Professional Documents

Culture Documents

CSX Intermodal Terminas-Charleston

Uploaded by

FrancisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CSX Intermodal Terminas-Charleston

Uploaded by

FrancisCopyright:

Available Formats

3D CONFINEMENT SYSTEM REINFORCES

GEOWEB ®

ACTIVE HEAVY LOAD AREAS AT CSX RAIL LAYDOWN YARD

CHARLESTON, SOUTH CAROLINA

PROJECT OVERVIEW:

The CSX Charleston Intermodal

terminal aggregate surface lot

required base reinforcement

due to poor subgrade condi-

PROJECT TEAM tions. The two areas included

OWNER: CSX Intermodal Terminals one area to support 120,000

ENGINEER: Wendi Leanhardt, P.E. CSX Facilities Manager, pound reach stackers lifting

South Region, Terminal Development, Jacksonville, FL

Monique Whitehead, CSX Terminal Manager and moving 10,000 pound con-

GENERAL CONTRACTOR: Polivka International Co., Inc. tainers and an existing grass

ON-SITE MANUFACTURER’S REP & MAT’L SUPPLIER: area to support empty chassis

Staci Smith, P.E., ACF Environmental

parking.

USE OF ON-SITE INFILL ELIMINATES HAULING OF FILL,

LIMITS DOWNTIME AT HIGH VOLUME TERMINAL

GEOWEB® LOAD SUPPORT DESIGN SOLUTIONS

SOLUTION Presto Geosystems provided sepa-

rate design recommendations for

CSX Project Engineer Wendi Lean-

the reach stacker and chassis park-

hardt contacted Staci Smith, PE, Re-

ing areas utilizing the on-site mate-

gional Engineer for ACF Environ-

Top photo: Chassis parking area rial which eliminated the need to

mental for assistance and solutions

Bottom photo: Loaded rail containers haul in select fill. Each design was

to stabilize a soft sub base for the

calculated factoring in the sub

container yard facilities. Wendi,

base type/strength, loading

Staci and Bryan Wedin, P.E., Chief

weight, and frequency of traffic.

Design Engineer for Presto Geosys-

tems, worked together to develop a

solution. CSX obtained geotechnical

information on the site’s soils to 1)

determine if it could be used for the

GEOWEB infill and 2) assess the cur-

rent base stability of each site.

3D CONFINEMENT SYSTEM REINFORCES

GEOWEB®

ACTIVE HEAVY LOAD AREAS AT CSX RAIL LAYDOWN YARD

CHARLESTON, SOUTH CAROLINA

ECONOMICAL AND EFFICIENT SOLUTION

SHORTENS DOWNTIME, REDUCES MAINTENANCE

Eliminating the need to import chassis parking area utilized a

costly fill, the downtime of the high strength woven geotextile

yard was significantly reduced and GEOWEB GW30V6 sections

which was especially important with a two inch wearing surface.

due to the high volume of trac- Both areas will have minimal

tor trailers the facility handles maintenance to maintain the

on a daily basis. surface.

The reach stacker area used a In both locations, the GEOWEB

high strength woven geotextile, sections were anchored with

three inches of aggregate base, ten, 18-inch long No. 4 rebar

GEOWEB GW30V6 (mid-size capped with Presto’s patented

cell, 6 inch deep) sections and ATRA® Stake Clips.

two-inch wearing surface. The

TOTAL GEOWEB-REINFORCED PROJECT:

A total of 1.75 acres of laydown yard was stabilized with the GEOWEB

Cellular Confinement System in May of 2015. As of December 2015, the

areas were functioning according the requirements set by CSX.

GEOSYNTHETIC SOLUTION

GEOWEB sections were placed over a high strength

woven geotextile. Locally-available aggregate infill ANCHORING of GEOWEB

was used, eliminating the need to import costly fill. SECTIONS

A two-inch wearing surface covers the top surface.

ATRA® Stake Clips are temporary

or permanent anchors to facilitate

construction of GEOWEB sections.

The lipped arm of the ATRA stake

clip head makes a secure connec-

tion with the GEOWEB cell wall.

ATRA® Drivers are used

with ATRA anchors to drive

anchors quickly and efficiently.

PRESTO GEOSYSTEMS

www.prestogeo.com

©2016 Presto Products Company. All Rights Reserved.

GEOWEB® is a registered trademark of Reynolds Presto Products Inc.

You might also like

- Carburadores ManualDocument205 pagesCarburadores Manualjorge alonso67% (3)

- Simplified Method For Performance-Based Siesmic Design of Suction Caisson Supporting Jacket OWTDocument23 pagesSimplified Method For Performance-Based Siesmic Design of Suction Caisson Supporting Jacket OWTDang Quang MinhNo ratings yet

- Bearing Capacity for Spread Footings Placed Near c - ϕ SlopesDocument5 pagesBearing Capacity for Spread Footings Placed Near c - ϕ SlopesEmre AkınayNo ratings yet

- Ssea 2022 58Document6 pagesSsea 2022 58Christian nuñezNo ratings yet

- Design and Analysis Software For Offshore Structures: Key ComponentsDocument8 pagesDesign and Analysis Software For Offshore Structures: Key Componentshoangmy0106No ratings yet

- SACSDocument8 pagesSACSalibbaaNo ratings yet

- The Nimble Node - Million-Channel Land Recording Systems Have ArrivedDocument8 pagesThe Nimble Node - Million-Channel Land Recording Systems Have ArrivedМаксим Валерьевич ТарасовNo ratings yet

- Bentley SACS: Offshore Wind Turbine AnalysisDocument2 pagesBentley SACS: Offshore Wind Turbine AnalysisRAM KUMARNo ratings yet

- 1999 Cost-Effective Load Transfer Restoration of JCP - Correa, A.Document2 pages1999 Cost-Effective Load Transfer Restoration of JCP - Correa, A.José M.No ratings yet

- Akers - A Method of Structural Load Prediction For High-Speed Planing Craft (SNAME)Document24 pagesAkers - A Method of Structural Load Prediction For High-Speed Planing Craft (SNAME)Tomislav TomoNo ratings yet

- Development and Applications of 3D Cartesian CFD TechnologyDocument5 pagesDevelopment and Applications of 3D Cartesian CFD TechnologyBuican GeorgeNo ratings yet

- AA-V6-I1-Making-the-Connection WYE ILSDocument3 pagesAA-V6-I1-Making-the-Connection WYE ILSAizat NajibNo ratings yet

- Design Considerations For III Dynamically Positioned VesselsDocument22 pagesDesign Considerations For III Dynamically Positioned VesselsSHARATHNo ratings yet

- Gps BulldozerDocument1 pageGps BulldozerToaca EugeniuNo ratings yet

- Current Design and Construction Practices For Micropile Supported Foundations of Electrical Transmission Structures in North AmericaDocument7 pagesCurrent Design and Construction Practices For Micropile Supported Foundations of Electrical Transmission Structures in North Americamarcus viniciusNo ratings yet

- Winter 95Document60 pagesWinter 95Artur SascovNo ratings yet

- Oilfield Review 3Document14 pagesOilfield Review 3Luis Alberto Colan GarciaNo ratings yet

- Predicting End Bearing Capacity of Post-Grouted Drilled Shaft in Cohesionless SoilsDocument10 pagesPredicting End Bearing Capacity of Post-Grouted Drilled Shaft in Cohesionless SoilsTran Tien DungNo ratings yet

- New Look at DCP Test With A Link To AASHTO SN ConceptDocument11 pagesNew Look at DCP Test With A Link To AASHTO SN ConceptMahdi SardarNo ratings yet

- Makai Lay SeismicDocument5 pagesMakai Lay SeismicIshan JoshiNo ratings yet

- Structural Coefficients of Cold Central-Plant Recycled Asphalt MixturesDocument7 pagesStructural Coefficients of Cold Central-Plant Recycled Asphalt Mixturescarlos mauricio castillo londoñoNo ratings yet

- Direct Strength Method (DSM) For Design of Cold-Formed Steel Sections Under Localised LoadingDocument2 pagesDirect Strength Method (DSM) For Design of Cold-Formed Steel Sections Under Localised LoadingMostafa HusseinNo ratings yet

- 2000 Shuttle ArDocument48 pages2000 Shuttle ArElga Pramono PutriNo ratings yet

- Structure For Helicopter ApplicationDocument19 pagesStructure For Helicopter ApplicationJan ScarNo ratings yet

- Conclusions and Recommendations: Validation and Application of The Embedded Pile Row-Feature in PLAXIS 2DDocument1 pageConclusions and Recommendations: Validation and Application of The Embedded Pile Row-Feature in PLAXIS 2DtehNo ratings yet

- NASA 153084main Fs RTF 3shuttleDocument2 pagesNASA 153084main Fs RTF 3shuttleNASAdocumentsNo ratings yet

- Articulo de Investigacion de Racks 1Document20 pagesArticulo de Investigacion de Racks 1J ZEGARRANo ratings yet

- Summary For Decision Makers On Second GenerationDocument22 pagesSummary For Decision Makers On Second GenerationAbdul QuaderNo ratings yet

- 10.1016 J.sandf.2014.04.015 UanwDocument8 pages10.1016 J.sandf.2014.04.015 Uanwzahra yousefiNo ratings yet

- 1241 004 PDFDocument7 pages1241 004 PDFSelçuk GülarıNo ratings yet

- Reservoir Characterization Using Expert Knowledge, Data and StatisticsDocument15 pagesReservoir Characterization Using Expert Knowledge, Data and StatisticsIky CahyaNo ratings yet

- Computer Pred I CT Ions For Axiaiiy-Loaded Piies With Non I Near SupportsDocument14 pagesComputer Pred I CT Ions For Axiaiiy-Loaded Piies With Non I Near SupportscmkohNo ratings yet

- Structures, Structural Dynamics and Materials ConferenceDocument15 pagesStructures, Structural Dynamics and Materials ConferenceBogdan PashistyNo ratings yet

- 2020 August, Preliminary Design of Post-Tensioned Transfer GirdersDocument7 pages2020 August, Preliminary Design of Post-Tensioned Transfer GirdersMonika jainNo ratings yet

- Performance-Based Seismic Design of Rocking Shallow Foundations in Cohesive SoilDocument14 pagesPerformance-Based Seismic Design of Rocking Shallow Foundations in Cohesive SoilSong FendaNo ratings yet

- (Moyes, Etal 2005) Piled Raft Design Process For A High-Rise Building On The Gold Coast, AustraliaDocument9 pages(Moyes, Etal 2005) Piled Raft Design Process For A High-Rise Building On The Gold Coast, AustraliaHarrison StamoudisNo ratings yet

- Introduction To Air-Insulated Substations: Koji KawakitaDocument6 pagesIntroduction To Air-Insulated Substations: Koji KawakitaKURAKULA VIMAL KUMARNo ratings yet

- Pages From Smith & Hendy 2009 5Document1 pagePages From Smith & Hendy 2009 5Napong SubanpongNo ratings yet

- HTTP WWW - Sciencedirecsdarticle PDFDocument12 pagesHTTP WWW - Sciencedirecsdarticle PDFabdallahNo ratings yet

- Fatigue Design Considerations For DeepwaterDocument13 pagesFatigue Design Considerations For DeepwaterkorohixNo ratings yet

- Materials Today: Proceedings: M. RamalakshmiDocument5 pagesMaterials Today: Proceedings: M. Ramalakshmisina maafNo ratings yet

- Gom Stone EnergyDocument2 pagesGom Stone EnergyMuhammad HaidarNo ratings yet

- Ground Treatment/Improvement Ground Treatment/Improvement: Materials Existing orDocument8 pagesGround Treatment/Improvement Ground Treatment/Improvement: Materials Existing orShahzada PhookNo ratings yet

- Pavement Design & Traffic Census WorkshopDocument38 pagesPavement Design & Traffic Census WorkshopJK HallNo ratings yet

- Physical Synthesis 2.0Document52 pagesPhysical Synthesis 2.0ravishopingNo ratings yet

- Missiles Rockets 1011 Un SeDocument969 pagesMissiles Rockets 1011 Un SeBuican GeorgeNo ratings yet

- Akhtar2006Document14 pagesAkhtar2006Ishaq Khan IKNo ratings yet

- Spacecraft Kinematic Mounts SimulationDocument15 pagesSpacecraft Kinematic Mounts Simulationhanson219100% (1)

- Zero-Offset Vertical Seismic Profiles: High-Resolution Attributes For Reservoir CharacterizationDocument2 pagesZero-Offset Vertical Seismic Profiles: High-Resolution Attributes For Reservoir CharacterizationHilman MardiyanNo ratings yet

- Seismic Design Criteria For Slab-Column ConnectionsDocument12 pagesSeismic Design Criteria For Slab-Column ConnectionsIvan Jansen S.No ratings yet

- BPG StGeorge Construction LoadingDocument3 pagesBPG StGeorge Construction LoadingH (Chief11)No ratings yet

- Developing A Risk Assessment Model For Trenchless Technology-Box Jacking TechniqueDocument12 pagesDeveloping A Risk Assessment Model For Trenchless Technology-Box Jacking TechniqueHồng Phương LêNo ratings yet

- Performance of Geogrid-Reinforced and PTC Pile-Supported Embankment in A Highway Widening Project Over Soft SoilsDocument10 pagesPerformance of Geogrid-Reinforced and PTC Pile-Supported Embankment in A Highway Widening Project Over Soft SoilsSUYADI SUYADINo ratings yet

- MT1 2020-21 Spring - Q5Document1 pageMT1 2020-21 Spring - Q5Yusuf ŞaşmazNo ratings yet

- ATK Advanced Booster PaperDocument6 pagesATK Advanced Booster PaperKaleb SmithNo ratings yet

- Point Loads On Precast Concrete FloorsDocument19 pagesPoint Loads On Precast Concrete Floorskhemindra narainNo ratings yet

- Lifting Analysis Preview)Document4 pagesLifting Analysis Preview)Faisal AjaNo ratings yet

- Inclined Pull-Out Capacity of Suction Caisson Embedded in SandDocument10 pagesInclined Pull-Out Capacity of Suction Caisson Embedded in SandDang Quang MinhNo ratings yet

- Shape Memory Alloy Mechanisms For CubeSatsDocument2 pagesShape Memory Alloy Mechanisms For CubeSatsأحمد الحسنNo ratings yet

- On Line Tour Page Under CEDAS RevisedDocument68 pagesOn Line Tour Page Under CEDAS RevisedVishnu S DasNo ratings yet

- Gallium Nitride-enabled High Frequency and High Efficiency Power ConversionFrom EverandGallium Nitride-enabled High Frequency and High Efficiency Power ConversionGaudenzio MeneghessoNo ratings yet

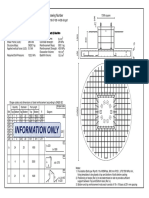

- FND - FLM 30m 2.5 0 8x455W at 360 (Shafa Construction - Beka Omniblast 1-E) 7.2cu Ref No. 19-07-08-14-29-41 PDFDocument1 pageFND - FLM 30m 2.5 0 8x455W at 360 (Shafa Construction - Beka Omniblast 1-E) 7.2cu Ref No. 19-07-08-14-29-41 PDFFrancisNo ratings yet

- SB1001 SPRIT BARGEDocument1 pageSB1001 SPRIT BARGEFrancisNo ratings yet

- A-300 ANCHOR BOATDocument1 pageA-300 ANCHOR BOATFrancisNo ratings yet

- A-500 ANCHOR BOATDocument2 pagesA-500 ANCHOR BOATFrancisNo ratings yet

- Nortek Signature 1000 500Document6 pagesNortek Signature 1000 500FrancisNo ratings yet

- FND - FLM 30m 2.5 0 7x455W 1way (Shafa Construction - Beka Omniblast 1-E) 9.4cu Ref No. 19-07-08-14-58-34 PDFDocument1 pageFND - FLM 30m 2.5 0 7x455W 1way (Shafa Construction - Beka Omniblast 1-E) 9.4cu Ref No. 19-07-08-14-58-34 PDFFrancisNo ratings yet

- Managing Asbestos in Buildings:: Who Is This Guidance For?Document10 pagesManaging Asbestos in Buildings:: Who Is This Guidance For?Lauren'sclub EnglishBimbel Sd-smaNo ratings yet

- L143 Managing X Working With Asbestos PDFDocument116 pagesL143 Managing X Working With Asbestos PDFEdwinHanNo ratings yet

- Acoustic Wave and Current ProfilerDocument6 pagesAcoustic Wave and Current ProfilerFrancisNo ratings yet

- FND - FLM 30m 2.5 0 7x455W 1way (Shafa Construction - Beka Omniblast 1-E) 9.4cu Ref No. 19-07-08-14-58-34 PDFDocument1 pageFND - FLM 30m 2.5 0 7x455W 1way (Shafa Construction - Beka Omniblast 1-E) 9.4cu Ref No. 19-07-08-14-58-34 PDFFrancisNo ratings yet

- FND - FLM 30m 2.5 0 8x455W at 360 (Shafa Construction - Beka Omniblast 1-E) 7.2cu Ref No. 19-07-08-14-29-41 PDFDocument1 pageFND - FLM 30m 2.5 0 8x455W at 360 (Shafa Construction - Beka Omniblast 1-E) 7.2cu Ref No. 19-07-08-14-29-41 PDFFrancisNo ratings yet

- High Steel Industrial Yard Lancaster PADocument1 pageHigh Steel Industrial Yard Lancaster PAFrancisNo ratings yet

- GWLS Geoweb Load Installation PDFDocument8 pagesGWLS Geoweb Load Installation PDFFrancisNo ratings yet

- RheaDocument1 pageRheaFrancisNo ratings yet

- High Steel Industrial Yard Lancaster PADocument1 pageHigh Steel Industrial Yard Lancaster PAFrancisNo ratings yet

- GWLS Geoweb Load Installation PDFDocument8 pagesGWLS Geoweb Load Installation PDFFrancisNo ratings yet

- BNSF Orillia Auto Storage YardDocument1 pageBNSF Orillia Auto Storage YardFrancisNo ratings yet

- KCSM Intermodal-MexicoDocument1 pageKCSM Intermodal-MexicoFrancisNo ratings yet

- GWLS Geoweb Load Installation PDFDocument8 pagesGWLS Geoweb Load Installation PDFFrancisNo ratings yet

- Bridge LoadingDocument23 pagesBridge LoadingSami IGNo ratings yet

- Headlight Beam Level Control (Manual)Document1 pageHeadlight Beam Level Control (Manual)BASILIO JARA HUERTANo ratings yet

- Subaru - CHASSISDocument520 pagesSubaru - CHASSISIS52100% (1)

- Sacindo Product Line BrochureDocument2 pagesSacindo Product Line BrochureRizkiRamadhanNo ratings yet

- Guide To Floating Production Systems - Everything You Need To Know - EMADocument14 pagesGuide To Floating Production Systems - Everything You Need To Know - EMADanish KhandelwalNo ratings yet

- B Inggris Modul 1Document14 pagesB Inggris Modul 1Melvin MendrofaNo ratings yet

- TR7 - in The Phantoms WakeDocument29 pagesTR7 - in The Phantoms WakeAionnie France100% (1)

- JaipurDocument12 pagesJaipurimmicouncilsukhjitNo ratings yet

- Clio2 Cup Rally enDocument67 pagesClio2 Cup Rally enjlee_296737No ratings yet

- Passage PlanningDocument14 pagesPassage PlanningJonieLachica100% (2)

- Technical Seminar Report (17691A0375)Document24 pagesTechnical Seminar Report (17691A0375)J Harsha Sai0% (1)

- Improvements and Challenges Associated With The Facilitation of Road Transport in MyanmarDocument37 pagesImprovements and Challenges Associated With The Facilitation of Road Transport in MyanmarmatijciogeraldineNo ratings yet

- Mercedes e Class Saloon 2016 w213 Comand Owners Manual 01Document557 pagesMercedes e Class Saloon 2016 w213 Comand Owners Manual 01Arun RajNo ratings yet

- Vacuum Conveying: C Series Conveyor Troubleshooting GuideDocument60 pagesVacuum Conveying: C Series Conveyor Troubleshooting Guidesafe150_239331910No ratings yet

- Ao Assignment 3Document3 pagesAo Assignment 3Sufyan MalikNo ratings yet

- Mechanical SystemsDocument3 pagesMechanical SystemsPfundzo MoeleNo ratings yet

- Mitsubishi-Canter 2015 EN US D9c70c6a1d (001-100)Document100 pagesMitsubishi-Canter 2015 EN US D9c70c6a1d (001-100)Omar Espinoza SanchezNo ratings yet

- Suspensys - Maintenance ManualDocument20 pagesSuspensys - Maintenance Manualdanilo.cassimiroNo ratings yet

- Stability and Computational Flow Analysis On Boat Hull: A. Srinivas, V. Chandra Sekhar, Syed Altaf HussainDocument6 pagesStability and Computational Flow Analysis On Boat Hull: A. Srinivas, V. Chandra Sekhar, Syed Altaf HussainlachuNo ratings yet

- Features of 1Gr-Fe EngineDocument1 pageFeatures of 1Gr-Fe EngineMaxi SardiNo ratings yet

- Expansion Joints HSDocument22 pagesExpansion Joints HSPalakNo ratings yet

- Modeling Diary Ferrari 156/85Document47 pagesModeling Diary Ferrari 156/85AndreaNo ratings yet

- DC 5-Speed Automatic Transmission: Section 3A1Document214 pagesDC 5-Speed Automatic Transmission: Section 3A1younes hackerNo ratings yet

- điện tửDocument42 pagesđiện tửHaiNo ratings yet

- Idoc - Pub - Lto Fines and Penalties Motorcycle Philippines PDFDocument6 pagesIdoc - Pub - Lto Fines and Penalties Motorcycle Philippines PDFJayson Quito BudionganNo ratings yet

- AMSA - Marine Notice - 03-2019 - Pilot Transfer ArrangementsDocument2 pagesAMSA - Marine Notice - 03-2019 - Pilot Transfer ArrangementsRamson RaymondNo ratings yet

- Aluminum Bulk Carrier SuperstructureDocument142 pagesAluminum Bulk Carrier SuperstructureCésar VenegasNo ratings yet

- 743rd Railway Operating Battalion Unknown LetterDocument8 pages743rd Railway Operating Battalion Unknown LetterNancyNo ratings yet

- Vande Bharat CaseDocument34 pagesVande Bharat CaseKLN CHUNo ratings yet