100% found this document useful (1 vote)

610 views22 pagesMaintenance of Pumps: Hammad Akber GTE

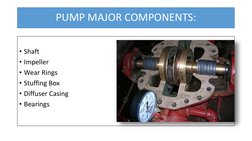

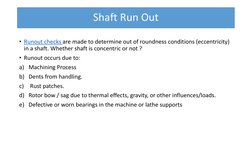

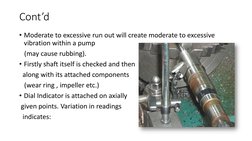

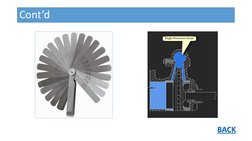

The document discusses maintenance of pumps. It outlines the major components of a pump that require maintenance including the shaft, impeller, wear rings, stuffing box, diffuser casing, and bearings. It describes various types of maintenance that can be performed such as preventative, predictive, periodic, and breakdown maintenance. Key maintenance activities discussed include checking shaft runout, balancing and float checking, measuring wear ring clearances, inspecting bearings, performing shaft alignment, and inspecting other components like the impeller, mechanical seal, gland packing, relief valve, and pump element. The goal of maintenance is to improve system reliability and prevent failures by closely monitoring pump components for issues.

Uploaded by

Zaidi OktariCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

610 views22 pagesMaintenance of Pumps: Hammad Akber GTE

The document discusses maintenance of pumps. It outlines the major components of a pump that require maintenance including the shaft, impeller, wear rings, stuffing box, diffuser casing, and bearings. It describes various types of maintenance that can be performed such as preventative, predictive, periodic, and breakdown maintenance. Key maintenance activities discussed include checking shaft runout, balancing and float checking, measuring wear ring clearances, inspecting bearings, performing shaft alignment, and inspecting other components like the impeller, mechanical seal, gland packing, relief valve, and pump element. The goal of maintenance is to improve system reliability and prevent failures by closely monitoring pump components for issues.

Uploaded by

Zaidi OktariCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd