Professional Documents

Culture Documents

Deep Controls Pneumatics Catalogue PDF

Uploaded by

sundarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Deep Controls Pneumatics Catalogue PDF

Uploaded by

sundarCopyright:

Available Formats

Since - 2001

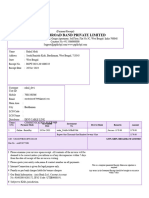

DEEP CONTROLS PNEUMATICS(AN ISO 9001 : 2015 CERTIFIED CO.)

A NAME OF POWER PRESS

Pneumatic Feeder

LINE AUTOMATION De-Coiler Cum Straightener

(Cradle Type

Company Profile :

Deep Controls Pneumatics is a high-tech company

devoted the Power Press Automation Industry. Its

business emphasizes on the feeding units. Deep

Controls Pneumatics also provides logistic solutions

and installation services according to the customer’s

requirement, it is a space saving & easy handling.

Main characteristic feature of the units are to increase

productivity and saving on cost by performing

Hydraulic De-Coiler

pushing & pulling movements.

High Speed Mechanical

Gripper Feeder To make the things possible, the design of units and

its operational viability has been kept as such that it

ready to deliver the requisite without any wastage

of time, money and give efficiency.

Deep Controls Pneumatics high performance team of

qualified managers, technical experts, Sales

Executives and trained workers provide the platform

for Deep Control’s rapid development.

Our Moto...

• To deliver the globally accepted products.

• To provide better after sales services to satisfy

the needs of the customers in time. De-Coiler

NC Servo Roll Feeder

A Word of Greetings

We totally appreciate supports from our clients and

affiliates which become our moto for remarkable

development in automation field. Our products have

been widely recognized in quality and reliability.

We will meet our client’s demand and also expect

continuing support from our clients. Our clients can

faith on us.

High Speed Cut to Length De-Coiler & Straightener

(2 in 1 Compact Type)

Air

Compressor

World Class Quality Products For Coil Feeding Systems

Precision Pneumatic Feeder, De-Coiler & High Speed

Mechanical Gripper Feeder

Why DEEP Pneumatic Feeder

Here are some very basic reasons with which it can be

proved that buying a DEEP Pneumatic Feeder is the right

thing to do. Installing a feeder on your press does not just

mean choosing a pneumatic clamp for feeding the material

You need to choose carefully the right feeder to develop

better productivity.

Pneumatic Feeder

Precision Accuracy of feeder 20 Micron is assured

depending upon tool Right to choose Right for every

needs. Light & Heavy Services for Thinner & Thicker Material

at Fast Speed with Double, Triple & Four Pulling Cylinder &

many series to follow Soon

Compact, Right and Strong Structure which has negligible

wear characteristics,

Durable in Indian working conditions because of extremely

hard Aluminum alloy feed body there is no oxidation due to

wet air remaining inside the feeder.

Quiet during operation.

De- Coilers

Low Air Consumption Makes it more economical because

it saves electricity.

Last but not the least, it is inexpensive compared with any

other option. Here is the way to increase the productivity

and life of your Dies/Tools.

DEEP De-Coilers automatically centers the coilers for

easy unwinding. Loop control system controls the unwinding

stock automatically.

To select your De-coilers please give the following information:

Width of coil.........mm Weight of Coil ..............Kg.

Inner Diameter of Coil ..............mm

Outer Diameter of Coil ..............mm

High Speed Mechanical Gripper Feeder Gripper Feeder

Application

Deep Gripper Feeder is ideal for accurate feeding of coil

material on medium & high speed presses with progressive

tools. With feeding accuracy to the tune of ± 20 microns.

To select your De-coilers please give the following information:

Strip Width ..............mm Stock Length ..............mm

Strip Thickness ...................mm

Stroke Length Thickness Speed

Type Model Width mm

mm mm max stroke / min

DP 5A 10-130 5-130 0.1-2.5 650

DP 8A 15-205 5-200 0.1-2.5 500

DP 12A 32-310 10-310 0.2-3.0 400

DP 16A 32-410 10-400 0.2-3.0 300

MAX Strip Strip Strip Cycles

TYPE Width (mm) in(mm) Thickness (mm) Min.

DP 1 55 55 1.20 260

DP 2 55 105 1.10 210

DP 3 55 155 1.00 180

Medium Duty Series

DP 4 55 205 1.00 130

DP 5 55 255 1.00 120

DP 6 55 305 1.00 100

DP 7 55 355 1.00 90

DP 8 105 55 1.20 170

DP 9 105 105 1.00 140

DP 10 105 155 1.00 120

DP 11 105 205 1.00 110

DP 12 105 255 1.20 100

DP 13 105 305 1.00 100

DP 14 105 355 1.00 90

DP 15 155 55 1.00 200

DP 16 155 105 1.00 160

DP 17 155 155 1.00 150

DP 18 155 205 1.00 130

DP 19 155 255 1.00 100

DP 20 155 305 1.00 90

DP 21 155 355 1.00 80

DP 22 205 105 1.50 180

DP 23 205 155 1.40 140

Medium Duty Series With

DP 24 205 205 1.40 130

Two Pilling Cylinders

DP 25 205 255 1.30 120

DP 26 205 305 1.20 110

DP 27 305 105 1.50 160

DP 28 305 155 1.40 130

DP 29 305 205 1.30 120

DP 30 305 255 1.20 110

DP 31 305 305 1.00 100

DP 32 305 355 1.00 90

DP 33 405 105 1.50 140

DP 34 405 155 1.40 130

DP 35 405 205 1.30 120

DP 36 405 255 1.20 100

DP 37 405 305 1.10 90

DP 38 405 355 1.00 80

DP 39 405 405 1.00 70

DPH 40 100 100 4.00 160

DPH 41 150 50 3.00 150

DPH 42 150 100 3.00 140

DPH 43 150 150 3.00 120

DPH 44 150 200 2.50 100

Heavy Duty

DPH 45 150 250 2.50 90

DPH 46 150 300 2.50 80

Series

DPH 47 150 350 2.50 70

DPH 48 150 400 2.50 60

DPH 49 200 100 3.00 130

DPH 50 200 150 2.60 110

DPH 51 200 200 2.50 100

DPH 52 200 250 2.40 90

DPH 53 200 300 2.30 80

DPH 54 200 350 2.30 70

DPH 55 200 400 2.30 60

DPH 56 300 100 4.00 120

Cylinder 2 Moving & 2 Fix Clamp

Heavy Duty Series With 2 Pulling

DPH 57 300 150 3.50 110

DPH 58 300 200 3.50 100

DPH 59 300 250 3.50 90

DPH 60 300 300 3.50 80

DPH 61 300 350 3.40 70

DPH 62 300 400 3.30 60

DPH 63 400 100 3.50 110

DPH 64 400 150 3.50 100

DPH 65 400 200 3.50 90

DPH 66 400 250 3.50 80

DPH 67 400 300 3.50 70

DPH 68 400 350 3.50 60

DPH 69 400 400 3.50 50

DPH 70 400 450 3.50 40

DPH 71 400 500 3.50 30

DPH 72 500 100 4.50 120

DPH 73 500 150 4.50 110

DPH 74 500 200 4.50 100

DPH 75 500 250 4.50 90

Heavy Duty Series With

DPH 76 500 300 4.50 80

3-1 Pulling Cylinder

DPH 77 500 350 4.50 70

DPH 78 500 400 4.00 60

DPH 79 500 450 4.00 50

DPH 80 500 500 4.00 40

DPH 81 500 550 4.00 30

DPH 82 500 600 4.00 20

DPH 83 600 100 4.50 120

DPH 84 600 150 4.50 110

DPH 85 600 200 4.50 100

DPH 86 600 250 4.50 90

DPH 87 600 300 4.50 80

DPH 88 600 350 4.50 70

DPH 89 600 400 4.50 60

DPH 90 600 450 4.50 50

DPH 91 600 500 4.50 40

DPH 92 600 550 4.50 30

DPH 93 600 600 4.50 20

Deep Coil-Handling / Straightening System

DEEP De-Coiler Cum Straightener combine coil De-Coiler Cum Straightener

straightening units are built to provide a straightened stock to

the press for better quality of finished products. Power driven (Cradle Type)

hardened and ground pinch rollers supported in needle

bearings, have enough power to unwind the stock. Hardened

and ground straightening rollers centrally adjustable are

supported in needle bearings. Loop control system

automatically trips the motor on & off and ensures the required

stock advance per minute. Variable driven in provided to match

the straightened feed according to the feed of the press. Four

power driven hardened & grown coil rollers in the cradle

mounted in distribution bearing arranged in arc to equilise

weight distribution. But inner frames are easily adjustable to

accommodate.

To select your, De-coiler-cum-straightner Please give the

following information :-

Width of material ...................mm.

Min & Max. Strip thickness .................. to ...............mm

Inner diameter of coil ...........................

Outer diameter of coil ...............mm. weight Coil..............kg

DEEP NC Servo Roll Feeders NC Servo Roll

DEEP in their endure to bring latest technology for feeder, Feeders

have brought NC Roll Feeder Technology for presses in

year 2002, Today with Installation in various part of country

to handle strip width from 100mm to 1500mm & thickness

from 0.1mm to 15.00mm fully programmable units have be

interlinked with small / medium / large presses.

To select your, NC Servo Roll Feeders Please give the following

information :-

Width of material ...................mm.

Min & Max. Strip thickness .................. to ...............mm

DEEP Sheet Straightener Motor driven straightening units

equipped with set of pinch rollers supported in needle bearings

& nos straightening rollers are supported in needle bearings. All Sheet Straightener

rollers are made from high chrome steel hardened and

ground. Each roller is adjustable from control to ensure

parallelism. Loop control system automatically trips the

motor on and off ensure the required stock advance per

minute. Variable drove (optional) is provided to match the

straighteners feed accordingly to the feed of the press.

To Select your strip, Straightening please give the following

information :-

Width of Material ...........................mm

Min. & Max. Thickness .................... to .....................mm

Type of Material ...........................mm

DEEP CONTROLS PNEUMATICS

You might also like

- (Eng) DAEMO FULL LINEUP - Catalog - 16p - 140211 (7th)Document16 pages(Eng) DAEMO FULL LINEUP - Catalog - 16p - 140211 (7th)Mahendra Tyre Works RaigarhNo ratings yet

- Electric Hydraulic Jacks Business Plan SummaryDocument21 pagesElectric Hydraulic Jacks Business Plan SummaryArsalaan Waheed92% (12)

- 1 2 HP Vayu Portable Air Compressor DomesticDocument2 pages1 2 HP Vayu Portable Air Compressor DomesticparthasarathyNo ratings yet

- Hydraulic Jack Final ProjectDocument21 pagesHydraulic Jack Final ProjectAdnan WattooNo ratings yet

- Terex Tools Rigid Brochure OriginalDocument15 pagesTerex Tools Rigid Brochure OriginalAndrea FilottoNo ratings yet

- Single Stage Belt Drive CompressorsDocument4 pagesSingle Stage Belt Drive Compressorsvictor AnanthNo ratings yet

- 2019 Q4 Hydraulics Catalog 3 3 DIGITAL 103119Document240 pages2019 Q4 Hydraulics Catalog 3 3 DIGITAL 103119Jaime Ocampo SalgadoNo ratings yet

- Water Jet PortfoliaDocument7 pagesWater Jet PortfoliaSagar KumarNo ratings yet

- Modern manufacturing techniques guarantee high quality compressor componentsDocument1 pageModern manufacturing techniques guarantee high quality compressor componentsHandy LeeNo ratings yet

- WC67K NC Hydraulic Plate Press Brake With E21 ControllerDocument6 pagesWC67K NC Hydraulic Plate Press Brake With E21 ControllerryneleeNo ratings yet

- Din Reactors CEDocument3 pagesDin Reactors CEvallamreddyNo ratings yet

- Maintain Petrol Pressure WashersDocument16 pagesMaintain Petrol Pressure WashershrmlynNo ratings yet

- Flexible Disc Couplings and Bearing Isolators: Altra MotionDocument28 pagesFlexible Disc Couplings and Bearing Isolators: Altra MotionEVERSON LIMA FERREIRANo ratings yet

- Alkitronic CLD L enDocument2 pagesAlkitronic CLD L enezeizabarrenaNo ratings yet

- Projetting HDMD Diesel High Pressure Units Web CompressedDocument12 pagesProjetting HDMD Diesel High Pressure Units Web CompressedYohanes RezaNo ratings yet

- 100AFEDocument191 pages100AFEchris pNo ratings yet

- Centrifugal Curvebook 2020Document64 pagesCentrifugal Curvebook 2020Ruwan Susantha PelawattaNo ratings yet

- Dongyang - Hydraulic BreakersDocument16 pagesDongyang - Hydraulic Breakersanon_469496164100% (1)

- Anhui Lai Fu CNC Machine Tool Co., Ltd. YL32 Series Four-Column Deep Drawing Hydraulic PressesDocument4 pagesAnhui Lai Fu CNC Machine Tool Co., Ltd. YL32 Series Four-Column Deep Drawing Hydraulic PressesBALANo ratings yet

- Cam IndexerDocument7 pagesCam IndexerkrishportNo ratings yet

- Packaged Units. PQ Series PQ036 - PQ360 3 TR Thru 30 TR 10 KW Thru 105 KWDocument39 pagesPackaged Units. PQ Series PQ036 - PQ360 3 TR Thru 30 TR 10 KW Thru 105 KWPANDIAN100% (1)

- Ritmo welding machines meet all jobsite needsDocument9 pagesRitmo welding machines meet all jobsite needsnour eldinNo ratings yet

- Products Catalogue 2019 ENG 355 BasicDocument16 pagesProducts Catalogue 2019 ENG 355 BasicBelzébuthAbscisseNo ratings yet

- Manual For Pneumatic Automatic Feeder SpecificationDocument18 pagesManual For Pneumatic Automatic Feeder SpecificationhaisamnagyNo ratings yet

- 01 Injection iTP BrochureDocument28 pages01 Injection iTP BrochureJason XueNo ratings yet

- Unique TyreDocument6 pagesUnique TyreEricka FlynnNo ratings yet

- M - OM - WP - Catalogue - WP - Catalogue - Cross 155 156Document16 pagesM - OM - WP - Catalogue - WP - Catalogue - Cross 155 156Рома БлошенкоNo ratings yet

- ABT60C Concrete Pump AIMIX - 202002Document17 pagesABT60C Concrete Pump AIMIX - 202002ahmad mahfuzNo ratings yet

- DENAIR Oil-Free Air CompressorDocument10 pagesDENAIR Oil-Free Air CompressorSAUL OSPINONo ratings yet

- Titan Machine Full CatalogDocument57 pagesTitan Machine Full Catalogzakatk857No ratings yet

- Flow Length vs. Part ThicknessDocument4 pagesFlow Length vs. Part Thicknessbalta_orozcoNo ratings yet

- Electrical Components Catalogue - (Parts) - 20160617 PDFDocument554 pagesElectrical Components Catalogue - (Parts) - 20160617 PDFCesar Ruben SosaNo ratings yet

- Hongruntong Marine Co., Ltd.Document27 pagesHongruntong Marine Co., Ltd.HONGRUNTONG MARINENo ratings yet

- KD Excavator Breaker Hammer AttachmentsDocument64 pagesKD Excavator Breaker Hammer AttachmentsKSC PARTS100% (1)

- Full Line Brochure 7-2021Document32 pagesFull Line Brochure 7-2021PrudzNo ratings yet

- Operation Manual: BW1500/12 MUD PUMPDocument29 pagesOperation Manual: BW1500/12 MUD PUMPЕвгенийNo ratings yet

- Liugong & Dealers Global: Strong Presence, Sublime SupportDocument16 pagesLiugong & Dealers Global: Strong Presence, Sublime SupportharleyNo ratings yet

- AMAWELD Catalogue NEWDocument8 pagesAMAWELD Catalogue NEWJoshita YoNo ratings yet

- Union Pump InformationDocument12 pagesUnion Pump Informationgeverett2765No ratings yet

- Pusher CentrifugeDocument4 pagesPusher Centrifugeberkay100% (1)

- Cti UxDocument8 pagesCti UxYogesh SainNo ratings yet

- Dva en 0915 EditDocument4 pagesDva en 0915 EditCamilo VelásquezNo ratings yet

- Basic 250 EngDocument9 pagesBasic 250 EngPurushothaman JayabalanNo ratings yet

- Braking Lifting System1Document8 pagesBraking Lifting System1bahramhooNo ratings yet

- WC67K CNC Hydraulic Sheet Metal Press Brake Bender Machine With DA41s SystemDocument7 pagesWC67K CNC Hydraulic Sheet Metal Press Brake Bender Machine With DA41s SystemryneleeNo ratings yet

- Tecothane TPU ClearDocument3 pagesTecothane TPU ClearKhoa HuynhdangNo ratings yet

- Daemo Eng (2ba)Document20 pagesDaemo Eng (2ba)Jairresistenciagt123No ratings yet

- HDB BreakersDocument88 pagesHDB Breakersmargotsilva96No ratings yet

- AMF Zero Point 2007 3GBDocument40 pagesAMF Zero Point 2007 3GBIon Vasilica BrosuNo ratings yet

- C. Cosmic DuctDocument14 pagesC. Cosmic DuctShubhrajeet TiwariNo ratings yet

- ENG RS Drum Screen Data SheetDocument5 pagesENG RS Drum Screen Data Sheetflorencio medina pumaNo ratings yet

- Hydraulic Deep Drawing PressDocument4 pagesHydraulic Deep Drawing PressHarjinder SinghNo ratings yet

- Sabroe Marine Condensing UnitDocument2 pagesSabroe Marine Condensing UnitStipe Vučetić0% (1)

- NGP003 Small Engine Exhaust Cat v2Document10 pagesNGP003 Small Engine Exhaust Cat v2Maria Karina Espino CardosoNo ratings yet

- General Brochure JongiaDocument12 pagesGeneral Brochure Jongiablahblah435No ratings yet

- ZYD-I Transformer Oil Regeneration SystemDocument22 pagesZYD-I Transformer Oil Regeneration SystemEdgarNo ratings yet

- BSB Series BRCDocument6 pagesBSB Series BRCsamiNo ratings yet

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- MBA 231 Marketing Management PDFDocument16 pagesMBA 231 Marketing Management PDFSNEHA SIVAKUMAR 1730152No ratings yet

- Low-Veroty Kantor - BleedDocument108 pagesLow-Veroty Kantor - BleedCrystal Printing LombokNo ratings yet

- Professional English Business General (, Penguin English) PDFDocument57 pagesProfessional English Business General (, Penguin English) PDFNadilla100% (1)

- Summative Test 3rd QDocument3 pagesSummative Test 3rd QDah RylNo ratings yet

- API 520 Part IpdfDocument100 pagesAPI 520 Part IpdfInes Prado AceboNo ratings yet

- APPENDIX TranscriptsDocument7 pagesAPPENDIX TranscriptsTrâm HuyềnNo ratings yet

- Prefabricated StructureDocument129 pagesPrefabricated Structureemraan Khan100% (1)

- Clothing Line Business Plan Example PDFDocument27 pagesClothing Line Business Plan Example PDFSimran Singh67% (3)

- Oracle Fusion Middleware Disaster Recovery Solution Using HP EVA StorageDocument29 pagesOracle Fusion Middleware Disaster Recovery Solution Using HP EVA Storagehelmy_mis1594No ratings yet

- Phoenix Petroleum Company BackgroundDocument6 pagesPhoenix Petroleum Company BackgroundJerome VillaseñorNo ratings yet

- Hazimah - Hanafiah - CAS PRESENTATION SLIDEDocument11 pagesHazimah - Hanafiah - CAS PRESENTATION SLIDEabdulhasnalNo ratings yet

- Rapid Developer - Module 1Document11 pagesRapid Developer - Module 1junemrsNo ratings yet

- Rameen Khan 5B.Document18 pagesRameen Khan 5B.Umair FarooquiNo ratings yet

- San Miguel Corp V InciongDocument7 pagesSan Miguel Corp V InciongReg AnasNo ratings yet

- Ralph Lauren Seeks Tax Refund Through LoopholeDocument3 pagesRalph Lauren Seeks Tax Refund Through LoopholeJeff Weiner100% (1)

- Annual Compliance Calendar - Companies Act, 2013 LISTED COMPANY - Series 527 PDFDocument13 pagesAnnual Compliance Calendar - Companies Act, 2013 LISTED COMPANY - Series 527 PDFGaurav SharmaNo ratings yet

- Sri Trang Gloves Company Profile and Focus on InnovationDocument20 pagesSri Trang Gloves Company Profile and Focus on InnovationRudy NASUHANo ratings yet

- GTPL KCBPL 26.11.2023Document1 pageGTPL KCBPL 26.11.2023rajkumarmodi9832No ratings yet

- Odisha HandicraftPolicy 2019Document20 pagesOdisha HandicraftPolicy 2019Sdrc IndiaNo ratings yet

- Common Reporting Standard (CRS) FactsheetDocument2 pagesCommon Reporting Standard (CRS) FactsheetFelix ChanNo ratings yet

- Report On Riverside County Coroner's OfficeDocument15 pagesReport On Riverside County Coroner's OfficeThe Press-Enterprise / pressenterprise.comNo ratings yet

- 14th WIEF Sponsorship BenefitsDocument2 pages14th WIEF Sponsorship BenefitsLatifiNo ratings yet

- The Durable Business: Momentum (Flywheel)Document1 pageThe Durable Business: Momentum (Flywheel)Ideas BcnNo ratings yet

- Assignment On HSBCDocument20 pagesAssignment On HSBCJackson Kasaku100% (1)

- Cse Dec 21 Free Mock Test Series Subject: Setting Up of Business Entities and ClosureDocument5 pagesCse Dec 21 Free Mock Test Series Subject: Setting Up of Business Entities and ClosureSimran TrehanNo ratings yet

- Bs AccountancyDocument239 pagesBs AccountancyMarites Mayo Cuyos80% (5)

- Ielts General Test 1Document6 pagesIelts General Test 1Jen MattNo ratings yet

- DeclarationLetter 11Document1 pageDeclarationLetter 11Amit YadavNo ratings yet

- 2-Linear Programming FormulationDocument43 pages2-Linear Programming FormulationDon DelundoNo ratings yet

- SL Customs Charges Dec2022Document2 pagesSL Customs Charges Dec2022Phúc LhNo ratings yet