Professional Documents

Culture Documents

Composol Pipework: Usage

Uploaded by

raj15080 ratings0% found this document useful (0 votes)

22 views1 pageOriginal Title

composol_pipework

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views1 pageComposol Pipework: Usage

Uploaded by

raj1508Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

CompoSol® Pipework

CompoSol® Pipework is an engineered and designed composite pressure

retaining repair system. It is used on pipes and piping systems, including bends,

tees, reducers and other complex geometries suffering from wall thinning

(including through-wall defects) caused by internal and external corrosion or

mechanical damage.

Usage

CompoSol® Pipework is used as a wet-lay-up around all types of ferrous and

non-ferrous pipes to restore operational integrity in line with the latest

international standard for pressure retaining composite repairs, ISO/TS24817.

Design

The design of a CompoSol® Pipework repair is governed by ISO/TS24817. Designs

consider a number of parameters including diameter, pressure, temperature,

defect size and defined life.

Application

Surfaces should be clean and free from loose rust and contamination. Preparation

should be in line with the requirements of the latest international standards.

CompoSol® Pipework should only be applied by applicators trained and

certificated in line with ISO/TS24817, ASME PCC2 and ACoReS Audit

requirements.

Benefits

• Cost effective and easy to apply

• Can be applied to surfaces prepared to ST2 standard

• Meets relevant International Engineering Standards

• Resistant to a wide range of chemicals encountered in petrochemical industry

• Can be applied under cold permit to work

• Can be used on all types of geometries

• Fire Rated to BS 476 Parts 6 and 7

Product Data

• Repairs can be made in excess of 120 Barg

• Application Temperature +10°C to +50°C

• Storage: In original containers in dry conditions between 5°C and 35°C

• Service Temperature –50°C to +150°C

Providing the Complete Composite Solution

• Protect from frost and excessive heat

4 Points Commercial Centre Craigshaw Road Aberdeen AB12 3AP

t: +44 (0)1224 879966 f: +44 (0)1224 873377

www.imgcomposites.com

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- Installation Manual HVAC Pipework and Ductwork 2012 PDFDocument24 pagesInstallation Manual HVAC Pipework and Ductwork 2012 PDFsasan490% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Kalzip Facade SystemsDocument24 pagesKalzip Facade SystemsAndon Setyo WibowoNo ratings yet

- Flue & Chimney SystemsDocument16 pagesFlue & Chimney SystemsAirtherm Flues LimitedNo ratings yet

- GRE PipeDocument8 pagesGRE Pipeadvis79100% (1)

- Pall - Black Powder FilterDocument12 pagesPall - Black Powder FilterHeymonth Chandra100% (1)

- Black PowderDocument7 pagesBlack PowderMarsyaNo ratings yet

- Tyco HV Cable and Arresters Ans InsulatorDocument104 pagesTyco HV Cable and Arresters Ans InsulatorRazvan MaresNo ratings yet

- Mechanical Design For Pressure VesselDocument26 pagesMechanical Design For Pressure VesselibicengNo ratings yet

- Al Bilad Company Profile PDFDocument53 pagesAl Bilad Company Profile PDFQuerubin R Yolando Jr.No ratings yet

- CUI Protective Coating Systems Part IDocument52 pagesCUI Protective Coating Systems Part Irty2No ratings yet

- Cooling TowerDocument72 pagesCooling TowerRobert Nixon100% (1)

- HDPE DrainageDocument48 pagesHDPE DrainageKarthikeyan SankarrajanNo ratings yet

- Silo TechnologyDocument12 pagesSilo TechnologyMichel Durán ContrerasNo ratings yet

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Chemical Injection PDFDocument4 pagesChemical Injection PDFermusat100% (1)

- Polyflow ExPERT Ecuador PresentationDocument29 pagesPolyflow ExPERT Ecuador PresentationRené Luis Perez MagneNo ratings yet

- Bolted Tanks - GeneralDocument2 pagesBolted Tanks - GeneralFarhan100% (2)

- SGL PT Brochure Graphite Block Heat ExchangersDocument16 pagesSGL PT Brochure Graphite Block Heat ExchangersdardocapoNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Year Minimills 2010Document8 pagesYear Minimills 2010mishtinilNo ratings yet

- Composol PipelineDocument1 pageComposol Pipelineraj1508No ratings yet

- Composol StructureDocument1 pageComposol Structureraj1508No ratings yet

- Composol Grab-Wrap: UsageDocument1 pageComposol Grab-Wrap: Usageraj1508No ratings yet

- Paint Repair MaintenanceDocument6 pagesPaint Repair MaintenanceRajiv Kumar M100% (1)

- Kingspan Low Pitch and Curved RoofDocument36 pagesKingspan Low Pitch and Curved RoofCathy-Anne MurphyNo ratings yet

- SEA PresentationDocument56 pagesSEA PresentationAliBenamerNo ratings yet

- Cold Bonding LNG TanksDocument4 pagesCold Bonding LNG TankskaybeeNo ratings yet

- IDT Imageprospekt 2012 Web enDocument46 pagesIDT Imageprospekt 2012 Web enjbharghavNo ratings yet

- BR Polyken Rev11 Sep10Document8 pagesBR Polyken Rev11 Sep10diaccessltd_17172961No ratings yet

- CS Corrosion Protection SystemDocument20 pagesCS Corrosion Protection SystemMichael AlbuquerqueNo ratings yet

- CW50MM Page42Document106 pagesCW50MM Page42Jacob Priyadharshan100% (1)

- PolykenDocument8 pagesPolykenVictor Hugo Bustos BeltranNo ratings yet

- En Media Files MC-Bauchemie Products en Technical Datasheet Emcoril ACDocument2 pagesEn Media Files MC-Bauchemie Products en Technical Datasheet Emcoril ACAjay SharmaNo ratings yet

- DDPS Reglassing PDFDocument2 pagesDDPS Reglassing PDFMahmoud Al HomranNo ratings yet

- Cabezales Stream FloDocument8 pagesCabezales Stream FlorovalanoNo ratings yet

- Slag PotsDocument4 pagesSlag Potsponnivalavans_994423No ratings yet

- 1LAB 000280 EasyDry DMB OA Bushing Nov 2012Document12 pages1LAB 000280 EasyDry DMB OA Bushing Nov 2012Jason BourneNo ratings yet

- Since The Beginning of The 20 Century, Between Tradition and InnovationDocument6 pagesSince The Beginning of The 20 Century, Between Tradition and InnovationrimshadtpNo ratings yet

- A Solution Ahead: de Dietrich® Optimix® ReactorDocument3 pagesA Solution Ahead: de Dietrich® Optimix® ReactorNguyễn Khánh HòaNo ratings yet

- Advantages of Covalence® Heat-Shrinkable ProductsDocument1 pageAdvantages of Covalence® Heat-Shrinkable Productsعزت عبد المنعمNo ratings yet

- APS - New Capability StatementDocument12 pagesAPS - New Capability StatementClarkFedele27No ratings yet

- EN TRACERTRACLOC SB DOC2213 - tcm505 35972 PDFDocument6 pagesEN TRACERTRACLOC SB DOC2213 - tcm505 35972 PDFermusatNo ratings yet

- Tie Bolt Hole Repair SystemDocument1 pageTie Bolt Hole Repair Systemsattar12345No ratings yet

- BestendigheidstabelDocument32 pagesBestendigheidstabeldroessaert_stijnNo ratings yet

- CERBERITE Hollow Glass Speciality Contact MaterialDocument5 pagesCERBERITE Hollow Glass Speciality Contact MaterialPramendraSinghNo ratings yet

- ALQ ALABRAJ PresentationCIVIL - Pipeline, Piping, Storage Tank PDFDocument95 pagesALQ ALABRAJ PresentationCIVIL - Pipeline, Piping, Storage Tank PDFSaleh Salman100% (1)

- Dow Corning® 895 Structural Glazing Sealant: Product InformationDocument1 pageDow Corning® 895 Structural Glazing Sealant: Product Informationjaga67No ratings yet

- ASCoolingTower Brochure DigitalDocument8 pagesASCoolingTower Brochure Digital2ravikanthNo ratings yet

- TDS R4d-IcDocument3 pagesTDS R4d-IcRavie OuditNo ratings yet

- Prime Surface Plate CoilDocument12 pagesPrime Surface Plate CoilGrimmo1979No ratings yet

- Surface Mining PresentationDocument66 pagesSurface Mining PresentationXena Nurraini Anun CakranegaraNo ratings yet

- ErbosanCatalogue PDFDocument20 pagesErbosanCatalogue PDFAna Silva PintoNo ratings yet

- Fabric Expansion JointsDocument20 pagesFabric Expansion JointsBradley NelsonNo ratings yet

- Clorosur FinalDocument23 pagesClorosur FinalvasucristalNo ratings yet

- Total Engineering Solutions: Mechanical - Electrical - PlumbingDocument12 pagesTotal Engineering Solutions: Mechanical - Electrical - PlumbingIrfanshah2013No ratings yet

- Nitrogen TankDocument9 pagesNitrogen TankVirnando NainggolanNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Application Note Clock Spring® MarkerDocument3 pagesApplication Note Clock Spring® Markerraj1508No ratings yet

- Field Marshal Sam Manekshaw On DisciplineDocument13 pagesField Marshal Sam Manekshaw On DisciplineDeltaForceNo ratings yet

- Design Parameter Unit Symbol Value RemarksDocument2 pagesDesign Parameter Unit Symbol Value Remarksraj1508No ratings yet

- Clock Spring: Application Note DurabilityDocument4 pagesClock Spring: Application Note Durabilityraj1508No ratings yet

- Design Parameter Unit Symbol Value RemarksDocument2 pagesDesign Parameter Unit Symbol Value Remarksraj1508No ratings yet

- India Today 5 Oct PDFDocument66 pagesIndia Today 5 Oct PDFraj1508No ratings yet

- 4 6026206739718735498 PDFDocument18 pages4 6026206739718735498 PDFraj1508No ratings yet

- Annexure V Bid MatrixDocument17 pagesAnnexure V Bid Matrixraj1508No ratings yet

- India Today 5 Oct PDFDocument66 pagesIndia Today 5 Oct PDFraj1508No ratings yet

- Outlook June 2020 PDFDocument56 pagesOutlook June 2020 PDFraj1508No ratings yet

- Annexure Iv BecDocument37 pagesAnnexure Iv Becraj1508No ratings yet

- Annexure VII Bidders Response SheetDocument2 pagesAnnexure VII Bidders Response Sheetraj1508No ratings yet

- Annexure III Scope of Work and Special ConditionsDocument7 pagesAnnexure III Scope of Work and Special Conditionsraj1508No ratings yet

- Hse 20180313 103526Document6 pagesHse 20180313 103526raj1508No ratings yet

- Schedule of Rates (Sor) : Section-Vii TENDER NO. GAIL/AGT/FL85/20075421/8000012800Document2 pagesSchedule of Rates (Sor) : Section-Vii TENDER NO. GAIL/AGT/FL85/20075421/8000012800raj1508No ratings yet

- Tableau Incoterms 202000Document5 pagesTableau Incoterms 202000souleymane sow100% (6)

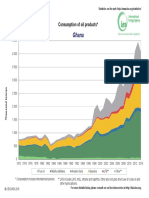

- Ghana: Consumption of Oil ProductsDocument1 pageGhana: Consumption of Oil Productsraj1508No ratings yet

- Glossary Trading of Oil and GasDocument136 pagesGlossary Trading of Oil and Gasprsiva2420034066No ratings yet

- Forecasting Demand For Petroleum Products in Ghana Using Time Series ModelsDocument14 pagesForecasting Demand For Petroleum Products in Ghana Using Time Series Modelsraj1508No ratings yet

- Ghana - Oil and Gas - ExportDocument5 pagesGhana - Oil and Gas - Exportraj1508No ratings yet

- Key World Energy TrendsDocument19 pagesKey World Energy TrendsBradley JohnsonNo ratings yet

- HD-Shell Nederland - USADocument29 pagesHD-Shell Nederland - USANhuyNo ratings yet

- Glossary of Terms Used in Oil IndustryDocument67 pagesGlossary of Terms Used in Oil Industryhrami2No ratings yet

- Composol Vessel: UsageDocument1 pageComposol Vessel: Usageraj1508No ratings yet