Professional Documents

Culture Documents

Tensioner With Inspection Hole: Application Example

Uploaded by

Federico CazzolliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tensioner With Inspection Hole: Application Example

Uploaded by

Federico CazzolliCopyright:

Available Formats

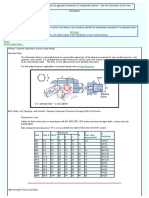

TENSIONER WITH INSPECTION HOLE

S355 galvanized carbon steel

DIN 1478

L R

code bar langth pcs/box

SSS12125 M12 125 1

SSS16170 M16 170 1

SSS20200 M20 200 1

R = right-hand thread

L = left-hand thread SSS24255 M24 255 1

SSS27255 M27 255 1

SSS30255 M30 255 1

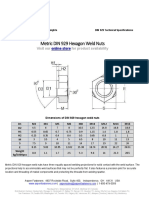

GEOMETRY OF THE TENSIONER ACCORDING TO DIN 1478

M12 M16 M20 M24 M27* M30

C [mm] 25,0 30,0 33,7 42,4 42,4 51,0

F [mm] 10 10 12 12 12 16

C E [mm] 4,0 4,5 5,0 5,6 5,6 6,3

A [mm] 125 170 200 255 255 255

K E B [mm] 15 20 24 29 40 36

F B

K [mm] 35 45 55 70 85 85

A

* size not included in DIN 1478

K = penetration depth of the threaded bar

STATIC VALUES - TENSILE STRENGTH

Fax Fax M12 M16 M20 M24 M27 M30

Nax,k [kN] 66,20 97,38 119,09 184,69 184,69 245,92

Namm [kg] 44,13 64,92 79,40 123,12 123,12 163,94

Nax,k are characteristic values according to EN 1993,, Namm are admissible values

Design values can be obtained from characteristic values as follows: Nax,d = Nax,k / γm0

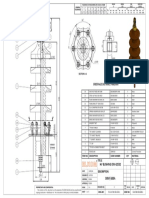

APPLICATION EXAMPLE

ITEMIZED LIST

• 1 disk for bracing

• 4 tensioners

• 4 hooks for bracing R

R • 4 hooks for bracing L

L

R • 8 threaded bars R - L *

L

NOTES

R = right-hand thread

L = left-hand thread * Products not provided by rothoblaas as they shall be dimensioned case by case

TENSIONER - 01

You might also like

- Metric DIN 7349 SpecDocument6 pagesMetric DIN 7349 SpecANIRBANNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Job Information: Engineer Checked Approved Name: Date: Structure TypeDocument9 pagesJob Information: Engineer Checked Approved Name: Date: Structure Typealvin ersandoNo ratings yet

- KOP en Technical Data SheetDocument6 pagesKOP en Technical Data SheetmcbluedNo ratings yet

- HHD - S.Technical - Information - ASSET - DOC - 2331274Document2 pagesHHD - S.Technical - Information - ASSET - DOC - 2331274Hoa Ly TrắngNo ratings yet

- Catalogo Adaptadores HidraulicosDocument97 pagesCatalogo Adaptadores HidraulicosGonzalo Villalobos SanchezNo ratings yet

- Large Diameter: Couplings OD355.6 - 816Document4 pagesLarge Diameter: Couplings OD355.6 - 816Joh SongthamNo ratings yet

- Metric DIN 439 Spec PDFDocument4 pagesMetric DIN 439 Spec PDFHasib SejdinovicNo ratings yet

- 13.-En_NT_Bolts_UtilcellDocument3 pages13.-En_NT_Bolts_Utilcellnu.arabiaNo ratings yet

- Bolt & Nut Torque Table PDFDocument6 pagesBolt & Nut Torque Table PDFFandy MaulanNo ratings yet

- FlangeDocument10 pagesFlangeNurul LailyahNo ratings yet

- Kpz-Cylinder Compact PN 0822 392 304-Page 43Document89 pagesKpz-Cylinder Compact PN 0822 392 304-Page 43Jamin SmtpngNo ratings yet

- Materials and Spare Parts (11.8.2016)Document7 pagesMaterials and Spare Parts (11.8.2016)MinNo ratings yet

- Bolt Size & Torque TableDocument5 pagesBolt Size & Torque TableFirman andikaNo ratings yet

- Metal Plug TorqueDocument2 pagesMetal Plug TorqueArun JaisonNo ratings yet

- Rfqr211351 - Enquiry For DriveDocument34 pagesRfqr211351 - Enquiry For DriveyuwonoNo ratings yet

- CounterboreDocument3 pagesCounterborejonNo ratings yet

- DIN 929 Hexagon Weld Nut Technical Specifications and DimensionsDocument4 pagesDIN 929 Hexagon Weld Nut Technical Specifications and DimensionsDobrica PetrovicNo ratings yet

- ISO - 7380 - Button Head Hexagon Socket Cap Screw PDFDocument5 pagesISO - 7380 - Button Head Hexagon Socket Cap Screw PDFKevinNo ratings yet

- ER Spring Collet Chuck System: Mounting Instructions For ER Collets DIN 6499-A and DIN 6499-BDocument10 pagesER Spring Collet Chuck System: Mounting Instructions For ER Collets DIN 6499-A and DIN 6499-BdavicocasteNo ratings yet

- Grundfosliterature 2616Document22 pagesGrundfosliterature 2616Sal MendezNo ratings yet

- Metric DIN 432 SpecDocument4 pagesMetric DIN 432 SpecivanNo ratings yet

- Datasheet CEMBRE CABLE GLANDS POLYAMIDE 1900-1901 SERIES (EN)Document6 pagesDatasheet CEMBRE CABLE GLANDS POLYAMIDE 1900-1901 SERIES (EN)manulo85No ratings yet

- ZSD-EX-TDS-PW-0028-General Item Hangers and Supports PDFDocument78 pagesZSD-EX-TDS-PW-0028-General Item Hangers and Supports PDFSreejesh SreeNo ratings yet

- Series: Male Connector: KJHDocument9 pagesSeries: Male Connector: KJHSorin IordacheNo ratings yet

- 12.1 - Cabinet and Harness Parts, GaugesDocument22 pages12.1 - Cabinet and Harness Parts, GaugesMiguel Angel RodriguezNo ratings yet

- About WELDA Anchor PlateDocument1 pageAbout WELDA Anchor PlateFircijevi KurajberiNo ratings yet

- Metric DIN 985 Nylon Insert Lock Nut Dimensions & SpecsDocument4 pagesMetric DIN 985 Nylon Insert Lock Nut Dimensions & Specsvikram jainNo ratings yet

- 01 - Cabinet and Harness Parts, GaugesDocument25 pages01 - Cabinet and Harness Parts, GaugesCristhian noe De la cruz RamónNo ratings yet

- HBS SOFTWOOD-en-technical-data-sheetDocument4 pagesHBS SOFTWOOD-en-technical-data-sheetKenan AvdusinovicNo ratings yet

- Concentrically Loaded ColumnsDocument4 pagesConcentrically Loaded ColumnsOmar TariqNo ratings yet

- THG Hooks Forged Hooks Catalogue SheetDocument5 pagesTHG Hooks Forged Hooks Catalogue SheetjhonNo ratings yet

- THG Hooks Forged Hooks Catalogue Sheet PDFDocument5 pagesTHG Hooks Forged Hooks Catalogue Sheet PDFjhonNo ratings yet

- Cable GlandsDocument4 pagesCable GlandsRicardo CessaNo ratings yet

- SAS System enDocument8 pagesSAS System enThomas SánchezNo ratings yet

- Electrical Components CatalogueDocument113 pagesElectrical Components Cataloguejose luis Ogalde acuña100% (2)

- CATALOGUE PAM-en-flangesDocument9 pagesCATALOGUE PAM-en-flangesDeepak JoyNo ratings yet

- Elk FJM 30 630 1Document1 pageElk FJM 30 630 1kajian19 juniNo ratings yet

- WH Me 062008Document1 pageWH Me 062008abdul.shukur4uNo ratings yet

- Heat Exchanger 521.49Document1 pageHeat Exchanger 521.49dejanpecicNo ratings yet

- Lecture # 20 & 21Document16 pagesLecture # 20 & 21VaridGuptaNo ratings yet

- Electrical Spare Parts Catalogue 2015.Document139 pagesElectrical Spare Parts Catalogue 2015.Enso E Rosales F100% (1)

- Parts BR 255Document7 pagesParts BR 255SMM ENTREPRISENo ratings yet

- 2013 Fuel Ex 5 6 7Document1 page2013 Fuel Ex 5 6 7bhpopayanNo ratings yet

- Company Name: Design Specifications Nozzles Couplings / SupportsDocument21 pagesCompany Name: Design Specifications Nozzles Couplings / Supportsmohsen ranjbarNo ratings yet

- Compact planetary gear motor technical specificationsDocument4 pagesCompact planetary gear motor technical specificationsRakesh B BalehosurNo ratings yet

- Fasteners Volume & Price DetailsDocument8 pagesFasteners Volume & Price DetailsmshNo ratings yet

- DIN 7980 Spring Lock Washer - Fasteners ChinaDocument2 pagesDIN 7980 Spring Lock Washer - Fasteners ChinaHala Ibrahim El-BassyouniNo ratings yet

- Wrench ClearancesDocument2 pagesWrench ClearancesRowan JoguilonNo ratings yet

- C Range Anchor: CompositionDocument1 pageC Range Anchor: CompositionDejan JanevNo ratings yet

- C Range Anchor: CompositionDocument1 pageC Range Anchor: CompositionDejan JanevNo ratings yet

- C Range Anchor: CompositionDocument1 pageC Range Anchor: CompositionDejan JanevNo ratings yet

- C Range Anchor: CompositionDocument1 pageC Range Anchor: CompositionDejan JanevNo ratings yet

- C Range Anchor: CompositionDocument1 pageC Range Anchor: CompositionDejan JanevNo ratings yet

- 0021 PDFDocument1 page0021 PDFDejan JanevNo ratings yet

- C Range Anchor: CompositionDocument1 pageC Range Anchor: CompositionDejan JanevNo ratings yet

- C range compact anchor unitsDocument1 pageC range compact anchor unitsDejan JanevNo ratings yet

- C Range Anchor: CompositionDocument1 pageC Range Anchor: CompositionDejan JanevNo ratings yet

- C Range Anchor: CompositionDocument1 pageC Range Anchor: CompositionDejan JanevNo ratings yet

- 5 Successful Open Innovation ExamplesDocument44 pages5 Successful Open Innovation ExamplesSambhav MehtaNo ratings yet

- Toaz - Info Super Coolant Af Nac PRDocument6 pagesToaz - Info Super Coolant Af Nac PRsugi yantoNo ratings yet

- CerebrumDocument26 pagesCerebrumsanthiyasandy100% (1)

- 1,2,4-Triazoles: A Review of Synthetic Approaches and The Biological ActivityDocument22 pages1,2,4-Triazoles: A Review of Synthetic Approaches and The Biological Activitymf720383270No ratings yet

- Liugong 938l Wheel Loader Parts ManualDocument20 pagesLiugong 938l Wheel Loader Parts Manualviolet100% (56)

- CJ1M Programming ManualDocument381 pagesCJ1M Programming ManualherpadianaNo ratings yet

- ISO Standards in ProcessDocument20 pagesISO Standards in ProcessYeni OktaviaNo ratings yet

- Meng 2nd Year Death Anniversary MassDocument6 pagesMeng 2nd Year Death Anniversary Massjoy in the spirit of the lordNo ratings yet

- LIST of Tools-BartenderDocument5 pagesLIST of Tools-BartenderLegal DepartmentNo ratings yet

- Electronic Control Module (ECM) : Shutdown SIS Previous ScreenDocument5 pagesElectronic Control Module (ECM) : Shutdown SIS Previous ScreenWladimir AmaguañaNo ratings yet

- E420 S1100 Fact SheetDocument7 pagesE420 S1100 Fact Sheetiskandarn_el5735No ratings yet

- SI 410 Weighing Indicator User ManualDocument64 pagesSI 410 Weighing Indicator User ManualShehab100% (2)

- BrinjalDocument2 pagesBrinjalGajananNo ratings yet

- HeavyMetalLimits For Leachability PROP 65 PB and CDDocument3 pagesHeavyMetalLimits For Leachability PROP 65 PB and CDspades24kNo ratings yet

- Aeroacoustic and Aerodynamic Optimization of Propeller BladesDocument14 pagesAeroacoustic and Aerodynamic Optimization of Propeller BladesWouterr GNo ratings yet

- The Effectiveness of Food Labelling in Controlling Ones Calorie IntakeDocument33 pagesThe Effectiveness of Food Labelling in Controlling Ones Calorie IntakeKisha Ghay SudariaNo ratings yet

- Guidelines For Dengue Surveillance Edition2.PDF WHODocument115 pagesGuidelines For Dengue Surveillance Edition2.PDF WHOFebyan Kuan Lu Hap100% (1)

- Rohail Hassan: ObjectiveDocument3 pagesRohail Hassan: ObjectiveNoumanKhanNo ratings yet

- Development of Automatic Mini Fan with PIR SensorDocument8 pagesDevelopment of Automatic Mini Fan with PIR SensorToheebdareNo ratings yet

- Paracetamol GuideDocument3 pagesParacetamol GuideJanine SantosNo ratings yet

- Fault Codes: Brake (DSC/DXC (Dynamic Stability Control) - Bosch 8.0 - Tyre Pressure Monitoring)Document5 pagesFault Codes: Brake (DSC/DXC (Dynamic Stability Control) - Bosch 8.0 - Tyre Pressure Monitoring)zacarias NiquiceNo ratings yet

- VIVI Ref Part 2 PDFDocument111 pagesVIVI Ref Part 2 PDFAaron OliverNo ratings yet

- Chords ListDocument5 pagesChords ListakshayNo ratings yet

- MRCP EthicsDocument33 pagesMRCP EthicstaherNo ratings yet

- Structural Dyanmics-Anna University Q PaperDocument7 pagesStructural Dyanmics-Anna University Q PaperVijay AravindNo ratings yet

- Unit 1 Purva Swadhyaya QuestionsDocument4 pagesUnit 1 Purva Swadhyaya QuestionsSurrender to Krishna AlwaysNo ratings yet

- Telangana Govt T-PRIDE Scheme GuidelinesDocument90 pagesTelangana Govt T-PRIDE Scheme GuidelinesitzprasuNo ratings yet

- MandrakeDocument6 pagesMandrakeEmry Kamahi Tahatai KereruNo ratings yet

- Tunics Step by StepDocument10 pagesTunics Step by Stepsarahmichelef100% (18)

- Easytronic Micro II 28 05 2010 08 35 20 Revision 05 Controller 1 PDFDocument10 pagesEasytronic Micro II 28 05 2010 08 35 20 Revision 05 Controller 1 PDFСергей Заика100% (1)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- Meltdown: Nuclear disaster and the human cost of going criticalFrom EverandMeltdown: Nuclear disaster and the human cost of going criticalRating: 5 out of 5 stars5/5 (5)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (3)

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideFrom EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNo ratings yet

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilFrom EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilRating: 5 out of 5 stars5/5 (1)

- Coating and Drying Defects: Troubleshooting Operating ProblemsFrom EverandCoating and Drying Defects: Troubleshooting Operating ProblemsRating: 5 out of 5 stars5/5 (1)

- Chemistry: a QuickStudy Laminated Reference GuideFrom EverandChemistry: a QuickStudy Laminated Reference GuideRating: 5 out of 5 stars5/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (90)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeRating: 4 out of 5 stars4/5 (1)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsFrom EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsNo ratings yet

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- Chemistry: 1001 Practice Problems For Dummies (+ Free Online Practice)From EverandChemistry: 1001 Practice Problems For Dummies (+ Free Online Practice)No ratings yet

- Transformer: The Deep Chemistry of Life and DeathFrom EverandTransformer: The Deep Chemistry of Life and DeathRating: 4.5 out of 5 stars4.5/5 (13)

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeFrom EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeRating: 5 out of 5 stars5/5 (1)

- A Perfect Red: Empire, Espionage, and the Quest for the Color of DesireFrom EverandA Perfect Red: Empire, Espionage, and the Quest for the Color of DesireRating: 4 out of 5 stars4/5 (129)