0% found this document useful (0 votes)

122 views4 pagesVertical vs. Horizontal Organizations

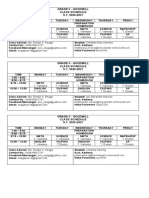

The document discusses vertical and horizontal organizational structures, as well as push and pull planning strategies. A vertical structure has a top-down hierarchy with high-level management making decisions and employees following orders. A horizontal structure is flat with more empowerment given to employees who can make decisions without manager approval. Push strategies involve producing to stock based on forecasts, while pull strategies involve producing to order based on actual demand. Kanban systems originated at Toyota and use visual signals to implement just-in-time pull production based on customer demand.

Uploaded by

Shirley Lucas EsagaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

122 views4 pagesVertical vs. Horizontal Organizations

The document discusses vertical and horizontal organizational structures, as well as push and pull planning strategies. A vertical structure has a top-down hierarchy with high-level management making decisions and employees following orders. A horizontal structure is flat with more empowerment given to employees who can make decisions without manager approval. Push strategies involve producing to stock based on forecasts, while pull strategies involve producing to order based on actual demand. Kanban systems originated at Toyota and use visual signals to implement just-in-time pull production based on customer demand.

Uploaded by

Shirley Lucas EsagaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd