Professional Documents

Culture Documents

Significant Achievement

Significant Achievement

Uploaded by

Mohammad Kamruzzaman0 ratings0% found this document useful (0 votes)

18 views1 pageThe document summarizes the responsibilities of a Manager of IE & Planning at BEXIMCO GROUP in Bangladesh from 2006 to 2008. The key responsibilities included:

1. Preparing booking summaries and monitoring production timelines to ensure on-time shipments.

2. Planning fabric requirements and production capacity to avoid delays or short shipments.

3. Tracking orders from fabric receipt through shipping to minimize losses.

Original Description:

Original Title

New Microsoft Office Word Document - Copy

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes the responsibilities of a Manager of IE & Planning at BEXIMCO GROUP in Bangladesh from 2006 to 2008. The key responsibilities included:

1. Preparing booking summaries and monitoring production timelines to ensure on-time shipments.

2. Planning fabric requirements and production capacity to avoid delays or short shipments.

3. Tracking orders from fabric receipt through shipping to minimize losses.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views1 pageSignificant Achievement

Significant Achievement

Uploaded by

Mohammad KamruzzamanThe document summarizes the responsibilities of a Manager of IE & Planning at BEXIMCO GROUP in Bangladesh from 2006 to 2008. The key responsibilities included:

1. Preparing booking summaries and monitoring production timelines to ensure on-time shipments.

2. Planning fabric requirements and production capacity to avoid delays or short shipments.

3. Tracking orders from fabric receipt through shipping to minimize losses.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

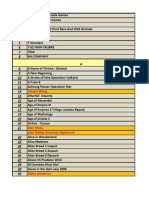

Company Size: Position:

3500 People (100%) Manager-IE & Planning From Jan-2006 to March-2008

Product: BEXIMCO GROUP, Sarabo, Kashempur, Gazipur, Dhaka

5 pocket denim, shorts, cargo,

Major Job Responsibility:

chino, skirt, twill & corduroy

1. Collect the drop details after order confirmation from merchandising department and

pant.

prepare month wise “Booking Summary or Order Recap” for better follow-up.

Buyer:

2. Review and follow up” Time and Action Plan” for all confirmed orders along with fabric and

H&H, C&A, G-Star, Cellio, JC

accessories arrival to ensure on time shipment with right quality and quantity.

Penny, Polo, etc.

3. Check and monitor the “Production capacity” and stock of fabric & accessories are

Scope:

aligned with the production planning in order to avoid shot shipment or late shipment.

Cutting, Sewing, Finishing,

4. Plans formulate & analyze the fabric requirement between different units of the same

Emb/Printing, Dry & wet

premises as per specific order. This process includes quality, quantity and on time delivery.

Process, IE & Lean.

5. Track the order from fabric booking to send the goods to leftover through fabric received,

Significant Achievement: cutting, print/embroidery & distribution among lines with the order requirements.

>Increase efficiency level from 6. Fix the average details after analyzing of sample and define the fabric delivery date, cutting

38% to 48%. and sewing starting date embellishment part received date, final inspection date and others

>Increase on time delivery from through setting the target of all process.

87% to 100 %. 7. Make checklist of all trims & accessories for uninterrupted input supply to ensure all

>Increase plan achievement from

procedures in tile and keep contact with store & merchandising team to update and in-

85% to 96%.

>Eliminate air lift cost, CPR &

house all trims & accessories on time.

discount. 8. Review available men & machines of the factory and make sure that production is running

>Reduce short shipment 3% to on required no of lines as per delivery requirement.

0%.

>Reduce cut to ship loss from 3% Prepare manpower planning & allocation based on capacity assessment & analysis to

to .50%.

finalize manpower budget and production target in order to maintain on time delivery.

Do capacity planning for the next one year and suggest management for booking orders

based on free capacity.

Prepare T&A for each and every order in respect of delivery date and lead times for

approvals, sourcing and production.

Do monthly, weekly and daily plan and provide it to concern people to smoothing

production function and on time shipment.

Prepare and follow up fabric requirement plan to ensure uninterrupted input supply in lines.

Set daily, weekly and monthly production target based on available manpower, capacity

factor and factory efficiency.

Monitor daily target vs. actual production and take initiative for any deviation or shortfall.

Coordinate with merchandising and other concern department for preproduction activities

and on time shipment.

You might also like

- Meteorological InstrumentsDocument12 pagesMeteorological InstrumentsPapa Pee0% (1)

- CA Rohan Nimbalkar - Summary - NotesDocument78 pagesCA Rohan Nimbalkar - Summary - NotesPrachi GuptaNo ratings yet

- My Erotic Masseur Has The Best Hands and Cock +: + CommentsDocument1 pageMy Erotic Masseur Has The Best Hands and Cock +: + Commentsdarius kingcadeNo ratings yet

- Steps in Production PlanningDocument12 pagesSteps in Production PlanningriteshvijhNo ratings yet

- Stormwater Drainage Plan and ReportDocument26 pagesStormwater Drainage Plan and ReportBeau HumeNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Risk Assessment Plant Room / Boiler House (Access and Carrying Out Maintenance Work - Staff & Contractors)Document2 pagesRisk Assessment Plant Room / Boiler House (Access and Carrying Out Maintenance Work - Staff & Contractors)Naveenkumar KuppanNo ratings yet

- Ieee 1344Document36 pagesIeee 1344Jose Antonio EstofaneroNo ratings yet

- Quality Manager & Production Manager CompetencyDocument6 pagesQuality Manager & Production Manager CompetencyManoj MehraNo ratings yet

- 10 Production Planning and SchedulingDocument3 pages10 Production Planning and Schedulingmarichu apiladoNo ratings yet

- Operation Planning and Controling (Notes)Document57 pagesOperation Planning and Controling (Notes)Vishal Ranjan100% (1)

- Sop PraptiDocument6 pagesSop PraptiRikhil NairNo ratings yet

- BS en 13036-1-2010Document14 pagesBS en 13036-1-2010Doiciel100% (1)

- Variuos Issues in Production PlanningDocument10 pagesVariuos Issues in Production PlanningJyoti RawalNo ratings yet

- Apparel Production, Planning and ControlDocument36 pagesApparel Production, Planning and ControlSNEHANo ratings yet

- Production Planning ControlDocument12 pagesProduction Planning ControlRaibatul AdawiyahNo ratings yet

- DiluentsDocument15 pagesDiluentsvishnukiranniperNo ratings yet

- Production Planning: What Is Production Control?Document28 pagesProduction Planning: What Is Production Control?Ghe de JesusNo ratings yet

- By S.waqas Khan W: Production Planning and ControlDocument8 pagesBy S.waqas Khan W: Production Planning and ControlKarunamoorthy PeriasamyNo ratings yet

- Capacity PlanDocument11 pagesCapacity PlanSivakumar KNo ratings yet

- Pom Module - 3Document7 pagesPom Module - 3suhailbapuji6No ratings yet

- Dyeing DGMDocument2 pagesDyeing DGMkrishna.greenhrNo ratings yet

- Production Planning and SchedulingDocument2 pagesProduction Planning and SchedulingTanmoy AntuNo ratings yet

- BodyDocument17 pagesBodyMosharaf HossainNo ratings yet

- Production Planning and ControlDocument34 pagesProduction Planning and ControlAkanksha RanjanNo ratings yet

- Module 5 PDFDocument8 pagesModule 5 PDFMechanical EngineeringNo ratings yet

- 1 IntroductionDocument16 pages1 IntroductionakidmahcoNo ratings yet

- Production Control Objectives: ITTS-QMS-PR13-F04Document2 pagesProduction Control Objectives: ITTS-QMS-PR13-F04zainahmedscribdNo ratings yet

- Production Planning and ControlDocument30 pagesProduction Planning and ControlregineNo ratings yet

- Steps in Production Planning & ControlDocument4 pagesSteps in Production Planning & ControlrohitpkNo ratings yet

- Operations Management Part - 3Document18 pagesOperations Management Part - 3Sai Rock SaiNo ratings yet

- Export Merchandising and Exim End Term Jury Report: National Institute of Fashion TechnologyDocument24 pagesExport Merchandising and Exim End Term Jury Report: National Institute of Fashion TechnologyGaurav RawatNo ratings yet

- Opc Unit-1Document5 pagesOpc Unit-1Aashish Singh IINo ratings yet

- Production Planning and Scheduling Production Planning Means To Fix The Production Goals Objectives of Production PlanningDocument3 pagesProduction Planning and Scheduling Production Planning Means To Fix The Production Goals Objectives of Production PlanningAurcus JumskieNo ratings yet

- Production Planning and ControlDocument5 pagesProduction Planning and ControlKailash KumarNo ratings yet

- PPCDocument94 pagesPPCManoz RijalNo ratings yet

- Production Planning and ControlDocument12 pagesProduction Planning and ControlPrathap AnNo ratings yet

- PPCDocument19 pagesPPCAnchuNo ratings yet

- UNIT II Need For PPC-Objectives-Functions-Information Required For PPC-ProductionDocument30 pagesUNIT II Need For PPC-Objectives-Functions-Information Required For PPC-Productionmohanmech2006886No ratings yet

- PPCS Shikha Mishra Roll No .12Document5 pagesPPCS Shikha Mishra Roll No .12Nidhi RanaNo ratings yet

- Week 1 Lecture 1: Engr. Abdul AleemDocument31 pagesWeek 1 Lecture 1: Engr. Abdul AleemArunNo ratings yet

- PPE Job DetailsDocument23 pagesPPE Job DetailsJaveed802No ratings yet

- The Job Responsibilities of IE OfficerDocument3 pagesThe Job Responsibilities of IE OfficerpiashNo ratings yet

- Basic Knowledge Doing IE Job in GarmentsDocument2 pagesBasic Knowledge Doing IE Job in Garmentssoban adilNo ratings yet

- Production Planning and Material Control ManagerDocument3 pagesProduction Planning and Material Control ManagerRajVardhanNo ratings yet

- Operations ManagementDocument12 pagesOperations ManagementkeerthiNo ratings yet

- Production Planning & Control: Syllabus ContentsDocument10 pagesProduction Planning & Control: Syllabus ContentsShivani SharmaNo ratings yet

- CV - MD Majharul IslamDocument6 pagesCV - MD Majharul IslamMd Majharul IslamNo ratings yet

- Replenishment - Six SigmaDocument52 pagesReplenishment - Six SigmaAbhishek KumarNo ratings yet

- Production Planning and Controlling 2-1Document22 pagesProduction Planning and Controlling 2-1radhikaNo ratings yet

- CH - 08 - Production Planning-Exam PreDocument8 pagesCH - 08 - Production Planning-Exam PreK.M. Sabbir NomanNo ratings yet

- Arc 155 - Rsw1Document10 pagesArc 155 - Rsw1Prescilo Nato Palor IVNo ratings yet

- Junior/ Industrial Engineer 100% Export Oriented Multinational Garment Industry No. of Vacancies Job Description / ResponsibilityDocument2 pagesJunior/ Industrial Engineer 100% Export Oriented Multinational Garment Industry No. of Vacancies Job Description / Responsibilityshamim hossainNo ratings yet

- CASE STUDY 1: Delay Leads To Delay: Ans (A)Document3 pagesCASE STUDY 1: Delay Leads To Delay: Ans (A)Blaze 2021No ratings yet

- Arun Mohanty: ObjectiveDocument4 pagesArun Mohanty: ObjectiveSAMSON GLOBALNo ratings yet

- Pre-Production Processes: by Prof. Lipsa Mohapatra Asst. Prof., FMS Department, NIFT, BhubaneswarDocument34 pagesPre-Production Processes: by Prof. Lipsa Mohapatra Asst. Prof., FMS Department, NIFT, BhubaneswarPuja PrasadNo ratings yet

- Manufacturing & Operations Management, Materials & LogisticsDocument17 pagesManufacturing & Operations Management, Materials & LogisticsZakir KhanNo ratings yet

- Lablu - OwnDocument10 pagesLablu - OwnNoshin TabassumNo ratings yet

- Production Planning and ControlDocument32 pagesProduction Planning and Controlsiddhi jainNo ratings yet

- Functions of PPC Unit 2Document42 pagesFunctions of PPC Unit 2Sujit ThiruNo ratings yet

- Production Planning and Control: Prepared By, Mr. Nishant AgrawalDocument52 pagesProduction Planning and Control: Prepared By, Mr. Nishant AgrawalColonel AlbalNo ratings yet

- Production Planning AND Production ControlDocument21 pagesProduction Planning AND Production ControlIsheanesu HungweNo ratings yet

- Majid Ali: Assistant of PPCDocument2 pagesMajid Ali: Assistant of PPCmajid aliNo ratings yet

- Indira School of Business Studies, Pune.: The Scope of Operations Management and Elaborate Any Two FunctionsDocument7 pagesIndira School of Business Studies, Pune.: The Scope of Operations Management and Elaborate Any Two FunctionsAnkita ShettyNo ratings yet

- Material and Procuction Management NotesDocument68 pagesMaterial and Procuction Management NotesMwanza MaliiNo ratings yet

- Module V - Operations Management: Dr.A.Abirami / OmDocument10 pagesModule V - Operations Management: Dr.A.Abirami / OmBalujagadishNo ratings yet

- Cherpumple Aditya Periwal, Gargi Pitale, Samir Tandon SBM, NmimsDocument6 pagesCherpumple Aditya Periwal, Gargi Pitale, Samir Tandon SBM, NmimsAniket ChavanNo ratings yet

- Operation Management Capacity Planning: Chapter 6Document25 pagesOperation Management Capacity Planning: Chapter 6Cool BuddyNo ratings yet

- Unit 2 (OPC)Document8 pagesUnit 2 (OPC)KANISHK VARDHAN SINGHNo ratings yet

- Movement ReportDocument1 pageMovement ReportMohammad KamruzzamanNo ratings yet

- Efeso BSM Dual Brand Lean LabsDocument6 pagesEfeso BSM Dual Brand Lean LabsMohammad KamruzzamanNo ratings yet

- Sample of ForecastingDocument18 pagesSample of ForecastingMohammad KamruzzamanNo ratings yet

- Otp StatusDocument13 pagesOtp StatusMohammad KamruzzamanNo ratings yet

- Abcd Checklist For Manufacturing ExcellenceDocument24 pagesAbcd Checklist For Manufacturing ExcellenceMohammad KamruzzamanNo ratings yet

- The Lean Canvas: Problem Solution Unique Value Prop. Unfair Advantage Customer SegmentsDocument7 pagesThe Lean Canvas: Problem Solution Unique Value Prop. Unfair Advantage Customer SegmentsMohammad KamruzzamanNo ratings yet

- Temakaw Fashion Limited: Style Cangaro Teen Target (100%) Target (50%) 75 SMV MPDocument1 pageTemakaw Fashion Limited: Style Cangaro Teen Target (100%) Target (50%) 75 SMV MPMohammad KamruzzamanNo ratings yet

- Temakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man 1 1Document3 pagesTemakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man 1 1Mohammad KamruzzamanNo ratings yet

- Temakaw Fashion LTD: Section SL No Process Sec SMV Target M/C Type R. M/C RemarksDocument1 pageTemakaw Fashion LTD: Section SL No Process Sec SMV Target M/C Type R. M/C RemarksMohammad KamruzzamanNo ratings yet

- Temakaw Fashion Limited: Section SL Process SMV TGT M/C Type R. M/C R.Man AttachmentDocument1 pageTemakaw Fashion Limited: Section SL Process SMV TGT M/C Type R. M/C R.Man AttachmentMohammad KamruzzamanNo ratings yet

- Temakaw Fashion LTD: Section SL No Process SMV Target M/C Type R. M/C RemarksDocument2 pagesTemakaw Fashion LTD: Section SL No Process SMV Target M/C Type R. M/C RemarksMohammad KamruzzamanNo ratings yet

- Temakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man Power SleeveDocument3 pagesTemakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man Power SleeveMohammad KamruzzamanNo ratings yet

- Temakaw Fashion LTD: Operation Buletin of CUNTIDocument2 pagesTemakaw Fashion LTD: Operation Buletin of CUNTIMohammad KamruzzamanNo ratings yet

- Temakaw Fashion Limited: Section SL Process SMV Target M/C Type R. M/C AttachmentDocument1 pageTemakaw Fashion Limited: Section SL Process SMV Target M/C Type R. M/C AttachmentMohammad KamruzzamanNo ratings yet

- Temakaw Fashion LTD: Operation Buletin of Cura Target (100 %) 76 Target (55 %) 41 SMV 44.22 MP 56Document4 pagesTemakaw Fashion LTD: Operation Buletin of Cura Target (100 %) 76 Target (55 %) 41 SMV 44.22 MP 56Mohammad KamruzzamanNo ratings yet

- Temakaw Fashion LTD: Section SL No Process SMV Target M/C Type R. M/C RemarksDocument1 pageTemakaw Fashion LTD: Section SL No Process SMV Target M/C Type R. M/C RemarksMohammad KamruzzamanNo ratings yet

- Distribution SystemDocument3 pagesDistribution SystemSouvik100% (1)

- New-Era 190825 03 PDFDocument2 pagesNew-Era 190825 03 PDFGNo ratings yet

- LUHBC NegoSale Batch 28050 090122Document8 pagesLUHBC NegoSale Batch 28050 090122Angelo James BruanNo ratings yet

- Vaxter Pharma June 2021Document9 pagesVaxter Pharma June 2021rahsreeNo ratings yet

- Circuit Setter Plus Model MC: Instruction ManualDocument4 pagesCircuit Setter Plus Model MC: Instruction Manualmacanipharoldf6220No ratings yet

- Flow MasterDocument7 pagesFlow Masterthedevilsdue9420No ratings yet

- IDb5e0db2f1-1996 Fiat Punto ManualDocument2 pagesIDb5e0db2f1-1996 Fiat Punto ManualBryant Tairua100% (1)

- 1.1 BackgroundDocument70 pages1.1 Backgroundapi-19793735No ratings yet

- Games 2Document136 pagesGames 2bungnabilNo ratings yet

- Qlik Connector For SAP - Installation Guide v7.0.0Document44 pagesQlik Connector For SAP - Installation Guide v7.0.0whistle59No ratings yet

- Unit8 Percentages ProportionalityDocument11 pagesUnit8 Percentages Proportionalitygiggia02No ratings yet

- How To Do A Systematic ReviewDocument58 pagesHow To Do A Systematic ReviewRirin KurniawatiNo ratings yet

- Receivables Management: "Any Fool Can Lend Money, But It TakesDocument37 pagesReceivables Management: "Any Fool Can Lend Money, But It Takesjai262418No ratings yet

- PDF Tableau Dashboard Cookbook Over 40 Recipes On Designing Professional Dashboards by Implementing Data Visualization Principles 1St Edition Jennifer Jane Stirrup Ebook Full ChapterDocument54 pagesPDF Tableau Dashboard Cookbook Over 40 Recipes On Designing Professional Dashboards by Implementing Data Visualization Principles 1St Edition Jennifer Jane Stirrup Ebook Full Chapteredward.goodwin495No ratings yet

- Dead Doctors Radio Broadcast and Podcast On KSCO Featuring Dead Doctors Don't Lie With Dr. Joel Wallach / YoungevityDocument4 pagesDead Doctors Radio Broadcast and Podcast On KSCO Featuring Dead Doctors Don't Lie With Dr. Joel Wallach / YoungevityJuan VicheNo ratings yet

- Plastic BagsDocument2 pagesPlastic Bagsapi-289380968No ratings yet

- TokenDocument6 pagesTokensaechang LiangNo ratings yet

- Iso 8528 1 2005 en PDFDocument8 pagesIso 8528 1 2005 en PDFhafezasadNo ratings yet

- Calculation of Empirical FormulaeDocument3 pagesCalculation of Empirical Formulaeaqsa chaudharyNo ratings yet

- CoDeSys Network VariablesDocument11 pagesCoDeSys Network Variablesalx 100No ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)