Professional Documents

Culture Documents

Software Verification: AISC-360-16 Example 004

Uploaded by

alejandro mantillaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Software Verification: AISC-360-16 Example 004

Uploaded by

alejandro mantillaCopyright:

Available Formats

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

AISC-360-16 Example 004

COMPOSITE COLUMN DESIGN

EXAMPLE DESCRIPTION

Determine if the 14-ft.-long encased composite member illustrated below is

adequate for the indicated dead and live loads. The composite member consists of

an ASTM A992 W-shaped section with normal weight (145 lb/ft3) concrete having

a specified compressive strength, fc′ = 5 ksi.

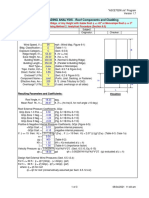

GEOMETRY, PROPERTIES AND LOADING

Member Properties Loading Geometry

W10x45 Height, L = 14 ft

PD = 32.0 kips

E = 29,000 ksi PL = 84.0 kips

Fy = 50 ksi

AISC-360-16 Example 004 - 1

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

TECHNICAL FEATURE OF ETABS TESTED

Compression capacity of composite column design.

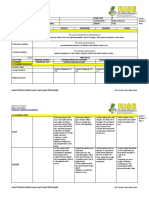

RESULTS COMPARISON

Independent results are referenced from Example I.9 from the AISC Design

Examples, Version 15.0.

Percent

Output Parameter ETABS Independent

Difference

Required Strength Pu (kip) 1,560 1,560 0.00%

Available Strength ΦPn (kip) 2,361.6 2,360 0.07%

COMPUTER FILE: AISC-360-16 EXAMPLE 004.EDB

CONCLUSION

The ETABS results show an acceptable comparison with the independent results.

AISC-360-16 Example 004 - 2

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

HAND CALCULATION

Properties:

Materials:

ASTM A992

E = 29,000 ksi, Fy = 50 ksi, Fu = 62 ksi

5000 psi normal weight concrete

Ec = 3,900 ksi, f c′ = 5 ksi, wconcrete = 145 pcf

Section dimensions and properties:

W10x45

bf = 8.02 in, d= 10.1 in, tf = 0.620 in

As = 13.3 in2, Isx = 248 in4, Isy = 53.4 in4

Concrete area

h1 = 24.0 in, h2 = 24.0 in.

Ag = 24 • 24 = 576 in 2 , Asr = 6.32 in 2 ,

8 • 0.79 =

Moment of inertia of reinforcing rebars about the elastic neutral axis of the composite

section:

πdb4 π(1) 4

I sri

== = 0.0491in.4

64 64

∑i 1=

I sri + ∑ i 1 I sri ei2

n n

=I=

sr

8 • 0.0491 + 6 • 0.79 • 9.52 + 2 • 0.79 • 02 in.4

=

= 428 in.4

Moment of inertia values for the concrete about each axis are determined as:

I cx = I gx − I sx + I srx

244

= − 248 − 428 = 26,972in.4

12

I cy = I gy − I sy + I sry

244

= − 53.4 − 428 = 27,167 in.4

12

AISC-360-16 Example 004 - 3

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

Design for Compression:

Required Compressive Strength:

Pu = 1.2 • PD + 1.6 • PL = 1.2 • 260 + 1.6 • 780 = 1,560 kips

Nominal Compressive Strength:

Pno = Fy • As + Fysr • Asr • 0.85 • f c′Ac

Pno = 50 • 13.3 + 60 • 6.32 + 0.85 • 5 • 556 = 3, 407.2 kips

Weak-axis Elastic Buckling Force:

A + Asr

0.25 + 3 s

C1 = ≤ 0.7

A

g

13.3 + 6.32

0.25 + 3

= ≤ 0.7

576

= 0.352 < 0.9 0.352 controls

EI eff = Es • I sy + Es • I sry + C1 • Ec • I cy

= 29, 000 • 53.4 + 29, 000 • 428 + 0.352 • 3,900 • 27,167

= 51, 255, 458 kip-in 2

Pe = π2 ( EI eff ) ( KL) 2 where K = 1.0 for a pin-ended member

π2 • 51, 255, 458

=Pe = 17,923.44 kips

1.0 • (14.0 • 12) 2

Available Compressive Strength:

Pno 3, 407.2

= = 0.190 < 2.25

Pe 17,923.44

Therefore, use AISC Specification Equation I2-2:

Pno

ΦPn =ΦPno 0.658 Pe =0.75 • 3, 407.2 • (0.658)0.190 =2,360 kips

AISC-360-16 Example 004 - 4

You might also like

- Software Verification: AISC-360-16 Example 001Document4 pagesSoftware Verification: AISC-360-16 Example 001alejandro mantillaNo ratings yet

- Software Verification: AISC-360-16 Example 003Document5 pagesSoftware Verification: AISC-360-16 Example 003alejandro mantillaNo ratings yet

- Software Verification: AISC-360-10 Example 002Document3 pagesSoftware Verification: AISC-360-10 Example 002alejandro mantillaNo ratings yet

- Software Verification: AISC-360-16 Example 002Document3 pagesSoftware Verification: AISC-360-16 Example 002alejandro mantillaNo ratings yet

- Civil Deisgn Report 620118389Document27 pagesCivil Deisgn Report 620118389Tajay BillingsNo ratings yet

- Staad BasicsDocument17 pagesStaad BasicsCindy SisonNo ratings yet

- Knee ConnectionsDocument13 pagesKnee ConnectionsNag RajNo ratings yet

- Structural Analysis and Design: STAAD - Pro Steel Design (FAQ)Document19 pagesStructural Analysis and Design: STAAD - Pro Steel Design (FAQ)Suhas NatuNo ratings yet

- Sfd-Csa-S16-14-60-117 Parte IiDocument58 pagesSfd-Csa-S16-14-60-117 Parte Iiedilberto lopezNo ratings yet

- Staad Analysis For StackDocument39 pagesStaad Analysis For StackABIDEEN BAMNENo ratings yet

- WE-5-2 Fin Plate ConnectionDocument10 pagesWE-5-2 Fin Plate ConnectionPedro AlmeidaNo ratings yet

- Pin Base ModuleDocument16 pagesPin Base ModuleMd Ahsanul KabirNo ratings yet

- 9 - Nested SecondaryDocument5 pages9 - Nested SecondaryTuanQuachNo ratings yet

- WIND LOADING ANALYSIS - Roof Components and CladdingDocument3 pagesWIND LOADING ANALYSIS - Roof Components and CladdingdantevariasNo ratings yet

- Unit 3 Limit State of ServiceabilityDocument55 pagesUnit 3 Limit State of ServiceabilityManoj SharmaNo ratings yet

- Design of BracingDocument4 pagesDesign of Bracingankkeshmundra1No ratings yet

- Platform-Report FinaleDocument24 pagesPlatform-Report FinaleFeroz Khan PatthanNo ratings yet

- Wind Loads Calculations by ASCE7 05 For Any BuildingDocument13 pagesWind Loads Calculations by ASCE7 05 For Any BuildingDaren ModestoNo ratings yet

- ASCE7 Wind For Cladding CN8 Block BDocument4 pagesASCE7 Wind For Cladding CN8 Block BCheng KoNo ratings yet

- Dessign Specifications For Truss PDFDocument1 pageDessign Specifications For Truss PDFDrGanesh KameNo ratings yet

- Seismic Design According To Codes Used in Palestine (Compatibility Mode)Document248 pagesSeismic Design According To Codes Used in Palestine (Compatibility Mode)NguyễnTúSơnNo ratings yet

- Checking Local Deflection of A Member For A Response Spectrum Load CaseDocument4 pagesChecking Local Deflection of A Member For A Response Spectrum Load CaseBilal A Barbhuiya100% (1)

- Wind LoadDocument5 pagesWind LoadPATEL JIGARNo ratings yet

- Software Verification: Example 17Document8 pagesSoftware Verification: Example 17sancloudNo ratings yet

- M1 195 C195 AO34-4-07-X00-MC-0-DD-S164: (MM) (MM) (MM) (MM) (MM) (MM)Document2 pagesM1 195 C195 AO34-4-07-X00-MC-0-DD-S164: (MM) (MM) (MM) (MM) (MM) (MM)innovativekarthiNo ratings yet

- Design of Brick Wall For Ware House:-: 1 DataDocument3 pagesDesign of Brick Wall For Ware House:-: 1 DataSovan PramanickNo ratings yet

- W14x43 To HSS6x6x1 - 2 Moment ConnDocument21 pagesW14x43 To HSS6x6x1 - 2 Moment ConnrajedmaglinteNo ratings yet

- Modul SapDocument77 pagesModul SapAda Bina AvizanNo ratings yet

- The - Thickness - of - Base - Plate - by - The - LRFD - The - I - Section Column - and - ConcreteDocument9 pagesThe - Thickness - of - Base - Plate - by - The - LRFD - The - I - Section Column - and - ConcretejscuencaNo ratings yet

- Wind - Load - ASCE 7-05Document3 pagesWind - Load - ASCE 7-05Siva ShankarNo ratings yet

- International Lateral LoadsDocument38 pagesInternational Lateral LoadsRamilArtates100% (1)

- Wind Analysis For Low-Rise Building, Based On ASCE 7-05 / IBC 2006 / CBC 2007 Input DataDocument5 pagesWind Analysis For Low-Rise Building, Based On ASCE 7-05 / IBC 2006 / CBC 2007 Input DataNAVEED AHMAD NAZNo ratings yet

- 13 - Single ZStrutDocument2 pages13 - Single ZStrutTuanQuachNo ratings yet

- Extended LECTUREDocument21 pagesExtended LECTUREbaraka100% (1)

- ASCE710EDocument40 pagesASCE710ENEONo ratings yet

- Connection DesignDocument33 pagesConnection DesignSri KalyanNo ratings yet

- Breeder House FoundationDocument16 pagesBreeder House FoundationRobbyTeresaNo ratings yet

- Kirby South East Asia: Aisc 2005 AsdDocument3 pagesKirby South East Asia: Aisc 2005 AsdthiệnNo ratings yet

- RAM Connection Input With CommentsDocument6 pagesRAM Connection Input With CommentsAhmed Saeed OokaNo ratings yet

- 14 Lecture Compression Member Laced Column DSSDocument24 pages14 Lecture Compression Member Laced Column DSSDeepak SahNo ratings yet

- Beam Pin Connection, Bsa, BSC (Single Shear Gusset Plate Type)Document6 pagesBeam Pin Connection, Bsa, BSC (Single Shear Gusset Plate Type)vijaystructuralNo ratings yet

- Multi-Tiered Braced Frame Design Based On AISC 341-16: Project: Client: Design By: Job No.: Date: Review byDocument2 pagesMulti-Tiered Braced Frame Design Based On AISC 341-16: Project: Client: Design By: Job No.: Date: Review byRidho ZiskaNo ratings yet

- Beam - Section Classification Is 800-2007Document6 pagesBeam - Section Classification Is 800-2007ranjitNo ratings yet

- Load Case, Load Combination, Modal Case Options. Choose The Load Case To Be DisplayedDocument5 pagesLoad Case, Load Combination, Modal Case Options. Choose The Load Case To Be DisplayedLivia15No ratings yet

- Column Beam Seismic ConnectionDocument8 pagesColumn Beam Seismic ConnectionPrakash Singh RawalNo ratings yet

- Filter Vessel Steel Structure DesignCalculation - Rev - ADocument29 pagesFilter Vessel Steel Structure DesignCalculation - Rev - AsridharNo ratings yet

- StruCad Evolution Getting Started TutorialDocument41 pagesStruCad Evolution Getting Started Tutorialnifty25No ratings yet

- View Topic - LOAD COMBINATION - (0.9) Dead Load + (1Document11 pagesView Topic - LOAD COMBINATION - (0.9) Dead Load + (1Bajrang GuptaNo ratings yet

- Beam DesignDocument7 pagesBeam DesignKasi ViswanathanNo ratings yet

- Flat Slab Punching Shear Check r1Document5 pagesFlat Slab Punching Shear Check r1Usama ChauguleNo ratings yet

- Member Stability CheckDocument3 pagesMember Stability CheckdamindaNo ratings yet

- Bridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-19Document5 pagesBridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-19Luis Alfredo Atencia VillarealNo ratings yet

- Unbraced LengthsDocument8 pagesUnbraced LengthsZoran MilutinovicNo ratings yet

- Slab DesignDocument18 pagesSlab DesignImranSohailNo ratings yet

- DOUBLE ANGLE (Rev.2.00)Document4 pagesDOUBLE ANGLE (Rev.2.00)Harjasa AdhiNo ratings yet

- A1. SGH CanopyDocument41 pagesA1. SGH CanopyMoustafaNo ratings yet

- GRC Design and LoadsDocument4 pagesGRC Design and Loadsmohamed rafiNo ratings yet

- Software Verification: AISC-360-10 Example 001Document4 pagesSoftware Verification: AISC-360-10 Example 001alejandro mantillaNo ratings yet

- Software Verification: AISC-360-16 Example 006Document5 pagesSoftware Verification: AISC-360-16 Example 006alejandro mantillaNo ratings yet

- TS 500-2000 (R2018) Example 002Document4 pagesTS 500-2000 (R2018) Example 002alejandro mantillaNo ratings yet

- EC-4-2004 Example 001Document8 pagesEC-4-2004 Example 001alejandro mantillaNo ratings yet

- ACI 318-08 Example 001Document5 pagesACI 318-08 Example 001RMM100% (1)

- ACI 318-08 Example 001Document5 pagesACI 318-08 Example 001RMM100% (1)

- ACI 318-14 ColumnaDocument4 pagesACI 318-14 ColumnaMoy ReapNo ratings yet

- Software Verification: AISC-360-16 Example 003Document4 pagesSoftware Verification: AISC-360-16 Example 003alejandro mantillaNo ratings yet

- Software Verification: AISC-360-16 Example 003Document4 pagesSoftware Verification: AISC-360-16 Example 003alejandro mantillaNo ratings yet

- Software Verification: AISC-360-16 Example 006Document5 pagesSoftware Verification: AISC-360-16 Example 006alejandro mantillaNo ratings yet

- Software Verification: AISC-360-16 Example 005Document3 pagesSoftware Verification: AISC-360-16 Example 005alejandro mantillaNo ratings yet

- Software Verification: AISC-360-10 Example 001Document4 pagesSoftware Verification: AISC-360-10 Example 001alejandro mantillaNo ratings yet

- CSA-S16-09 Example 001 PDFDocument8 pagesCSA-S16-09 Example 001 PDFMohamed Abo-ZaidNo ratings yet

- AISC DG11 2nd Edition Example 001 PDFDocument12 pagesAISC DG11 2nd Edition Example 001 PDFMohamed Abo-ZaidNo ratings yet

- AISC DG31 Example 004Document15 pagesAISC DG31 Example 004alejandro mantillaNo ratings yet

- EC-4-2004 Example 001Document8 pagesEC-4-2004 Example 001alejandro mantillaNo ratings yet

- Software Verification: AISC-360-10 Example 002Document9 pagesSoftware Verification: AISC-360-10 Example 002Mohamed Abo-ZaidNo ratings yet

- BS-5950-90 Example 001Document7 pagesBS-5950-90 Example 001alejandro mantillaNo ratings yet

- AISC DG31 Example 003Document14 pagesAISC DG31 Example 003alejandro mantillaNo ratings yet

- AISC DG02 Example 002Document6 pagesAISC DG02 Example 002f tshNo ratings yet

- AISC DG02 Example 004 PDFDocument11 pagesAISC DG02 Example 004 PDFMohamed Abo-ZaidNo ratings yet

- AISC DG02 Example 003 PDFDocument7 pagesAISC DG02 Example 003 PDFMohamed Abo-ZaidNo ratings yet

- Software Verification: AISC DG02 Example 001Document5 pagesSoftware Verification: AISC DG02 Example 001f tshNo ratings yet

- NetKey Guide PDFDocument10 pagesNetKey Guide PDFMohamed Abo-ZaidNo ratings yet

- Welcome To ETABSDocument59 pagesWelcome To ETABSalejandro mantilla100% (1)

- CSiXRevit ManualDocument102 pagesCSiXRevit Manualalejandro mantillaNo ratings yet

- Next-Generation Densifier: Cure+Document2 pagesNext-Generation Densifier: Cure+Froilan EspinosaNo ratings yet

- Pipe Rolers and SupportDocument16 pagesPipe Rolers and SupportAhmed YousriNo ratings yet

- Experiment 9: Direct Titration of Lead With Eriot and Edta SynopsisDocument2 pagesExperiment 9: Direct Titration of Lead With Eriot and Edta SynopsisAhmed AliNo ratings yet

- Abstrak GranitDocument2 pagesAbstrak GranitAhmad Alam Faizal HasibuanNo ratings yet

- Experiment 8: Properties of Organic Compounds With Carbonyl GroupDocument7 pagesExperiment 8: Properties of Organic Compounds With Carbonyl GroupMarita AlcansadoNo ratings yet

- IDFL Test Summary - Air Permeability A4Document1 pageIDFL Test Summary - Air Permeability A4Keith WilsonNo ratings yet

- 241 Lecture 12Document25 pages241 Lecture 12Lissa HannahNo ratings yet

- Specimen MS - Paper 1 OCR Chemistry As-LevelDocument17 pagesSpecimen MS - Paper 1 OCR Chemistry As-LevelAbdullah HassanyNo ratings yet

- Module 3 Chm02L Physical and Chemical Changes - RevisedDocument9 pagesModule 3 Chm02L Physical and Chemical Changes - RevisedemmanNo ratings yet

- Maintenance Tips On OilDocument12 pagesMaintenance Tips On OilAndrea StoneNo ratings yet

- Murex Oxy Cutting Poster 2008 PDFDocument1 pageMurex Oxy Cutting Poster 2008 PDFPCNo ratings yet

- USD Method Wall Footing Design in Excel SheetDocument11 pagesUSD Method Wall Footing Design in Excel SheetABAMELANo ratings yet

- JAMB Chemistry Past Question 1983 2004Document119 pagesJAMB Chemistry Past Question 1983 2004iamprecious2allNo ratings yet

- Vol 31 PhotochemistryDocument69 pagesVol 31 PhotochemistryRicardo Gamboa CastellanosNo ratings yet

- VMS WetarDocument24 pagesVMS WetarErwin AnshariNo ratings yet

- Space and MaterialityDocument12 pagesSpace and MaterialitySoupriti DasNo ratings yet

- Grade 8, Quarter 3Document39 pagesGrade 8, Quarter 3Leisor Euqirdnam Oyacnub94% (16)

- Effect of Si, Cu and Processing Parameters On Al-Si-Cu HPDC CastingsDocument24 pagesEffect of Si, Cu and Processing Parameters On Al-Si-Cu HPDC Castingskt rajaNo ratings yet

- Cambridge IGCSE: Combined Science 0653/42Document24 pagesCambridge IGCSE: Combined Science 0653/42Hin Wa LeungNo ratings yet

- BS en 14692-2017 - TC - (2020-08-27 - 08-40-55 Am) PDFDocument28 pagesBS en 14692-2017 - TC - (2020-08-27 - 08-40-55 Am) PDF梁山伯No ratings yet

- Nature and The Antiquity of Ancient Metallurgical Slags Found in Rajasthan and GujaratDocument5 pagesNature and The Antiquity of Ancient Metallurgical Slags Found in Rajasthan and GujaratlfilipNo ratings yet

- Rotating Fatigue PDFDocument2 pagesRotating Fatigue PDFMia FarhanaNo ratings yet

- Surface & Coatings Technology: J. VetterDocument28 pagesSurface & Coatings Technology: J. VetterAlireza BagherpourNo ratings yet

- Nano DeBeeDocument2 pagesNano DeBeeCarmen RaveNo ratings yet

- Heat and Mass Transfer of Single Droplet Particle DryingDocument9 pagesHeat and Mass Transfer of Single Droplet Particle DryingLiliam Teresita Manrique DelgadoNo ratings yet

- Reactivity Series QPDocument5 pagesReactivity Series QPSalman Farsi TaharatNo ratings yet

- Nano SensorsDocument16 pagesNano SensorsAnkusjNo ratings yet

- Blocks & M Sand RegisterDocument2 pagesBlocks & M Sand Registersurendra kumarNo ratings yet

- ChemistryPaper FullDocument20 pagesChemistryPaper FullChanderpal BarupalNo ratings yet

- Answers To End-Of-Chapter Questions For Chapter 2, Basic IdeasDocument2 pagesAnswers To End-Of-Chapter Questions For Chapter 2, Basic IdeasAliNo ratings yet

- A Welder’s Handbook to Robotic ProgrammingFrom EverandA Welder’s Handbook to Robotic ProgrammingRating: 5 out of 5 stars5/5 (3)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Evil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityFrom EverandEvil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (3)

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesFrom EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesRating: 2.5 out of 5 stars2.5/5 (3)

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- How to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionFrom EverandHow to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionRating: 3.5 out of 5 stars3.5/5 (129)

- Arduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!From EverandArduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!Rating: 3 out of 5 stars3/5 (1)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- ChatGPT: The Future of Intelligent ConversationFrom EverandChatGPT: The Future of Intelligent ConversationRating: 3.5 out of 5 stars3.5/5 (8)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Create Profitable Side Hustles with Artificial IntelligenceFrom EverandCreate Profitable Side Hustles with Artificial IntelligenceNo ratings yet

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)