0% found this document useful (0 votes)

686 views66 pagesUnderstanding The GC Inlet: Which One Is More Appropriate For Your Method?

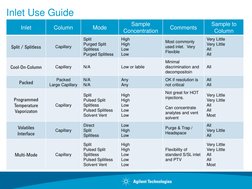

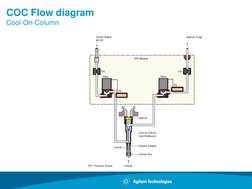

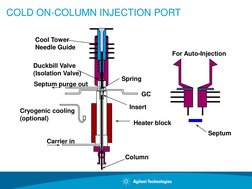

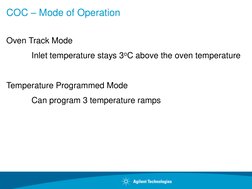

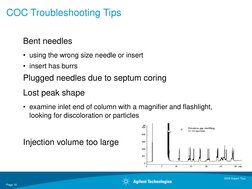

The document discusses different gas chromatography inlet types and their appropriate uses based on factors like sample concentration, volatility, column type, and analysis goals. It provides diagrams and descriptions of cool on-column, programmed temperature vaporization, volatiles interface, purged packed, and split/splitless inlets. Key considerations for each inlet include sample type, concentration level, temperature requirements, and whether trace, percentage, or high temperature analysis is needed.

Uploaded by

Scott Thomas WeilandCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

686 views66 pagesUnderstanding The GC Inlet: Which One Is More Appropriate For Your Method?

The document discusses different gas chromatography inlet types and their appropriate uses based on factors like sample concentration, volatility, column type, and analysis goals. It provides diagrams and descriptions of cool on-column, programmed temperature vaporization, volatiles interface, purged packed, and split/splitless inlets. Key considerations for each inlet include sample type, concentration level, temperature requirements, and whether trace, percentage, or high temperature analysis is needed.

Uploaded by

Scott Thomas WeilandCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd