Professional Documents

Culture Documents

T H e R M o

Uploaded by

LinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T H e R M o

Uploaded by

LinaCopyright:

Available Formats

ThermoProbe, Inc.

TP7 USER MAINTENANCE

RECOMMENDED OPERATION DISPLAY CHECK

To properly use this instrument the operator When the instrument is first turned on, the display

should be familiar with API 7 and the will briefly show all possible character segments.

International Safety Guide For Oil Tankers and This will look like: 888.8. If any segments fail to

Terminals. show, the instrument should not be used and it is

likely that the glass display is cracked.

SPOOL-LOCK

ERROR CODES

To avoid unwanted dispatch or tangling of Two error codes have been established to

the cable, a threaded spool-lock is located on provide the user information in case a

the case where the ground wire is attached. maintenance situation has occurred.

When using the instrument simply turn the

screw out so that the cable spool can freely E1 - Short Circuit or Under Range

spin. E2 - Open Circuit or Over Range

AUTO-SHUTOFF “E1” When this happens, one of two

situations has exists. In most cases, the probe

The TP7 is equipped for automatic shut off after circuit has been shorted; usually meaning the

approximately 2 minutes. Battery life is cable has been smashed at some point.

extended since the unit cannot be left on Secondly, “E1” represents a below range

unattended. reading. The temperature being gauged is

below the measurable specified range.

LOW BATTERY ALERT

“E2” When this occurs, there are also two

possible situations. The first and most likely is

LO - Battery Voltage Low that the probe circuit has a discontinuity. This

may occur as a result of a cut cable, bad

When the TP7 is switched on, it will termination at the circuit board or damaged

immediately check the status of the battery. A sensor. Check the cable terminal making sure

low battery situation will result with a flashing of the wires are correctly inserted into the

“LO” to the display for a few seconds before the connector on the board. Secondly, “E2”

temperature reading is available. The battery represents an over range reading, meaning the

needs to be replaced soon after the warning is temperature at the sensor has risen above the

observed, this is especially important if the unit measurable specified limit of the unit.

will be used in low light situations where the

backlight will be illuminated.

°F/°C DISPLAY UNITS

BATTERY REPLACEMENT

PROCEDURE The TP7 may display the temperature reading

in Fahrenheit or Celsius units. To change the

PERFORM BATTERY REPLACEMENT ONLY IN readout from one unit to the other remove the

AN AREA KNOWN TO BE NONHAZARDOUS. switch plate and slide the circuit board through

APPROVED BATTERIES. See Identification plate the top. The selector is located above the

for approved batteries. battery and the letters F and C can be seen on

the surface of the board. Place the selector

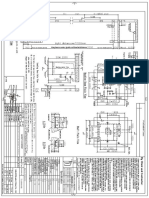

Remove the three-faceplate screws; turn the shunt on the center and upper pin for °F and

unit upside down allowing the faceplate- center and lower pin for °C. See illustration on

circuit board module to fall into your hand. next page. There is no need for recalibration if

The battery is then readily accessible for the there is a change in the temperature units.

manual replacement.

REPLACING THE PROBE ASSEMBLY FACEPLATE-CIRCUIT BOARD MODULE

When attaching a new probe assembly to circuit, it is necessary F/C

to pay attention to the polarity of the probe. SELECTOR

(Other Side of

Black Wire (shielding with shrink wrap) = (-) Board)

White Wire (signal lead) = (+)

95.8F

Polarity markings are located on the circuit board in front of the

finger connector. See illustration.

Reversed wires will inhibit proper probe grounding and may

cause false readings. - +

If a probe assembly is replaced with one of the same length, the SPAN

calibration will be within + 0.2 °F at 32 °F and within +0.6 °F ZERO

at 200 °F. It is recommended that a recalibration be performed

to make the instrument as accurate as possible.

PROBE WIRE

TERMINALS ( Other Side)

CALIBRATION

The TP7 design allows extended calibration periods. If

accuracy is not within specifications check cable integrity and

inspect the circuit board for possible corrosion, particularly near

the cable terminals. Calibration adjustments will not properly

correct these problems.

To verify/calibrate the instrument to the best possible accuracy

over a wide range, the following items are necessary:

-A certified thermometer.

-A circulated refrigerated bath, with a temperature near:

32.0 °F/ 0.0 °C (Bath 1)

-A circulated hot bath with a temperature:

190-200 °F /88-93°C (Bath 2)

-Small flat head adjustment screwdriver or similar tool.

AUTHORIZED REPAIR

:

1. Remove the 3 faceplate screws and lift assembly from housing.

2. Using the illustration (to the right) find the adjustment trims.

3. Adjust the ZERO with the probe assembly in Bath 1. It is recommend that service done beyond

4. Adjust the SPAN with the probe assembly in Bath 2. the scope of this article be presented to

5. Repeat several times or until no adjustment is necessary. ThermoProbe Inc. or one of its distributors.

Any servicing by unauthorized parties may

void the Intrinsic Safety and the warranty.

ThermoProbe, Inc.

112-A Jetport Drive

Pearl, MS 39208 USA

Voice: +1 601-939-1831

Fax: +1 601-355-1831

www.thermoprobe.net

You might also like

- OXY3690MPDocument6 pagesOXY3690MPrinthusNo ratings yet

- WES51Document7 pagesWES51Kevin WellsNo ratings yet

- LCQ and Deca Series Ion Gauge TroubleshootingDocument2 pagesLCQ and Deca Series Ion Gauge TroubleshootingGopiNo ratings yet

- RTD ScaleDocument2 pagesRTD Scalethe Xquisite100% (1)

- SMP10 SMP20 v2 3Document24 pagesSMP10 SMP20 v2 3Luis SahuaNo ratings yet

- T 231Document20 pagesT 231HoàngViệtAnhNo ratings yet

- Stuart FusiometroDocument60 pagesStuart FusiometroAlejandra RinconNo ratings yet

- DLRO200 UG enDocument15 pagesDLRO200 UG enชัชวาล เมตตาNo ratings yet

- Manual Ec2002mDocument4 pagesManual Ec2002mReinaldo Trindade ProençaNo ratings yet

- Wesd51 Oi PLDocument7 pagesWesd51 Oi PLelfrichNo ratings yet

- TVR II Troubleshooting ManualDocument37 pagesTVR II Troubleshooting ManualJesus0% (1)

- 4.solution To Disabled Cooling Function-20161104Document14 pages4.solution To Disabled Cooling Function-20161104Juan PabloNo ratings yet

- 2009-10-17 160959 Tech Sheet - 110.62042100Document6 pages2009-10-17 160959 Tech Sheet - 110.62042100Ramesh SarvaryNo ratings yet

- Manual Topworx D Series Discrete Valve Controllers Topworx en 82606 PDFDocument67 pagesManual Topworx D Series Discrete Valve Controllers Topworx en 82606 PDFWanderson PessoaNo ratings yet

- Whirlpool Kitchen 8302067Document8 pagesWhirlpool Kitchen 8302067Alejandro MarquezNo ratings yet

- Operation Manual: Inverter Air-Conditioner DetectorDocument17 pagesOperation Manual: Inverter Air-Conditioner DetectorLUIS FERNANDO PINONo ratings yet

- Owner's Manual (KJR 08)Document4 pagesOwner's Manual (KJR 08)Catalino Peralta Segovia100% (1)

- Panasonic PT-50LC14Document105 pagesPanasonic PT-50LC14Imthiyas AhmedNo ratings yet

- 400 Series Temperature Control Installation GuideDocument4 pages400 Series Temperature Control Installation GuideDonian Liñan castilloNo ratings yet

- Infrared Thermometer GUN Instructions: Control CompanyDocument2 pagesInfrared Thermometer GUN Instructions: Control CompanyESABIUS YOS LUIS SALUNo ratings yet

- Secadora Electrolux Manual de ServicioDocument8 pagesSecadora Electrolux Manual de Servicioorkys TenorioNo ratings yet

- Electrolux 2Document12 pagesElectrolux 2Juan Garcia HernandezNo ratings yet

- Megger DLRO200 ManualDocument15 pagesMegger DLRO200 Manualtriyan saefudinNo ratings yet

- PreheaterDocument8 pagesPreheaterLeo LiuNo ratings yet

- SI0487Document3 pagesSI0487vanthe140591No ratings yet

- The T.Racks: Digital Speaker Processor Model Ds2/4Document11 pagesThe T.Racks: Digital Speaker Processor Model Ds2/4Maxime SorelNo ratings yet

- TD51731 CC Trouble ShootingDocument14 pagesTD51731 CC Trouble ShootingFreddy JironNo ratings yet

- CF 18NHHZXBMDocument95 pagesCF 18NHHZXBMZedecuxNo ratings yet

- Split Units AlaramDocument27 pagesSplit Units AlaramnihaalNo ratings yet

- IzuruDocument43 pagesIzuruChris TsiarasNo ratings yet

- 5154 Poeng0200Document12 pages5154 Poeng0200Royal Revolt 01No ratings yet

- Air Cooled Chiller Operation GuideDocument28 pagesAir Cooled Chiller Operation GuidemodussarNo ratings yet

- Stuart SMPDocument14 pagesStuart SMPPattha ThoraritNo ratings yet

- FFSG5115PA0 - Manual de ServicioDocument12 pagesFFSG5115PA0 - Manual de ServicioCarmen Adriana Garcia MendozaNo ratings yet

- Beko P7 PDPDocument125 pagesBeko P7 PDPwajkNo ratings yet

- WR Thermostat 1F95-391Document12 pagesWR Thermostat 1F95-391Fred MundellNo ratings yet

- Passive Cooker Istruzioni enDocument18 pagesPassive Cooker Istruzioni enFabio TavanoNo ratings yet

- ZIAD Line Master Line Monitor Manual Apr88 OCRDocument33 pagesZIAD Line Master Line Monitor Manual Apr88 OCRBrookeClarkeNo ratings yet

- Pinnacle 27 Service ManualDocument15 pagesPinnacle 27 Service ManualMike Scudder0% (1)

- Body Electrical SystemDocument59 pagesBody Electrical SystemLeonardo Gómez Berniga100% (1)

- TL1 Thermometer InstructionsDocument37 pagesTL1 Thermometer InstructionsJose MorenoNo ratings yet

- Partida 918 Topworx PDFDocument67 pagesPartida 918 Topworx PDFGustavo Adolfo Beltran MagañaNo ratings yet

- Cooking Test ModeDocument13 pagesCooking Test ModepasantitoNo ratings yet

- 259-16749 Elfläktstyrn CorvetteDocument2 pages259-16749 Elfläktstyrn CorvetteSjoling8211No ratings yet

- TACm Instruction Obs Ver 560Document4 pagesTACm Instruction Obs Ver 560Aidan PitsisNo ratings yet

- Error Codes PDFDocument10 pagesError Codes PDFRosemarie QuitorianoNo ratings yet

- Samsung Microwave TrainingDocument23 pagesSamsung Microwave Trainingbody2030No ratings yet

- WL 601 R 2Document2 pagesWL 601 R 2taaj77No ratings yet

- Digital LED Thermometer with Microcontroller AVR ATtiny13From EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Rating: 5 out of 5 stars5/5 (1)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- SPE-182968-MS Well Integrity ManagementDocument14 pagesSPE-182968-MS Well Integrity ManagementJuan Camilo Lugo BecerraNo ratings yet

- Miltonroy Mroy XT 33005 07 Us PDFDocument16 pagesMiltonroy Mroy XT 33005 07 Us PDFLinaNo ratings yet

- Water Vapor 0.2-5 MGL For GasDocument1 pageWater Vapor 0.2-5 MGL For GasLinaNo ratings yet

- Information Data Sheet Detector Tube Ethyl Mercaptan - 0,5 Part No. (US) : 804589 Part No. D5086815Document1 pageInformation Data Sheet Detector Tube Ethyl Mercaptan - 0,5 Part No. (US) : 804589 Part No. D5086815LinaNo ratings yet

- Agents Classified by The IARC Monographs, Volumes 1 - 123Document37 pagesAgents Classified by The IARC Monographs, Volumes 1 - 123LinaNo ratings yet

- Classifications Alpha OrderDocument1 pageClassifications Alpha OrderLinaNo ratings yet

- Bomba Neumática LINC 84T 10-11-12-14 IOM PDFDocument24 pagesBomba Neumática LINC 84T 10-11-12-14 IOM PDFLinaNo ratings yet

- R111 2 E04Document37 pagesR111 2 E04Firmansyah Budhi SaputhraNo ratings yet

- TITULADORDocument42 pagesTITULADORFerney OrtizNo ratings yet

- Bomba Neumática LINC 84T 10-11-12-14 IOM PDFDocument24 pagesBomba Neumática LINC 84T 10-11-12-14 IOM PDFLinaNo ratings yet

- R071 E08Document22 pagesR071 E08LinaNo ratings yet

- Oiml D10Document11 pagesOiml D10WilljetNo ratings yet

- Bomba Neumática LINC 84T 10-11-12-14 IOMDocument24 pagesBomba Neumática LINC 84T 10-11-12-14 IOMLinaNo ratings yet

- INS CX en-USDocument36 pagesINS CX en-USLinaNo ratings yet

- QM VX en-USDocument12 pagesQM VX en-USLinaNo ratings yet

- Corrosion Inhibitors for Steel in Acidic Oil & Gas EnvironmentsDocument25 pagesCorrosion Inhibitors for Steel in Acidic Oil & Gas Environmentsjangri1098No ratings yet

- MiltonRoy MRoy XT 33005 07 UsDocument16 pagesMiltonRoy MRoy XT 33005 07 UsLinaNo ratings yet

- Advance Power Electronics and Control - Unit 3 - Week 2Document4 pagesAdvance Power Electronics and Control - Unit 3 - Week 2raghu_chandra_3No ratings yet

- Roman ArchitectureDocument7 pagesRoman ArchitectureKaavya.RNo ratings yet

- Field ManualDocument22 pagesField ManualDamienNo ratings yet

- 980L, 980M and 982M Wheel Loader Cooling SystemDocument2 pages980L, 980M and 982M Wheel Loader Cooling SystemIsrael MichaudNo ratings yet

- Slipform Rate AnalysisDocument5 pagesSlipform Rate Analysischaithra_140% (1)

- Lamp DesignationDocument2 pagesLamp DesignationCarolyne DaleNo ratings yet

- Rudder Boost System: From No. 2 Dual-Fed BusDocument8 pagesRudder Boost System: From No. 2 Dual-Fed BusAlex GuáncNo ratings yet

- Page 58Document1 pagePage 58Abhishek ShatagopachariNo ratings yet

- Versamate Cleanroom Receptacle PR19Document1 pageVersamate Cleanroom Receptacle PR19Anonymous llBSa7No ratings yet

- Motor overload protection & universal motor controller guideDocument60 pagesMotor overload protection & universal motor controller guideMelly SyafriliaNo ratings yet

- 1 Revised MRP Metal 100723Document24 pages1 Revised MRP Metal 100723Jainam ShahNo ratings yet

- D 6Document47 pagesD 6gilmer flores mamaniNo ratings yet

- Breaker Failure ProtectionDocument28 pagesBreaker Failure Protectiontanmaybeckham07100% (1)

- Nissan Altima: Motor 3.5L Vq35De CODIGOS P0011 y P0021Document9 pagesNissan Altima: Motor 3.5L Vq35De CODIGOS P0011 y P0021waltech2005No ratings yet

- HQL - LED - PRO - Family KSADocument7 pagesHQL - LED - PRO - Family KSARoudy J. MhawasNo ratings yet

- 432 434 1elektroDocument4 pages432 434 1elektrodenisNo ratings yet

- Ring Beam Center (Guide Rail Bracket) Distance: MR Door With Lock, by CustomerDocument1 pageRing Beam Center (Guide Rail Bracket) Distance: MR Door With Lock, by CustomerEdhimj UnmeNo ratings yet

- Closed Loop Current Sensors GuideDocument9 pagesClosed Loop Current Sensors GuideLong NguyenNo ratings yet

- Cuba MV-Switchgear WiringDocument371 pagesCuba MV-Switchgear WiringPedro kNo ratings yet

- British Residency 2Document15 pagesBritish Residency 2Syeda Sameeha MaryamNo ratings yet

- Sirius D32Document15 pagesSirius D32amshahidNo ratings yet

- Accord 2006 Master SwitchDocument10 pagesAccord 2006 Master SwitchinternetexNo ratings yet

- 306 Cooling Fan Operation PrincipleDocument7 pages306 Cooling Fan Operation PrincipleGinanjar Purnama100% (1)

- Conservation Roof Lights by VeluxDocument1 pageConservation Roof Lights by VeluxthespecifierNo ratings yet

- Maintenance of TrafoDocument4 pagesMaintenance of TrafoNauval Bangbang Dwi PutraNo ratings yet

- En 01.251 - RM 70go! 2.0 Short Manual Help v2Document63 pagesEn 01.251 - RM 70go! 2.0 Short Manual Help v2andrew stablesNo ratings yet

- Ambient Light Detector Under 40 CharactersDocument4 pagesAmbient Light Detector Under 40 CharactersFrederic MbaNo ratings yet

- Principles of Electric Motor Control in 40 CharactersDocument19 pagesPrinciples of Electric Motor Control in 40 Charactersolanvillegas2003No ratings yet

- Phrasal VerbsDocument14 pagesPhrasal VerbsPipiripiNo ratings yet

- Ignition System Circuit GuideDocument10 pagesIgnition System Circuit GuideCarlos Awo OsaureNo ratings yet