0% found this document useful (0 votes)

53 views26 pagesAction Plan for East Transition Projects

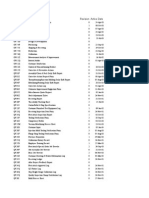

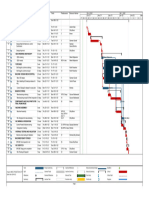

1. The document outlines 8 action items to be completed by various dates regarding layout optimization, scrap management, and station building.

2. Key tasks include identifying minimum and maximum scrap quantities, validating functionality of items before release, preparing detailed scrap forms, and engaging teams on IT items and unused equipment.

3. Additional tasks involve researching acrylic cutting equipment specifications, salvaging scrap materials, and scheduling evaluations of unknown scrap items.

Uploaded by

Hanafi HasbiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

53 views26 pagesAction Plan for East Transition Projects

1. The document outlines 8 action items to be completed by various dates regarding layout optimization, scrap management, and station building.

2. Key tasks include identifying minimum and maximum scrap quantities, validating functionality of items before release, preparing detailed scrap forms, and engaging teams on IT items and unused equipment.

3. Additional tasks involve researching acrylic cutting equipment specifications, salvaging scrap materials, and scheduling evaluations of unknown scrap items.

Uploaded by

Hanafi HasbiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd