Professional Documents

Culture Documents

SBD en Technical Data Sheet

Uploaded by

JonathanFallasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SBD en Technical Data Sheet

Uploaded by

JonathanFallasCopyright:

Available Formats

SBD EN 14592

SELF-DRILLING DOWEL

TAPERED TIP

The new tapered self-perforating tip minimises insertion times in tim-

ber-to-metal connection systems and guarantees applications in hard-

to-reach positions (reduced application force).

GREATER STRENGTH

Higher shear strengths than the previous version.

The 7.5 mm diameter ensures higher shear strengths than other solu-

tions on the market and enables optimisation of the number of fasteners.

DOUBLE THREAD

The thread close to the tip (b1) facilitates screwing. The longer un-

der-head thread (b2) allows quick and precise closing of the joint.

CYLINDRICAL HEAD

It allows the dowel to penetrate beyond the surface of the timber sub-

strate. It ensures an optimal appearance and meets fire-strength requisites.

BIT INCLUDED

DIAMETER [mm] SBD 3,5 7,5 8

LENGTH [mm] 25 95 235 240

SERVICE CLASS SC1 SC2 SC3 SC4

ATMOSPHERIC CORROSIVITY C1 C2 C3 C4 C5

WOOD CORROSIVITY T1 T2 T3 T4 T5

VIDEO

Scan the QR Code and watch

MATERIAL

Zn electrogalvanized carbon steel the video on our YouTube

ELECTRO

PLATED channel

FIELDS OF USE

Self-drilling system for concealed timber-to.

steel joints.

It can be used with screw guns running at 600-

2100 rpm, minimum applied force 25 kg, with:

• steel S235 ≤ 10.0 mm

• steel S275 ≤ 10.0 mm

• steel S355 ≤ 10.0 mm

• ALUMINI, ALUMIDI and ALUMAXI brackets

284 | SBD | METAL

MOMENT RESTORING

It restores shear and moment forces in con-

cealed centreline joints of large beams.

EXCEPTIONAL SPEED

The only dowel that drills a 5 mm thick S355

plate in 20 seconds (horizontal application

with an applied force of 25 kg).

No self-drilling pin exceeds the application

speed of the SBD with its new tip.

METAL | SBD | 285

Fastening of Rothoblaas pillar-holder with internal knife plate F70. Rigid ”knee“ joint with

double internal plate (LVL).

CODES AND DIMENSIONS

SBD L ≥ 95 mm SBD L ≤ 75 mm

d1 CODE L b1 b2 pcs b2 d1 CODE L b1 b2 pcs

b2 [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

SBDS7595 95 40 10 50 7,5 SBD7555 55 - 10 50

b1 TX 40 SBD7575

SBDS75115 115 40 10 50 75 30 10 50

SBDS75135 135 40 10 50

7,5 SBDS75155 155 40 20 50

TX 40 SBDS75175 175 40 40 50

SBDS75195 195 40 40 50

b1

SBDS75215 215 40 40 50

SBDS75235 235 40 40 50

GEOMETRY AND MECHANICAL CHARACTERISTICS

SBD L ≥ 95 mm SBD L ≤ 75 mm

S S

dK dK

d1 Lp d1

b2 b1 b2 b1 Lp

L L

SBD L ≥ 95 mm SBD L ≤ 75 mm

Nominal diameter d1 [mm] 7,5 7,5

Head diameter dK [mm] 11,00 11,00

Tip length Lp [mm] 20,0 24,0

Effective length Leff [mm] L-15,0 L-8,0

Characteristic yield

My,k [Nm] 75,0 42,0

moment

286 | SBD | METAL

INSTALLATION | ALUMINIUM PLATE

plate single plate

[mm]

ALUMINI 6

ALUMIDI 6

ALUMAXI 10

It is suggested to have a milling in the wood equal to the thickness of the plate increased by at least 1 mm.

40 kg

25 kg

ta

B

s

ta

s

pressure to be applied 40 kg pressure to be applied ta t25

a kg

recommended screwdriver Mafell A 18M BL recommended screwdriver B Mafell A 18M BL

recommended speed 1st gear (600-1000 rpm) recommended speed 1st gear (600-1000 rpm)

INSTALLATION | STEEL PLATE

plate single plate double plate

[mm] [mm]

S235 steel 10 8

S275 steel 10 6

S355 steel 10 5

It is suggested to have a milling in the wood equal to the thickness of the plate increased by at least 1 mm.

40 kg 40 kg

25 kg 25 kg

ta

ta

s

B

B

s

ti

s

ta

ta

s s s

pressure to be applied 40 kg ta

pressure to be applied ta 25 kg ta ti ta

recommended screwdriver Mafell A 18M BL B

recommended screwdriver Mafell A 18M BL B

recommended speed 2nd gear (1000-1500 rpm) recommended speed 2nd gear (1500-2000 rpm)

PLATE HARDNESS

The steel plate hardness can greatly vary the pull-through times of the dowels.

Hardness is in fact defined as the material's strength to drilling or shear.

In general, the harder the plate, the longer the drilling time.

The hardness of the plate does not always depend on the strength of the steel, it can vary from point to point and is

strongly influenced by heat treatments: standardised plates have a medium to low hardness, while the hardening process

gives the steel high hardnesses.

METAL | SBD | 287

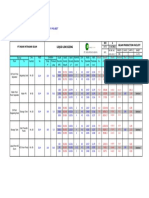

TIMBER-TO-METAL-TO-TIMBER STRUCTURAL VALUES CHARACTERISTIC VALUES

EN 1995:2014

1 INTERNAL PLATE - DOWEL HEAD INSTALLATION DEPTH 0 mm

s

ta ta

B

7,5x55 7,5x75 7,5x95 7,5x115 7,5x135 7,5x155 7,5x175 7,5x195 7,5x215 7,5x235

beam width B [mm] 60 80 100 120 140 160 180 200 220 240

head insertion depth p [mm] 0 0 0 0 0 0 0 0 0 0

exterior wood ta [mm] 27 37 47 57 67 77 87 97 107 117

0° 7,48 9,20 12,10 12,88 12,41 15,27 16,69 17,65 18,41 18,64

30° 6,89 8,59 11,21 11,96 11,56 13,99 15,23 16,42 17,09 17,65

Rv,k load-to-grain

45° 6,41 8,09 10,34 11,20 10,86 12,96 14,05 15,22 16,00 16,62

[kN] angle

60° 6,00 7,67 9,62 10,58 10,27 12,10 13,07 14,12 15,08 15,63

90° 5,66 7,31 9,01 10,04 9,77 11,37 12,24 13,18 14,19 14,79

1 INTERNAL PLATE - DOWEL HEAD INSTALLATION DEPTH 15 mm

p s

ta ta

B

7,5x55 7,5x75 7,5x95 7,5x115 7,5x135 7,5x155 7,5x175 7,5x195 7,5x215 7,5x235

beam width B [mm] 80 100 120 140 160 180 200 220 240 -

head insertion depth p [mm] 15 15 15 15 15 15 15 15 15 -

exterior wood ta [mm] 37 47 57 67 77 87 97 107 117 -

0° 8,47 9,10 11,92 12,77 13,91 15,22 16,66 18,02 18,64 -

30° 7,79 8,49 11,17 11,86 12,82 13,95 15,20 16,54 17,43 -

Rv,k load-to-grain

45° 7,25 8,00 10,55 11,11 11,93 12,92 14,02 15,20 16,31 -

[kN] angle

60° 6,67 7,58 10,03 10,48 11,19 12,06 13,04 14,09 15,21 -

90° 6,14 7,23 9,59 9,95 10,56 11,33 12,21 13,16 14,17 -

288 | SBD | METAL

TIMBER-TO-METAL-TO-TIMBER STRUCTURAL VALUES CHARACTERISTIC VALUES

EN 1995:2014

2 INTERNAL PLATES - DOWEL HEAD INSTALLATION DEPTH 0 mm

s s

ta ti ta

B

7,5x55 7,5x75 7,5x95 7,5x115 7,5x135 7,5x155 7,5x175 7,5x195 7,5x215 7,5x235

beam width B [mm] - - - - 140 160 180 200 220 240

head insertion depth p [mm] - - - - 0 0 0 0 0 0

exterior wood ta [mm] - - - - 45 50 55 60 70 75

interior wood ti [mm] - - - - 38 48 58 68 68 78

0° - - - - 20,07 22,80 25,39 28,07 29,24 31,80

30° - - - - 18,20 20,91 23,19 25,56 26,55 29,07

Rv,k load-to-grain

45° - - - - 16,67 19,36 21,39 23,51 24,36 26,63

[kN] angle

60° - - - - 15,41 18,01 19,90 21,81 22,55 24,60

90° - - - - 14,35 16,73 18,64 20,38 21,01 22,89

2 INTERNAL PLATES - DOWEL HEAD INSTALLATION DEPTH 10 mm

p s s

ta ti ta

B

7,5x55 7,5x75 7,5x95 7,5x115 7,5x135 7,5x155 7,5x175 7,5x195 7,5x215 7,5x235

beam width B [mm] - - - 140 160 180 200 220 240 -

head insertion depth p [mm] - - - 10 10 10 10 10 10 -

exterior wood ta [mm] - - - 50 55 60 75 80 85 -

interior wood ti [mm] - - - 28 45 50 65 70 75 -

0° - - - 16,56 20,07 23,22 25,65 28,89 30,50 -

30° - - - 15,07 18,20 21,29 23,14 26,32 27,78 -

Rv,k load-to-grain

45° - - - 13,86 16,67 19,53 21,11 24,05 25,50 -

[kN] angle

60° - - - 12,85 15,41 18,01 19,43 22,10 23,62 -

90° - - - 12,00 14,35 16,73 18,01 20,46 22,02 -

METAL | SBD | 289

MINIMUM DISTANCES FOR DOWELS SUBJECT TO SHEAR

F α=0° F α=90°

d1 [mm] 7,5 d1 [mm] 7,5

a1 [mm] 5∙d 38 a1 [mm] 3∙d 23

a2 [mm] 3∙d 23 a2 [mm] 3∙d 23

a3,t [mm] max(7∙d ; 80 mm) 80 a3,t [mm] max(7∙d ; 80 mm) 80

a3,c [mm] max(3,5∙d ; 40 mm) 40 a3,c [mm] max(3,5∙d ; 40 mm) 40

a4,t [mm] 3∙d 23 a4,t [mm] 4∙d 30

a4,c [mm] 3∙d 23 a4,c [mm] 3∙d 23

α = load-to-grain angle

d = d1 = nominal dowel diamter

stressed end unloaded end stressed edge unload edge

-90° < α < 90° 90° < α < 270° 0° < α < 180° 180° < α < 360°

a2 α F

F

a2 α α a4,t a4,c

F α

F

a1 a1 a3,t a3,c

NOTES

• Minimum distances FOR CONNECTORS SUBJECTED TO SHEAR STRESS in accordance with EN 1995:2014.

EFFECTIVE NUMBER FOR SHEAR-STRESSED DOWELS

The load-bearing capacity of a connection made with several dowels, all of the same type and

size, may be lower than the sum of the load-bearing capacities of the individual connection Ref,V,k

system.

For a row of n dowels arranged parallel to the direction of the grain (α = 0°) at a distance a1 , the

characteristic effective load-bearing capacity is equal to:

a1 a1

Ref,V,k = nef RV,k

The nef value is given in the table below as a function of n and a1 .

a1( * ) [mm]

40 50 60 70 80 90 100 120 140

2 1,49 1,58 1,65 1,72 1,78 1,83 1,88 1,97 2,00

3 2,15 2,27 2,38 2,47 2,56 2,63 2,70 2,83 2,94

n 4 2,79 2,95 3,08 3,21 3,31 3,41 3,50 3,67 3,81

5 3,41 3,60 3,77 3,92 4,05 4,17 4,28 4,48 4,66

6 4,01 4,24 4,44 4,62 4,77 4,92 5,05 5,28 5,49

( * ) For intermediate a values a linear interpolation is possible.

1

STRUCTURAL VALUES

GENERAL PRINCIPLES NOTES

• Characteristic values according to EN 1995:2014. • For the calculation process a timber characteristic density ρk = 385 kg/m3

has been considered.

• Design values can be obtained from characteristic values as follows:

For different ρk values, the strength on the table on the timber side can be

Rk kmod converted by the kdens,v coefficient

Rd =

γM R’V,k = kdens,v RV,k

The coefficients γM and kmod should be taken according to the current R’ax,kρ = kdens,ax Rax,k

k 350 380 385 405 425 430 440

regulations used for the calculation. 3

R’[kg/m

head,k

=] kdens,ax Rhead,k

• Mechanical strength values and dowels geometry comply with CE marking C-GL C24 C30 GL24h GL26h GL28h GL30h GL32h

according to EN 14592.

kdens,v 0,90 0,98 1,00 1,02 1,05 1,05 1,07

• The values provided are calculated using 5 mm thick plates and a 6 mm

thick milled cut in the wood. Values are relative to a single SBD dowel. Strength values thus determined may differ, for higher safety standards,

• Dimensioning and verification of timber elements and steel plates must be from those resulting from an exact calculation.

carried out separately.

• The dowels must be positioned in accordance with the minimum distances.

• The effective length of SBD (L ≥ 95 mm) dowels takes into account the di-

ameter reduction in the vicinity of the self-drilling tip.

290 | SBD | METAL

INSTALLATION

It is suggested to have a milling in the wood equal to the thickness of the plate, increased by at least 1-2 mm, placing SHIM

spacers between the wood and the plate to centre it in the milling.

In this way, the steel residue from the drilling of the metal has an outlet to escape and does not obstruct the passage of the

drill through the plate, thus avoiding overheating of the plate and timber and also preventing the generation of smoke during

installation.

Cutter increased by 1 mm on each side. Shavings obstructing the

holes in the steel during

drilling (spacers not in-

stalled).

To avoid breakage of the tip at the moment of pin-plate contact, it is recommended to reach the plate slowly, pushing with

a lower force until the moment of impact and then increasing it to the recommended value (40 kg for top-down applica-

tions and 25 kg for horizontal installations). Try to keep the dowel as perpendicular as possible to the surface of the timber

and the plate.

Intact tip after correct installation of the dowel. Broken (cut) tip due to excessive force during impact with metal.

If the steel plate is too hard, the dowel tip may shrink significantly or even melt. In this case, it is advisable to check the mate-

rial certificates for any heat treatment or hardness tests performed. Try decreasing the force applied or alternatively changing

the type of plate.

Tip melted during installation on a too hard plate without spacers Reduction of the tip when drilling the plate due to the high hard-

between timber and plate. ness of the plate.

METAL | SBD | 291

Powered by TCPDF (www.tcpdf.org)

You might also like

- Self-Drilling Dowel: Steel and AluminumDocument6 pagesSelf-Drilling Dowel: Steel and AluminumLucas SeñaNo ratings yet

- KOP en Technical Data SheetDocument6 pagesKOP en Technical Data SheetmcbluedNo ratings yet

- CONNECT TIMBERS WITH A CONCEALED LOCK T CONNECTORDocument14 pagesCONNECT TIMBERS WITH A CONCEALED LOCK T CONNECTORmilivoj ilibasicNo ratings yet

- Polycrystalline Diamond - PCD Tools - Sigma Toolings, Fine Boring Tools, Cutting Tools ManufacturerDocument3 pagesPolycrystalline Diamond - PCD Tools - Sigma Toolings, Fine Boring Tools, Cutting Tools ManufacturerSigma ToolingsNo ratings yet

- HBS en Technical Data SheetDocument20 pagesHBS en Technical Data SheetManistaNo ratings yet

- Essential guide to welding strips, fluxes and wires for electroslag and submerged arc applicationsDocument36 pagesEssential guide to welding strips, fluxes and wires for electroslag and submerged arc applicationssanketpavi21No ratings yet

- HBS en Technical Data SheetDocument14 pagesHBS en Technical Data SheetJonathanFallasNo ratings yet

- Full Threaded Screw With Cylindrical Head: TensionDocument24 pagesFull Threaded Screw With Cylindrical Head: TensionSichen DongNo ratings yet

- Comparison of Pipe Lengths CS & SSDocument2 pagesComparison of Pipe Lengths CS & SSSumantra ChattopadhyayNo ratings yet

- Reinforcement Steel WorksDocument28 pagesReinforcement Steel WorksPooja PawarNo ratings yet

- 12 TerminalDocument1 page12 Terminalgrhvg_mct8224No ratings yet

- HBS SOFTWOOD-en-technical-data-sheetDocument4 pagesHBS SOFTWOOD-en-technical-data-sheetKenan AvdusinovicNo ratings yet

- KVS Diaphragm Valves Technical SpecificationsDocument8 pagesKVS Diaphragm Valves Technical SpecificationsThinh Chu100% (1)

- Shear StudDocument7 pagesShear StudcongtubatdaNo ratings yet

- EN10025 - Steel Grades SpecificationsDocument6 pagesEN10025 - Steel Grades SpecificationsFYNo ratings yet

- British Steel Product Range BrochureDocument128 pagesBritish Steel Product Range BrochureHari PrasadNo ratings yet

- Anchor Channel Typical Product Catalogue 2019.4.9 PDFDocument43 pagesAnchor Channel Typical Product Catalogue 2019.4.9 PDFSultana KhanumNo ratings yet

- Bahra Cables & Busbars IntroductionDocument4 pagesBahra Cables & Busbars IntroductionSalmanNo ratings yet

- Ficha Tecnica E - McmiDocument9 pagesFicha Tecnica E - McmiTECNOINDUSTRIASNo ratings yet

- KIRII CeilingSuspensionSystemDocument7 pagesKIRII CeilingSuspensionSystemCLENTH FLORentinoNo ratings yet

- About WELDA Anchor PlateDocument1 pageAbout WELDA Anchor PlateFircijevi KurajberiNo ratings yet

- Conveyor Chain 102 0 101Document2 pagesConveyor Chain 102 0 101ayrtonNo ratings yet

- R-Series Coriolis Flow Density MetersDocument16 pagesR-Series Coriolis Flow Density MetersMojtaba AdhamiNo ratings yet

- 2300JKVDocument44 pages2300JKVapi-3756260100% (1)

- Lock T Evo - en - 02-20 PDFDocument10 pagesLock T Evo - en - 02-20 PDFmilivoj ilibasicNo ratings yet

- Jf'Ol TBQJ'LK: Underwater Mateable Miniature ConnectorsDocument6 pagesJf'Ol TBQJ'LK: Underwater Mateable Miniature ConnectorsJonathan RiveraNo ratings yet

- Totem Burrs Catalogue 2015Document34 pagesTotem Burrs Catalogue 2015bhuvneshNo ratings yet

- E Mcqi2Document13 pagesE Mcqi2EloNo ratings yet

- SCF 1 - 96Document96 pagesSCF 1 - 96GILBERTO ALTUNARNo ratings yet

- 2-Pole-LES-50Hz.pdfDocument66 pages2-Pole-LES-50Hz.pdfhrga.branzbsd55No ratings yet

- 1vap428831-Db SCBDocument4 pages1vap428831-Db SCBHoon MiewJieNo ratings yet

- 3-1 Steel-BarsDocument29 pages3-1 Steel-BarsKarl Jade LabucayNo ratings yet

- Modular terminal blocks and plug-in connection solutionsDocument1 pageModular terminal blocks and plug-in connection solutionssieged_rj3165No ratings yet

- Leveling Bases and Anti-Vibration HandlesDocument10 pagesLeveling Bases and Anti-Vibration HandlesK Mohana PraneshNo ratings yet

- 10 TerminalDocument1 page10 Terminalgrhvg_mct8224No ratings yet

- m705 grn360 Kv20series20flyDocument2 pagesm705 grn360 Kv20series20flyKek Siang MingNo ratings yet

- Seamless Cold Drawn Precision Tubes According To EN-10305-1 (DIN 2391) E235+C/+N (St. 35 BK/NBK) E355+C/+N (ST 52 BK / NBK)Document32 pagesSeamless Cold Drawn Precision Tubes According To EN-10305-1 (DIN 2391) E235+C/+N (St. 35 BK/NBK) E355+C/+N (ST 52 BK / NBK)jean bouNo ratings yet

- Strap Wrench RidgidDocument1 pageStrap Wrench Ridgidroy sihalohoNo ratings yet

- Catalogue of Products Ekoplastik SystemDocument8 pagesCatalogue of Products Ekoplastik SystemDeuk Yun KwonNo ratings yet

- LT32046Document4 pagesLT32046Bry MoralesNo ratings yet

- Kaiser Aluminum Hard Alloy Drawn Seamless Tube Capabilities PDFDocument7 pagesKaiser Aluminum Hard Alloy Drawn Seamless Tube Capabilities PDFanhthoNo ratings yet

- 1.1 - Distribution Deadend-Suspension Cat D-DS - 200108Document4 pages1.1 - Distribution Deadend-Suspension Cat D-DS - 200108Ali KhaniNo ratings yet

- SDL D (Plinth Beam)Document14 pagesSDL D (Plinth Beam)SURAJ SINHANo ratings yet

- 77e5-B005 (Hydraulic Cylinder)Document4 pages77e5-B005 (Hydraulic Cylinder)Sandeep JoshiNo ratings yet

- E Mcqi2Document11 pagesE Mcqi2Fernando GómezNo ratings yet

- Schedule of Quantity - Proposal Schedule of Quantity - EngineeringDocument1 pageSchedule of Quantity - Proposal Schedule of Quantity - EngineeringSumantra ChattopadhyayNo ratings yet

- Reinforced Angle Brackets For Buildings: StrengthDocument4 pagesReinforced Angle Brackets For Buildings: StrengthKenan AvdusinovicNo ratings yet

- THG Hooks Forged Hooks Catalogue Sheet PDFDocument5 pagesTHG Hooks Forged Hooks Catalogue Sheet PDFjhonNo ratings yet

- THG Hooks Forged Hooks Catalogue SheetDocument5 pagesTHG Hooks Forged Hooks Catalogue SheetjhonNo ratings yet

- CMK2 Series Specifications・How to order・Dimensions (2MB)Document114 pagesCMK2 Series Specifications・How to order・Dimensions (2MB)Moch ChoezainiNo ratings yet

- Heavy-Duty Cable Cutters: 718F, 704, 705 and 706Document1 pageHeavy-Duty Cable Cutters: 718F, 704, 705 and 706Eslam SadekNo ratings yet

- Industrial Cable Glands Selection GuideDocument6 pagesIndustrial Cable Glands Selection GuideProcurement PardisanNo ratings yet

- IAC Acoustic Louvres 6ppDocument6 pagesIAC Acoustic Louvres 6ppSantiago J. ramos jrNo ratings yet

- 8 TerminalDocument1 page8 Terminalgrhvg_mct8224No ratings yet

- Acoples Lovejoy CS-LS (Jaw)Document1 pageAcoples Lovejoy CS-LS (Jaw)marcelo castilloNo ratings yet

- Advanced Structural DesignDocument22 pagesAdvanced Structural DesignSarvag NarsudeNo ratings yet

- Sample Inspection Report - MMRDADocument45 pagesSample Inspection Report - MMRDATech 5No ratings yet

- Chip Resistors GuideDocument6 pagesChip Resistors Guideh_878236333No ratings yet

- PFERD Tools Main Catalogue Chamfering Grinding Cutting Deburring-581Document1 pagePFERD Tools Main Catalogue Chamfering Grinding Cutting Deburring-581sandi prasetyaNo ratings yet

- (J) LCA (Life Cycle Assessment) of EVP e Engineering Veneer Product Plywood Glued Using A Vacuum Moulding Technology From Green VeneersDocument12 pages(J) LCA (Life Cycle Assessment) of EVP e Engineering Veneer Product Plywood Glued Using A Vacuum Moulding Technology From Green VeneersmedyramdNo ratings yet

- ART. LCA PANELDocument19 pagesART. LCA PANELJonathanFallasNo ratings yet

- Wood Life CycleDocument12 pagesWood Life CyclehecgutzapNo ratings yet

- ART LCA GLULAM BEAMDocument21 pagesART LCA GLULAM BEAMJonathanFallasNo ratings yet

- 2022 - 07 - HBS Plate - UsaDocument11 pages2022 - 07 - HBS Plate - UsaJonathanFallasNo ratings yet

- 2022 - 07 - HBS Plate - UsaDocument11 pages2022 - 07 - HBS Plate - UsaJonathanFallasNo ratings yet

- Transport Engineering Exam QuestionsDocument8 pagesTransport Engineering Exam QuestionssreenathNo ratings yet

- Desain Pondasi 1Document27 pagesDesain Pondasi 1Hendra CenNo ratings yet

- Ready Mix ConcreteDocument2 pagesReady Mix ConcreteALL Best0% (1)

- Buried Box Design To BD 31 (BS 5400 Standard)Document5 pagesBuried Box Design To BD 31 (BS 5400 Standard)mohammed boraNo ratings yet

- Regulators Guide Canal Water DistributionDocument11 pagesRegulators Guide Canal Water DistributionM.E.T EC CIVIL DEPARTMENTNo ratings yet

- 07 Rock Bolts - NZDocument4 pages07 Rock Bolts - NZkevin smithNo ratings yet

- Clotan Steel IBR Brochure DigitalDocument6 pagesClotan Steel IBR Brochure DigitalPieter SteenkampNo ratings yet

- EI2303 Industrial Instrumentation 2Document6 pagesEI2303 Industrial Instrumentation 2Ramanathan SunderNo ratings yet

- Boilers InspectionDocument62 pagesBoilers Inspectionrty288% (16)

- PilingDocument16 pagesPilingMohammad Nadwan Wan Rosli100% (1)

- CodeWalker Collision Material ColoursDocument4 pagesCodeWalker Collision Material ColoursMiASMR eNo ratings yet

- TERRATEC Microtunnelling BrochureDocument5 pagesTERRATEC Microtunnelling BrochureGustavo BenitesNo ratings yet

- Is 883 1994 PDFDocument21 pagesIs 883 1994 PDFkrishnanunniNo ratings yet

- Question Paper Code: X10249: Reg. No.Document4 pagesQuestion Paper Code: X10249: Reg. No.Srikrishnan Dhanaji0% (1)

- SATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionDocument2 pagesSATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionNino Celso AstilleroNo ratings yet

- Elastic and Inelastic Stability of ColumnsDocument19 pagesElastic and Inelastic Stability of Columnsgreen77parkNo ratings yet

- Software Verification: AISC-360-16 Example 004Document4 pagesSoftware Verification: AISC-360-16 Example 004alejandro mantillaNo ratings yet

- Drip Legs Definition Purpose Configuration Selection Installation and Sizing PDFDocument4 pagesDrip Legs Definition Purpose Configuration Selection Installation and Sizing PDFFaizal KhanNo ratings yet

- Laboratory ManualDocument26 pagesLaboratory Manualtg.natasha adawiyah bt tg mohd yusoffNo ratings yet

- Wall-mounted Air Conditioner Specifications and Installation FeaturesDocument3 pagesWall-mounted Air Conditioner Specifications and Installation FeaturesPrimero Valencia LuisNo ratings yet

- 4 Two-Way Floor Slabs 2020Document53 pages4 Two-Way Floor Slabs 2020wasimNo ratings yet

- Beam Deflection Tables - MechaniCalcDocument9 pagesBeam Deflection Tables - MechaniCalcDave TruongNo ratings yet

- Paste Thickener Design and Operation Selected To Achieve Downstream RequirementsDocument23 pagesPaste Thickener Design and Operation Selected To Achieve Downstream RequirementsAlfredo CollantesNo ratings yet

- Soil CharacteristicsDocument2 pagesSoil CharacteristicsCassandra DunnNo ratings yet

- Base Ring AnalysisDocument9 pagesBase Ring Analysisasirul_meNo ratings yet

- Before The National Green Tribunal Southern Zone, Chennai. APPLICATION No. 291 of 2014 (SZ)Document25 pagesBefore The National Green Tribunal Southern Zone, Chennai. APPLICATION No. 291 of 2014 (SZ)Heman ChandarNo ratings yet

- Client: PT Insani Mitrasani Gelam Project: Gelam Production Facility Project Subject: Liquid Line Sizing Ref.: API 14E, GPSA Sec .17Document1 pageClient: PT Insani Mitrasani Gelam Project: Gelam Production Facility Project Subject: Liquid Line Sizing Ref.: API 14E, GPSA Sec .17Elias EliasNo ratings yet

- DIN933 M16x50 PLAINDocument1 pageDIN933 M16x50 PLAINthoavit100% (1)

- ITA-AITES Main Glossary of TermsDocument50 pagesITA-AITES Main Glossary of TermsswhuntNo ratings yet

- Landscape Irrigation Products Catalog: The Intelligent Use of WaterDocument196 pagesLandscape Irrigation Products Catalog: The Intelligent Use of WaterCosmin BonghezNo ratings yet