0% found this document useful (0 votes)

194 views45 pagesSpur Gear

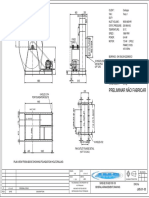

The document describes the spur gear, its parts, and how to draw one. It defines a spur gear as the simplest form of toothed wheel with radial teeth parallel to the axis. It explains how to calculate details like number of teeth, diameters, and dimensions. It outlines the steps to construct a spur gear drawing by first calculating values, then drawing the outer diameter, root diameter, pitch diameter, and bisecting the base circle using the radius to form the gear teeth profile.

Uploaded by

keishasantiagoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

194 views45 pagesSpur Gear

The document describes the spur gear, its parts, and how to draw one. It defines a spur gear as the simplest form of toothed wheel with radial teeth parallel to the axis. It explains how to calculate details like number of teeth, diameters, and dimensions. It outlines the steps to construct a spur gear drawing by first calculating values, then drawing the outer diameter, root diameter, pitch diameter, and bisecting the base circle using the radius to form the gear teeth profile.

Uploaded by

keishasantiagoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd