Professional Documents

Culture Documents

Partes de Martillo - 3

Uploaded by

Coni Fuenzalida Varela0 ratings0% found this document useful (0 votes)

10 views1 pageThe document provides inspection points and remedies for daily breaker inspections. It lists items to check such as bolts, hoses, fittings and leaks. Specific points include tie rods, brackets, hydraulic pipes and oil levels. Remedies include retightening, replacing damaged parts and consulting service for further inspection. The document also lists checking wear on tools, greasing procedures and hydraulic oil contamination levels. Regular inspection and maintenance by a service station every six months is recommended to keep breakers in best operating condition.

Original Description:

Original Title

partes de martillo_3

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides inspection points and remedies for daily breaker inspections. It lists items to check such as bolts, hoses, fittings and leaks. Specific points include tie rods, brackets, hydraulic pipes and oil levels. Remedies include retightening, replacing damaged parts and consulting service for further inspection. The document also lists checking wear on tools, greasing procedures and hydraulic oil contamination levels. Regular inspection and maintenance by a service station every six months is recommended to keep breakers in best operating condition.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views1 pagePartes de Martillo - 3

Uploaded by

Coni Fuenzalida VarelaThe document provides inspection points and remedies for daily breaker inspections. It lists items to check such as bolts, hoses, fittings and leaks. Specific points include tie rods, brackets, hydraulic pipes and oil levels. Remedies include retightening, replacing damaged parts and consulting service for further inspection. The document also lists checking wear on tools, greasing procedures and hydraulic oil contamination levels. Regular inspection and maintenance by a service station every six months is recommended to keep breakers in best operating condition.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

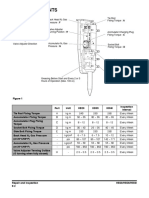

DAILY BREAKER INSPECTION

Inspection Item Inspection Point Remedy

Looseness, missing and Tie rod Check looseness.

damage to bolts and nuts Bracket mounting bolts Retighten securely.

Looseness, ofhose fittings, Hydraulic pipes for breaker - oil Retighten securely.

visible damage to hoses and hoses Replace seriously damaged parts.

oil leakage

Abnormal oil leakage Connections of back head and Consult with DOOSAN service station for

cylinder Clearance between front further inspection.

head & tool (*But small leakage is

normal from front-head)

Abnormal wear and cracks Tool Deformed, burred and worn out tool

on tool should be repaired.

Excessively worn tool needs to be

replaced.

Greasing Grease at start and every 2 or 3 Grease front head.

hours using head grease pump.

Pumping; 5 ~ 10 imes

(Greasing position and method

shown at left.)

When greasing, press the tool

against on the round.

Level and contamination of Conditions of hydraulic oil Contamination of hydraulic oil caries with

hydraulic oil operating conditions, the oil color tells the

level of contamination.

Criteria for judging contamination is

specifically set by DOOSAN.

When contamination is excessive, drain

and flush the hydraulic oil tank and fill it

with new oil.

Missing rubber plugs and Rubber plugs A seriously damaged part must be

snap rings Snap rings replaced.

(Silence type reaker) Check every 3 month, if the wear- If it is worn too much or damaged,

Clearance of wear plate, plate, guide-plate, cushions are replace the parts.

guide plate, cushion etc… good or not

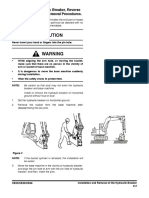

REGUALR BREAKER

INSPECTION AND

MAINTENANCE

Regular inspection is essential for keeping hydraulic breaker

operating in the best condition consult with the DOOSAN service

station for regular inspection and maintenance. Customers are

recommended to contact the service station for inspection within

six months after delivery.

Repair and Inspection HB20/HB30/HB40

9-4

You might also like

- Ram 2500 2010 6.7DDocument286 pagesRam 2500 2010 6.7Dcarlos martinezNo ratings yet

- Digital Booklet - Britney Spears - Work B CH (Single)Document5 pagesDigital Booklet - Britney Spears - Work B CH (Single)Gâu EheheNo ratings yet

- Tree of Qliphoth: Temple of Ascending FlameDocument30 pagesTree of Qliphoth: Temple of Ascending FlameGatuo Angel ToniNo ratings yet

- Backhoe English PDFDocument1 pageBackhoe English PDFGino AndersonNo ratings yet

- C10836834 PDFDocument1 pageC10836834 PDFFabian LopezNo ratings yet

- Safety & Maintenance Checklist - D7E Track-Type Tractors V0611.2Document1 pageSafety & Maintenance Checklist - D7E Track-Type Tractors V0611.2cherifNo ratings yet

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Document201 pagesMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNo ratings yet

- Bringing Words To LifeDocument23 pagesBringing Words To LifeKatarina Mijatovic100% (3)

- Safety & Maintenance Checklist - Demolition Hydraulic Excavators V0611.2Document1 pageSafety & Maintenance Checklist - Demolition Hydraulic Excavators V0611.2cherif100% (3)

- Agilent GcmsDocument26 pagesAgilent Gcmsviktor_gligorovNo ratings yet

- HDB Series Service Training (All) 2016 - R2Document44 pagesHDB Series Service Training (All) 2016 - R2Jorge RojasNo ratings yet

- Construction Techniques For Bored Piling in Sand Using Polymer FluidsDocument10 pagesConstruction Techniques For Bored Piling in Sand Using Polymer FluidsjohnNo ratings yet

- Safety & Maintenance Checklist - Landfill Compactors V0611.2Document1 pageSafety & Maintenance Checklist - Landfill Compactors V0611.2cherifNo ratings yet

- Safety & Maintenance Checklist - Backhoe Loaders V0611 - 2E2Document1 pageSafety & Maintenance Checklist - Backhoe Loaders V0611 - 2E2Abdellatef HossamNo ratings yet

- Report For Oil ProcessingDocument83 pagesReport For Oil ProcessingabhayNo ratings yet

- Manual Servicio Eaton Serie 10 PDFDocument16 pagesManual Servicio Eaton Serie 10 PDFCesar MoraNo ratings yet

- Excavator Instructors NotesDocument31 pagesExcavator Instructors NotesWALTER EMMANUEL FLORES COSCONo ratings yet

- Trends Q1-W3Document13 pagesTrends Q1-W3Samano PaodacNo ratings yet

- Troubleshooting John Deere 510DDocument5 pagesTroubleshooting John Deere 510Denriquevazquez27No ratings yet

- C10836843 PDFDocument1 pageC10836843 PDFsandrobhaNo ratings yet

- Static Var CompensatorDocument29 pagesStatic Var CompensatorCarlos Fabian GallardoNo ratings yet

- Goetze Poster TTC Rings PRMGT1706 en LRDocument1 pageGoetze Poster TTC Rings PRMGT1706 en LRAung Myin ThuNo ratings yet

- BG28-03 Rotary Planentary Oil Change ProcedureDocument3 pagesBG28-03 Rotary Planentary Oil Change ProcedureSIVARAMANJAGANATHANNo ratings yet

- John Deere Engine TroubleshootingDocument6 pagesJohn Deere Engine TroubleshootingAbubakar FaroukNo ratings yet

- Lubrication Guide F2321 07-20-2021Document22 pagesLubrication Guide F2321 07-20-2021reman partsNo ratings yet

- Hoists 22: Check The Oil Level Through The Inspection GlassDocument6 pagesHoists 22: Check The Oil Level Through The Inspection GlassM RefaiNo ratings yet

- Lubrication Guide - F2314 - 07-20-2021Document22 pagesLubrication Guide - F2314 - 07-20-2021RaphaelNo ratings yet

- kx80 Página 152Document1 pagekx80 Página 152PabloNo ratings yet

- Bulletin TH Pump Repair 1Document14 pagesBulletin TH Pump Repair 1macanipharoldf6220No ratings yet

- Spicer : Powr-LokDocument15 pagesSpicer : Powr-LokOcelio MucudosNo ratings yet

- Morse Hy-Vo Chain: Sprocket Wear - Light Wear - Heavy Wear - Pitting Lubrication Smells Bad and Is Dark in ColorDocument1 pageMorse Hy-Vo Chain: Sprocket Wear - Light Wear - Heavy Wear - Pitting Lubrication Smells Bad and Is Dark in ColorAleksandrNo ratings yet

- Service & Check Vehicle Before Road Trip - Write UpDocument2 pagesService & Check Vehicle Before Road Trip - Write UpSyed Mohamad Adha Bin Syed Mohd MazlyNo ratings yet

- Gold BookDocument142 pagesGold BookSerhii NedvyhaNo ratings yet

- Lubrication: Necessity of Lubrication Lubricating PointsDocument3 pagesLubrication: Necessity of Lubrication Lubricating PointsrccanarimNo ratings yet

- ABL-74T Machine MaintenanceDocument1 pageABL-74T Machine MaintenanceChris McNairNo ratings yet

- 2016 Harley Davidson Street Bob 66867 Páginas 90 103Document14 pages2016 Harley Davidson Street Bob 66867 Páginas 90 103Antonio Alves Pereira FilhoNo ratings yet

- Ection Aintenance and Ervice: Revision November 2009Document24 pagesEction Aintenance and Ervice: Revision November 2009ddrb23No ratings yet

- Group 2 Operational Checks and TroubleshootingDocument5 pagesGroup 2 Operational Checks and TroubleshootingAndré TarginoNo ratings yet

- Manual Canrig 06Document8 pagesManual Canrig 06sertecs polNo ratings yet

- Compressors Tanabe Marine Compressors Service Documents: For H-Series CompressorDocument31 pagesCompressors Tanabe Marine Compressors Service Documents: For H-Series CompressorАндрей СтупакNo ratings yet

- Cat Safety & Maintenance Checklist - SYKES PUMPSDocument1 pageCat Safety & Maintenance Checklist - SYKES PUMPSAlberto KelsoNo ratings yet

- 04 - Lubrication System-1Document8 pages04 - Lubrication System-1Marcos Mo CatalanNo ratings yet

- Hydraulic Disc Brake Hose Length Adjustment & Bleed GuideDocument57 pagesHydraulic Disc Brake Hose Length Adjustment & Bleed GuideFrancisco ReyesNo ratings yet

- Worm Speed Reducers MnualDocument10 pagesWorm Speed Reducers MnualMayur ShendgeNo ratings yet

- Troubleshooting: LiningDocument48 pagesTroubleshooting: Liningplanner samulosNo ratings yet

- GR3050 & GR3100: Preventative MaintenanceDocument24 pagesGR3050 & GR3100: Preventative Maintenanceabelmonte_geotecniaNo ratings yet

- Screw Conveyor Engineering GuideDocument2 pagesScrew Conveyor Engineering GuideSidney MedlingNo ratings yet

- Avid Elixir Bleed and Hose Leght Adjustment GuideDocument57 pagesAvid Elixir Bleed and Hose Leght Adjustment GuideboemiusNo ratings yet

- Bomba de Vacio Gast Lubricated Laboratory 23 Series RotaryDocument8 pagesBomba de Vacio Gast Lubricated Laboratory 23 Series RotaryRafael Rueda AlvarezNo ratings yet

- 4-Wheeler General Service Checklist: Test Run-Vehicle DiagnosisDocument8 pages4-Wheeler General Service Checklist: Test Run-Vehicle DiagnosisaravNo ratings yet

- Air Heater Maintenace/Trouble Shooting and RemediesDocument13 pagesAir Heater Maintenace/Trouble Shooting and Remediesjp mishraNo ratings yet

- ABS FR Installation Manual ENDocument4 pagesABS FR Installation Manual ENignacioramirez0% (1)

- JH Step#4 Training Module Lubrication 2Document16 pagesJH Step#4 Training Module Lubrication 2Anonymous pC7MGONo ratings yet

- Maintenance-Log-Mud PumpDocument4 pagesMaintenance-Log-Mud PumpSarah RavikumarNo ratings yet

- 10 Daily Checks PDFDocument16 pages10 Daily Checks PDFandresNo ratings yet

- ENGINE TroubleshootingDocument37 pagesENGINE TroubleshootingsolomonNo ratings yet

- Maintenance InstructionsDocument3 pagesMaintenance InstructionsNavnath GawasNo ratings yet

- ICHEM Reviewer 2Document4 pagesICHEM Reviewer 2Rick James RojasNo ratings yet

- AS AM Replacement en Problem Cause SolutionDocument1 pageAS AM Replacement en Problem Cause SolutionAntony ContrerasNo ratings yet

- PennBarry Efficient Silent Inline Fans IOM Bearing LubricationDocument5 pagesPennBarry Efficient Silent Inline Fans IOM Bearing LubricationPatrick FoNo ratings yet

- Basic Chain Lubrication GuideDocument2 pagesBasic Chain Lubrication GuideRakesh PawarNo ratings yet

- Series 10 Dual Displacement: Parts and Repair InformationDocument20 pagesSeries 10 Dual Displacement: Parts and Repair InformationAлександрNo ratings yet

- Maintenance Check Sheet - DISCOVERY 3 4 ARMOURED DIESEL MODELS - MilesDocument2 pagesMaintenance Check Sheet - DISCOVERY 3 4 ARMOURED DIESEL MODELS - MilesCristiano DellazariNo ratings yet

- RWRG0031 - Splitter, Cylinder, Dry / Oil Ingestion On 13 - 18 SpeedsDocument2 pagesRWRG0031 - Splitter, Cylinder, Dry / Oil Ingestion On 13 - 18 SpeedsBart JohnNo ratings yet

- Rwrg0031en Us PDFDocument2 pagesRwrg0031en Us PDFBart JohnNo ratings yet

- HEMM Excavator01Document9 pagesHEMM Excavator01miningnova2No ratings yet

- Compresor de Aire Atlas Copco XAS96Document9 pagesCompresor de Aire Atlas Copco XAS96Coni Fuenzalida VarelaNo ratings yet

- Partes de MartilloDocument1 pagePartes de MartilloConi Fuenzalida VarelaNo ratings yet

- Partes de Martillo - 4Document1 pagePartes de Martillo - 4Coni Fuenzalida VarelaNo ratings yet

- Conversion Table For Charging Nitrogen Gas Pressure To Back HeadDocument1 pageConversion Table For Charging Nitrogen Gas Pressure To Back HeadConi Fuenzalida VarelaNo ratings yet

- Charging of Nitrogen Gas Into AccumulatorDocument1 pageCharging of Nitrogen Gas Into AccumulatorConi Fuenzalida VarelaNo ratings yet

- Excavadora 17 PDFDocument1 pageExcavadora 17 PDFConi Fuenzalida VarelaNo ratings yet

- Installation and Removal of The Hydraulic BreakerDocument1 pageInstallation and Removal of The Hydraulic BreakerConi Fuenzalida VarelaNo ratings yet

- Do Not Allow The Breaker To Fall To Break A RockDocument1 pageDo Not Allow The Breaker To Fall To Break A RockConi Fuenzalida VarelaNo ratings yet

- Caution: To Install The Hydraulic Breaker, Reverse The Fore Mentioned Removal ProceduresDocument1 pageCaution: To Install The Hydraulic Breaker, Reverse The Fore Mentioned Removal ProceduresConi Fuenzalida VarelaNo ratings yet

- Operating Posision Spanner Gate ValveDocument1 pageOperating Posision Spanner Gate ValveConi Fuenzalida VarelaNo ratings yet

- Do Not Continue To Hammer For More Than One MinuteDocument1 pageDo Not Continue To Hammer For More Than One MinuteConi Fuenzalida VarelaNo ratings yet

- Operate Breaker at Proper Engine Speed.: Lever Position DuringDocument1 pageOperate Breaker at Proper Engine Speed.: Lever Position DuringConi Fuenzalida VarelaNo ratings yet

- Stop Operation As Soon As Hose Vibrate ExcessivelyDocument1 pageStop Operation As Soon As Hose Vibrate ExcessivelyConi Fuenzalida VarelaNo ratings yet

- Charging of Nitrogen Gas Into AccumulatorDocument1 pageCharging of Nitrogen Gas Into AccumulatorConi Fuenzalida VarelaNo ratings yet

- Excavadora 8Document1 pageExcavadora 8Coni Fuenzalida VarelaNo ratings yet

- Nitrogen Gas Charging Pressure To Accumulator: Adapter HandleDocument1 pageNitrogen Gas Charging Pressure To Accumulator: Adapter HandleConi Fuenzalida VarelaNo ratings yet

- Operation (Breaking) : Proper Position of The ToolDocument1 pageOperation (Breaking) : Proper Position of The ToolConi Fuenzalida VarelaNo ratings yet

- Excavadora 2 PDFDocument1 pageExcavadora 2 PDFConi Fuenzalida VarelaNo ratings yet

- Inspection and Charging of Nitrogen Gas in Accumulator WarningDocument1 pageInspection and Charging of Nitrogen Gas in Accumulator WarningConi Fuenzalida VarelaNo ratings yet

- Warning Sticker: Use Hearing Protection Use Eye Protection Use Breathing Protection Read The Manual Before UseDocument1 pageWarning Sticker: Use Hearing Protection Use Eye Protection Use Breathing Protection Read The Manual Before UseConi Fuenzalida VarelaNo ratings yet

- If Gas Is Insufficient, Adjust To Specified Valve As Shown in The Previous Page. (Note. 2)Document1 pageIf Gas Is Insufficient, Adjust To Specified Valve As Shown in The Previous Page. (Note. 2)Coni Fuenzalida VarelaNo ratings yet

- NWPC Annual Report 2014Document56 pagesNWPC Annual Report 2014lupethe3No ratings yet

- The Marine WorkoutDocument7 pagesThe Marine WorkoutAndres Eco AldeanoNo ratings yet

- MineralsDocument40 pagesMineralsGhillian Mae GuiangNo ratings yet

- Manual Safety SignDocument49 pagesManual Safety SignMuamar DhikriNo ratings yet

- Tom MCQ UNIT 2Document14 pagesTom MCQ UNIT 2Kumar PachareNo ratings yet

- Master Thesis In-Depth InterviewsDocument5 pagesMaster Thesis In-Depth Interviewsrqopqlvcf100% (1)

- Algorithm Exam HelpDocument9 pagesAlgorithm Exam HelpProgramming Exam HelpNo ratings yet

- R 69 CP TDSDocument2 pagesR 69 CP TDSKripesh Kumar DubeyNo ratings yet

- Manual Usuario Hiki User-Manual-5392612Document174 pagesManual Usuario Hiki User-Manual-5392612Rafael MunueraNo ratings yet

- Singtel Annual Report 2023 Higher ResDocument275 pagesSingtel Annual Report 2023 Higher ResJL ChuaNo ratings yet

- Seward Stomacher 400Document2 pagesSeward Stomacher 400ugomiesterNo ratings yet

- Abe Tos 2023Document28 pagesAbe Tos 2023DelenayNo ratings yet

- Clean India Green India: Hindi VersionDocument3 pagesClean India Green India: Hindi VersionkaminiNo ratings yet

- New Alternatives For Continuity Plates in I-Beam To Box ColumnsDocument15 pagesNew Alternatives For Continuity Plates in I-Beam To Box ColumnstaosyeNo ratings yet

- Vis DK 25 Programming GuideDocument210 pagesVis DK 25 Programming GuideshrihnNo ratings yet

- Recovery in Credit GrantedDocument21 pagesRecovery in Credit GrantedMaria Ysabella Yee80% (5)

- 0332713Document200 pages0332713JS DUFFEYNo ratings yet

- Gene KnockDocument5 pagesGene KnockAnne Marian JosephNo ratings yet

- Database Efficiency and TuningDocument22 pagesDatabase Efficiency and TuningJyothy SwaroopNo ratings yet

- Newsflash MagazineDocument64 pagesNewsflash MagazineIan LuoNo ratings yet

- 7th Circular Motion SolutionsDocument60 pages7th Circular Motion SolutionsAjay D KumarNo ratings yet

- Media FillDocument13 pagesMedia FillraghuNo ratings yet

- Mid Term Asssignment - The Five Senses - PrimaryDocument5 pagesMid Term Asssignment - The Five Senses - PrimaryPrajna MoodabidriNo ratings yet