100% found this document useful (8 votes)

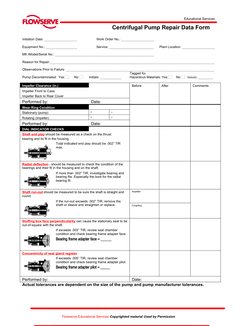

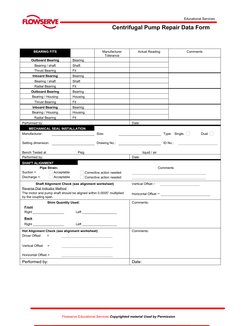

3K views2 pagesCentrifugal Pump Repair Data Form: Performed By: Date

Repair data form for pumps created by Flowserve

Uploaded by

Gerardo HgCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

100% found this document useful (8 votes)

3K views2 pagesCentrifugal Pump Repair Data Form: Performed By: Date

Repair data form for pumps created by Flowserve

Uploaded by

Gerardo HgCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd