Professional Documents

Culture Documents

Positive Displacement Air Blowers - Sizes 1 & 2: Based On Success

Uploaded by

Robert R. TiinOriginal Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPositive Displacement Air Blowers - Sizes 1 & 2: Based On Success

Uploaded by

Robert R. TiinHR

ROTARY

BLOWERS

Positive Displacement

Air Blowers - Sizes 1& 2

Based on Success

HR Blowers are one of the world’s leading air blower

manufacturers and have a reputation for quality, innovation

and service.

Design Features Specification

The conservative load carrying capacity of CASING: The cylinder and headplates are

the larger diameter rolling element bearings manufactured from cast iron. The gearcase

ensures an extended operating life. is manufactured from aluminium.

Timing gear life is also extended by IMPELLERS AND SHAFTS: The impellers are

controlled lubrication systems. made from SG iron, and cast with integral

The computer calculated impeller profiles shafts. The shaft diameter of machines in

ensure maximum volumetric efficiency the HR Blowers range is larger than that of User Benefits

with minimum absorbed power without earlier designs, enabling increased operating

The delivered air is guaranteed

sacrificing torsional rigidity. pressures to be achieved without increasing

to be oil free because internal

blower size.

The high rigidity of the impeller / shafts lubrication is unnecessary, and

permits a higher pressure rise to be GEARS: The precision ground and hardened because all HR Blowers Positive

obtained than with other machines of steel spur gears are taper mounted onto Displacement Air Blowers are

comparable size. the impeller shafts. The timing of the constructed with air gaps which

The generous shaft diameter keeps drive impellers relative to each other is accurately completely isolate bearing and gear

stresses low. maintained at all times. lubrication from the compression

BEARINGS: The bearings are of generous chamber.

Gear and shaft strength is substantially

increased by the use of taper mounted gears proportions to give long operational life. Noise levels are kept to a minimum.

which do not need keyways for location. Grease lubricated double row ball bearings Mechanical noise levels have been

Setting of the gear wheels to obtain correct are used at the drive end of the blower. In reduced by the running accuracy of

timing of the impellers is simplified, a addition to their normal duty of carrying the taper mounted gears. Air noise

feature that facilitates field maintenance. radial loads associated with the differential is reduced by carefully designed air

air pressure on the rotating impellers, the ports and the elimination of

Precision ground and hardened steel gears

ball bearings provide axial location of the resonant unbraced surfaces.

are used to ensure smooth, silent running

impellers. Parallel roller bearings at the rear The blower can be installed for

and accurate tming of the rotating impellers.

end splash lubrication by oil from the gears. either vertical or horizontal air flow

A controlled lubrication system is provided

to ensure efficient operation without waste LUBRICATION: An advanced design of simply by repositioning the

of energy in the gearcase. controlled gear wheel lubrication enables mounting feet. Installation costs

the gears to operate at a high pitch line can be reduced by versatility of

Specially designed rotary oil seals are used

velocity without the need for an oil pump. mounting arrangement.

in the gearcase. This feature eliminates

maintenance associated with the use of Simple, maintenance free oil throwers fitted The generous diameter of the drive

lip seals. behind each bearing in the gearcase prevent shaft permits the use of V-belt drives

leakage of oil. without the need for a double outer

Design and manufacture is in accordance

DIRECTION OF ROTATION: Detachable bearing.

with metric standards.

mounting feet enable the blower to be All machines are performance

Use as an Exhauster positioned for either vertical or horizontal tested under the most arduous

If used as an exhauster and dust or liquids air flow. Standard machines have a right design conditions before despatch.

could be drawn into the machine due to hand drive shaft for vertical air flow, and a Air blowers can also be used as air

inadequate filtration, closed end rotors bottom drive shaft for horizontal air flow. exhausters. Performance charts on

should be specified. This will minimise risk If machines are required with a left hand or application.

of loss of dynamic balance due to material top drive shaft, all that needs to be done is

inside the rotors. turn the gearcase and trough through 180º.

Centre timing permits clockwise or anti-

clockwise drive shaft rotation.

Dimensions Horizontal Vertical All dimensions in millimetres

Flow Flow

Size A B C D E FH HH E FV HV G J K L M N P Q R S T U V W X Y

HR10

454 165 219 95 95

100

220 21 180

HR11

504 190 244 120 120

70 130 205 180 155 153 173 155 65 32.018/32.002 5.0/5.2 9.964/10.00 14 12 6 8 18

HR12

597 235 292 165 165

125

250 23 210

HR13

667 270 327 200 200

HR20

525 190 253 113 113

125 250 18 210

HR21

600 227 290 150 150

83 150 220 195 175 173 193 157.5 80 35.018/35.002 5.0/5.2 9.964/10.00 14 12 23 6 8

HR22

700 277 340 200 200

150 285 22 240

HR23

790 322 385 245 245

Net Weight Size 10: 76kg Size 20: 111kg

Size 11: 82kg Size 21: 124kg

Size 12: 102kg Size 22: 142kg

Size 13: 106kg Size 23: 158kg

Blower Performance

300 mbar 500 mbar 700 mbar 1000 mbar 300 mbar 500 mbar 700 mbar 1000 mbar

HR Speed m /

3

kW m /

3

kW m /

3

kW m / kW

3

HR Speed m /

3

kW m /

3

kW m /

3

kW m3/ kW

Size rpm hour hour hour hour Size rpm hour hour hour hour

3485 514 6.0 490 9.3 472 12.7 449 17.8 3260 953 10.8 914 17.0 884 23.1 846 32.4

3000 429 5.1 406 8.0 388 10.9 365 15.3 3000 865 10.0 826 15.6 796 21.3 758 29.8

10 2500 342 4.3 319 6.7 301 9.1 278 12.7 20 2700 763 9.0 725 14.1 694 19.2 656 26.8

2000 256 3.4 232 5.4 214 7.3 2300 627 7.6 589 12.0 558 16.3 521 22.8

1500 169 2.6 146 4.0 127 5.5 1900 492 6.3 453 9.9 423 13.5 385 18.9

1500 356 5.0 317 7.8 287 10.6

3485 697 7.8 666 12.3 641 16.9 611 23.8

3000 583 6.7 552 10.6 527 14.6 496 20.5 3260 1362 14.8 1307 23.6 1264 32.4 1210 45.6

11 2500 465 5.6 434 8.9 409 12.1 378 17.0 3000 1236 13.6 1181 21.7 1138 29.8 1084 42.0

2000 347 4.5 316 7.1 291 9.7 21 2700 1091 12.2 1036 19.5 992 26.8 939 37.7

1500 229 3.3 198 5.3 173 7.3 2300 897 10.4 842 16.6 799 22.8 745 32.1

1900 703 8.6 648 13.7 605 18.9 551 26.6

3485 1032 11.0 987 17.8 951 24.5

1500 509 6.8 454 10.8 411 14.9

3000 864 9.5 819 15.3 783 21.1

12 2500 690 7.9 645 12.7 609 17.6 3260 1923 20.1 1850 32.4 1792 44.7

2000 516 6.3 471 10.2 3000 1746 18.5 1673 29.8 1615 44.1

1500 343 4.7 298 7.6 22 2700 1543 16.6 1470 26.8 1412 37.0

2300 1271 14.2 1198 22.8 1140 31.5

3485 1299 13.5 1244 22.0

1900 1000 11.7 927 18.9 869 26.0

3000 1088 11.7 1034 18.9 Maximum pressure rise for size

1500 728 9.2 655 14.9 598 20.6

13 2500 871 9.7 817 15.8 13 is 550 mbar. See

2000 654 7.8 600 12.6 performance chart for details 3260 2432 24.8 2344 40.3

1500 437 5.8 383 9.5 3000 2210 22.8 2122 37.0 Maximum pressure rise for size

23 2700 1954 20.5 1867 33.4 23 is 550 mbar See performance

2300 1613 17.5 1525 28.4 chart for details.

1900 1272 14.5 1184 23.5

1500 931 11.4 843 18.5

The volume of air delivered is measured at inlet conditions of 15°C and 1013 mbar absolute

Bridge Mills, Huddersfield Road, Holmfirth, West Yorkshire HD9 3TW

Following the Company’s policy of constant development, we reserve

Tel: 01484 691858 Fax: 01484 680467 the right to alter any detail specified or illustrated in this publiciation

without notice and without incurring any obligation to provide such

Email: sales@hrblowers.co.uk modifications on machines previously delivered.

You might also like

- Positive Displacement Air Blowers - Sizes 3& 4: Based On SuccessDocument2 pagesPositive Displacement Air Blowers - Sizes 3& 4: Based On SuccessRobert R. TiinNo ratings yet

- HR Blowers Positive Displacement Air Blowers Sizes 3&4 SpecificationDocument2 pagesHR Blowers Positive Displacement Air Blowers Sizes 3&4 Specificationrelli10No ratings yet

- Premium Transmission Gear BoxDocument80 pagesPremium Transmission Gear BoxShipra Shalini83% (6)

- HHE-VL-Recip-Compressor-Flyer-June-2021-pdf - Original FileDocument2 pagesHHE-VL-Recip-Compressor-Flyer-June-2021-pdf - Original Fileaatishsehgal94No ratings yet

- Natural Gas QSG Brochure Updated PagesDocument8 pagesNatural Gas QSG Brochure Updated PagespabloNo ratings yet

- B Vip CompressorDocument6 pagesB Vip CompressorFelipe FiusaNo ratings yet

- Powerful ZAXIS-3G Series ExcavatorsDocument11 pagesPowerful ZAXIS-3G Series ExcavatorsJi Uvex83% (6)

- Cameron CCDocument6 pagesCameron CCYogesh Badhe100% (1)

- Extruder GB Rating PDFDocument19 pagesExtruder GB Rating PDFDwi HaadiNo ratings yet

- Char Lynn 6kDocument25 pagesChar Lynn 6kRafael SoaresNo ratings yet

- RH 120e HandbookDocument8 pagesRH 120e HandbookEgyiri Frederick100% (1)

- Motor Grader Terex DimensionDocument16 pagesMotor Grader Terex DimensionMaulana Fajriansyah100% (2)

- Compresor CentrifugoDocument6 pagesCompresor Centrifugoalegria_systemsNo ratings yet

- Compressor FS604 Data SheetDocument4 pagesCompressor FS604 Data SheetprimmughalNo ratings yet

- Install and Maintain Premium Helical Geared MotorsDocument8 pagesInstall and Maintain Premium Helical Geared MotorsKUNALJAYNo ratings yet

- GD NG Rotary Screws PDFDocument8 pagesGD NG Rotary Screws PDFgilar herliana putraNo ratings yet

- High Performance and Rugged Motor GradersDocument4 pagesHigh Performance and Rugged Motor GradersMamta RaybageNo ratings yet

- Air CompressorDocument4 pagesAir CompressorPeix HichamNo ratings yet

- SANY SR250 Rotary Drilling RigDocument8 pagesSANY SR250 Rotary Drilling RigSandeep Kumar DangdaNo ratings yet

- Air CompressorDocument4 pagesAir CompressorHENRYNo ratings yet

- Fan & Blowers: Motorized Impellers and Centrifugal BlowersDocument20 pagesFan & Blowers: Motorized Impellers and Centrifugal BlowersLochana DeshappriyaNo ratings yet

- B Series Engine Familiarization GuideDocument79 pagesB Series Engine Familiarization GuideEdi Ianto100% (2)

- Mhi Integrally Geared CompressorsDocument6 pagesMhi Integrally Geared CompressorscandhareNo ratings yet

- Bronchure Power Plants H029 1310 E CHRIS MARINEDocument12 pagesBronchure Power Plants H029 1310 E CHRIS MARINEjennybelenNo ratings yet

- Aerator PremiumDocument10 pagesAerator PremiumvijaykumarnNo ratings yet

- Tilting Pad Thrust BearingDocument6 pagesTilting Pad Thrust BearingChristopher GarciaNo ratings yet

- GE's New L250 Inline Diesel Engine Offers Compact Power and Emissions ComplianceDocument6 pagesGE's New L250 Inline Diesel Engine Offers Compact Power and Emissions ComplianceMartin KratkyNo ratings yet

- Psi Max2000 AgitatorsDocument167 pagesPsi Max2000 Agitatorssaipem880% (1)

- Char Lynn 2kDocument34 pagesChar Lynn 2kJas Sum100% (1)

- Ep Series Extruder GearboxDocument15 pagesEp Series Extruder GearboxShyam J VyasNo ratings yet

- CP PetDocument4 pagesCP PetjayeshNo ratings yet

- Steel Wheel Roller: Bw5AsDocument4 pagesSteel Wheel Roller: Bw5AsArman Seorang MelankolisNo ratings yet

- HP2 Info SheetDocument13 pagesHP2 Info SheetDurandt de WetNo ratings yet

- Wheel: EislehiesDocument8 pagesWheel: EislehiesCarlos Arturo AcevedoNo ratings yet

- Ir Turbo-Air-6000 A4Document6 pagesIr Turbo-Air-6000 A4Aris Fitama ZeinauraNo ratings yet

- Sany Excavators SY135 Tier 3Document9 pagesSany Excavators SY135 Tier 3csbersama100% (2)

- Blowers TS R: Everest Twin Lobe Rotary Air BlowersDocument1 pageBlowers TS R: Everest Twin Lobe Rotary Air Blowersankitsaxena123No ratings yet

- C CO OM MP PR RE ES SS SE ED DA Aiir RS SY YS ST TE EM MS S: Piston Air CompressorsDocument4 pagesC CO OM MP PR RE ES SS SE ED DA Aiir RS SY YS ST TE EM MS S: Piston Air CompressorsarieprachmanNo ratings yet

- AERMOTOR Windmill Catalog Page50Document1 pageAERMOTOR Windmill Catalog Page50cristobal_tl2277No ratings yet

- Sany Excavators SY135CDocument9 pagesSany Excavators SY135Ccsbersama100% (4)

- Catalogo Engimax Motores IsuzuDocument38 pagesCatalogo Engimax Motores IsuzuAlexis SanchezNo ratings yet

- ENGIMAX Komatsu Liner KitDocument24 pagesENGIMAX Komatsu Liner KitahmedalgaloNo ratings yet

- Generator Design, Frame Size 710-1250: ABB Contact For India LinksDocument1 pageGenerator Design, Frame Size 710-1250: ABB Contact For India Linksgurunathan14No ratings yet

- HPH BrochureDocument12 pagesHPH BrochureCristhian Vilca SilvestreNo ratings yet

- KAY BlowersCatalogueDocument8 pagesKAY BlowersCatalogueParomita Mukherjee Misra80% (5)

- The Maximizer Pumping UnitDocument16 pagesThe Maximizer Pumping UnitJORGE ELIECER RUEDA PINZONNo ratings yet

- Quincy Gas Screw CompressorsDocument8 pagesQuincy Gas Screw CompressorsLauren KirchNo ratings yet

- Komatsu Liner KitDocument34 pagesKomatsu Liner KitMANCHING MOKNo ratings yet

- D155A-5Document6 pagesD155A-5Riaz Mohamed RasheedNo ratings yet

- Riner Hydraulic MotorDocument6 pagesRiner Hydraulic Motora_salehiNo ratings yet

- EATON - Motores Hidraulicos PDFDocument34 pagesEATON - Motores Hidraulicos PDFAparecidaMarques100% (1)

- BE RWKIICM CatalogDocument12 pagesBE RWKIICM CatalogNGAWI JATINo ratings yet

- Ariel Compressor DatasheetDocument8 pagesAriel Compressor Datasheetadewunmi olufemiNo ratings yet

- Cce WL B Series 821b 921b Brochure 06-09-2009Document28 pagesCce WL B Series 821b 921b Brochure 06-09-2009Renato Evangelista100% (1)

- HCR 1200 IIDocument4 pagesHCR 1200 IIRolando Vera100% (2)

- D VipDocument6 pagesD VipClemente Rafael Marval EscalonaNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Terminal Lugs. PinnionDocument2 pagesTerminal Lugs. PinnionRobert R. TiinNo ratings yet

- Mechnical LuggsDocument1 pageMechnical LuggsRobert R. TiinNo ratings yet

- Glamox DALI: You Define. We ConnectDocument11 pagesGlamox DALI: You Define. We ConnectRobert R. TiinNo ratings yet

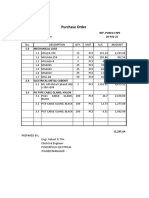

- Purchase Order: Lun Masla AquacultureDocument2 pagesPurchase Order: Lun Masla AquacultureRobert R. TiinNo ratings yet

- Boundary Line 1: Service AreaDocument1 pageBoundary Line 1: Service AreaRobert R. TiinNo ratings yet

- Powerplug Electrical Goods TradingDocument1 pagePowerplug Electrical Goods TradingRobert R. TiinNo ratings yet

- ABS-Encapsulated Low-Voltage Current Transformers For Indoor Use (Window-Type) - 1Document1 pageABS-Encapsulated Low-Voltage Current Transformers For Indoor Use (Window-Type) - 1Robert R. TiinNo ratings yet

- Condensing Unit Manual InstructionDocument11 pagesCondensing Unit Manual InstructionRobert R. TiinNo ratings yet

- Vicinity Map: Land Use & ZoningDocument1 pageVicinity Map: Land Use & ZoningRobert R. TiinNo ratings yet

- 65 Tons Horizontal Cement Silo Quotation 20210210Document4 pages65 Tons Horizontal Cement Silo Quotation 20210210Robert R. TiinNo ratings yet

- Ventilating Fan Specifications: Model 40KQTDocument3 pagesVentilating Fan Specifications: Model 40KQTRobert R. TiinNo ratings yet

- Bahay Ni Iking - Rev04 - FLOOR PLANSDocument1 pageBahay Ni Iking - Rev04 - FLOOR PLANSRobert R. TiinNo ratings yet

- Puhui Industry Part Project Cases in The Philippines - Suki From Puhui IndustryDocument12 pagesPuhui Industry Part Project Cases in The Philippines - Suki From Puhui IndustryRobert R. TiinNo ratings yet

- EasyLogic PM2000 Series - METSEPM2110 PDFDocument3 pagesEasyLogic PM2000 Series - METSEPM2110 PDFArabian controls switchgearNo ratings yet

- WQ Submersible Sewage Pump CH enDocument40 pagesWQ Submersible Sewage Pump CH enRobert R. TiinNo ratings yet

- Robert Tiin LED Vapor Tight Sales QuoteDocument1 pageRobert Tiin LED Vapor Tight Sales QuoteRobert R. TiinNo ratings yet

- Cold Room Panel Specification and DataDocument9 pagesCold Room Panel Specification and DataRobert R. TiinNo ratings yet

- Shanghai Tongke Flow Technology Co.,Ltd Quotation List: Client: Lun Masla Aquaculture Attn: Mr. Robert R. TiinDocument1 pageShanghai Tongke Flow Technology Co.,Ltd Quotation List: Client: Lun Masla Aquaculture Attn: Mr. Robert R. TiinRobert R. TiinNo ratings yet

- Puhui Industry Part Project Cases in The Philippines - Suki From Puhui IndustryDocument12 pagesPuhui Industry Part Project Cases in The Philippines - Suki From Puhui IndustryRobert R. TiinNo ratings yet

- 2-Page Product Description Amarex KRT WiDocument2 pages2-Page Product Description Amarex KRT WiRobert R. TiinNo ratings yet

- Finish Product Picture: 1 HP Paddle Wheel Aerator - STD - B12 Specification SheetDocument5 pagesFinish Product Picture: 1 HP Paddle Wheel Aerator - STD - B12 Specification SheetRobert R. TiinNo ratings yet

- Estimate FenceDocument2 pagesEstimate FenceRobert R. Tiin100% (1)

- Solar Guide Resistance TestDocument1 pageSolar Guide Resistance TestRobert R. TiinNo ratings yet

- PUMP r2Document1 pagePUMP r2Robert R. TiinNo ratings yet

- AQUI S AirstoneDocument1 pageAQUI S AirstoneRobert R. TiinNo ratings yet

- SF SummaryDocument1 pageSF SummaryRobert R. TiinNo ratings yet

- 8 Verti Crete Spec SheetDocument6 pages8 Verti Crete Spec SheetRobert R. TiinNo ratings yet

- 1.0 Building Grounding: Cost Estimate: Retrofit and RoofingDocument2 pages1.0 Building Grounding: Cost Estimate: Retrofit and RoofingRobert R. TiinNo ratings yet

- CPKN Complementary SizesDocument68 pagesCPKN Complementary SizesRobert R. TiinNo ratings yet

- PRX SeriesDocument56 pagesPRX SeriesFARIDNo ratings yet

- Sr. Description No. NoDocument17 pagesSr. Description No. Nosushilalway4uNo ratings yet

- JMC 38x28mm Fixed Vane FanDocument3 pagesJMC 38x28mm Fixed Vane FanJMCproductsNo ratings yet

- GE CC Axial CompressorDocument28 pagesGE CC Axial CompressormishraenggNo ratings yet

- Seleccion de SoplantesDocument69 pagesSeleccion de Soplantesmartin.rubenNo ratings yet

- Section Vii Blower A. DescriptionDocument6 pagesSection Vii Blower A. DescriptionDiego OrtizNo ratings yet

- Exp 2 ME LAB 3Document14 pagesExp 2 ME LAB 3q234asdfasdfNo ratings yet

- Bomba de Vácuo Sotorbilt 4mrDocument12 pagesBomba de Vácuo Sotorbilt 4mrWormInchNo ratings yet

- Fan Damper Selection Fe 2600Document4 pagesFan Damper Selection Fe 2600Guilherme AugustoNo ratings yet

- Hvac Systems For TheatresDocument18 pagesHvac Systems For Theatresagitent100% (1)

- PipingDocument300 pagesPipingparry1701100% (1)

- SOPLADOR Submittal SO6689 Las Bambas Revision 0Document209 pagesSOPLADOR Submittal SO6689 Las Bambas Revision 0Massia Ruiz Urteaga de CuevaNo ratings yet

- Process Equipment Design and DrawingDocument35 pagesProcess Equipment Design and DrawingKutty Krishnan MankaraNo ratings yet

- Pneumatic ConveyingDocument18 pagesPneumatic ConveyingFaisalNo ratings yet

- U Match R410a Service ManualDocument149 pagesU Match R410a Service Manualhaicuong286No ratings yet

- CV Template Mechanical FitterDocument4 pagesCV Template Mechanical Fitteradijayateknik.bjbNo ratings yet

- Ebmpapst 8214 JNDocument1 pageEbmpapst 8214 JNminghin1No ratings yet

- MBBR Wastewater Treatment Basin Sizing and Aeration Calculations - S.I. UnitsDocument30 pagesMBBR Wastewater Treatment Basin Sizing and Aeration Calculations - S.I. Unitsdiego80% (5)

- Fcu Method StatementDocument3 pagesFcu Method StatementBalajiNo ratings yet

- Lennox AHU - CB29M SeriesDocument22 pagesLennox AHU - CB29M SeriesbolamoNo ratings yet

- CHW A Magic AireDocument16 pagesCHW A Magic AireMiguel AngelNo ratings yet

- Heat rate, thermal conductivity, hydrostatics, steel expansionDocument24 pagesHeat rate, thermal conductivity, hydrostatics, steel expansionSurya Kiran75% (4)

- KSKV SVM 2017: Installation and Maintenance of Single Phase Ventilation FansDocument12 pagesKSKV SVM 2017: Installation and Maintenance of Single Phase Ventilation FansAinul Mardiah AhmadNo ratings yet

- The Science of Compressed Air: QUINCY QSI 245i-500i Rotary Screw Air Compressor 50-100 HPDocument8 pagesThe Science of Compressed Air: QUINCY QSI 245i-500i Rotary Screw Air Compressor 50-100 HPDe Luna BraulioNo ratings yet

- Spencer CompressorDocument20 pagesSpencer Compressoricingrock100% (1)

- Astm E547-00Document5 pagesAstm E547-00ELENA NAVAS100% (1)

- Ventilatoren Zement enDocument49 pagesVentilatoren Zement enFran Jimenez100% (1)

- Pumps, Fans, Blowers, and CompressorsDocument68 pagesPumps, Fans, Blowers, and CompressorsBren SisonNo ratings yet

- Bus Parts, School - Thomas-Freightliner, International-Navistar, BluebirdDocument284 pagesBus Parts, School - Thomas-Freightliner, International-Navistar, Bluebirdviemey1952100% (3)

- Silo For BlendingDocument8 pagesSilo For Blendingindia_aseem100% (3)