Professional Documents

Culture Documents

Progressive Cavity Pump F Series - Model N: Technical Characteristics

Uploaded by

PoyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Progressive Cavity Pump F Series - Model N: Technical Characteristics

Uploaded by

PoyaCopyright:

Available Formats

PROGRESSIVE CAVITY PUMP

F Series - Model N

Technical characteristics

Flow rates: up to 60 m3/h

Max Pressure: up to 8 bar (116 psi)

Max working temp: 180° C

Shaft Rotation: ACW

Motor:

o 1.5 kW – 2 poles

o 2.2 kW – 2 poles

o 3 kW – 2 poles

o 4 kW – 2 and 4 poles

o 7.5 kW – 4 poles

o 11 kW – 4 poles

Body pump:

Transmission shaft: pin joint o G25

Seals: Packing seal o SS 304

Motor coupling: CLOSE COUPLED o SS 316

o Flange diam. 160 / 200 / 250 / 300 mm related Stator material: NBR

to the pumps sizes Rotor material:

o Female drive shaft SS 316 / carbon steel with chrome (HCP) o SS 304

o Diam. 19 / 24 / 25 / 28 / 30 / 32 / 35 / 40 mm related o SS 420 B

to the pumps sizes o SS 316

Seko progressive cavity pump FN Series is the ideal solution for the conveying of a great variety of substances, including

chemicals. Thanks to their continuous flow, no vibrations, very high priming, flow reversibility and low pulsation conveyance in

proportion to rotation speed makes it possible to use them in any branch of industry. Seko FN Series pumps have no valves

therefore they are suitable for conveying liquids with suspended solids, or pasty. Suitable for heavy duties services, the most

important application of FN Series pumps is the waste water treatment and in industry. They are employed for the transfer of:

Conveying : raw, primary, secondary sludge

Thickened sludges

Sludges in in filter press

Other industrial applications:

Petrochemistry

Chemical industry as caustic soda, resins, colorants, acid solutions.

Sugar refinery with their products basis of beet, cane sugar

Agriculture

Breeding as animal feed, pasty slurry, biological waste water

Building as colorings, cement, mortar, bentonite

Paper industry as starch, glue

Ship building industry as waste oil, oily bilge water

Fish industry as fish flours, entrails and other cutted fish parts

Mining industry

Drilling

Refinery

Ceramic industry as clayey sludges, lime, glaze

Available on request: pumps with performances up to 48 bar and 9000 l/h and several body pump material configuration to get

the best solution for each process.

1 of 4 Technical data can be changed without notice.

TD_Progressive_Cavity_Pump_F_Series_Model_N_rev.0.1

PROGRESSIVE CAVITY PUMP

F Series - Model N

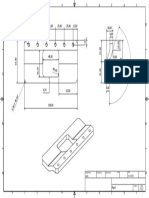

PUMP KEY CODE

2 of 4 Technical data can be changed without notice.

TD_Progressive_Cavity_Pump_F_Series_Model_N_rev.0.1

PROGRESSIVE CAVITY PUMP

F Series - Model N

HYDRAULIC CHARACTERISTICS

Flow Rate

FN Series

Cast Iron

14,5

SS 304

SS 316

+MTV*

at Max Pressure Max Backpressure Electric Motor

Pump Model m 3 /h RPM/1' bar psi [kW / Poles]

F N 0 2 2 V 8 V 0 E 2 C / S 000 0,6 - 2,8 100 - 500 2 29 1,5 / 2

F N 0 2 0 0 5 V 0 E 2 C / S / K 000 1 - 5 80 - 400 2 29 1,5 / 2

F N 0 4 0 0 5 V 0 G 2 C / S / K 000 1 - 5 80 - 400 4 58 2,2 / 2

F N 0 8 2 V 5 V 0 G 2 C / S / K 000 0,5 - 2,5 80 - 400 8 116 2,2 / 2

F N 0 8 0 0 5 V 0 H 2 C / S / K 000 1 - 5 80 - 400 8 116 3 / 2

F N 0 2 0 1 0 V 0 G 2 C / S / K 000 2 - 10 80 - 400 2 29 2,2 / 2

F N 0 4 0 1 0 V 0 H 2 C / S / K 000 2 - 10 80 - 400 4 58 3 / 2

F N 0 8 0 1 0 V 0 I 2 C / S / K 000 2 - 10 80 - 400 8 116 4 / 2

F N 0 3 0 2 0 V 0 I 4 C / S / K 000 4 - 20 80 - 400 3 43,5 4 / 4

F N 0 2 0 2 6 V 0 I 4 C / S / K 000 5 - 26 80 - 400 2 29 4 / 4

F N 0 4 0 4 0 V 0 M 4 C / S / K 000 8 - 40 80 - 400 4 58 7,5 / 4

F N 0 2 0 6 0 V 0 O 4 C / S / K 000 12 - 60 50 - 250 2 29 11 / 4

Monoblock (*) +MTR Models with fix flow rate ( Gear Reducer )

available on request

PUMP HEAD MATERIAL

Material C S K

Rotor SS 420B SS 304 SS 316

Stator NBR-Perburan NBR-Perburan NBR-Perburan

Mech. Seal Sic/Sic/EPDM Mech. Seal Sic/Sic/EPDM Mech. Seal Sic/Sic/EPDM

Seals or or or

Packing seal Packing seal Packing seal

3 of 4 Technical data can be changed without notice.

TD_Progressive_Cavity_Pump_F_Series_Model_N_rev.0.1

PROGRESSIVE CAVITY PUMP

F Series - Model N

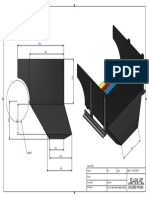

DIMENSIONS

FLANGE

MODEL L1 L2 DN1 DN2 F2 H1 H2 Kg

FN022V8 397 608 40 40 - 102 192 22

FN02005

FN082V5 573 780 50 50 125 102 197 39

FN04005

FN02010

FN04010 704 946 65 65 165 102 202 57

FN08005

FN03020

922 1202 80 80 215 143 278 106

FN08010

FN02026 1002 1282 80 80 215 143 278 109

FN04040 1054 1359 100 100 215 155 312 161

FN02060 1354 1691 125 125 265 170 340 235

ACCESSORIES (on request)

Probe & Thermoregulator Baseplate By pass

4 of 4 Technical data can be changed without notice.

TD_Progressive_Cavity_Pump_F_Series_Model_N_rev.0.1

You might also like

- Service Instructions: SP 1A - SP 5ADocument11 pagesService Instructions: SP 1A - SP 5AMuhammad AlpianNo ratings yet

- Brosur Yuema Gear PumpDocument16 pagesBrosur Yuema Gear PumpHafidz FerdianNo ratings yet

- MPP Side Channel Pump For Low NPSH Methanol Appl PDFDocument3 pagesMPP Side Channel Pump For Low NPSH Methanol Appl PDFAnonymous ua66zYwrpNo ratings yet

- Self-Priming Centrifugal Pumps: Operating RangeDocument20 pagesSelf-Priming Centrifugal Pumps: Operating Rangeajo2402No ratings yet

- Catalogo KSB SPBlocDocument8 pagesCatalogo KSB SPBlocRuddy Fabrizio Galvez Justiniano0% (1)

- Po-So/6.5 Submersible Motor Pumps: SpecificationDocument22 pagesPo-So/6.5 Submersible Motor Pumps: SpecificationRafatNo ratings yet

- 95 Series, Flat Face Coupling (Carbon Steel) Iso-16028 and Htma Standard, PlugDocument2 pages95 Series, Flat Face Coupling (Carbon Steel) Iso-16028 and Htma Standard, PlugSHANENo ratings yet

- Rating 5.4 m3h - 120m - MV 5-24 - 3.7kW-2900rpm-380V-3Ph-50Hz PDFDocument3 pagesRating 5.4 m3h - 120m - MV 5-24 - 3.7kW-2900rpm-380V-3Ph-50Hz PDFTrung TrịnhNo ratings yet

- Datasheet MS1 Seko SpringDocument4 pagesDatasheet MS1 Seko SpringfsiscomanNo ratings yet

- 6 G Flow Series Catalogue - 50HzDocument18 pages6 G Flow Series Catalogue - 50HzIwan KurniawanNo ratings yet

- IFS BJM SK37C DatasheetDocument2 pagesIFS BJM SK37C DatasheetpaachangaNo ratings yet

- Pumps Spec Series2400 8 09Document8 pagesPumps Spec Series2400 8 09Hamatouty TottiNo ratings yet

- Kolmeks Pump Catalogue Low PDFDocument260 pagesKolmeks Pump Catalogue Low PDFsriguruprasathsNo ratings yet

- NKM-G NKP-G: Standardised Enbloc Centrifugal PumpsDocument36 pagesNKM-G NKP-G: Standardised Enbloc Centrifugal PumpsRoberthNo ratings yet

- FT - RF.4 enDocument4 pagesFT - RF.4 enpeter ortega colmenaresNo ratings yet

- RA FittingsDocument16 pagesRA FittingsDejanNo ratings yet

- OIL PIT PUMP FOR TRANSFORMER 63 GPM at 8MDocument5 pagesOIL PIT PUMP FOR TRANSFORMER 63 GPM at 8MRamil LazNo ratings yet

- NORD-Clincher Shaft Mount Ordering GuideDocument1 pageNORD-Clincher Shaft Mount Ordering GuideErc Nunez VNo ratings yet

- A8PO Bent Axis Pumps - IsODocument21 pagesA8PO Bent Axis Pumps - IsOAttral HONo ratings yet

- TESTO ITC KORINNA 28mm Allargato: Monoblock Directional Control ValveDocument132 pagesTESTO ITC KORINNA 28mm Allargato: Monoblock Directional Control ValveHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- ROOFTOP - TEMPBLUE - 20210210 - Opt - Ficha TécnicaDocument4 pagesROOFTOP - TEMPBLUE - 20210210 - Opt - Ficha TécnicaPablo Andres Espin MartinNo ratings yet

- ZAMIL PY Series Installation, Operation & Maintenance ManualDocument33 pagesZAMIL PY Series Installation, Operation & Maintenance Manualambuenaflor67% (9)

- Condensing Unit Vertical Discharge 60 HZ R410A: 36KBTU Model Has A Different GrillDocument1 pageCondensing Unit Vertical Discharge 60 HZ R410A: 36KBTU Model Has A Different GrilljuanNo ratings yet

- Data Sheet F6SS-48 24Document4 pagesData Sheet F6SS-48 24melakuNo ratings yet

- PFHL - 9 Hi - Lo Gear PumpDocument2 pagesPFHL - 9 Hi - Lo Gear PumpTelassin TauilNo ratings yet

- Asco 8344 PDFDocument2 pagesAsco 8344 PDFOsman Lopez SalasNo ratings yet

- O&M Manual - An Series Börger Pump - Rotex - Nord IntegralDocument266 pagesO&M Manual - An Series Börger Pump - Rotex - Nord IntegralRicardo VeraNo ratings yet

- Mad G SeriesDocument4 pagesMad G SeriesKali Dass KMNo ratings yet

- Pumpworks 610-BB3Document6 pagesPumpworks 610-BB3Padmanabhan VenkateshNo ratings yet

- Butterfly Valves - CatalogDocument30 pagesButterfly Valves - CatalogRamzi BEN AHMEDNo ratings yet

- Katalog Produk PompaDocument35 pagesKatalog Produk PompaRiyan SiregarNo ratings yet

- Katalog POMPA ARITA 2022Document30 pagesKatalog POMPA ARITA 2022Washiul RizkiNo ratings yet

- Nimco Monoblock Control ValvesDocument66 pagesNimco Monoblock Control ValvesHui ChenNo ratings yet

- Data Sheet F6SS-30 46Document4 pagesData Sheet F6SS-30 46melakuNo ratings yet

- Pump Catalog 2017 enDocument124 pagesPump Catalog 2017 enBassam AmirNo ratings yet

- Vertical Multistage Centrifugal Pumps CatalogDocument8 pagesVertical Multistage Centrifugal Pumps CatalogAlia MhdNo ratings yet

- HF Alte Portate en 60HzDocument4 pagesHF Alte Portate en 60HzJohn Alfred VillaNo ratings yet

- HF Alte Portate en 60HzDocument4 pagesHF Alte Portate en 60HzJohn Alfred VillaNo ratings yet

- RKP Product Info New Gear Pump En-2006-03Document9 pagesRKP Product Info New Gear Pump En-2006-03Arko RoosNo ratings yet

- Zupcaste Pumpe 2pfDocument13 pagesZupcaste Pumpe 2pfmilokisrNo ratings yet

- 1GSL07M-L4C: Operating DataDocument3 pages1GSL07M-L4C: Operating DataSteve MertzanisNo ratings yet

- John Deere Spraymaster - Centrifugal Pump RepairDocument36 pagesJohn Deere Spraymaster - Centrifugal Pump RepairTim LeeNo ratings yet

- Goulds Pumps: 5"-11" Stainless Steel Submersible TurbineDocument4 pagesGoulds Pumps: 5"-11" Stainless Steel Submersible TurbineMauricio OrtizNo ratings yet

- TB Hydro MIV CatalogueDocument2 pagesTB Hydro MIV CatalogueavinashuklaNo ratings yet

- Positive Displacement Dosing Pump: The Right Dosing ChoiceDocument12 pagesPositive Displacement Dosing Pump: The Right Dosing ChoiceTrungGVNo ratings yet

- Catalogue Ebara FSADocument3 pagesCatalogue Ebara FSAanita abubakarNo ratings yet

- Amrut BrochureDocument19 pagesAmrut BrochureArvind Patel100% (1)

- TDB FHA 50HZ Rev 2Document36 pagesTDB FHA 50HZ Rev 2quangsang1311No ratings yet

- Sodium Chloride TransferDocument4 pagesSodium Chloride Transfer511231103No ratings yet

- Individual Pumps: Variable Displacement Axial Piston Pump Type V60NDocument4 pagesIndividual Pumps: Variable Displacement Axial Piston Pump Type V60Nhamid hoorshadNo ratings yet

- Pedrollo Close Coupled Centrifugal Pump - Semi Open Impeller - NGA PDFDocument5 pagesPedrollo Close Coupled Centrifugal Pump - Semi Open Impeller - NGA PDFSartika Nur AisyahNo ratings yet

- Selfeeder ElectricDocument32 pagesSelfeeder Electricasta seikiNo ratings yet

- Catalog EbaraDocument18 pagesCatalog EbaraEnergi Primer100% (1)

- RF Series: Low Pressure FiltersDocument10 pagesRF Series: Low Pressure FiltersRestu OktapianaNo ratings yet

- Bombas Plasticas MANUAL PDFDocument41 pagesBombas Plasticas MANUAL PDFcapry_cornio@yahoo.com100% (1)

- Sjpsu 37499 BydhmlDocument14 pagesSjpsu 37499 BydhmlLeonardo MartinezNo ratings yet

- Vertical & Horizontal Multistage Pumps - MV & MH SeriesDocument11 pagesVertical & Horizontal Multistage Pumps - MV & MH Seriesluis777_33No ratings yet

- TS 90 100 01Document4 pagesTS 90 100 01Lakee911No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Chute Hopper (New) - 02-DrawingsDocument1 pageChute Hopper (New) - 02-DrawingsPoyaNo ratings yet

- JackDocument1 pageJackPoyaNo ratings yet

- Heavy Duty Electro-Mechanical Linear ActuatorsDocument7 pagesHeavy Duty Electro-Mechanical Linear ActuatorsPoyaNo ratings yet

- User 2/12/2020: Designed by Checked by Approved by Date DateDocument1 pageUser 2/12/2020: Designed by Checked by Approved by Date DatePoyaNo ratings yet

- 17Chute-New Version02Document3 pages17Chute-New Version02PoyaNo ratings yet

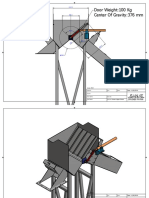

- Door Weight:100 KG Center of Gravity:376 MM: Crusher PayamDocument2 pagesDoor Weight:100 KG Center of Gravity:376 MM: Crusher PayamPoyaNo ratings yet

- Screen Upper Chute JackDocument1 pageScreen Upper Chute JackPoyaNo ratings yet

- Maximum Water Flow CapacitiesDocument5 pagesMaximum Water Flow CapacitiesPoyaNo ratings yet

- DIMER E - Catalogue O Rings - EN PDFDocument43 pagesDIMER E - Catalogue O Rings - EN PDFPoyaNo ratings yet

- BearingDocument34 pagesBearingIrwan SattuNo ratings yet

- Daido Chain CatalogDocument147 pagesDaido Chain CatalogAmanda Rezende100% (1)

- GWPD8Document12 pagesGWPD8PoyaNo ratings yet

- DIMER E - Catalogue O Rings - EN PDFDocument43 pagesDIMER E - Catalogue O Rings - EN PDFPoyaNo ratings yet

- Warman AH Pump BrochureDocument4 pagesWarman AH Pump BrochureLodyNo ratings yet

- Pump Iran Kafkesh 2Document20 pagesPump Iran Kafkesh 2PoyaNo ratings yet

- PCodesDocument1 pagePCodesPoyaNo ratings yet

- لیست آماده تراشDocument1 pageلیست آماده تراشPoyaNo ratings yet

- Evo TestDocument1 pageEvo TestPoyaNo ratings yet

- Pump IranDocument108 pagesPump IranPoyaNo ratings yet

- گزارش ریخته گریDocument1 pageگزارش ریخته گریPoyaNo ratings yet

- فرمول تولید خامDocument1 pageفرمول تولید خامPoyaNo ratings yet

- اولیهDocument1 pageاولیهPoyaNo ratings yet

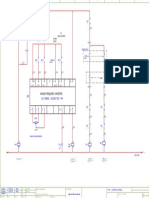

- Main Control SwitchDocument1 pageMain Control SwitchPoyaNo ratings yet

- Burner 1 Burner 2 Burner 3 Burner 4: 27 28 N PE 29 27 30 N PE 31 27 32 N PE 33 27 34 N PE 35Document1 pageBurner 1 Burner 2 Burner 3 Burner 4: 27 28 N PE 29 27 30 N PE 31 27 32 N PE 33 27 34 N PE 35PoyaNo ratings yet

- 1 Project Description 3 Customer: Ed. DWG NO.: 97.07.ELEC Standard Date 10/28/2018Document1 page1 Project Description 3 Customer: Ed. DWG NO.: 97.07.ELEC Standard Date 10/28/2018PoyaNo ratings yet

- Project Description 2 Customer: Combustion Air Fan 3PH / 380V / 11KW Wagon Motor 3PH / 380V /3KWDocument1 pageProject Description 2 Customer: Combustion Air Fan 3PH / 380V / 11KW Wagon Motor 3PH / 380V /3KWPoyaNo ratings yet

- Wagon Out Wagon in Wagon in Reduce SpeedDocument1 pageWagon Out Wagon in Wagon in Reduce SpeedPoyaNo ratings yet

- 2 Project Description 4 CustomerDocument1 page2 Project Description 4 CustomerPoyaNo ratings yet

- Wagon Frequency Inverter 1FI: IN Reduce SpeedDocument1 pageWagon Frequency Inverter 1FI: IN Reduce SpeedPoyaNo ratings yet

- Designing HVAC For Pharmaceutical Research Facilities: ASHRAE JournalDocument5 pagesDesigning HVAC For Pharmaceutical Research Facilities: ASHRAE JournalJose RivasNo ratings yet

- 12 Physics Exemplar Chapter 14Document11 pages12 Physics Exemplar Chapter 14Haarish KrishnamurthyNo ratings yet

- Service Bulletin Trucks: Special Tools, Group 2Document46 pagesService Bulletin Trucks: Special Tools, Group 2mattkidoNo ratings yet

- CH 8 Class 12 Chem PDFDocument12 pagesCH 8 Class 12 Chem PDFDhanushNo ratings yet

- Pio Joe Sleiman 11D Science Capstone ProjectDocument18 pagesPio Joe Sleiman 11D Science Capstone ProjectpiojoesleimanNo ratings yet

- Actvidiad 2Document4 pagesActvidiad 2Jose Luis Rojas GarabitoNo ratings yet

- A Level Physics Units & SymbolDocument3 pagesA Level Physics Units & SymbolXian Cong KoayNo ratings yet

- Gk247a T-014 PDFDocument1 pageGk247a T-014 PDFsujit5584No ratings yet

- Opgc Owners Engineer - CPPDocument18 pagesOpgc Owners Engineer - CPPwas00266No ratings yet

- Lista Stand Iec 60034Document4 pagesLista Stand Iec 60034nikola CHECNo ratings yet

- English Assignment Class 5Document5 pagesEnglish Assignment Class 5vemuna katjiuanjoNo ratings yet

- Wind Power ProjectDocument96 pagesWind Power ProjectBina Das MazumdarNo ratings yet

- CHEM 397 Experiment QDocument20 pagesCHEM 397 Experiment QazinthepantsNo ratings yet

- Station Area Planning Guide October 2017 PDFDocument116 pagesStation Area Planning Guide October 2017 PDFAnonymous EnrdqTNo ratings yet

- Theoretical Study of Hydrogen Bond Formation in Trimethylene Glycol-Water ComplexDocument13 pagesTheoretical Study of Hydrogen Bond Formation in Trimethylene Glycol-Water ComplexChern YuanNo ratings yet

- UCMP Unit 1Document16 pagesUCMP Unit 1Sreedhar ReddyNo ratings yet

- Hydraulic Construction EquipmentDocument24 pagesHydraulic Construction EquipmentAYUSH PARAJULINo ratings yet

- BTech Project Midterm ReviewDocument12 pagesBTech Project Midterm ReviewNikhil WaghalkarNo ratings yet

- GE Gas Turbine Generator Frame 6 Spare PartsDocument2 pagesGE Gas Turbine Generator Frame 6 Spare PartsAxelrose04100% (1)

- Symmetry ElementsDocument27 pagesSymmetry Elementssekar20120No ratings yet

- Mechanical Operation Slurry TransportDocument113 pagesMechanical Operation Slurry TransportIsrarulHaqueNo ratings yet

- Variable Valve Timing Lab ReportDocument14 pagesVariable Valve Timing Lab ReportSyed Imtinan AhmedNo ratings yet

- Motor Load MonitorDocument4 pagesMotor Load MonitorRenghat RumahorboNo ratings yet

- My M.SC Thesis ..Document33 pagesMy M.SC Thesis ..Mallika P. Shivam100% (1)

- Daf ElectricDocument74 pagesDaf ElectricHarlinton descalzi67% (6)

- An Experimental Study On Usage of Hollow Glass Spheres (HGS) For Reducing Mud Density in Geothermal DrillingDocument7 pagesAn Experimental Study On Usage of Hollow Glass Spheres (HGS) For Reducing Mud Density in Geothermal DrillingifebrianNo ratings yet

- رافضیت کے معمار ج1،9 - compressedDocument310 pagesرافضیت کے معمار ج1،9 - compressedAkramNo ratings yet

- 61R Compact Raise Borer Technical Specification WorksheetDocument4 pages61R Compact Raise Borer Technical Specification WorksheetRoiNo ratings yet

- EC ElectromagneticsDocument51 pagesEC ElectromagneticsNilamani Umashankar JenaNo ratings yet

- MGG155N2: Gaseous Generator Parts ManualDocument94 pagesMGG155N2: Gaseous Generator Parts ManualYAKOVNo ratings yet