Professional Documents

Culture Documents

No Body Gets Hurt During Crude Oil Transfer Cooler Train 1 Isolation

Uploaded by

chineduOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

No Body Gets Hurt During Crude Oil Transfer Cooler Train 1 Isolation

Uploaded by

chineduCopyright:

Available Formats

"No Body Gets Hurt"

ISOLATION (LOTO) / PROCEDURE

Date:

CRUDE OIL TRANSFER COOLER TRAIN 1

Location

Job (Isolation) Description: ISOLATION OF CRUDE OIL TRANSFER COOLER TRAIN 1 FOR MANUAL VALVES REPLACEMENT

Equipment Name: CRUDE OIL TRANSFER COOLER #1

Tag No.

Isolation Device: MANUAL VALVES

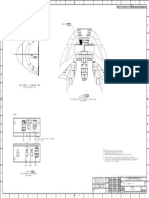

Ref. Drawing #

Prepared By

Approved to Progress Name: Sign: Date:

ICC #

SPADE/BLIN

D LOCATION

POINT ID STEPS EQUIPMENT ID DESCRIPTION TYPE/METHOD ISOLATION STATE ON

RESPONSIBILITY

MARKED-UP

P&ID

PREPARATION

1 N/A OBTAIN REQUIRED PERMITS AND APPROVAL N/A NA N/A OPERATIONS

2 N/A PREPARE ISOLATION TAGS, ISOLATION LOCK SETS, ISOLATION CONTROL POINT (LOCKBOX) N/A NA N/A OPERATIONS

3 N/A ENSURE THE COTP #10 AND #11 HAS BEEN STOPPED

ISOLATION

1 RETURN ICC 4338 ON LTI TO IN PLACE, THEN PERFORM DEISOLATION

N/A N/A N/A OPERATIONS

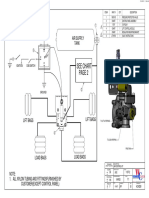

1 2 SDV-62312-1 CLOSE AND DISCONNECT AIR SUPPLY TO SDV FROM THE COTPs TO THE COTC #1

M/LOCK CLOSED (I) N/A OPERATIONS

2 3 SDV-62312-2 CLOSE AND DISCONNECT AIR SUPPLY TO SDV FROM THE COTC #2 TO CRUDE STORAGE TANK

M/LOCK CLOSED (I) N/A OPERATIONS

3 4 L-623-187 CLOSE 12" BALL VALVE DOWNSTREAM LV-62309-1

M/LOCK CLOSED (I) N/A OPERATIONS

4 5 L-623-188 CONFIRM THAT 10" GATE VALVE ON LV-62309-1 BYPASS IS CLOSE THEN LOCK AND TAG

M/LOCK CLOSED (I) N/A OPERATIONS

5 6 L-623-168 CLOSE 12" BALL VALVE ON THE COMMON OUTLET OF THE CRUDE OIL TRANSFER PUMPS

M/LOCK CLOSED (I) N/A OPERATIONS

6 7 L-623-169 CONFIRM THAT 12" GATE VALVE ON THE COMMON OUTLET OF THE CRUDE OIL TRANSFER PUMPS BYPASS IS CLOSE, THEN LOCK AND TAG

M/LOCK CLOSED (I) N/A OPERATIONS

7 8 L-623-173 CLOSE 8" BALL VALVE ON THE CRUDE OIL TRANSFER PUMPS RECYCLE LINE

M/LOCK CLOSED (I) N/A OPERATIONS

8 9 L-623-174 CONFIRM THAT 6" GATE VALVE ON THE CRUDE OIL TRANSFER PUMPS RECYCLE LINE BYPASS IS CLOSE, THEN LOCK AND TAG

M/LOCK CLOSED (I) N/A OPERATIONS

9 10 1PBA-62310 RACK OUT AND LOCK BREAKER FOR CRUDE OIL TRANFER PUMP 10

E/LOCK OPEN (I) N/A ELECTRICAL

10 11 1PBA-62311 RACK OUT AND LOCK BREAKER FOR CRUDE OIL TRANFER PUMP 11

E/LOCK OPEN (I) N/A ELECTRICAL

INITIAL DRAINING OF COOLER

11 1 BDV 62312-3 OPEN BDV ON COTC OIL SIDE AND TO DRAIN COOLER AND THEN CLOSE THEREAFTER

TAG CLOSED (I) N/A OPERATIONS

12 2 L-623-192 OPEN MANUAL VALVE TO CLOSED DRAIN, DOWNSTREAM OF BDV TO DRAIN THEN CLOSE AFTER DRAINING

M/LOCK CLOSED (I) N/A OPERATIONS

13 3 L-623-194 OPEN 1" GLOBE VALVE ON COTC OIL SIDE INLET DRAIN LINE TO HAZARDOUS OPEN DRAIN TO CONFIRM ZERO LIQUID AND THEN CLOSE THEREAFTER

TAG CLOSED (I) N/A OPERATIONS

14 4 GZVC OPEN 3/4" DRAIN VALVE ON THE SIDE INLET T-STRAINER TO DRAIN TO CONFIRM ZERO ENERGY

M/LOCK CLOSED (I) N/A OPERATIONS

BLIND SWINGING

1 BLD 1 SWING BLIND 1

TAG CLOSED (I) FMS

2 BLD 2 SWING BLIND 2

TAG CLOSED (I) FMS

FLUSHING OF OIL SIDE

1 L-623-189 REMOVE FLANGE FROM 2" VALVE L-623-189 ON THE OIL OUTLET OF THE COOLER FOR FLUSHING (INLET), THEN COMMENCE FLUSH TO CLOSE DRAIN

FMS

REMOVE FLANGE FROM 2" PIPE IMMEDIATELY AFTER THE COTC INLET SDV-62312-1 AND THEN HOOKUP CONNECTOR FOR FLUSHING (OUTLET) TO CHECK FOR

2 CLEANLINESS FMS

FINAL DRAINING OF COOLER

1 L-623-194 OPEN COTC OIL INLET TO OPEN DRAIN LINE TO CONFIRM ZERO LIQUID AND THEN CLOSE THEREAFTER

TAG CLOSED (I) N/A OPERATIONS

FLUSHING OF WATER SIDE

1 TG-62312-2 DISCONNECT TG FROM THE THERMOWELL AND HOOK UP HOSE FOR FLUSHING

FMS

2 TG-62312-3 DISCONNECT TG FROM THE THERMOWELL AND HOOK UP HOSE FOR FLUSHING

FMS

ZERO ENERGY DEMONSTRATION

1 1" GZVC (L-623-194) OPEN 1" OIL SIDE MANUAL VALVE TO ATMOSPHERE TO DEMONSTRATE ZERO ENERGY AND CLOSE THEREAFTER

TAG CLOSED (I) N/A OPERATIONS

15 2 3/4" NJTG OPEN 3/4" BLEED VALVE UPSTREAM OF PSV-62312-2 ON THE WATER SIDE TO ATMOSPHERE TO DEMONSTRATE ZERO ENERGY AND CLOSE

TAG CLOSED (I) N/A OPERATIONS

You might also like

- Who Are The Pleiadian Emissaries of LightDocument3 pagesWho Are The Pleiadian Emissaries of LightMichelle88% (8)

- Dead Reckoning and Estimated PositionsDocument20 pagesDead Reckoning and Estimated Positionscarteani100% (1)

- Unofficial Fanbook Made With Permission - Incar-NationDocument24 pagesUnofficial Fanbook Made With Permission - Incar-NationBrockPetersdorf-Nelson100% (1)

- 7810-8110-CA-1201-651-002 - A1 - Inlet Sep.Document19 pages7810-8110-CA-1201-651-002 - A1 - Inlet Sep.gopal krishnan0% (1)

- Listado de Instrumentos - DescripciónDocument33 pagesListado de Instrumentos - DescripciónDaniel Camargo Perez100% (1)

- Valvula Contrabalance CBV1 10 S O A 30Document21 pagesValvula Contrabalance CBV1 10 S O A 30Judith Daza SilvaNo ratings yet

- VCNG Manual Tuga Eng Vol IIDocument226 pagesVCNG Manual Tuga Eng Vol IIolegprikhodko280975% (4)

- Loveology: God. Love. Marriage. Sex. and The Never-Ending Story of Male and Female. by John Mark Comer, SamplerDocument32 pagesLoveology: God. Love. Marriage. Sex. and The Never-Ending Story of Male and Female. by John Mark Comer, SamplerZondervan40% (5)

- 8 Benefits of Benefit Realization ManagementDocument2 pages8 Benefits of Benefit Realization ManagementchineduNo ratings yet

- Solar/Wind/Diesel Hybrid Energy System With Battery Storage For Rural ElectrificationDocument15 pagesSolar/Wind/Diesel Hybrid Energy System With Battery Storage For Rural ElectrificationWelde AynaleNo ratings yet

- Lauren Tarshis - (I Survived 05) - I Survived The San Francisco Earthquake, 1906Document66 pagesLauren Tarshis - (I Survived 05) - I Survived The San Francisco Earthquake, 1906Olga de Ramos100% (1)

- RD I PC p00 2002 - Rev.3 - Dcs I o ListDocument87 pagesRD I PC p00 2002 - Rev.3 - Dcs I o ListInsan AzizNo ratings yet

- Assembly Line-1 Skill Matrix: Minimum Skill Required L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2Document1 pageAssembly Line-1 Skill Matrix: Minimum Skill Required L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2 L-2artiNo ratings yet

- EAPL/CP/SFT 0090 CONTROL PLANDocument24 pagesEAPL/CP/SFT 0090 CONTROL PLANspdhimanNo ratings yet

- Drawing Title Design General NotesDocument25 pagesDrawing Title Design General NotesSaid Ahmed Salem100% (1)

- Final CBLMDocument66 pagesFinal CBLMRanilyn UrbiztundoNo ratings yet

- Prenatal DevelopmentDocument23 pagesPrenatal DevelopmentLF90No ratings yet

- Max Brooks - The Zombie Survival Guide (Scanned Book)Document270 pagesMax Brooks - The Zombie Survival Guide (Scanned Book)tusko88% (8)

- 2 X 660MW NCC POWER PROJECT VALVE SCHEDULEDocument53 pages2 X 660MW NCC POWER PROJECT VALVE SCHEDULEkkumar_717405No ratings yet

- 15.5kV, 27kV and 38kV Solid Insulated Vacuum Recloser for Power DistributionDocument8 pages15.5kV, 27kV and 38kV Solid Insulated Vacuum Recloser for Power DistributionEdwin QuispeNo ratings yet

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument22 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405No ratings yet

- Sas Scada Hob - 030312Document42 pagesSas Scada Hob - 030312ahmedNo ratings yet

- Creative 2nd QuarterDocument6 pagesCreative 2nd QuarterJanice CordovaNo ratings yet

- Crude Oil Cooler Train 1valve Change Out: Isolation (Loto) / ProcedureDocument2 pagesCrude Oil Cooler Train 1valve Change Out: Isolation (Loto) / ProcedurechineduNo ratings yet

- Anritsu Site Master S331B10580-00028F Maintenance ManualDocument16 pagesAnritsu Site Master S331B10580-00028F Maintenance ManualThe VaultNo ratings yet

- Crown Specialized For Steel Contracting Co. Ltd. Welding Inspection ReportDocument1 pageCrown Specialized For Steel Contracting Co. Ltd. Welding Inspection ReportYasar AliNo ratings yet

- Field Instrument ListDocument15 pagesField Instrument Listmohamedsaib438No ratings yet

- 5051 - Copilot ClockDocument4 pages5051 - Copilot ClockMarty SmallwoodNo ratings yet

- NE/SA556: Dual TimerDocument11 pagesNE/SA556: Dual TimerRicardo LimonNo ratings yet

- NBC Jaf GQC RT A 150,151,152,153Document4 pagesNBC Jaf GQC RT A 150,151,152,153Akansha SharmaNo ratings yet

- L2ra FormDocument5 pagesL2ra FormAndreas Yanuarius WijayaNo ratings yet

- CHL-0714 60181509Document1 pageCHL-0714 60181509Femi AgbanaNo ratings yet

- 5n-Lee - Serviceable TagDocument1 page5n-Lee - Serviceable TagFemi AgbanaNo ratings yet

- Unserviceable: ComponentDocument1 pageUnserviceable: ComponentFemi AgbanaNo ratings yet

- D113R1202 DRW04 PDFDocument1 pageD113R1202 DRW04 PDFSP6H-18 Yap JRNo ratings yet

- Unserviceable: ComponentDocument1 pageUnserviceable: ComponentFemi AgbanaNo ratings yet

- Ec Ma 26 Camaras QNDDocument46 pagesEc Ma 26 Camaras QNDMartin Bolivar JaimesNo ratings yet

- MD921 RevC (DV 1 Recorder)Document6 pagesMD921 RevC (DV 1 Recorder)Matias Contreras KöbrichNo ratings yet

- Saudi Aramco Pipeline Safety SheetDocument1 pageSaudi Aramco Pipeline Safety SheetJohn BuntalesNo ratings yet

- Caverton Helicopters Limited landing light part removal documentDocument1 pageCaverton Helicopters Limited landing light part removal documentFemi AgbanaNo ratings yet

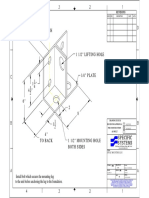

- Oreja de IzajeDocument1 pageOreja de IzajeEl Aro De La CalleNo ratings yet

- BFA902 As BuiltDocument37 pagesBFA902 As Builtbenjamin paulinaNo ratings yet

- Schneider 885 VAVDocument8 pagesSchneider 885 VAVJulio SantosNo ratings yet

- Esquematico de Control SDV-360Document1 pageEsquematico de Control SDV-360CARLOS CASTILLO MARTINEZNo ratings yet

- Smart Cell-Bilge - Instructions For Replacing Smar - 231030 - 112222Document6 pagesSmart Cell-Bilge - Instructions For Replacing Smar - 231030 - 112222velmuruganNo ratings yet

- Replace Bilge Oil Alarm Smart Cell InstructionsDocument6 pagesReplace Bilge Oil Alarm Smart Cell InstructionsCosta0% (1)

- Unserviceable: ExpendableDocument1 pageUnserviceable: ExpendableFemi AgbanaNo ratings yet

- A174256 PDFDocument188 pagesA174256 PDFHassan KabeerNo ratings yet

- REV Description Date Approval: RevisionsDocument2 pagesREV Description Date Approval: RevisionsLONG Trương MinhNo ratings yet

- F225 OtiDocument1 pageF225 OtiAhmed WagihNo ratings yet

- Released For Production: Tong SpecificationDocument1 pageReleased For Production: Tong SpecificationFerney FonsecaNo ratings yet

- r201 000 3Document1 pager201 000 3Anand KumarNo ratings yet

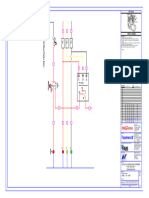

- Power Circuit For D.O.L. Starting For Motor Rotation Refer To Installation Layout Sn-100462-D001Document1 pagePower Circuit For D.O.L. Starting For Motor Rotation Refer To Installation Layout Sn-100462-D001jhonNo ratings yet

- Catalogue Recloser EntecDocument8 pagesCatalogue Recloser EntecKiệt Phan Thế AnhNo ratings yet

- Detail - Frame: Standard SymbolsDocument1 pageDetail - Frame: Standard SymbolsLallamaNo ratings yet

- TK-103-FGL-34 Holiday InspectionDocument1 pageTK-103-FGL-34 Holiday InspectionjoseNo ratings yet

- Dimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 010Document1 pageDimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 010Wijaya GultomNo ratings yet

- Safety Instruction Sheet For Cross Country Pipeline - Critical PipingDocument1 pageSafety Instruction Sheet For Cross Country Pipeline - Critical PipingJohn BuntalesNo ratings yet

- ACK250Document6 pagesACK250karthegreNo ratings yet

- Pioneer Xr-A550md SMDocument115 pagesPioneer Xr-A550md SMDONNYNo ratings yet

- Nameplate Abbreviations Nameplate Schedule 2 DWG. DD-950025 DETAIL 031-A Nameplate Schedule 2 DWG. DD-950025 DETAIL 031-BDocument1 pageNameplate Abbreviations Nameplate Schedule 2 DWG. DD-950025 DETAIL 031-A Nameplate Schedule 2 DWG. DD-950025 DETAIL 031-BBachir GeageaNo ratings yet

- 3.0JMS Cable TrenchDocument3 pages3.0JMS Cable TrenchMohd Khairi AhmadNo ratings yet

- DVR 450H SDocument172 pagesDVR 450H SNewfieFixerNo ratings yet

- Pioneer DVR 520 Service ManualDocument174 pagesPioneer DVR 520 Service Manualapi-3822758No ratings yet

- WEI CM 00026 01 SD 7008 - R02 - Instrument & JB Location LayoutDocument19 pagesWEI CM 00026 01 SD 7008 - R02 - Instrument & JB Location LayoutRAHMAT AZUARDINo ratings yet

- E Smart Cell - BilgeDocument6 pagesE Smart Cell - Bilgejose antonio alonso lagoNo ratings yet

- Legends: CCTV Box Camera Fixed Type (Ip65) CCTV Dome Camera Fixed Type (Ip65)Document1 pageLegends: CCTV Box Camera Fixed Type (Ip65) CCTV Dome Camera Fixed Type (Ip65)Lucky MalihanNo ratings yet

- Field: Zimbabwe Electricity Transmission Distribution CompanyDocument3 pagesField: Zimbabwe Electricity Transmission Distribution CompanyLawson SangoNo ratings yet

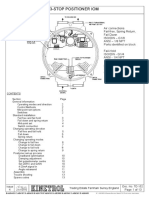

- P3 3-STOP POSITIONER IOM GUIDEDocument13 pagesP3 3-STOP POSITIONER IOM GUIDEvjNo ratings yet

- Subdivision: of Lot 984, Cad 446-D, Santiago CadastreDocument1 pageSubdivision: of Lot 984, Cad 446-D, Santiago CadastreKenneth T. GuillermoNo ratings yet

- Technical details on indicators and gaugesDocument5 pagesTechnical details on indicators and gaugesPRO ECUNo ratings yet

- STEALTH 2 Torque Conversion ChartDocument2 pagesSTEALTH 2 Torque Conversion Chartluisantoniojimenezperez31No ratings yet

- STEALTH 2 Torque Conversion ChartDocument2 pagesSTEALTH 2 Torque Conversion Chartluisantoniojimenezperez31No ratings yet

- Bills of Material Costing ComponentsDocument3 pagesBills of Material Costing ComponentschineduNo ratings yet

- STEALTH 2 Torque Conversion ChartDocument2 pagesSTEALTH 2 Torque Conversion Chartluisantoniojimenezperez31No ratings yet

- STEALTH 2 Torque Conversion ChartDocument2 pagesSTEALTH 2 Torque Conversion Chartluisantoniojimenezperez31No ratings yet

- Megaprojects and Risk Management Emaar PropertiesDocument21 pagesMegaprojects and Risk Management Emaar PropertieschineduNo ratings yet

- STEALTH 2 Torque Conversion ChartDocument2 pagesSTEALTH 2 Torque Conversion Chartluisantoniojimenezperez31No ratings yet

- Management Accouting SampleDocument5 pagesManagement Accouting SamplechineduNo ratings yet

- Applying Project Tools StrategicallyDocument3 pagesApplying Project Tools StrategicallychineduNo ratings yet

- Project Value & FramingDocument3 pagesProject Value & FramingchineduNo ratings yet

- Organizing For Projects: Monique AubryDocument3 pagesOrganizing For Projects: Monique AubrychineduNo ratings yet

- Project Value - Project FramingDocument1 pageProject Value - Project FramingchineduNo ratings yet

- Financial Accounting AssignmentDocument3 pagesFinancial Accounting AssignmentchineduNo ratings yet

- Management Accouting Sample For Job ServicesDocument4 pagesManagement Accouting Sample For Job ServiceschineduNo ratings yet

- Systemic Board PMDocument3 pagesSystemic Board PMchineduNo ratings yet

- Organizational Structure GoverDocument3 pagesOrganizational Structure GoverchineduNo ratings yet

- PRC For PipingDocument1 pagePRC For PipingchineduNo ratings yet

- Concluding Remarks On Stakeholder ManagementDocument2 pagesConcluding Remarks On Stakeholder ManagementchineduNo ratings yet

- Other Book by Gover PDFDocument1 pageOther Book by Gover PDFchineduNo ratings yet

- Stakeholder Subprocess in ProjectDocument3 pagesStakeholder Subprocess in ProjectchineduNo ratings yet

- Managing Programs of ProjectsDocument2 pagesManaging Programs of ProjectschineduNo ratings yet

- List of Figure Gover HandbookDocument4 pagesList of Figure Gover HandbookchineduNo ratings yet

- Content For Gover HandbookDocument9 pagesContent For Gover HandbookchineduNo ratings yet

- Benefits Realization Management FrameworkDocument2 pagesBenefits Realization Management FrameworkchineduNo ratings yet

- Managing Portfolios of ProjectDocument2 pagesManaging Portfolios of ProjectchineduNo ratings yet

- List of Table Gover HandbookDocument2 pagesList of Table Gover HandbookchineduNo ratings yet

- Applying The BRM ProcessDocument2 pagesApplying The BRM ProcesschineduNo ratings yet

- Reduce Carbon Footprint Benefits MapDocument2 pagesReduce Carbon Footprint Benefits MapchineduNo ratings yet

- Manage Implementation ChangeDocument2 pagesManage Implementation ChangechineduNo ratings yet

- Telecom Business Management Systems Net ProjectDocument68 pagesTelecom Business Management Systems Net ProjectRahul RaiNo ratings yet

- ECF/SSF : 08 : 11: Rotex Double Rack and Pinion Actuator SeriesDocument20 pagesECF/SSF : 08 : 11: Rotex Double Rack and Pinion Actuator SeriesProcess Controls & ServicesNo ratings yet

- ResearchDocument44 pagesResearchGwend MemoracionNo ratings yet

- Preschool ADHD QuestionnaireDocument2 pagesPreschool ADHD QuestionnaireAnnaNo ratings yet

- Pe 3 (Module 1) PDFDocument6 pagesPe 3 (Module 1) PDFJoshua Picart100% (1)

- Argacel TCW_enDocument2 pagesArgacel TCW_enUtpalNo ratings yet

- ASTM G 38 - 73 r95Document7 pagesASTM G 38 - 73 r95Samuel EduardoNo ratings yet

- All+DPPs+in+One+ +M+and+DDocument136 pagesAll+DPPs+in+One+ +M+and+DSumit RajNo ratings yet

- Class of 2016 Graduate ListsDocument16 pagesClass of 2016 Graduate ListscallertimesNo ratings yet

- 202-Nido 2024Document27 pages202-Nido 2024tabhonor69No ratings yet

- CẤU TẠO TỪ VÀ TỪ LOẠIDocument15 pagesCẤU TẠO TỪ VÀ TỪ LOẠIccnsdNo ratings yet

- Wilkinson 2001Document44 pagesWilkinson 2001Toño Gaspar MuñozNo ratings yet

- Nanotechnology in TextilesDocument4 pagesNanotechnology in Textileskevin cagud PhillipNo ratings yet

- Hypomorphic Mutations in PRF1, MUNC13-4, and STXBP2 Are Associated With Adult-Onset Familial HLHDocument6 pagesHypomorphic Mutations in PRF1, MUNC13-4, and STXBP2 Are Associated With Adult-Onset Familial HLHLeyla SaabNo ratings yet

- Manual vs Air Rotor Stripping SEM EvaluationDocument8 pagesManual vs Air Rotor Stripping SEM Evaluationlocos3dNo ratings yet

- Literature Review On OscilloscopeDocument5 pagesLiterature Review On Oscilloscopedhjiiorif100% (1)

- UX5HPDocument2 pagesUX5HPNazih ArifNo ratings yet

- Resume Dianne Ostrander 4-27-06-09Document2 pagesResume Dianne Ostrander 4-27-06-09api-12400587No ratings yet

- Monitoring Rock and Soil Mass Performance: To The ConferenceDocument1 pageMonitoring Rock and Soil Mass Performance: To The ConferenceÉrica GuedesNo ratings yet