Professional Documents

Culture Documents

Tesco: Synthetic Blend Grease NLGI #1 - Cold Weather

Uploaded by

lucas ronaldo coronel mendozaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tesco: Synthetic Blend Grease NLGI #1 - Cold Weather

Uploaded by

lucas ronaldo coronel mendozaCopyright:

Available Formats

Bulletin 87100e

¸ TOP DRIVES CASING DRILLING® AZIMUTH TUBULAR SERVICES™

TESCO

Synthetic Blend Grease

NLGI #1 - Cold Weather

Superior protection for equipment against heavy

loads, dirt, dust, water, and heat.

PRODUCT OF CHOICE FOR EXTREME

APPLICATIONS

Superior Equipment Protection for TESCO Mud Saver

Valves.

• Patented Synthetic Blend Calcium Sulfonate Grease

• Protects and Stays in Place Under Severe Load Conditions

• Contains High Concentraion of Moly and Graphite to

Reduce Heat, Friction and Abrasive Wear.

• Lasts 2 to 5 Times Longer Than Conventional Greases.

• Superior Water Resistance- won’t wash out during

operation, even when totally submerged.

• Bearing Speeds Up to 20,000 RPM’s.

• Reduces Grease Inventory to Save Money

• Wide Operating Temperature Range- NLlGI #1 remains

effective to 204°C (400°F) continuous and 260°C (500°F)

intermittent with monitored lubrication, and down to

-34°C (-29°F).

Meets or Exceeds the Following Performance

Requirements:

• US Steel Mill Grease Specifications:

- Roll Neck Grease, Req. No. 340

- Extreme Pressure Grease Req. No. 350

- Extra duty EP Grease Req. No. 352

- Extreme-Temp. Req. No. 355, 370 & 372

- Ball and Roller Bearing, Req. No. 371

- Mill Utility grease Req. No. 375

• Military Spec. MIL-G-23549C

• Federal Specification VV-G-632a

• CASE 251H EP

• Caterpillar MPGM

• Chrysler MS 3551E

• General Motors Specification GM 6031-M

• DIN 51 825, DIN 51 818

Part Number Order Information:

Case Lot (48Tubes) #731142-48T

Bulk 181.4kg (400lb) Drum #731142-400LB

Bulk 54.4kg (120lb) Keg #731142-120LB

Bulk 15.8kg (35lb) Pail #731142-35LB

Better Ways to The Bottom™

www.tescocorp.com

TESCO ULTREX™ Synthetic Blend Grease NLGI #1

A total additive package that sets it apart from other Greases

Additives Performance

Calcium Sulfonate Base Extremely water resistant, heavier than water to resist washouts even

in submerged environments. Withstands high heat and provides

additional extreme pressure protection under heavy loads.

Adhesive and Cohesive Polymers,Tackiness Agents Highly-elastic polymers hold grease together and in place to prevent

the entry of contaminants, squeeze-out, channeling and sling-off.

Rust and Corrosion Inhibitors Blocks out corrosive elements such as acids, water, condensate and

steam by forming a protective barrier on equipment surfaces to prevent

chemical wear.

Extreme Pressure (EP) Agents Heat seeking additive which increases the ability of the lubricant to

prevent the extreme wear that can occur under loads.

Anti-Wear Agents Forms a lubricant film on metal surfaces in the presence of heavy loads

and high temperatures. Prevents cold welding.

Oxidation Inhibitors Extends service life of the lubricant by retarding the oxidation or

breakdown process.

Shock Load Reducers Cushions impact to minimize the stress, vibration and chatter that can

occur under heavy loads and during start-stop operations.

Friction Reducers Plates out on metal surfaces to prevent friction and wear under heavy loads.

Molybdenum Disulfide Layered solid lubricant that plates on metal surfaces to provide

excellent protection against wear on heavily loaded surfaces and in

dusty, dirty environments.

Graphite Layered solid that provides added protection at high temperatures and

improves lubrication in wet conditions.

PHYSICAL PROPERTIES USED FOR:

Heavy industrial equipment exposed to high/low

Properties GREEN # 1 temperatures, high speed wheel bearings, anti-friction

Penetration ASTM D 217 313 bearings, open gears, turbine pumps, paper and pulp

Multistroke penetration ASTM D 217 325 mills, steel mills, chemical plants, and waste water

Wheel bearing leakage ASTM D 1263 NA plants construction equipment, sewage treatment plants,

Water washout ASTM D 1264 <0.2% irrigation equipment, non-domestic water pumps, wet

mining, scroll saws, kiln cars high speed wheel bearings,

Due to ongoing product development, all specifications are subject to change without notice.

Pressure Oil separation ASTM D 1742 0.5

Four-ball Index ASTM D 2596 101 boat trailer bearings, sleeve bearings, chassis, utility

Four-ball (weld) ASTM D 2596 1000+ trucks, buses, sea-going vessels, coastal and wharf

Four-ball (wear scar) ASTM D 2596 0.41 equipment, inland waterway applications.

Timken method ASTM D 2509 60

Rust test ASTM D 1743 Pass NOT FOR:

Copper corrosion ASTM D 130 1B Any application with a continuous temperature

Low Temperature Limit -34°C (-29°F) exceeding 127°C or 260°F intermittently without

Dropping Point ASTM D 2265 302 monitored lubrication.

High Temperature Limit 127°C (260°F)

Base Oil Viscosity @ 40°C(104°F) 1130.87

Printed in Canada / October 2006 / POD

Better Ways to The Bottom™

Email: lubricants@tescocorp.com Web: www.tescocorp.com

Corporate Headquarters World Wide Operations

6204 - 6A Street S.E. 11330 Brittmoore Park Drive

Calgary, Alberta, Canada T2H 2B7 Houston, Texas, USA 77041

Tel: 403 692-5700 • Fax: 403 692-5710 Tel: 713 849-5900 • Fax: 713 849-0075

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- QR-N Valve Service PDFDocument4 pagesQR-N Valve Service PDFluisedonossaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- TG Series: Power Take-OffDocument24 pagesTG Series: Power Take-OffJose Daniel RiveirosNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- RFR VERTEX IRNF Assembly DrawingsDocument31 pagesRFR VERTEX IRNF Assembly Drawingslucas ronaldo coronel mendozaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- You can easily find tires that cost more or are better known, but no one has Sumitomo’s unique mix of technology, quality, and valueDocument20 pagesYou can easily find tires that cost more or are better known, but no one has Sumitomo’s unique mix of technology, quality, and valueAlexis ValleNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- EP021 - BU3-1500 Operation ManualDocument30 pagesEP021 - BU3-1500 Operation Manuallucas ronaldo coronel mendozaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- C ClutchesDocument131 pagesC ClutchesjonarosNo ratings yet

- Pride International Co: (N) Vicad Battery No (H) Halogen Lamps No (I) Not Able To IdentifyDocument1 pagePride International Co: (N) Vicad Battery No (H) Halogen Lamps No (I) Not Able To Identifylucas ronaldo coronel mendozaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- STVC WichitaDocument15 pagesSTVC Wichitalucas ronaldo coronel mendozaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- WPT 36W Aux BrakeDocument12 pagesWPT 36W Aux Brakelucas ronaldo coronel mendozaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Valve HD-2 PDFDocument12 pagesValve HD-2 PDFlucas ronaldo coronel mendoza50% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Firestone w013589082Document1 pageFirestone w013589082lucas ronaldo coronel mendozaNo ratings yet

- Acople Tipo EngranajeDocument54 pagesAcople Tipo Engranajeyamid muñozNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Acople Tipo EngranajeDocument54 pagesAcople Tipo Engranajeyamid muñozNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Wild Well Control - Technical Date BookDocument57 pagesWild Well Control - Technical Date Bookgabriel851007No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- IADC Safety Alert Mud Pumps GDDocument1 pageIADC Safety Alert Mud Pumps GDlucas ronaldo coronel mendozaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Oil and Gas Well Drilling Safety StandardsDocument1 pageOil and Gas Well Drilling Safety Standardslucas ronaldo coronel mendozaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Pump Alert System Protects Key Systems: ZzzpxvwdqjfrqwurovfrpDocument2 pagesPump Alert System Protects Key Systems: Zzzpxvwdqjfrqwurovfrplucas ronaldo coronel mendozaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Technicaldata: Section Pages Section Pages Section PagesDocument41 pagesTechnicaldata: Section Pages Section Pages Section PagesAngel David Mantilla AlvarezNo ratings yet

- Azt - Ua D-Pilotair Valves enDocument12 pagesAzt - Ua D-Pilotair Valves enJose Silvestre GuevaraNo ratings yet

- SC-900-1000 Actuator and PositionersDocument52 pagesSC-900-1000 Actuator and Positionerslucas ronaldo coronel mendozaNo ratings yet

- tp9974 PDFDocument2 pagestp9974 PDFAzizi AbdullahNo ratings yet

- H-4 Controlair Valve: Description of ModelsDocument12 pagesH-4 Controlair Valve: Description of Modelslucas ronaldo coronel mendoza100% (1)

- Installationand Maintenance Sheet: Lubricator Model PL08 With Variations and AccessoriesDocument3 pagesInstallationand Maintenance Sheet: Lubricator Model PL08 With Variations and Accessorieslucas ronaldo coronel mendozaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Catalago Da ValvulaDocument12 pagesCatalago Da ValvulaAlexandre CorreaNo ratings yet

- C ClutchesDocument131 pagesC ClutchesjonarosNo ratings yet

- 261 267 PDFDocument7 pages261 267 PDFlucas ronaldo coronel mendozaNo ratings yet

- Type D Pilotair ValveDocument24 pagesType D Pilotair Valvelucas ronaldo coronel mendozaNo ratings yet

- 118 Series Centrifugal Pump PartsDocument8 pages118 Series Centrifugal Pump PartsalexmaldonadohdzNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Instruction Manual: Metal Mud Balance (Machined Balance)Document2 pagesInstruction Manual: Metal Mud Balance (Machined Balance)lucas ronaldo coronel mendozaNo ratings yet

- Magnum Features:: One Company Unlimited Solutions One Company Unlimited SolutionsDocument35 pagesMagnum Features:: One Company Unlimited Solutions One Company Unlimited Solutionslucas ronaldo coronel mendozaNo ratings yet

- D2 - Seismic Building Code Review PDFDocument97 pagesD2 - Seismic Building Code Review PDFmanojmoryeNo ratings yet

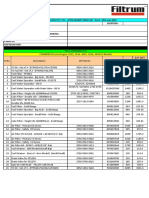

- Location:-Fleetguard Filters Pvt. Ltd. - After Market Price List W.E.F. 18Th June 2018 Distributor Name: - Address: - Office Contact No. For Queries / Order Booking: - Distributor Contact PersonDocument23 pagesLocation:-Fleetguard Filters Pvt. Ltd. - After Market Price List W.E.F. 18Th June 2018 Distributor Name: - Address: - Office Contact No. For Queries / Order Booking: - Distributor Contact PersonDadasaheb More100% (2)

- SPS Malaysia Case StudyDocument4 pagesSPS Malaysia Case StudyMuhammad Abdur RafayNo ratings yet

- RDshimano 5500 ManualDocument4 pagesRDshimano 5500 ManualOleg MelnikovNo ratings yet

- Half Wave RectifierDocument4 pagesHalf Wave RectifierrodinooNo ratings yet

- Project: Inventory Management System For Music Store: SynopsisDocument7 pagesProject: Inventory Management System For Music Store: SynopsisSoumitra ChakravartyNo ratings yet

- India Geological India: GovernmentDocument7 pagesIndia Geological India: GovernmentAshish KumarNo ratings yet

- Brown Slidey T-PlansDocument4 pagesBrown Slidey T-PlansPhillipe El Hage0% (1)

- 1.2. Modular Programming - En-UsDocument12 pages1.2. Modular Programming - En-UsChandrasekhar K100% (1)

- Sage X3 - User Guide - HTG-Printing CLOB Comments PDFDocument8 pagesSage X3 - User Guide - HTG-Printing CLOB Comments PDFcaplusinc100% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- RECTGRP E0731 k170 01 7617 PDFDocument33 pagesRECTGRP E0731 k170 01 7617 PDFRamelan Ayah AlidanSyaffaNo ratings yet

- 2nd Quarter Week 3 Parallel CircuitDocument12 pages2nd Quarter Week 3 Parallel CircuitjNo ratings yet

- Study On The Strength of EarthbagsDocument28 pagesStudy On The Strength of EarthbagsZherrinore Rasay100% (1)

- Dropped ObjectsDocument26 pagesDropped Objectsgunnery0250% (2)

- Melab1 Exp3Document11 pagesMelab1 Exp3John Ferben Sallena DepnagNo ratings yet

- Shotcrete Slope StabilizationDocument7 pagesShotcrete Slope StabilizationJ. Kumar Infraprojects Ltd100% (1)

- Aspect Security The Unfortunate Reality of Insecure LibrariesDocument20 pagesAspect Security The Unfortunate Reality of Insecure Libraries99patinoNo ratings yet

- Python3 Tutorial PDFDocument26 pagesPython3 Tutorial PDFferronatto11100% (1)

- How To Decode METARDocument14 pagesHow To Decode METARkikiNo ratings yet

- For Drifting and Tunneling: Sandvik RT300-seriesDocument6 pagesFor Drifting and Tunneling: Sandvik RT300-seriesДамир НазиповNo ratings yet

- Lubricating Oil PDFDocument30 pagesLubricating Oil PDFLonghuynh LêNo ratings yet

- Unified Schedule of Rates Iw DeptDocument96 pagesUnified Schedule of Rates Iw Deptanirbanpwd76No ratings yet

- Pedestal Column For Tower-Usd: Ast (MM 2) Ab (MM 2)Document18 pagesPedestal Column For Tower-Usd: Ast (MM 2) Ab (MM 2)Joy lauriaNo ratings yet

- Verification Manual COMPRESS 2021Document149 pagesVerification Manual COMPRESS 2021Unidos Con PuerresNo ratings yet

- How To Crack Wi-Fi Passwords-For Beginners!: Join The DiscussionDocument59 pagesHow To Crack Wi-Fi Passwords-For Beginners!: Join The DiscussionRedouaneZaridNo ratings yet

- 16 Mark Questions OOADDocument9 pages16 Mark Questions OOADsaravanan_saptc100% (2)

- Volvo Plane Ice ReportDocument18 pagesVolvo Plane Ice ReportAreebNo ratings yet

- Industrial VisitDocument22 pagesIndustrial VisitInvincible GamerNo ratings yet

- KBMM PDFDocument2 pagesKBMM PDFRicardo Garcia FuentesNo ratings yet

- TransformerDocument17 pagesTransformerRunNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)