Professional Documents

Culture Documents

CEPCO PC Poles and PHC Piles structural details

Uploaded by

Anonymous eCD5ZROriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CEPCO PC Poles and PHC Piles structural details

Uploaded by

Anonymous eCD5ZRCopyright:

Available Formats

Concrete Engineering Products Berhad

(Co. No. 88143-P)

CEPCO PC Poles

Structural Details

Concrete Engineering Products Berhad

(Co. No. 88143-P)

HEAD OFFICE

Tingkat 22, Menara Promet, Jalan Sultan Ismail,

P.O. Box 11919, 50762 Kuala Lumpur.

Tel: +6 (03) 2144 1066 Fax: +6 (03) 2144 4885

SG PETANI FACTORY &

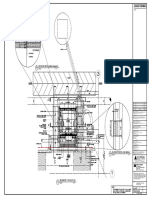

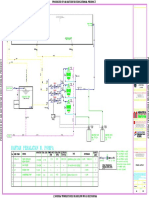

WIRE ARRANGEMENT DRAWING

NORTHERN BRANCH SALES OFFICE

Lot 63, Bakar Arang Industrial Estate,

08000 Sungai Petani, Kedah.

Tel: +6 (04) 421 0891, 421 5587, 422 3548

Fax: +6 (04) 422 1263

PASIR GUDANG FACTORY &

SOUTHERN BRANCH SALES OFFICE

PLO 337, Jalan Suasa,

Pasir Gudang Industrial Estate,

81700 Pasir Gudang, Johor.

Tel: +6 (07) 251 1048, 251 1050, 252 3110

Fax: +6 (07) 251 4066

SECTIONAL DRAWING AT G.L.

RAWANG FACTORY

PT 643, Batu 20, Jalan Ipoh,

48000 Rawang, Selangor Darul Ehsan.

STRUCTURAL DRAWINGS

Tel: +6 (03) 6091 4201, 6091 4314

Fax: +6 (03) 6091 4287

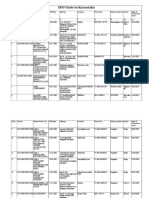

STANDARD POLE PROPERTIES

Dimensions PC Wire NT Wire Design

(Nos.) (6.0 mm Ø) Embedded Design Nominal NILAI FACTORY

Pole Length Top End Bottom End Bending

Length (m) Load Weight Lot 7106, Kaw. Perindustrian Nilai,

Marking (m) Diameter Diameter Moment

7.1Ø 9.0Ø L1 L2 EL (kN) (kg)

L DT (mm) DB (mm) (kg-m) 71800 Nilai, Negeri Sembilan.

7.5M-1.1 KN 7.5 100 175 4 - 4.0 - 1.30 1.1 650 220 Tel: +6 (06) 799 2841, 799 2842

7.5M-2.0 KN 7.5 140 240 4 - 4.0 - 1.30 2.0 1190 350 Fax: +6 (06) 799 2839

9.0M-2.0 KN 9.0 140 260 4 - 5.0 3.5 1.50 2.0 1450 450

10M-5.0 KN 10.0 190 323

Poles of other specifications can be manufactured on order

- 8 4.0 - 1.70 5.0 4030 780

SIRIM

CERTIFIED TO MS ISO

9001:2000

Prestressed Spun

Registration No. AR0126,

AR0318, AR0989 &

AR0367

Concrete Piles and Poles

Concrete Engineering Products Berhad

(Co. No. 88143-P)

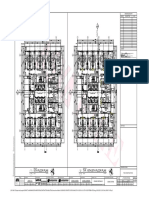

CEPCO PHC Piles CEPCO PHC Piles CEPCO PHC Piles

Structural Details Structural Properties (Grade 80) Typical Connection Details

REINFORCEMENT DETAILS WELDED JOINT DETAIL CLASS A ( Effective Prestress ≥ 4.0 N/mm 2 ) Outer

HT REINFORCEMENT DETAILS

Outer Moment Calculated *Allowable Dia. of CEPCO PHC Piles H

Wall Length PC Bar Area of Nominal Effective Pile D (mm)

Diameter of Inertia Bending Moment Axial Diam L

Thickness L Concrete Weight Prestress (mm) Numbers

D Diam Num Area Concrete Cracking Ultimate Load (mm) (mm)

(mm) (m) (cm2) (kg/m) (N/mm2)

(mm) (mm) (pcs) (cm2) (cm4) (t-m) (t-m) (t) 250 15 4 600 75

300 60 6-12 7.1 6 2.40 452 34,608 2.1 3.5 85 118 4.9 300 15 5 600 75

350 15 6 750 75

350 60 6-12 7.1 6 2.40 547 59,925 2.8 4.1 104 142 4.1

400 20 4 900 75

400 65 6-12 7.1 8 3.20 684 99,577 4.2 6.3 129 178 4.4

450 20 5 900 75

450 70 6-12 7.1 10 4.00 836 155,956 6.0 8.9 158 217 4.5

500 20 6 1050 75

500 80 6-12 7.1 12 4.80 1,056 241,199 8.1 11.8 200 274 4.3 600 20 7 1200 75

600 90 6-12 9.0 12 7.68 1,442 483,427 14.6 22.7 270 375 4.9 700 25 7 1350 75

800 25 8 1500 75

CLASS B ( Effective Prestress ≥ 5.0 N/mm 2 )

900 25 9 1650 75

Outer Moment Calculated *Allowable 1000 25 10 1800 75

Wall Length PC Bar Area of Nominal Effective

Diameter of Inertia Bending Moment Axial

Thickness L Concrete Weight Prestress NOTES:-

D Diam Num Area Concrete Cracking Ultimate Load 1. The above recommendation is applicable for standard spun piles not

(cm2) (N/mm2)

(mm)

(mm) (m)

(mm) (pcs) (cm2) (cm4) (t-m) (t-m) (t)

(kg/m)

Selection of Pile Hammer 2.

subjected to tensile load.

In-situ con crete plug for marine piles has to be designed based on

250 55 6-12 7.1 6 2.40 337 17,289 1.5 3.0 62 88 6.3 required loading.

300 60 6-12 7.1 7 2.80 452 34,608 2.3 4.1 84 118 5.6

350 70 6-15 7.1 9 3.60 616 64,115 3.5 6.2 115 160 5.3

400 80 6-15 9.0 8 5.12 804 109,378 5.4 10.1 149 209 5.8

450 80 6-15 9.0 8 5.12 930 166,570 6.8 11.4 174 242 5.1

500 90 6-15 9.0 10 6.40 1,159 255,324 9.4 15.8 217 301 5.1

600 100 6-15 9.0 14 8.96 1,571 510,509 16.0 26.5 293 408 5.2

9.0 / 20 / 12.80/

700 110 6-36 2,039 918,012 25.7 43.5 379 530 5.6

10.7 14 12.60

800 120 6-36 10.7 18 16.20 2,564 1,527,870 37.8 63.9 475 666 5.7

900 130 6-36 10.7 20 18.00 3,145 2,397,074 50.1 79.9 587 818 5.2 TYPICAL ARRANGEMENT OF PILE

1000 140 6-36 10.7 24 21.60 3,782 3,589,571 67.5 106.5 706 983 5.2 CUSHION BLOCKS

WELDED JOINT DETAIL CLASS C ( Effective Prestress ≥ 7.0 N/mm 2 )

RECOMMENDED HAMMER SIZES

Outer Moment Calculated *Allowable

Wall Length PC Bar Area of Nominal Effective

Diameter of Inertia Bending Moment Axial Hydraulic Hammer Weight

Thickness L Concrete Weight Prestress Pile 3T 3T - 5T 7T - 9T 9T - 12T 12T - 16 T 16T - 20T

(tons)

D Diam Num Area Concrete Cracking Ultimate Load Diameter (mm)

(mm) (m) (cm2) (kg/m) (N/mm2)

(mm) (mm) (pcs) (cm2) (cm4) (t-m) (t-m) (t) 250, 300 X

400 80 6-15 9.0 12 7.68 804 109,378 6.7 15.1 144 209 8.1 350 X

450 80 6-15 9.0 12 7.68 930 166,570 8.4 17.0 169 242 7.2 400 X

450 X X

500 90 6-15 9.0 16 10.24 1,159 255,324 12.1 25.2 209 301 7.6

500 X

9.0/ 20/ 12.80/

600 100 6-30 1,571 510,509 19.3 37.9 286 408 7.1 600 X X

10.7 14 12.60

700 X X

9.0 / 28/ 17.92/

700 110 6-36 2,039 918,012 31.0 62.1 368 530 7.6 800 X X

10.7 20 18.00

DETAIL ‘Y’ 800 120 6-36 10.7 24 21.60 2,564 1,527,870 44.0 85.2 466 666 7.3 900 X

1000 X

a = EFFECTIVE THROAT THICKNESS 900 130 6-36 10.7 28 25.20 3,145 2,397,074 59.8 111.8 573 818 7.0

PLUS 2mm CORROSION ALLOWANCE Range of Working Load (Tonne) 40-60 40-140 80-230 140-320 200-420 280-500

1000 140 6-36 10.7 36 32.40 3,782 3,589,571 83.5 159.7 685 983 7.4

NOTES:-

Note **** In compliance with MS 1314 : Part 4 : 2004 – Precast Concrete Piles (subject to change without prior notice) 1. The above table gives the general recommendation for hydraulic hammer sizes.

& modified to suit BS 8004 : 1986 – Code of Practice for Foundations 2. The actual hammer selection will depend on the pile length, bearing capacity and ground conditions.

and also BS 8110 : 1985 – Structural use of Concrete

You might also like

- Cepco Brochure 2017Document2 pagesCepco Brochure 2017siranepNo ratings yet

- Official Website Department of Occupational Safety and Health - Steam Boiler Manufacturer CompanyDocument1 pageOfficial Website Department of Occupational Safety and Health - Steam Boiler Manufacturer CompanyHaziqNo ratings yet

- Pantech Group - One-Stop Center for Pipes, Valves, FittingsDocument148 pagesPantech Group - One-Stop Center for Pipes, Valves, Fittingslandworth2450No ratings yet

- Business Unit: Pipe Rack Full Depth Slab Double Tee Box GriderDocument3 pagesBusiness Unit: Pipe Rack Full Depth Slab Double Tee Box GriderFardzanela SuwartoNo ratings yet

- Brosur Wika PDFDocument17 pagesBrosur Wika PDFbramNo ratings yet

- PERODUADocument4 pagesPERODUAAmirul AimanNo ratings yet

- Construction issue at Jacobs Engineering Singapore Pte LtdDocument1 pageConstruction issue at Jacobs Engineering Singapore Pte LtdLhagva DalaibatNo ratings yet

- Datalogic-1100726326-Cap 60x60Document2 pagesDatalogic-1100726326-Cap 60x60ShanmugamNo ratings yet

- Email ListDocument300 pagesEmail ListDaniel XiaoNo ratings yet

- Pelan Aim Gem EntDocument1 pagePelan Aim Gem EntwanzzNo ratings yet

- Parklinks North Tower Landscape Design PlansDocument1 pageParklinks North Tower Landscape Design PlansCarl AgomaaNo ratings yet

- Girder PDFDocument1 pageGirder PDFCarl AgomaaNo ratings yet

- ISO 90012015 ISO 140012015 ISO 450012018 (Florence, Hanover, Midway, AlcoTec)Document6 pagesISO 90012015 ISO 140012015 ISO 450012018 (Florence, Hanover, Midway, AlcoTec)Jeisson trujilloNo ratings yet

- M.Cop: BLOW-UP DETAIL (Metal Support)Document23 pagesM.Cop: BLOW-UP DETAIL (Metal Support)Ken John KuroshimaNo ratings yet

- Name of Company Place Production Contact Person: Adani Electricity (Previous Green)Document100 pagesName of Company Place Production Contact Person: Adani Electricity (Previous Green)Anand Venugopal MenonNo ratings yet

- Orange BOOK 2019-Compressed CompressedDocument258 pagesOrange BOOK 2019-Compressed CompressedmaxNo ratings yet

- S-PRB1-101Document1 pageS-PRB1-101Mike Luis VillaflorNo ratings yet

- List of Professional EngineersDocument66 pagesList of Professional EngineersabdulradhiaqilNo ratings yet

- CompDocument4 pagesCompsyuhaimi82No ratings yet

- TPIB Panel Workshop Revised 20190711Document3 pagesTPIB Panel Workshop Revised 20190711greatteacher87No ratings yet

- Majikan Job Fair N9 2022Document26 pagesMajikan Job Fair N9 2022Haziq “AjiBoy” MhnBzNo ratings yet

- 971 Japanese Company in MalaysiaDocument278 pages971 Japanese Company in MalaysiaWan HazlizamNo ratings yet

- ESAB ISO CertificateDocument6 pagesESAB ISO CertificateAbhiram C AnilNo ratings yet

- Kayu GetahDocument2 pagesKayu GetahJuliana HarunNo ratings yet

- Jinko Location MapDocument1 pageJinko Location MapColourful PelangiNo ratings yet

- 06 KRC P1 Gen 06Document1 page06 KRC P1 Gen 06Dhieyasna IbnuNo ratings yet

- Invoice KBC IlanGODocument1 pageInvoice KBC IlanGOIzhar AminuddinNo ratings yet

- List of Professional Engineers No Name Contact & Email EmployerDocument66 pagesList of Professional Engineers No Name Contact & Email Employervictoria lohNo ratings yet

- ASP-mvac-dwg-th-ou-1 - Layout Prinsip Outdoor Unit Type e Townhouse - r00Document1 pageASP-mvac-dwg-th-ou-1 - Layout Prinsip Outdoor Unit Type e Townhouse - r00Chandra SautraNo ratings yet

- World Leader in Sophisticated Packaging SystemsDocument12 pagesWorld Leader in Sophisticated Packaging SystemsYOGI 420No ratings yet

- Ilan Group Operation Enterprise: Imran AminuddinDocument1 pageIlan Group Operation Enterprise: Imran AminuddinIzhar AminuddinNo ratings yet

- KVDTDocument1 pageKVDTatokkuNo ratings yet

- PSG Wise Permanent Vendor List 31-12-2016Document58 pagesPSG Wise Permanent Vendor List 31-12-2016kumarneerajNo ratings yet

- AS3 ARCHI 120.70-5th Storey PlanDocument1 pageAS3 ARCHI 120.70-5th Storey Plan陳佳玲No ratings yet

- Do You Know Your Local Distributor? Search Results: Aaa Hydraulics (India) PVT - LTD, Am Trident Tech PVT LTDDocument4 pagesDo You Know Your Local Distributor? Search Results: Aaa Hydraulics (India) PVT - LTD, Am Trident Tech PVT LTDAvijitSinharoyNo ratings yet

- 2nd Day Auto ExpoDocument7 pages2nd Day Auto ExpoTina KhandelwalNo ratings yet

- Kunangojantanprofile CompleteDocument54 pagesKunangojantanprofile CompleteokiNo ratings yet

- EOU Units in Karnataka ListDocument46 pagesEOU Units in Karnataka ListSK Business group100% (1)

- 34 - 36 Electric DrawingDocument206 pages34 - 36 Electric DrawingMohamedAl-gamalNo ratings yet

- List of CompanyDocument8 pagesList of CompanyFaiznaim Jaafar100% (1)

- 03 - ERP-XH-16-224 HRSG Preferred Vendor List - REV00Document3 pages03 - ERP-XH-16-224 HRSG Preferred Vendor List - REV00smartleo_waloNo ratings yet

- VSO With InterchangeDocument1 pageVSO With InterchangeTomi ArfanNo ratings yet

- Inyectoras Horizontales MedianasDocument6 pagesInyectoras Horizontales MedianasAldy MadytiaNo ratings yet

- MehediDocument1 pageMehediNazmul ManikNo ratings yet

- Industrial Training Company Contact ListDocument37 pagesIndustrial Training Company Contact ListJerome Wong75% (4)

- NTPC Barauni - Ballasted - Module Layout - R0Document3 pagesNTPC Barauni - Ballasted - Module Layout - R0Prince MittalNo ratings yet

- Marantz PM-15S1K1G Service ManualDocument51 pagesMarantz PM-15S1K1G Service ManualBon BencavNo ratings yet

- TPIB-Panel-Workshops-2018-01-10 (Done Excel, Pending CC)Document6 pagesTPIB-Panel-Workshops-2018-01-10 (Done Excel, Pending CC)Chyh KunNo ratings yet

- Contact Us - Bumi Armada BerhadDocument1 pageContact Us - Bumi Armada BerhadSergey ManNo ratings yet

- 100% - CD - CUB Warehouse Archi Fit OutDocument42 pages100% - CD - CUB Warehouse Archi Fit OutMEAGAN CHNGNo ratings yet

- Hal Part10Document10 pagesHal Part10Anil SargarNo ratings yet

- Robert PangerapanDocument1 pageRobert Pangerapantyok sajaNo ratings yet

- Purchase Order #: SOR006602 / TOPO009747 ConsigneeDocument2 pagesPurchase Order #: SOR006602 / TOPO009747 Consigneezarul arjunaNo ratings yet

- Easyparcel ERC530802389MYDocument1 pageEasyparcel ERC530802389MYSurie AiniezaNo ratings yet

- Potongan Dudukan FittingDocument1 pagePotongan Dudukan FittingIvan Sitorus ZvNo ratings yet

- Diagram Kolam DewasaDocument1 pageDiagram Kolam DewasaIvan Sitorus ZvNo ratings yet

- NTU 2-Fire Rated Door - FD7ADocument1 pageNTU 2-Fire Rated Door - FD7AADAM LOONo ratings yet

- I Sections - Wide Flange Beams - European HEDocument2 pagesI Sections - Wide Flange Beams - European HEAnonymous eCD5ZRNo ratings yet

- Xbloc Design Guidelines 2014 671 15039173271578936988 PDFDocument24 pagesXbloc Design Guidelines 2014 671 15039173271578936988 PDFlollazzoNo ratings yet

- 9188 Survitec Mooring Rope Facilities Fact File v14Document11 pages9188 Survitec Mooring Rope Facilities Fact File v14Saptarshi BasuNo ratings yet

- I Section Wide Flange EU PDFDocument2 pagesI Section Wide Flange EU PDFAnonymous eCD5ZRNo ratings yet

- BS 648 1964 - Schedule of Weight of Building MaterialDocument50 pagesBS 648 1964 - Schedule of Weight of Building MaterialAnonymous eCD5ZRNo ratings yet

- BS 5328-3 1990 (Withdrawn)Document16 pagesBS 5328-3 1990 (Withdrawn)Anonymous eCD5ZRNo ratings yet

- BS 5328-4-1990 PDFDocument12 pagesBS 5328-4-1990 PDFWayne ChongNo ratings yet

- EUROPEAN WIDE FLANGE BEAMS: Dimensions and PropertiesDocument1 pageEUROPEAN WIDE FLANGE BEAMS: Dimensions and PropertiesAnonymous eCD5ZRNo ratings yet

- 3D View PDFDocument1 page3D View PDFAnonymous eCD5ZRNo ratings yet

- SI - PUB - Bedok Canal SI Report 2015 PDFDocument124 pagesSI - PUB - Bedok Canal SI Report 2015 PDFAnonymous eCD5ZRNo ratings yet

- BS 648 1964 - Schedule of Weight of Building MaterialDocument50 pagesBS 648 1964 - Schedule of Weight of Building MaterialAnonymous eCD5ZRNo ratings yet

- Rolling Contact Phenomena - Kalker PDFDocument84 pagesRolling Contact Phenomena - Kalker PDFAnonymous eCD5ZRNo ratings yet

- Forces On PilesDocument31 pagesForces On PilesAnonymous eCD5ZRNo ratings yet

- Palsticity - Thick CylindersDocument10 pagesPalsticity - Thick CylindersAnonymous eCD5ZRNo ratings yet

- Elements of CFD - Wesseling PDFDocument164 pagesElements of CFD - Wesseling PDFAnonymous eCD5ZRNo ratings yet

- Surge ControlDocument14 pagesSurge Control31jamesNo ratings yet

- 09 KolmDocument44 pages09 Kolmakiakis800No ratings yet

- Elements of CFD - Wesseling PDFDocument164 pagesElements of CFD - Wesseling PDFAnonymous eCD5ZRNo ratings yet

- A Continuum Treatment of GrowthDocument31 pagesA Continuum Treatment of GrowthAnonymous eCD5ZRNo ratings yet

- FEM BatheDocument1,051 pagesFEM BatheAnonymous eCD5ZRNo ratings yet

- Programming The Finite Element Method - I Smith-D Griffiths - Imp PDFDocument478 pagesProgramming The Finite Element Method - I Smith-D Griffiths - Imp PDFAnonymous eCD5ZRNo ratings yet

- Yang 11 PH DDocument242 pagesYang 11 PH DmaxlentiNo ratings yet

- Non-Linear FEM Modelling of Steel Fibre Reinforced Concrete PDFDocument133 pagesNon-Linear FEM Modelling of Steel Fibre Reinforced Concrete PDFAnonymous eCD5ZRNo ratings yet

- Thesis Johannes Van GinkelDocument50 pagesThesis Johannes Van GinkelAnonymous eCD5ZRNo ratings yet

- Hardening and yield surfaces in plasticityDocument15 pagesHardening and yield surfaces in plasticitysujayan2005No ratings yet

- Time Dependent Viscoelastic Rheological Response of Pure, Modified and Synthetic Bituminous BindersDocument47 pagesTime Dependent Viscoelastic Rheological Response of Pure, Modified and Synthetic Bituminous BindersAnonymous eCD5ZRNo ratings yet

- FEM Analysis of Pneumatic-Tire-Sand InteractionsDocument25 pagesFEM Analysis of Pneumatic-Tire-Sand InteractionsAnonymous eCD5ZRNo ratings yet

- Introduction to TensorsDocument410 pagesIntroduction to TensorsAnonymous eCD5ZRNo ratings yet

- Supporting Presentation For Lecturers of Architecture/Civil EngineeringDocument16 pagesSupporting Presentation For Lecturers of Architecture/Civil EngineeringJoshua WalkerNo ratings yet

- 15TH FLOOR & 16-25TH FLOOR TRIBE HOTEL-Layout1Document1 page15TH FLOOR & 16-25TH FLOOR TRIBE HOTEL-Layout1Mark Joey DavidNo ratings yet

- BingDocument5 pagesBingdheaNo ratings yet

- Internship Report On Commercial Building: Project Guide Ms. Mahalakshmi M Assistant ProfessorDocument17 pagesInternship Report On Commercial Building: Project Guide Ms. Mahalakshmi M Assistant ProfessorvenkateshsrinivasanNo ratings yet

- Midas 2021 Men - PSC Box GirdersDocument117 pagesMidas 2021 Men - PSC Box GirdersJin-hwan KimNo ratings yet

- Sse ProfileDocument9 pagesSse ProfilePriyankNo ratings yet

- Islamic ArchitectureDocument37 pagesIslamic ArchitectureUday DokrasNo ratings yet

- Pit Side Wall and Base Slab CalculationDocument2 pagesPit Side Wall and Base Slab CalculationJahid HasnainNo ratings yet

- Pre-Fab Technology For BuildingsDocument74 pagesPre-Fab Technology For BuildingsJayarama Chari100% (2)

- Chapter 3 Types of RoomsDocument24 pagesChapter 3 Types of Roomsnizam100% (1)

- Checklist For Supervision of Reinforced Soil Wall PDFDocument4 pagesChecklist For Supervision of Reinforced Soil Wall PDFChin Thau WuiNo ratings yet

- Contractor Quality Control Plan For Civil WorkDocument6 pagesContractor Quality Control Plan For Civil WorkUday PratapNo ratings yet

- Vocab - City - CountrysideDocument3 pagesVocab - City - CountrysideLinh Ngô ThịNo ratings yet

- Estimate BungalowDocument8 pagesEstimate BungalowJ.P.Almera ArDesignNo ratings yet

- Bar Bending Schedule (BBS) Estimate of Steel in Building ConstructionDocument7 pagesBar Bending Schedule (BBS) Estimate of Steel in Building Constructionဒုကၡ သစၥာNo ratings yet

- Schedule SamyangDocument1 pageSchedule SamyangPT. TUNGGAL PRATAMA GUNAWAN KONTRAKTORNo ratings yet

- Inspection (Singapore)Document54 pagesInspection (Singapore)TAMILNo ratings yet

- National Gypsum Plaster Products (Veneer Systems)Document28 pagesNational Gypsum Plaster Products (Veneer Systems)mtim360No ratings yet

- Astm C14 PDFDocument4 pagesAstm C14 PDFBrahim Rabaj0% (1)

- 1 Gothic Architecture Part IDocument22 pages1 Gothic Architecture Part IesbeeiNo ratings yet

- Market Survey of Interior FurnitureDocument18 pagesMarket Survey of Interior FurnitureCHEEKOTI VIVEKNo ratings yet

- Form Ceklist ProjectDocument2 pagesForm Ceklist ProjectdarsunNo ratings yet

- Burnham Park Master Development PlanDocument3 pagesBurnham Park Master Development Planalex050508No ratings yet

- Main Topics: Important Topics - Professional PracticeDocument2 pagesMain Topics: Important Topics - Professional PracticecuttayNo ratings yet

- Bill of Quantities Construction DocumentDocument26 pagesBill of Quantities Construction Documentkandy saidNo ratings yet

- Combined Footing Design Based On ACI 318-02Document3 pagesCombined Footing Design Based On ACI 318-02reynoldNo ratings yet

- Lecture 1Document17 pagesLecture 1Kaaviyan ThirunyanamNo ratings yet

- Master Architect B V Doshi PDFDocument72 pagesMaster Architect B V Doshi PDFanushaNo ratings yet

- Rental Inspection Checklist TemplateDocument3 pagesRental Inspection Checklist TemplateMaged HumaidNo ratings yet

- Modern Architecture in The Philippines and The Quest For Filipino StyleDocument6 pagesModern Architecture in The Philippines and The Quest For Filipino Styledonna benitoNo ratings yet