Professional Documents

Culture Documents

Determining Concrete Permeability

Uploaded by

Yinna RuizOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Determining Concrete Permeability

Uploaded by

Yinna RuizCopyright:

Available Formats

Research and Development Laboratories

of the

(

Portland Cement Association

RESEARCH DEPARTMENT

Bulletin 133 ‘.

A Proposed Simple Test Method for

Determining the Permeability of Concrete

By

I. L. Tyler and Bernar,d Erlin

Reprinted from the

Journal of the PCA Research and Development Laboratories

Vol. 3, No. 3, 2-7 (September, 1961)

(c) Portland Cement Association, 1961

A PROPOSED SIMPLE TEST METHOD FOR

DETERMINING THE PERMEABILITY OF CONCRETE

By

1. L. Tyler and Bernard Erlin

PORTLAND CEMENT ASSOCIATION

RESEARCH AND DEVELOPMENT LABORATORIES

5420 Old Orchard Road

Skokie, Illinois

1. L. Tyler Bernard Erlin

A Proposed Simple Test Method

for Determining

BY

the Permeability l.’ L. Tyler, Research Counselor, and

Bernard Erlin, Assoc. Research Petrographer

Research and Development Laboratories

of Concrete Portland Cement Association

INTRODUCTION partment of Highways, originally intended

for determining air content of hardened

The permeability of concrete to water under pressure

is a property of interest to nearly ell designers of con.

concrete. Fig. 1 shows the apparatus. It

crete structures, While the interest in this property hes consists essentially of a watertight pressure

been mainly associated with hydraulic structures it is vessel into which the specimen is placed,

also important to other types of construction that may a hand pump for applying the hydraulic

come in contact with water; such as basement walls pressure, pressure gages for measuring hy-

and floors, retaining walls and even pavements.

draulic head, and a graduated glass cylin-

A number of different methods for measuring per- der for measuring the amount of water

meability have been usad in the pas+, All of them

pumped into the pressure vessel. The pres-

require measurement of the rate of water flow under

pressure through the concrete aftar steady rates of

sure chamber is just large enough to ac-

flow have been attained. Since the flow of water commodate a 6 x 12-in. specimen, thus

through concrete is slow and test specimens must kseping the volume not occupied by the

usually ba of considerable thickness, the length of specimen to a minimum. The hand pump,

time to make a test is often a matter of weeks.

of a leak-proof positive displacement de-

With the thought of providing a more rapid method sign, takes its water supply by gravity from

of test for permeability, a somewhat different ap-

the glass graduate. All fittings are leak

proach to the problem is offered using the ordinary

6 x 12-in, concrete specimen normally made for com-

proof, including the top of the pressure

pressive strength tests. The mathod dapends on mess. vessel which is sealed by means of a molded

urament of the rate at which watar under pre~sure is rubber “O” ring.

forced into the concre+a cylinder and the total amount

of water that can be forced in. It is not offered as a

TEST PROCEDURE

fully developad test ma+hod, but rather to interest

others in its possibilities.

For testing, the specimen is placed in

the water-filled vessel, the top bolted in

APPARATUS place and water pumped into the system

The method uses a slight modification

of the high pressure apparatus developed *Numbers in parentheses refer to references at

by J. D. Lindsayfl J* of the Illinois De- end of paper.

2 Journal of fhe PCA Research and

from the glass graduate. Air is removed to 5000 psi and then allowing the pressure

from the system before hydraulic pressure to drop to 4000 psi as water was forced

is applied. Volume of water in the contain- into the specimen. When pressure had

er is corrected for the expansion of the dropped to 4000 psi, additional water was

system and compression of the water. Com- pumped iinto the container to restore the

pressibility of the test specimen is neglected. 5000 psi and the process repeated during

No correction for compressibility of meas- the test period. The mean of this pressure

ured additional water pumped into the range (4500 psi) was used as the test pres-

system is made. sure. Tests were also made in 300 to 200

The early tests were made by first pump- psi and 50 to 40 psi pressure ranges. Later

ing the apparatus containing the specimen tests have all been made at constant

pressure.

THEORY—ASSUMPTIONS AND

APPROXIMATIONS

Validity of the test method, which de-

pends primarily on the rate at which water

is forced into the specimen and the total

amount that can be forced into the speci-

men, is subject to a number of assumptions,

and accuracy of the calculations of per-

meability coefficient depends on several

simplifying approximations. The principal

assumptions are as follows:

1. Degree of saturation at start of test

is uniform throughout the specimen.

Fog-cured or possibly sealed speci-

mens would satisfy this condition rea-

sonably well.

2. Penetration of water is at a uniform

rate from all faces (see (2) and (3)

under following approximations).

3. Complete saturation is attained in the

region into which water has been

forced.

4. Back pressure from air compressed

within the concrete cylinder is neg-

ligible. This should be valid during

early stages of test.

5. Temperature effects are negligible.

6. Compressibilities of the specimen and

of the “ultimate particle” are neg-

lected.

7. Humidity within the specimen at time

of test i’s 100~0 (no ‘tension in the

water).

Approximations made in calculating the

permeability coefficient are as follows:

1. Surface area of the specimen is as de-

termined from the 6 x 12-in. dimen-

sions. At start of the test the error is

appreciable (as shown by very early

penetration rates) but after a few min-

Fig. I— Permeability Apparatus. utes of test this error seems negligible.

Development Laboratories September 1961 3

2, Parallel flow is assumed from the cyl- tion it is convenient to plot qz versus t and

indrical surface and from the ends. use the slope of the resulting nearly straight

The fact that flow from the cylindri- line directly in the equation. Departure of

cal surface is actually converging is plotted points from this straight line near

probably not important during the start of the test probably indicates that

early stages of the test. A correction actual area of the test cylinder is larger

could be applied but seems unwar- than the surface calculated from dimensions

ranted in view of other approxima- of the cylinder because of surface irregu-

tions that are made. larities.

3. Corner effects are neglected. These INITIAL TESTS

should be minor at early stages of the

test. Two 6 x 12-in. concrete cylinders of near-

ly identical composition were chosen for

Two slightly different approaches have the initial tests, Specimens No. 1 and No.

been used in calculating the permeability 2 listed in Table 1. Fig. 2 shows plots of

coefficient K. (K is in cubic feet per second time versus quantity of water forced into

across a 1 sq ft area under 1 ft of head the specimens, the data needed for com-

through 1 ft of thickness.) The two ap- putation of permeability coefficients using

proaches covered by equations (1) and (2) equation (1). Fig. 3 shows plots of time

below and following explanations, are iden- versus qz used in calculating the coeffi-

tical except for the approximations used cients using equation (2). Table 2 gives

in the calculations. pertinent information on permeability of

Specimens No. 1 and No. 2. The value of

K=~ &......, (1)

Q (in cu ft) was found to be O.OI3 for

Specimen No. 1 and 0.012 for Specimen

Also No. 2. Values of Aq/At were taken from the

plots on Fig. 2 and q’/t (slope) from Fig. 3,

K++

Results in this case show fortuitously close

agreement in K values,

q’ 0.05

=——........(2)

t AhQ One difficulty of the test is the length of

time required to measure the amount of

in which water required to completely saturate the

q=qu?ntity of water forced into specimens, in the determination of Q. The

cyhnder at time of making the rest of the test involving use of equation

determination. (2) takes only an hour or two but the de-

l=lengthof flow path, feet. termination of Q takes about 7 days for

t= time after start of test, seconds. high-quality concrete and at least two days

A=surface area of 6x12-in. cylin- for low-quality concrete using a pressure

der, 1.96 sq ft. of 5000 psi in the apparatus. Several ap-

a=average areaat right angles to proaches to a rapid determination of Q

flow path, sq ft. have been considered but so far have not

h=head, ft (from gage pressure). been satisfactory, An empirical approxima-

Q= total amount of water that can tion that seems reasonably close has been

be forced into cylinder, cu ft. used for air-entrained concrete with the

two aggregates used in these tests for test

In using equation (1) the length of flow ages of 7 to 28 days:

path, 1, is determined for the volume of the

shell of concrete found to be completely Q= 0.002X% air+ 0.002

saturated at the time of the rate of flow It is not usable for non-air-entrained con-

determination. This volume is equal to crete.

q/Q times the volume of the 6 x 12-in.

cylinder. The area, a, is the average of the TEST RESULTS

areas of the 6 x 12-in. cylinder and the area Table 1 shows some of the results that

of the concentric inner cylinder not yet have been obtained to date on cylinders

saturated. Aq/At is scaled from the plot of made with a laboratory blend of cements

water inflow versus time, and two aggregate combinations, both with

Equation (2) is applicable only during l-in. top-size aggregate. All specimens, ex-

early stages of the test, In using this equa- cept Specimen No. 20, were cured in the

4 Journal of ffte PCA Research and Development Laboratories September 1961

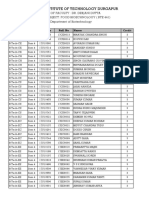

TABLE 1—PERMEABILITY DATA

Specc Awre- % Sacks Curing Test Pressure

gat.” ak /.. yd oal/sack No. days psi Kxl 012

I A 5,2 5.9 4.6 45 —mOlst 5000.4000 0.13

2 A 5,4 5.9 4.6 6&moist 5000.4000 0.13

11 A 0,4 4,0 8.2 47—ln018t 300.200 1.4

16 A 0.3 4,0 8.2 33—mOlst 50-40 6.1

17 8 1,1 4.0 7.6 7—mOist 30 29,7

18 8 1.1 4,0 7.6 I 4—mW 50 5.3

19 8 1.1 4,0 7.6 28—moM 400 2.2

20 B 1,1 4.0 7.6 1—moist 20 12,700,0

3—50% r.h.

21 A 5,3 6,0 4,5 8—mdst 50 1.8

22 A 5.3 6.0 4,5 1s—moist 600 0.79

23 A 5.3 6.0 4.5 20—rnolst 500 0.3.5

24 A 5.3 6.0 4.5 28—mdst 500 0,084

26 A 4.5 &o 4.5 7—mOlst 50 1.9

27 A 4,5 6.0 4.5 7—mOlst 250 3.3

28 A 4,5 6.0 4,5 7—mOlst t —

29 A 4.5 6.o 4.5 14—moist 200 1,9

30 A 4.5 6.o 4.5 14—mOISt 600 0.69

31 A 5. I 6.0 4.6 1o—moist 250 2,3

32 A 5. I 6,0 4,6 1o-moist 250 0.8

33 A 5.1 6,0 4.6 1O—mold 250 2.4

36 A 6.3 4.0 6,3 13—moist 450 5.7

A 6,3 4.0 6.3 13—mOi,t 25o 5.4

K A 6.3 4.0 6.3 13—mOlst 250 5.6

39 A 6,3 4.0 6.3 13—nwist 250 10.0

40 A &3 4.0 6.3 13—mOl*t 250 10.3

41 8 6. I 4.0 6.2 7—m019t 250 26.0

42 8 6,1 4,0 6,2 9—mOlst 250 I 7,0

43 8 6. I 4.0 6.2 14—nl.alst 250 5.6

44 8 6.1 4.0 6.2 21 —moist 2s0 2.5

45 8 6,1 4,0 6,2 28—m.lst 250 1,2

●Aggregate A—Elgin Sand, Ea. Clake Gravel.

A.a.ar.gate B—Elgln Sand, Elg!n Gravel.

fMeasured rate of abs.rptio. submerged.

r , , , > I ,

&=40 Xlo-’

~,”=”

,005 ~

-9

At =

.003

.001

9 1,

9-10 -11-12-1-2-3-4-5 9-10 -11-12-I-2-3-4-5 9-10 -11-12-1:2-3-4-5

AM N PM AM N PM AM N PM

FIRST DAY SECOND DAY THIRD DAY

Fig. 2 — High Pressure Permeability Tests on Two Concrete Cylinders.

12

II

10

I1 XIO-6

K(spec#2)= 6,6x0 .05x 10-’0=0.13x10-’2

1.96x I0400x0.012 ,/

/

‘.fl

,0

K (spec#l ) = 7x0,05 x10-’0=0,13x10-’2

1.96x I0400x0,013

Slope = 7x10-’0

Q = 0013

I 1

0 5 10 15 20

Time, Thousands of Seconds

Fig, 3—Specimens No. I and No. 2 Tested a+ 45oO psi.

fog room until time of test. This specimen cured in the moist room for 7 days and

w~s removed after 1 day in the mo~st room placed under test; one in the pressure ap-

and placed in 50 per cent relative humidity paratus under 50 psi; another in the pres-

storage for 3 days before testing. The ex- sure apparatus under 250 psi (approximate-

tremely high permeability coefficient, over ly 2 hours later); and the third immersed

12000x 10-lZ as measured by this method in water and weighed (after being wiped

of test, shows the very bad effects on per- dry) at intervals. The specimens were of

meability by early drying. It showed fur- rich, low w/c concrete thought to be the

ther that a partially dried specimen cannot most likely to be deficient in internal mois-

be tested by the method proposed in this ture even under fog curing (Specimens No.

paper and brought up some question about 26, 27 and 28 in Table I).

the validity of assumption 7 regarding the

An inspection of Table 1 shows that the

relative humidity within the specimen at

permeability coefficient for Specimen No.

time of test. The shape of the q’/t curve

26 at 50 psi was ,1.9 x 10-” and for Speci-

for this specimen indicated excessive sur-

men No. 27 at 250 psi was 3.3 x 10-lZ. In

face drying and non-uniformity of moisture

addition, Specimen No. 28 tested for ab- 1

content as required by assumption 1. I

sorption during the water immersion for

REPRODUCIBILITY 312 hours showed a gain in weight of only

/

As a result of findings on Specimen No. TABLE 2—PERMEABILITY DATA USING

20, it was decicled to make tests on dupli- EQUATIONS (1) AND (2)—SPECIMENS 1 AND 2

cale specimens at equal moist-cured ages at

different hydraulic

soned tha L if internal

pressures. It was rea-

negative pressures

+&en lime.f

Test I AVAf

la I Kx\Or2

I.eq, (1) !s1 day (4 P,d 84X1

o-9 0.034 1.75 0.1s

were appreciable within the specimen the 2nd day (4 p.m.] 40XI 0+ 0.064 I .60 0.15

3rd day (4 p.m.] 23x1 0+ 0,091 I ,44 0.;;

lower pressure lest should indicate the -eq, (2)

higher coefficient of permeability. In ad-

2...+ (1)Id day 4 p.m.) 57XIo-p 0,033

dition, a’ third specimen cast from the same 2“d d.:4 ,.m.) 40:0+ oi3 ~ij $i~

batch of concrete was fabricated for ab- 3rd day (4 p.m.) 25xI 0-9 0.088

— —

-eq, (2) – 0.13

sorption tests. The three specimens were

Journal of the PCA Research and

23 grams. From this it would appear that

under conditions of fog curing the per-

meability measurement would not be great-

ly affected by a deficiency of water within

the test specimen. O—AM Entr., ned

x — No” A,, En,,.,.ed

However, the difference between 1.9

x 1O-’Z and 3.3 x 10-~z in the permeability

coefficient raised another question con-

cerning the effect of pressure on the per-

meability determination and another pair

) of specimens from the same batch, Speci-

mens No. 29 and 30, were tested at 14

I days. With this pair the apparent effects of

pressure were reversed and it was concluded

tentatively that variations among specimens

should be investigated before effects of dif-

ferences in test pressure were considered

further. Accordingly arrangements were

made to compare results on a few suppos-

o 7 14 21 28

edly identical specimens all tested at the Fog Curing DOW

same pressure.

Fig. 4 — Permeability vs Curing Time.

Results from three such specimens, Spec-

imens No. 31, 32 and 33, are shown in can be made. There could be advantages

Table 1 suggesting that results having at for either method, depending on the pur-

least 50 per cent deviation from a mean pose of the test.

of several tests might reasonably be ex- Results from the investigation to date

pected at the K = 2 X 10-12 level of perme- suggest that the test method described may

ability. Results from Specimens No. 36 and be useful for comparisons of relative per-

40 inclusive suggest a slightly better agree- meabilities of different concrete mixtures.

ment at the K = 8 x 10-12 level. A number It is the hope of the authors that others

of possibilities that might account for such may find the proposed method of sufficient

deviations can be advanced. The most merit to warrant further study of its use-

likely seems to be the nonuniformity among fulness to the concrete industry.

test specimens. In view of lack of reproduci-

ACKNOWLEDGMENT

bility of results found in other methods of

permeability testing, the degree of conform- The authors wish to acknowledge the

ity suggested here seems well within reason most helpful advice of Dr. T. C, Powers

considering the present state of develop- on theoretical considerations involved in

ment of the proposed method. the method, the assistance of the Research

and Development Shops in fabricating the

The other specimens listed in Table 1 excellent equipment used in the test, and

show K values that seem to be reasonably the assistance of the Applied Research Sec-

comparable among themselves. However, tion in making the test cylinders.

these values are generally well below those

that have been obtained by othersf z) (~) REFERENCES

using clifferen t procedures for measuring 1. Lindsay, J. D., “Illinois Develops High Pressure

j permeability. Fig. 4 shows the effect of Air Meter for Determining Air Content of

duration of moist curing on permeability Hardened Concrete,” Proceedings, Highway Re-

search Board, 35, 424-435 (1956).

as measured by the proposed procedure,

and something of the effects of cement con- 2. Ruettgers, Arthur, Vidal, E. N., and Wing, S. P.,

“An Investigation of the Permeability of Mass

tent. Effects of air entrainment do not

Concrete with Particular Reference to Boulder

seem to be large with cement contents held Dam,” Proceedings, American Concrete Institute,

constant. 31, 382-416 (1935),

It seems likely that the pvofmsed method 3. U.S. Army, Corps of Engineers, Waterways Ex-

periment Station, Vicksburg, Mississippi, “Per-

should not show values of K that are di- meability and Triaxial Tests of Lean Mass

rectly comparable with those of other pro- Concrete,” Technical Memorandum No. 6-380

cedures that require establishing a constant (March, 1954), 62 pages with Appendix of 25

rate of outflow before the determination pages,

Development Laboratories September 1961 7

Bulletins Published by the

Research Department

Research and Development Laboratories

of the

Portland Cement Association

100. “List of Published Bulletins and Papers of the Research Department,”

May, 1.959 (Also lists earlier research papers of the Portland Cement

Association).

101. “Determination of the Apparent Density of Hydraulic Cement in Water

Using a Vacuum Pycnometer,” by C. L. FORD.

Reprinted from ASTM BWletin, No. 231, 81-84 (July, 1958).

102. “Long-Time Study of Cement Performance in Concrete-Chapter 11.

Report on Condition of Three Test Pavements After 15 Years of Serv-

ice,” by FRANK H. JACKSON.

Reprinted from Journal of the American Co?acTete Institute (June, 1958); Pro-

ceedings, 54, 1017-1082 (1957-1958).

103. “Effect of Mixing and Curing Temperature on Concrete Strength,” by

PAUL KLIEGER,

Reprinted from Jotmnal oj the American Concrete Institute (June, 1958); Pro-

ceedings, 54, 1063-1081(1957-1958).

104. “The Successive Determination of Manganese, Sodium and Potassium

Oxide in Cement by Flame Photometry,” by C. L. FORD.

Reprinted from ASTM Bulletin, No. 233, 57-83 (October, 1958).

105. “The Surface Energy of Tobermorite,” by STEPHEN 13RUNAUER, D. L.

KANTRO and C. H, WEISE.

Reprinted from Canadian Journal of Chemistw, 37, 714-724 (April, 1959).

106. “The Flow of Water in Hardened Portland Cement Paste,” by T. C.

POWERS, H. M. MANN and L. E. COPELAND.

Reprinted from Higitwav Research Boawt Special Report 40, 308-323 ( 195S).

107. “The Ball-Mill Hydration of Tricalcium Silicate at Room Temperature,”

by D. L. KANTRO, STEPHEN BRUNAUER and C. H. WEISE.

Reprinted from Journal of CoUotd Science, 14, 383-376 (1959).

108. “Quantitative Determination of the Four Major Phases of Portland

Cement by Combined X. Ray and Chemical Analysis,” by L. E. CoPE-

LAND) STEPHEN BRUNAUER, D. L. KANTRO, EDITH G. SCHULZ and C. H. WEISE.

Reprinted from Analuttcal Che?nist?w, 31, 1521-1530 (September, 1959).

109. “Function of New PCA Fire Research Laboratory,” by C. C. CARLSON.

Re rinted from the Journal of the PCA Research and Development Labora-

tor? es, 1, No. 2, 2-13 (May, 1959).

110. “Capillary Continuity or Discontinuity in Cement Pastes,” by T. C.

POWERS, L. E. COPELAND and H. M. MANN.

Re rinted from the Jou?’naL of the PCA Research and Development Labora-

tor res, 1, No. 2, 38-48 (May, 1959).

111. “Petrography of Cement and Concrete,” by L. S. BROWN,

Reprinted from the Journal of the PCA Research and Development Labora-

tories, 1, No. 3, 23.34 (September, 1959),

112, “The Gravimetric Determination of Strontium Oxide in Portland

Cement,” by C. L, FORD.

Reprinted from ASTM BuUetW No. 24S, ‘71-75 (April, 1960).

113. “Quantitative Determination of the Four Major Phases in Portland

Cement by X-Ray Analysis,” by STEPHEN BRUNAUm, L. E. COPIZLAND,

D. L. KANTRO. C. H. WEISE and EDITH G, SCHULZ.

Reprinted from Proceedings of the American Society for Testing MatertaLs, 59,

1091-1100 (1959).

114. “Long-’llme Study of Cement Performance in Concrete-Chapter 12.

Concrete Exposed to Sea Water and Fresh Water,” by I. L. TYLRR.

Reprinted from Jotmaal of the American Concrete Institute (March, 1960);

Proceedings, 56, 625-836 (1960).

115, “A Gravimetric Method for the Determination of Barium Oxide in Port-

land Cement,” by C. L, FORD.

Reprinted from ASTM Bulletin, No. 247, 77-60 (July, 1960).

116. “The Thermodynamic Functions for the Solution of Calcium Hydroxide

in Water, ” by S. A. GREENBERG and L. E. COP~LAND,

Reprinted from Journal of Pit@cat Chem.istrv, 64, 1057-1059 (August, 190J3).

117. “Investigation Hydrated Silicates. I. Volubility Products,”

of Colloidal

by S. A. GREENBERG, T. N. CHANG and ELAINE ANDERSON.

Reprinted from Journal of Ph@ca2 Chemtstw, 64, 1161-1156 (September, 1960).

118. “Some Aspects of Durability and Volume Change of Concrete for Pre-

stressing,” by PAUL KLIEGER.

Reprinted from the Journal of the PCA Research and Development Labora-

torlee, 2, No. 3, 2-13 (September, 1960).

119. “Concrete Mix Water—How Impure Can It Be?” by HAROLD H. STEINOUR.

Reprinted from the Journal of the PCA Research and Development Labora-

tories, 2, No. 3, 32-50 (September, 1660).

120. “Corrosion of Pre8tressed Wire in Concrete,” by G, E. MONFORE and

G. J. VERBECK.

Reprinted from Journal of the American Conc~ete Institute (November, 1960):

Proceedings, 57, 491-515 (September, 1960).

121. “Freezing and Thawing Tests of Lightweight Aggregate Concrete,” by

PAUL KLIEGER and J, A. HANSON.

Reprinted from Journal of the American Concrete In$titute (January, 1961);

Proceedings, 57, 779-796 (1981).

122. “A Cement-Aggregate Reaction That Occurs With Certain Sand-Gravel

Aggregates,” by WILLIAM LERCH.

Reprinted from the Journal of the PCA Research and Development Labo7ato.

ries, 1, No. 3, 42-50 (September, 1959).

123. “Volume Changes of Concrete Affected by Aggregate Type,” by

HAROLD ROPER.

Re rinted from tbe Journal of the PCA Research and Development Labora-

tor$’es, 2, No. 3, 13-19 (September, 1960).

124. “A Short Method for the Flame Photometric Determination Qf Magne-

sium, Manganic, Sodium, and Potassium Oxides in Portland Cement,”

by C. L. FORD.

Reprinted from ASTM BuUettn, No. 250, 25-29, (December, 1960).

125. “Some Physical Aspects of the Hydration of Portland Cement,” by

T. C. POWERS.

Reprinted from the Journal of the pCA Resea~ch and Development Labora-

tories, 3, No. 1, 47-56 (January, 1961).

126. “Influence of Physical Characteristics of Aggregates on Frost Re-

sistance of Concrete, ” by GEORGE VIIRBIIC~ and ROBERT LANDGREN.

Reprinted from Proceedings of the American Societg jov Testing Materials’, 60,

1063-1079(1960).

127. “Determination of the Free Calcium Hydroxide Contents of Hydrated

Portland Cements and Calcium Silicates,” by E, E. PRESSLER, STEPHEN

BRUNAUER, D. L. KANTRO, and C. H, WEISE,

Reprinted from Analuticat Chemistw, 33, No. 7, 677-262 (June, 1961).

128. “An X-ray Diffraction Investigation of Hydrated Portland Cement

Pastes,” by D. L. KANTRO, L. E. COPELAND, and ELAINE R, ANDERSON,

Reprinted from Proceedings of the American SoctetM for Testing il’fdt?TWS, 60,

1020-1036 (1960),

129. “Dimensional Changes of Hardened Portland Cement Pastes Caused

by Changes of Temp&ature,” by R. A. H’ELMUTH.

To be reprinted from Hi@wa~ Research Board Proceedings 40 (1061).

130. “Progress in the Chemistry of Cement, 1887.1960,” by HAROLD H,

STEINOUR,

Reprinted from the JOUT?UZ1 of the PCA Research and Development Labora-

tories, 3, No. 2, 2-11 (MaY, 1961).

131, “Research on Fire Resistance of Prestressed Concrete,” by HUBERT

WOODS,including discussion by V, PASCHKXS, and author’s closure.

Reprinted from Journal of the Stracttwat Division, Proceedings of the A?ne?+

can ~ociet~ of Civil Engineers, P?’oc. Pape~ 2640, 86, ST 11, 53-04 (November,

1960); Discussion, 87, ST 2, 59-60 (February, 1961); Closure, 87, ST 5, 61 (June,

1961).

132. “Centralized Control of Test Furnaces in the PCA Fire Research Labo-

ratory,” by PHIL J. TATMAN,

Reprinted from the Journal o the PCA Research and Development Labora-

tories, 3, No. 2, 22-26 (May, 1L 1),

133. “A Proposed Simple Test Method for Determining the Permeability of

Concrete,” by I. L. TYLER and BERNARD ERLIN,

Reprinted from the Journal of the PCA Research and Development Labora-

tories, 3, No, 3, 2-7 (September, 1901).

You might also like

- Porous Media: Fluid Transport and Pore StructureFrom EverandPorous Media: Fluid Transport and Pore StructureRating: 4 out of 5 stars4/5 (1)

- SPE 21439 MS (November)Document12 pagesSPE 21439 MS (November)Lulut Fitra FalaNo ratings yet

- Evaluation of Pile Intergrity Using Cross Hole Sonic Logging TestDocument5 pagesEvaluation of Pile Intergrity Using Cross Hole Sonic Logging TestDayah MahadiNo ratings yet

- The Shear Strength of Singapore Marine Clays, 1987Document10 pagesThe Shear Strength of Singapore Marine Clays, 1987freezefreezeNo ratings yet

- Sorptivity of MortarDocument11 pagesSorptivity of MortarSarah Neha AbrahamNo ratings yet

- V3i8 Ijertv3is080539Document5 pagesV3i8 Ijertv3is080539nileshNo ratings yet

- Pile Lenght TestingDocument3 pagesPile Lenght TestingNORMAL L.No ratings yet

- PermeabilityDocument27 pagesPermeabilitySushma DakeyNo ratings yet

- Lab Report 4 CEG453Document6 pagesLab Report 4 CEG453azrainNo ratings yet

- Norma Astm D2688-83Document14 pagesNorma Astm D2688-83Over 102No ratings yet

- Blight (1962)Document8 pagesBlight (1962)AmirNo ratings yet

- E. B I HT: National Building Research Institute, PretoriaDocument8 pagesE. B I HT: National Building Research Institute, PretoriaGracie AzevedoNo ratings yet

- The Initial Surface Absorption Test (ISAT) : An Analytical ApproachDocument7 pagesThe Initial Surface Absorption Test (ISAT) : An Analytical ApproachNuril IshakNo ratings yet

- Tibbets Et Al., 2020, Relating Water PermDocument11 pagesTibbets Et Al., 2020, Relating Water PermÁlvaro MendozaNo ratings yet

- Improvement of Compressive Strength and Permeability Test On Pervious ConcreteDocument10 pagesImprovement of Compressive Strength and Permeability Test On Pervious ConcreteSathavara BrijeshNo ratings yet

- Cui Et Al. 2017Document10 pagesCui Et Al. 2017Manaswini VadlamaniNo ratings yet

- JPVT 139 05 October2017Document11 pagesJPVT 139 05 October2017Dr. Sandeep Rangrao DesaiNo ratings yet

- Engineering in Chalk: Pumping TestsDocument7 pagesEngineering in Chalk: Pumping Testsmaribo2005No ratings yet

- Evaluation of Analyses of Downstream Piping of WeirsDocument8 pagesEvaluation of Analyses of Downstream Piping of WeirsmahnazNo ratings yet

- PIT EvaluationDocument4 pagesPIT EvaluationChikkanna TNo ratings yet

- The Measurement of Water Transport in Porous MaterDocument18 pagesThe Measurement of Water Transport in Porous MaterViníciusNo ratings yet

- Experimental Study On The Relationship Between Permeability and Strength of Pervious ConcreteDocument9 pagesExperimental Study On The Relationship Between Permeability and Strength of Pervious Concretehemel hasanNo ratings yet

- Efficient Test Setup For Determining The Water-Permeability of ConcreteDocument6 pagesEfficient Test Setup For Determining The Water-Permeability of ConcreteRabish ANo ratings yet

- Tests To Establish Concrete Pumpability Jl74-19Document11 pagesTests To Establish Concrete Pumpability Jl74-19saiNo ratings yet

- Rapid Estimation of Chloride Diffusion Coefficient in ConcreteDocument9 pagesRapid Estimation of Chloride Diffusion Coefficient in ConcreteYash DhabaliaNo ratings yet

- Foster, M.a. and Fell, R. (2001). Assessing Embankment Dam Filters That Do Not Satisfy Design Criteria, Journal of Geotechnical and GeoenvironDocument10 pagesFoster, M.a. and Fell, R. (2001). Assessing Embankment Dam Filters That Do Not Satisfy Design Criteria, Journal of Geotechnical and Geoenviron万少震No ratings yet

- InfluenceThickRadiusLeakPropag JASA 2019Document12 pagesInfluenceThickRadiusLeakPropag JASA 2019Оскар СкусселNo ratings yet

- In Situ Characterisation of The Depth and Mass of Water Intrusion in Unsaturated Cement Pastes Via X-Ray Computed TomographyDocument10 pagesIn Situ Characterisation of The Depth and Mass of Water Intrusion in Unsaturated Cement Pastes Via X-Ray Computed TomographyharveykwanNo ratings yet

- Shukla 2020 InfluencesoilbackfillasceDocument7 pagesShukla 2020 InfluencesoilbackfillasceOscar ScusselNo ratings yet

- Construction and Building Materials: Bradley J. Putman, Andrew I. NeptuneDocument6 pagesConstruction and Building Materials: Bradley J. Putman, Andrew I. NeptunemargarethsmNo ratings yet

- Practical 2 - Permeability of Sand BedDocument15 pagesPractical 2 - Permeability of Sand BedGolley BeckyNo ratings yet

- Testing Methods For Shale CompatibilitiyDocument9 pagesTesting Methods For Shale CompatibilitiySwapnil ThakurNo ratings yet

- Evaluation of Undrained Shear Strength of Marine Clay Using Cone Penetration Resistance at South Pars Field in IranDocument14 pagesEvaluation of Undrained Shear Strength of Marine Clay Using Cone Penetration Resistance at South Pars Field in IranDr.Ch.Rama Vara Prasad Assistant Professor, CE, VRSECNo ratings yet

- Interpretation of Cone Penetration Tests - Part IDocument17 pagesInterpretation of Cone Penetration Tests - Part IJai Jadav100% (2)

- IGC-2015 Submission 296Document7 pagesIGC-2015 Submission 296Rahul KolateNo ratings yet

- The California Bearing Ratio Method For The Design On Flexible Roads and Runaways-DavisDocument15 pagesThe California Bearing Ratio Method For The Design On Flexible Roads and Runaways-DavisAnonymous GnfGTwNo ratings yet

- DigesterThinning Erosion Corrosion TappiJDocument8 pagesDigesterThinning Erosion Corrosion TappiJyukun gaiNo ratings yet

- Construction and Building Materials: S. Kothandaraman, S. Kandasamy, K. SivaramanDocument8 pagesConstruction and Building Materials: S. Kothandaraman, S. Kandasamy, K. SivaramanVijayNo ratings yet

- Interpretation of Cone Penetration Tests - Part IDocument17 pagesInterpretation of Cone Penetration Tests - Part IwabiyeomunguyeNo ratings yet

- Development of in Situ Permeability Test Using Constant Discharge Method For Sandy SoilsDocument5 pagesDevelopment of in Situ Permeability Test Using Constant Discharge Method For Sandy Soilsdhan singhNo ratings yet

- Aadnoy 2007Document7 pagesAadnoy 2007Víctor CarvallidoNo ratings yet

- Research C E N T E R Library: Vicksburg, MississippiDocument57 pagesResearch C E N T E R Library: Vicksburg, Mississippiodo18No ratings yet

- Cleaning and evaluating horizontal wells using coiled tubingDocument1 pageCleaning and evaluating horizontal wells using coiled tubingDaniel SalaNo ratings yet

- Grout Pressures Around A Tunnel LiningDocument6 pagesGrout Pressures Around A Tunnel LiningkapolaNo ratings yet

- Authigenic Clay Minerals On PermeabilityDocument8 pagesAuthigenic Clay Minerals On Permeabilityc_b_umashankarNo ratings yet

- Analysis of The Water Absorption Test To Assess The Intrinsic Permeability of Earthen MaterialsDocument9 pagesAnalysis of The Water Absorption Test To Assess The Intrinsic Permeability of Earthen MaterialsHa DeborahNo ratings yet

- Measurement of Rate of Absorption of Water by Hydraulic-Cement ConcretesDocument6 pagesMeasurement of Rate of Absorption of Water by Hydraulic-Cement ConcretesEver Brayan Choquehuanca GutierrezNo ratings yet

- Construction and Building Materials: Ali Akbar Ramezanianpour, Amirreza Pilvar, Mahdi Mahdikhani, Faramarz MoodiDocument8 pagesConstruction and Building Materials: Ali Akbar Ramezanianpour, Amirreza Pilvar, Mahdi Mahdikhani, Faramarz Moodidevildriver_990No ratings yet

- Rock Index Classification - Engineering ManualDocument2 pagesRock Index Classification - Engineering ManualkapsarcNo ratings yet

- Specification of Concrete For Marine Environments: A Fresh ApproachDocument12 pagesSpecification of Concrete For Marine Environments: A Fresh ApproachILIAS PROKONo ratings yet

- Specification of Concrete For Marine Environments: A Fresh ApproachDocument12 pagesSpecification of Concrete For Marine Environments: A Fresh ApproachRestie TeanoNo ratings yet

- Under WaterDocument21 pagesUnder WaterAnand Sagar RathodNo ratings yet

- Applying Surface Back PressureDocument10 pagesApplying Surface Back PressureCavidan IbrahimliNo ratings yet

- Aldea 2000Document5 pagesAldea 2000Ravi ThejaNo ratings yet

- Seepage Behavior and Grouting Effects For Large Rock CavernsDocument8 pagesSeepage Behavior and Grouting Effects For Large Rock CavernskrainajackaNo ratings yet

- Permeability Determination in An Alluvial Dam Foundation: C&techniqueDocument14 pagesPermeability Determination in An Alluvial Dam Foundation: C&techniquemercedesNo ratings yet

- Onset of Tunnel Scour Below Subsea PipelinesDocument15 pagesOnset of Tunnel Scour Below Subsea PipelinesZadeh NormanNo ratings yet

- Reservoir ChachteristicDocument97 pagesReservoir ChachteristicTarek GanatNo ratings yet

- Estimating Coefficient of Consolidation From Piezocone TestsDocument12 pagesEstimating Coefficient of Consolidation From Piezocone TestsagugNo ratings yet

- Modeling Piping Phenomenon in Earth DamsDocument3 pagesModeling Piping Phenomenon in Earth DamsStanislav KotaškaNo ratings yet

- rx194 PDFDocument22 pagesrx194 PDFYinna RuizNo ratings yet

- Determining Concrete PermeabilityDocument11 pagesDetermining Concrete PermeabilityYinna RuizNo ratings yet

- rx087 PDFDocument21 pagesrx087 PDFYinna RuizNo ratings yet

- rx194 PDFDocument22 pagesrx194 PDFYinna RuizNo ratings yet

- rx087 PDFDocument21 pagesrx087 PDFYinna RuizNo ratings yet

- Let Us Be HappyDocument2 pagesLet Us Be HappyMarjule DechavezNo ratings yet

- The Future - G&VDocument6 pagesThe Future - G&VManuelHerreraMontoyaNo ratings yet

- Ceph Reference ArchitectureDocument12 pagesCeph Reference ArchitectureGermgmaan100% (1)

- Mitsubishi Motors: Service ManualDocument29 pagesMitsubishi Motors: Service ManualCristobalNo ratings yet

- General ALT Model For Step Stress TestDocument12 pagesGeneral ALT Model For Step Stress TestAnshul NautiyalNo ratings yet

- Hydromechanical Piercing Perforation: Oil Service Innovation TechnologiesDocument8 pagesHydromechanical Piercing Perforation: Oil Service Innovation TechnologiesЕлена ПаниотNo ratings yet

- HydrotherapyDocument52 pagesHydrotherapyMpt Sports100% (1)

- CaseStudy AmtrakDocument14 pagesCaseStudy Amtraksnob_kNo ratings yet

- Tables and Bar ChartsDocument7 pagesTables and Bar ChartsVictoria FedoseevaNo ratings yet

- Am 363 PDFDocument4 pagesAm 363 PDFsunsirNo ratings yet

- The Picture of Dorian GrayDocument137 pagesThe Picture of Dorian GrayАнгелаС.No ratings yet

- List of Students Allotted in Open Elective Subjects (B. Tech and M. Tech (Dual Degree) Integrated MSc. - 4th Semester - Regular - 2018 - 19) - 2 PDFDocument26 pagesList of Students Allotted in Open Elective Subjects (B. Tech and M. Tech (Dual Degree) Integrated MSc. - 4th Semester - Regular - 2018 - 19) - 2 PDFArpan JaiswalNo ratings yet

- PSUTIL Documentation for Monitoring System ResourcesDocument77 pagesPSUTIL Documentation for Monitoring System ResourcesImam RiadiNo ratings yet

- GLOBAL GAME AFK IN THE ZOMBIE APOCALYPSE GAME Chapter 201-250Document201 pagesGLOBAL GAME AFK IN THE ZOMBIE APOCALYPSE GAME Chapter 201-250ganesh sarikondaNo ratings yet

- MD R2 Nastran Release GuideDocument276 pagesMD R2 Nastran Release GuideMSC Nastran BeginnerNo ratings yet

- Foreign Body Airway ObstructionDocument6 pagesForeign Body Airway ObstructionReeja RajeshNo ratings yet

- Dsa 5300Document8 pagesDsa 5300Nguyen Van ToanNo ratings yet

- Pharmaceutical Ingredients and Excipient - LastpptDocument72 pagesPharmaceutical Ingredients and Excipient - LastpptFANTANo ratings yet

- Sample Article Used by MeDocument14 pagesSample Article Used by MeMagnum OpusNo ratings yet

- The Respiratory System - Freebie GuideDocument4 pagesThe Respiratory System - Freebie GuideIndustria Quimica0% (1)

- GROHE Specification Sheet 19443000-1Document2 pagesGROHE Specification Sheet 19443000-1Fred PrzNo ratings yet

- Model Question Paper and Solution 2022Document14 pagesModel Question Paper and Solution 2022R Y AnushNo ratings yet

- Differential Equations CookbookDocument2 pagesDifferential Equations CookbookAugustinZNo ratings yet

- Design Calculations of Thrust Blocks at Lower Indira: L&T Construction Water & Effluent Treatment ICDocument3 pagesDesign Calculations of Thrust Blocks at Lower Indira: L&T Construction Water & Effluent Treatment IClagnajit dasNo ratings yet

- Brief History About Volley BallDocument1 pageBrief History About Volley BallAmbrad, Merlyn H.No ratings yet

- Lecture No.3 Part 1 (Fan)Document6 pagesLecture No.3 Part 1 (Fan)Mohsen HassanNo ratings yet

- 5 Variable K-MapDocument15 pages5 Variable K-MapBen SewellNo ratings yet

- Full Report-Disinfectant and SanitizerDocument19 pagesFull Report-Disinfectant and Sanitizermohd addinNo ratings yet

- Cheese Yoghurt and Ripening Cultures Reference Chart May 2020Document7 pagesCheese Yoghurt and Ripening Cultures Reference Chart May 2020AbitNo ratings yet

- Practice Quiz M1 (Ungraded) - MergedDocument22 pagesPractice Quiz M1 (Ungraded) - MergedAbdullah Abdullah100% (1)