal Kimia Sains Dan AplikasiDocument7 pagesJurnal Kimia Sains Dan AplikasiTariojanahNo ratings yet

- Synergistic Effects of Bimetallic PtPd-TiO2 Nanocatalysts in Oxidation ofDocument54 pagesSynergistic Effects of Bimetallic PtPd-TiO2 Nanocatalysts in Oxidation ofmohdhafizmdaliNo ratings yet

- Electrolytic Concentration of Aqueous Solutions of Nitric Acid. I. Henry Jermain Maude CreightonDocument7 pagesElectrolytic Concentration of Aqueous Solutions of Nitric Acid. I. Henry Jermain Maude Creightoneduard morarNo ratings yet

- Eature: ArticleDocument8 pagesEature: Articleadit 1180 gantengNo ratings yet

- Green Composites and Their Properties A Brief IntroductionDocument5 pagesGreen Composites and Their Properties A Brief IntroductionYASHWANTH.M.KNo ratings yet

- AireFrig Flyer 2016 V25Document2 pagesAireFrig Flyer 2016 V25Ong MatNo ratings yet

- Msc.1-Circ.1453-Rev.1 - Guidelines For The Submission of Information and Completion of The Format For The Properti... (Secretariat)Document8 pagesMsc.1-Circ.1453-Rev.1 - Guidelines For The Submission of Information and Completion of The Format For The Properti... (Secretariat)jimNo ratings yet

- Daftar PustakaDocument6 pagesDaftar PustakavitawidNo ratings yet

- CRSI-Designers Responsibility For Rebar Design PDFDocument16 pagesCRSI-Designers Responsibility For Rebar Design PDFk_maheswari3397No ratings yet