Professional Documents

Culture Documents

Davco K10 Dampflex Waterproofing Compound

Uploaded by

Vasanth Kumar0 ratings0% found this document useful (0 votes)

71 views2 pagesOriginal Title

K10-Dampflex

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

71 views2 pagesDavco K10 Dampflex Waterproofing Compound

Uploaded by

Vasanth KumarCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Hybrid PU Waterproofing Compound

K10

DAMPFLEX

WATERPROOFING AND SEALING MEMBRANE

DESCRIPTION TECHNICAL DATA

Davco K10 Dampflex is Hybrid PU Waterproofing Appearance Grey Paste

Compound for wet areas.

Specific Gravity 1.15kg/L

Touch Dry 1 hour before it skins

CHARACTERISTICS

• Ready-to-use, ease of application Elongation >500%

• Fast dry

Tensile Strength 1.5 MPa

• Extremely flexible, high elongation, absorb

vibration Drying time 20° C 24 hours

• Water based, non-toxic, non-flammable

• Bonds to various substrates Specifications are subject to change without notification.

Results shown are typical but reflect test procedures used.

USES Actual field performance will depend on installation methods

and site conditions.

• Provides a seamless waterproofing system which is

ideal for use in shower recess prior to tiling.

• Can also be used to waterproof terraces and

balconies.

• Bond to various substrates, e.g. concrete, render,

existing tile, gypsum, metal/wooden surfaces, fibre

cement/particle boards.

ADVANTAGES

• Davco K10 Dampflex is a premixed waterproofing

membrane, making it easy to use directly out of the

container.

• Davco K10 Dampflex is extremely flexible enabling it

to cater for limited floor movement while absorbing

vibration.

• Davco K10 Dampflex is a water based product

therefore it is non-toxic and non-flammable.

• Marbles and tiles can be fixed directly on Davco K10

Dampflex using Davco Tile Adhesive

Hybrid PU Waterproofing Compound

K10

DAMPFLEX

WATERPROOFING AND SEALING MEMBRANE

SURFACE PREPARATION APPLICATION

General : • Damp the surface.

• Wallboards flooring grade particle board and fibrous • Apply the area with Davco K10 Dampflex directly

cement sheet must be firmly fixed in accordance with from the can.

manufacturer’s instructions. • Allow to dry for 2-4 hours at 25°C, depends on

• Screw or nail heads must be sealed with epoxy temperature, humidity and substrate.

resin. • Apply a second coat and allow it to dry for 12 hours

• Gyprock joints need to be covered with 50mm wide at 20°C (the application shall be minimum of 2 coats or

gyprock tape. 3rd coat may be necessary to ensure that the whole

• All the surface must be structurally sound, dry and surface is uniformly applied and no pinholes are left on

free from dust, grease, wax, oil, curing compounds, and the surface).

other loose contaminating materials. All loose mortar or • Protection screed can be carried out 24 hours after

plaster, etc must be removed and then the entire area application of final coat.

cleaned to remove dust and dirt. • Davco K10 Dampflex must be protected by

New Concrete : rendering or screed after 2 weeks of application.

• All new concrete slabs must be allowed to cure for • Tools and access can be cleaned up with water

at least 4 weeks before applying Davco K10 Dampflex. while it is still wet.

Old Concrete :

• Clean the surface with a strong commercial grade PRECAUTION

detergent or degreaser, then remove all residue with • Temperature range for use: 10°C to 45°C.

fresh water using a high-pressure hose. • Do not thin - Product is supplied ready to use.

• Allow the surface to dry thoroughly for at least 24 • Do not add sand to Davco K10 Dampflex as this will

hours. Prior to using Davco K10 Dampflex, check and reduce flexibility and could cause cracking.

remove all protrusions from the surface, which may • Do not use where negative hydrostatic pressure is

pierce the membrane. evident.

Render : • Surfaces must not allow water to stagnate.

• Newly rendered surfaces must be allowed to cure

for at least 7 days. COVERAGE

Metal/Wooden Surfaces:

Approx. 0.8-1.2 kg/sqm at thickness 600-700 micron

• Ensure that all surfaces are totally free of rust.

(dry film, 2 coats), depending upon site condition.

• Prime the surface using Lanko 162 Flowprime.

Cracks :

• Small hairline cracks, which experience no

PACKAGING

• 20 kg container and 5 kg container

movement, may be filled by the first application of

Davco K10 Dampflex.

• For hairline cracks wider than 2mm, a joint filler STORAGE

should be applied along the length of the crack prior to 1 year from date of manufacture if stored in unopened

the application of Davco K10 Dampflex. original packing in dry, frost-free conditions.

• Structural cracks up to or greater than 2mm wide,

which experience movement, must be filled firstly with

Lanko 603 Polyurethane prior to application of Davco

K10 Dampflex. DISCLAIMER

Product Preparation: The use of this product is beyond the manufacturer's control, and liability is

restricted to the replacement of material proven faulty. The manufacturer is

• Do not thin, product is supplied ready to use not responsible for any loss or damage arising from incorrect usage. All

workmanship must be carried out in accordance with ParexGroup's specific

instructions.

The information contained herein is to the best of our knowledge true and

accurate. No warranty is implied or given as to its completeness or accuracy

in describing the performance or suitability of the product for a particular

application. Users are asked to check that the literature in their possession is

the latest issue. Rev 2/2015

ParexGroup Construction Products Pvt. Ltd.

202 New Udyog Mandir No. 2, 7C Mogul Lane, Mahim (W), Mumbai 400 016, INDIA. Tel: +91 (22) 2447 5051 | Fax: +91 (22)

2447 5056

www.parex-group.in

You might also like

- K10 Elastocoat NewDocument2 pagesK10 Elastocoat NewSUCHARIT100% (1)

- Davco k10 Polyurethane PlusDocument2 pagesDavco k10 Polyurethane PlusSUCHARITNo ratings yet

- Parex k10 Pu Plus Terrace WaterproofingDocument2 pagesParex k10 Pu Plus Terrace Waterproofingप्रज्ञेश कुमारNo ratings yet

- Davco K10 SOVACRYL PH FinalDocument2 pagesDavco K10 SOVACRYL PH FinalBon TraquenaNo ratings yet

- DAVCO K11 waterproofing membraneDocument2 pagesDAVCO K11 waterproofing membraneRon Jovi GarciaNo ratings yet

- Davco K11 Flex - Brochure (Brochure)Document2 pagesDavco K11 Flex - Brochure (Brochure)John Joseph IdanoNo ratings yet

- Davco k10 PlusDocument3 pagesDavco k10 PlusTARGET TRADE LINKSNo ratings yet

- Flexible Cement Waterproof CoatingDocument2 pagesFlexible Cement Waterproof CoatingDharryl Dharryl DharrylNo ratings yet

- Polyurethane - weberdry_RBE-LDocument2 pagesPolyurethane - weberdry_RBE-LAbdel Razak Al AsmarNo ratings yet

- Dura FlexDocument2 pagesDura FlexMuktaf Ajib El WatsiNo ratings yet

- Mariseal 250Document2 pagesMariseal 250acsimonNo ratings yet

- K10 GRS 2000: Root Resistant Waterproofing MembraneDocument2 pagesK10 GRS 2000: Root Resistant Waterproofing MembraneRandi RahmanNo ratings yet

- Davco Dampfast Data Sheet PDFDocument4 pagesDavco Dampfast Data Sheet PDFShanaei MiskinNo ratings yet

- Lavatex 2000...Document2 pagesLavatex 2000...ArifNo ratings yet

- Flexdek 2600Document2 pagesFlexdek 2600Query TANo ratings yet

- Sika Davco k10 Plus Data SheetDocument4 pagesSika Davco k10 Plus Data SheetJiang TerenceNo ratings yet

- POLYCELL PU 510WB 22sDocument2 pagesPOLYCELL PU 510WB 22snorlailiNo ratings yet

- SUNKOTE High Build Waterproof CoatingDocument2 pagesSUNKOTE High Build Waterproof CoatingSunilNo ratings yet

- k10 SovacrylDocument2 pagesk10 Sovacryleqbalalam1984No ratings yet

- AQUASHIELD PU PLUS December 2018Document2 pagesAQUASHIELD PU PLUS December 2018Anoop ShankarNo ratings yet

- Hydroblocker Superelastic: Liquid MembraneDocument2 pagesHydroblocker Superelastic: Liquid MembraneSemir SpahicNo ratings yet

- Olycryl Olycryl: Acrylic Based Waterproofing CoatingDocument2 pagesOlycryl Olycryl: Acrylic Based Waterproofing CoatingVaittianathan MahavapillaiNo ratings yet

- Maxseal: Flexible Waterproof Coating Against Positive and Negative Pressure For Concrete and MasonryDocument4 pagesMaxseal: Flexible Waterproof Coating Against Positive and Negative Pressure For Concrete and Masonrychong pak limNo ratings yet

- TDS Weberdry RoofDocument2 pagesTDS Weberdry RoofMahendra Singh BudhathokiNo ratings yet

- Duraflex DSDocument2 pagesDuraflex DSFeyiNo ratings yet

- WP - Brochure - Sika Davco Bitkote - 3 - Jan - 20Document2 pagesWP - Brochure - Sika Davco Bitkote - 3 - Jan - 20Ade KurniawanNo ratings yet

- Drylok Extreme Masonry Waterproofer PdsDocument5 pagesDrylok Extreme Masonry Waterproofer Pdscarlos_raul_nNo ratings yet

- Ficha Técnica Thompsons WaterSealDocument3 pagesFicha Técnica Thompsons WaterSealerick alvaradoNo ratings yet

- Conbextra EPGPDocument2 pagesConbextra EPGPm.elsanee.cubicNo ratings yet

- Abe. Proof PU ECO: PolyurethaneDocument2 pagesAbe. Proof PU ECO: Polyurethanecremildo maetinhoNo ratings yet

- NITOPROOFDocument4 pagesNITOPROOFTejinder KumarNo ratings yet

- Sikaceram - 116 StandardDocument3 pagesSikaceram - 116 StandardMash-out VivA (www.VivA.com)No ratings yet

- Abe Construction Chemicals Duraflex DatasheetDocument2 pagesAbe Construction Chemicals Duraflex DatasheetEthanNo ratings yet

- K10 Sovacryl PDFDocument2 pagesK10 Sovacryl PDFfaraz zeeshanNo ratings yet

- Flexcrete 500: Epoxy Polysulfide Waterproofing CoatingDocument2 pagesFlexcrete 500: Epoxy Polysulfide Waterproofing CoatingSuresh YadavNo ratings yet

- Duroflex 1K: Product Data SheetDocument4 pagesDuroflex 1K: Product Data SheetVaittianathan MahavapillaiNo ratings yet

- Technical Data Sheet: Lasteek Rwe500Document2 pagesTechnical Data Sheet: Lasteek Rwe500Engr KamalNo ratings yet

- Crystalline Water ProofingDocument3 pagesCrystalline Water ProofingAbubakar Ashraf AnjumNo ratings yet

- TDS Weberfloor 620 PMB PlusDocument3 pagesTDS Weberfloor 620 PMB PlusBurak AkyazıNo ratings yet

- Silicate Sealer, Floor Hardener: Description Typical Properties & Application DataDocument1 pageSilicate Sealer, Floor Hardener: Description Typical Properties & Application DataTomás Nunes da SilvaNo ratings yet

- Renovating Plaster: A Pre-Mixed Lightweight Plaster For Damp Proofing ApplicationsDocument1 pageRenovating Plaster: A Pre-Mixed Lightweight Plaster For Damp Proofing ApplicationswassimmahfouzNo ratings yet

- 4650 Aquastop FlexibleDocument4 pages4650 Aquastop Flexiblewawen03No ratings yet

- K11 Slurry 613 PDFDocument3 pagesK11 Slurry 613 PDFNanie RidzwanNo ratings yet

- Acrylic WaterProofing Liquide TDSDocument3 pagesAcrylic WaterProofing Liquide TDSMohamed MagdiNo ratings yet

- Fairmate Waterproofing - PunjabDocument128 pagesFairmate Waterproofing - PunjabAyush GoyalNo ratings yet

- Hyperdesmo 815Document5 pagesHyperdesmo 815Roger DaoudNo ratings yet

- XL70 W Textured Coating Mar 2019Document2 pagesXL70 W Textured Coating Mar 2019Raj K SharmaNo ratings yet

- Sikatop® Seal-107 In: Product Data SheetDocument4 pagesSikatop® Seal-107 In: Product Data SheetMukesh RajNo ratings yet

- Sika® Concrete Crack Fix: Product Data SheetDocument3 pagesSika® Concrete Crack Fix: Product Data SheetHamidreza AraghianNo ratings yet

- Sikatop®-107 Seal KH: Product Data SheetDocument4 pagesSikatop®-107 Seal KH: Product Data SheetReab SimanthNo ratings yet

- Polyhard: Mineral Based Dry Shake Floor HardenerDocument2 pagesPolyhard: Mineral Based Dry Shake Floor HardenerAlexi ALfred H. TagoNo ratings yet

- XL70 SolventDocument3 pagesXL70 SolventRaj K SharmaNo ratings yet

- Ideal Rock Umido Tec EngDocument2 pagesIdeal Rock Umido Tec EngPedroNo ratings yet

- Maxseal Flex EngDocument4 pagesMaxseal Flex EngMohit Rakesh GuptajiNo ratings yet

- Fosroc Conbextra EPGP: Constructive SolutionsDocument2 pagesFosroc Conbextra EPGP: Constructive SolutionsVincent JavateNo ratings yet

- Bostik Boscolastic Rev1Document2 pagesBostik Boscolastic Rev1decenabuilders2016No ratings yet

- RF#7 Datasheet - 3 PDFDocument2 pagesRF#7 Datasheet - 3 PDFAung Naing Latt AungNo ratings yet

- Fosroc Dekguard S TDSDocument3 pagesFosroc Dekguard S TDSManoharan RNo ratings yet

- Aqua-Cure VOXDocument2 pagesAqua-Cure VOXChris ChanonaNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Waterproof Coatings For High Rise Construction PDFDocument1 pageWaterproof Coatings For High Rise Construction PDFVasanth KumarNo ratings yet

- CGLE Notice 2018 05.05.2018Document46 pagesCGLE Notice 2018 05.05.2018Shashi PrakashNo ratings yet

- Waterproof Coatings For High Rise Construction PDFDocument1 pageWaterproof Coatings For High Rise Construction PDFVasanth KumarNo ratings yet

- DR Fixit Flexi Pu 270 I PDFDocument4 pagesDR Fixit Flexi Pu 270 I PDFDeepak KhannaNo ratings yet

- Powder Metallurgy: Dr. Chaitanya Sharma Phd. Iit RoorkeeDocument46 pagesPowder Metallurgy: Dr. Chaitanya Sharma Phd. Iit RoorkeeShivam DixitNo ratings yet

- OBJECTIVESDocument5 pagesOBJECTIVESlaila100% (1)

- Formation of Chemical Bondings and Covalent CompoundsDocument44 pagesFormation of Chemical Bondings and Covalent CompoundsMenaga IlangkovanNo ratings yet

- Class 10 Chemistry Chapter 8 Revision NotesDocument3 pagesClass 10 Chemistry Chapter 8 Revision NotesMd TaaseenNo ratings yet

- Baral Chemical Product Cost Analysis DetailDocument27 pagesBaral Chemical Product Cost Analysis DetailHamayet Rasel82% (11)

- Fire Cabinet - SF - 600 SeffcoDocument4 pagesFire Cabinet - SF - 600 Seffcosuresh kumarNo ratings yet

- Design of Culvert - Excel SheetDocument17 pagesDesign of Culvert - Excel Sheethafiz zain saeed67% (3)

- Air Liquide MRPL Overview and Air Liquide Geismar Utility ServicesDocument15 pagesAir Liquide MRPL Overview and Air Liquide Geismar Utility ServicesPland SpringNo ratings yet

- Repair Pocket Guide B31Document2 pagesRepair Pocket Guide B31Adolfo Israel Ayuso SaezNo ratings yet

- Painting and Coating Technical SpecificationDocument54 pagesPainting and Coating Technical SpecificationJessica RodriguezNo ratings yet

- Chemicals StatusDocument1 pageChemicals StatusfahadullahNo ratings yet

- Nystrom Expansion Joint System CatalogDocument48 pagesNystrom Expansion Joint System CatalogRonnie1478No ratings yet

- AstroCel® IDocument1 pageAstroCel® IDesiana PermataNo ratings yet

- Perfad™ 8400: High Performance Polymeric Lubricity AdditiveDocument5 pagesPerfad™ 8400: High Performance Polymeric Lubricity AdditiveShaara NeyNo ratings yet

- Netcol5000-A025 In-Row Air Cooled Smart Cooling Product Quick Guide (300 MM Width)Document34 pagesNetcol5000-A025 In-Row Air Cooled Smart Cooling Product Quick Guide (300 MM Width)Myo Min HeinNo ratings yet

- Experimental Study On Partial Replacement of Cement in Concrete by Incineration Ash of Municipal SolidDocument4 pagesExperimental Study On Partial Replacement of Cement in Concrete by Incineration Ash of Municipal SolidInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- WWW DGet Best Top Lamination Adhesive Manufacturers in India - Dic Ic Co in Products Lamination-AdhesivesDocument5 pagesWWW DGet Best Top Lamination Adhesive Manufacturers in India - Dic Ic Co in Products Lamination-Adhesivesdezmark DigitalNo ratings yet

- EagleBurgmann - ED01081 - ED4 - Table of Materials For Mechanical Seals - 02.10Document2 pagesEagleBurgmann - ED01081 - ED4 - Table of Materials For Mechanical Seals - 02.10calr207186No ratings yet

- Carta de Color 5000 - 4500Document2 pagesCarta de Color 5000 - 4500JuanNo ratings yet

- Cutting Tool Technology: Review QuestionsDocument17 pagesCutting Tool Technology: Review QuestionsKhaled ShaabanNo ratings yet

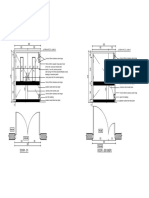

- General Notes:: CCTV and Smoke Detector ScheduleDocument1 pageGeneral Notes:: CCTV and Smoke Detector ScheduleLhewiz BrionesNo ratings yet

- Dossing ChemicalsDocument4 pagesDossing ChemicalsHamid UllahNo ratings yet

- Powder Metallurgy: Professor DR Andanastuti Muchtar KM2833 Manufacturing Processes Sem 1 Session 2019/2020Document26 pagesPowder Metallurgy: Professor DR Andanastuti Muchtar KM2833 Manufacturing Processes Sem 1 Session 2019/2020SajjadNo ratings yet

- Glass-Fibre Reinforced Plastic Pipeline and Piping SystemsDocument10 pagesGlass-Fibre Reinforced Plastic Pipeline and Piping SystemsTurbo Snail RNo ratings yet

- GF Indonesia Brochure PR UTS 0417 Garda SuryaDocument12 pagesGF Indonesia Brochure PR UTS 0417 Garda SuryaRival Juney Christian PatrasNo ratings yet

- Design Example - Deep Mass Concrete Pad BaseDocument5 pagesDesign Example - Deep Mass Concrete Pad BaseAnonymous xcFcOgMi100% (1)

- NEMA and IP TestingDocument4 pagesNEMA and IP TestingAnonymous j5apk2AumNo ratings yet

- UNIT 10 Organic ChemistryDocument51 pagesUNIT 10 Organic ChemistryTristan PereyNo ratings yet

- Eaton Brochure 03 - 401-2010 (Eaton Vickers) ENGLISH.Document7 pagesEaton Brochure 03 - 401-2010 (Eaton Vickers) ENGLISH.jddiazmNo ratings yet

- Door - D1 Door - Ds1 (Mep) : Inside InsideDocument1 pageDoor - D1 Door - Ds1 (Mep) : Inside InsideSaZanAwalNo ratings yet