Professional Documents

Culture Documents

NFPA 497 Guidelines

Uploaded by

AV Shrinivas0 ratings0% found this document useful (0 votes)

25 views3 pagesArea classification document

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentArea classification document

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views3 pagesNFPA 497 Guidelines

Uploaded by

AV ShrinivasArea classification document

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

497-6

spark discharge to ignite methane under the same test condi-

dons. (SieIEC 793.)

MIE (Minimum Ignition Energy). The minimum energy

requited from a capacitive spark discharge to ignite the most

‘easily ignitable mixture of a gas oF vapor.

Chapter 2 Classification of Combustible Materials

21 National Blectrical Code® Criteria,

21.1 Article 500 of the NEC designates as hazardous (class-

fed) any area in which a combustible material is or may be

present in the atmosphere in sulficient concentration to pro-

uce an ignitable mixture. Article 500 designates three major

categories of hazardous areas: Clas 1, Glass Il, and Class I,

Ina Class | hazardous area, the material present is a flam-

‘mable gas or vapor.

In a Class Il hazardous area, the material present is a com-

bustle dus.

In a Class II] hazardous area, the material present is an

Ignitable fiber or ying.

‘This recommended practice i limited to Class I hazardous

(classified) areas.

‘The Class I category is further subdivided into either Class

1, Divison 1 or Division 2; or Class I, Zone 0, Zone 1, or Zone

Ba follows:

(2) Class I, Divison I in which the combustible material is

present normally or frequently

(b) Class I, Division 2 in which the combustible material is

present asa result of infrequent failure of equipment or con

(©) Class I, Zone 0 in which the combustible material is

present contsiuously or for long periods

(@) Class I, Zone 1 in which the combustible material is

likely to be present normally or frequently because of repair

‘or maintenance operations or because of leakage

(6) Class, Zone 2in which the combustible material is not

likely to occur in normal operation, and ifit does occu it will

‘exist only for a short period

24.2° ‘The intent of Article 500 of the NECis o prevent com

Dustible material from being ignited by elecuical equipment

and wiring systems,

2.2 Behavior of Class I (Combustible Material) Gases,

‘Vapors, and Liquids.

22.1 LighterthamAir (Vapor Density Less than 1.0) Gases.

“These gases tend to dissipate rapidly in the atmosphere. They

will not affect as great an area a8 heavierthan-air gases or va

pors. Exeept in enclosed spaces, such gases seldom accumu

late to form an ignitable mixture near grade level where most

clecuical installations are located, A lightershan-air gas that

has been cooled sufficiently may behave as a heavierthan air

‘525 until it absorbs heat from the surrounding atmosphere,

2.2.2 Heavierthan-Air (Vapor Density Greater than 1,0) Cases.

‘These gases tend to fall t grade level when released, The gas

‘may remain fora significant period of time, unless dispersed by

natural or forced ventilation, A heaviershan-air gas chat has

‘beer heated suficienly wo decrease its density may belive as 2

1997 Exton

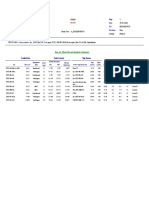

CLASSIFICATION OF FLAMMABLE LIQUIDS

lighterthanair gas until cooled by the surrounding. atmo-

sphere.

228 Applicable to AU! Densities. As the gus diffoses into the

‘surrounding air, the density ofthe mixture approaches that of sir.

224 Compressed Liquefied Gases. These gases are stored,

above their normal boiling point but are kept in the liqui

state by pressure, When released, the liquid immediately ex-

pands and vaporizes, creating large volumes of cold gas. The

‘old gat behaves like a heaviershan air gas

2.2.5 Cryogenic Flammable Liquids and Other Cold Lique-

fied Combustible Materials. Cryogenic liquids are generally

handled below -150°F (-101°C). These behave like flammable

liquids when they are spilled. Small liquid spills will immedi

ately vaporize, but larger spills may remain in the liquid state

for an extended time. As the liquid absorbs heat, it vaporizes

and may form an ignitable mixture. Some liquefied combust-

ble materials (not eryogenic) are stored at low temperatures

and at pressures close to atmospheric pressure; these include

‘anhydrous ammonia, propane, ethane, ethylene, and propy-

lene. These materials wil behave as described above.

226 Flammable Liquids. When released in appreciable quan

tity, a Class 1 quid all begin to evaporate ata rate that depends

‘on its volatl: the lower the fash point, the greater the vola-

ity; hence, the faster the evaporation. The vapors of Clas! lig

‘ds form ignitable mixtures with aie at ambient temperatures

‘more or less readily, Even when evolved rapidly, the vapors tend

‘0 disperse rapidly, becoming diluted to a concentration below

the lover flammable iit. Until this dispersion takes place hone

ever, these vapors will behave like heavierthan air gases. Class I

liquids normally vil produce ignitable mixtures that will travel

some finite disance form the point of origin; thus, they will

normally tequire area clasification for proper electrical system

design,

22.7 Combustible Liquids. A combustible liquid will form

aan igntable mixture only when heated above its flash point.

22.7.1. With Class I liquids, the degree of hazard is lower be-

cease the vapor release rate is low atthe normal handling wd

Sorage temperatures, In general, there liquids will not form

ignitable mixtures with air at ambient temperatures unless

heated above their flash points. Als, the vapors will not travel

as far because they tend to condense as they are cooled by am-

bent air Cass I liquids should be considered capable of pro-

ducing an ignitable mixwre near the point of release when

handled, processed, or stored under conditions where the liq-

‘uid may exceed its lash point.

227.2. Class IIA liquide have flash points at or above 140°F

(60°C) but below 200°F (98.4°C). These liquids do not form ig-

niable mixtures with air at ambient temperatures unless

heated above their fash points. Furthermore, the vapors cool

rapidly in air and condense. Hence, the extent of the area re-

quiring electrical classification wil be very small or nonexistent.

22.1.3 Class IIB liquids have flash points at or above 200°

(@3.4°C). These liquids seldom evolve enough vapors to form

‘gnitable mixtures even when heated, and they are seldom ig-

nited by properly installed and maintained general purpose

clecirical equipment. A Class [IIB liquid will cool Below is

flash point very quickly when released. Therefore, area class-

fication is seldom needed and Class TB liquids are not in

‘duded in Table 2.

CLASSIFICATION OF CLASS (COMBUSTIBLE MATERIAL) AREAS

down of the containers or system, or as the result of the ab-

normal operation of the equipment with which the liquids or

gases are handled, processed, or used.

(©) Ignitable mixtures normally are prevented by postive

mechanical ventilation, but may become hazardous as the

result of failure or abnormal operation of the verdilation

‘equipment.

(€) The area is adjacent to a Class 1, Zone 1 location, from

Which ignitable concentrations of flammable gases or vapors

could be communicated, unless such communication is pre-

vented by adequate positive pressure ventilation from 2 source

and effective safeguards against ventilation failure

are provided.

The Zone 2 classification usually includes locations where

volatile flammable liquids or flammable gases or vapors are

"used, but which would become hazardous only in case of an ac-

cident or of some unusual operating condition,

33-Undlasified Areas.

$3.1 Experience hasshown tha the release ofignitabie mi

tures from some operations and apparatus is 30 infrequent

“that area clasification is not necessary. For example, it ROL

.

usualy necessary to caniy the following areas where combus-

Ube materials are processed, stored, or handled:

(8) Areas that have adequate ventilation, where combust-

ble materials are contained within suitable, wellmainained,

closed piping systems

(@) Areas that lack adequate ventilation, but where piping

systems are without vahe, fitings, anges, and similar acces

Stories that may be prome t leake

(o) Areas where combustible materials are sored in sult

able containers

S82. Areas considered to have adequate ventilation include

the following:

(a) An outside area

(8) A building, room, or space that is substantially open

and free of obstriction fo the natural passage of ar either

vertically or horizontally (Such areas may be roofed over with:

ho wall may be roofed over and closed on one side, or may

be provided with suitably designed windbreaks)

(©) An enclosed or partly enclosed space provided with

ventilation equivalent to natural ventilation (The ventilation

system must have adequate safeguards against failure.)

33.3 Open flames and hot surfaces associated withthe op

ation of certain equipment, such as boilers and fired heaters,

provide inherent thermal ignition sourees. Electrical classifica

tion is not appropriate in the immediate vicinity ofthese facil-

ities. However, it is prudent to avoid installing electrical

equipment that could be a primary ignition source for poten-

jal leak sources in pumps, valves, and 0 forth, or in waste

product and fuel feed lines.

33.4 Experience indicates that Class IIIB liquids seldom

evolve enough vapors to form ignitable mixtures even when

heated, and are seldom ignited by properly installed and

‘maintained general purpose electrical equipment.

38.5 Experience has shown that some halogenated liquid

hydrocarbons, such as. tichloroethylene; I, 1,LArichloroet

hhane; methylene chloride; and 1,l-dichloro-Lluoroethane

497-19

(HCRC-141b), which do not have flash points, but do have a

flammable range, are for practical purposes nonflammable

‘and do not require special eleetrcal equipment for hazardous

(classified) locations,

3.4 Extent of Classified Areas.

341 The extent of a Division 1 or Division 2; or Zone 0,

‘Zone 1, oF Zane 2 area requires careful consideration of the

following factors:

(@) The combustible material

(b) The vapor density of the material

(c) The temperature of the material

(@) The processor storage pressure

(@) The size of release

(®) The ventilation

$4.2 The firs step is w identify the materials being han-

dled and their vapor densities. Hydrocarbon vapors and gases

are generally heavier dhan air, while hydrogen and methane

fare lighter than air, The following guidelines apply:

(2) In the absence of walls, enclosures, or other barziers,

and in the absence of air currents or similar disturbing forces,

the combustible material wil disperse. Heavierthan-sir vapors

‘will rave primarily downward and oupwardslighterhanair v=

‘pors will rvel upward and outward, Ifthe source ofthe vapors

Js single point, the horizontal area covered by the vapor will

bea circle.

(») For heaviershanair vapors released at or near grade

level, ignitable mixtures are most likely to be found below

grade level; next most likely at grade level; with decreasing

likelihood of presence as height above grade increases. For

lighterthan-air gases, the opposite is rue! there is litle or no

havard at and below grade but greater hazard above grade,

{c) In cases where the source of the combustible material

is above grade or below grade or in cates where the combusti-

ble material is released under pressure, the limits of the elas

fied area are altered substantilly. Also, a very mild breeze

‘may extend these limits. However, a stronger breeze may

accelerate dispersion of the combustible material so that the

extent ofthe classified area is greatly reduced. Thus, dimen-

‘ional limits recommended for either Class, Division 1 or Di-

‘mut be based on experience rather than relying solely on the

theoretical diffusion of vapors.

S43. The size ofa building and is design may influence con

siderably the elassifcation ofthe enclosed volume. In the case

inadequately ventilated room, it may be appropri-

the entire room as Class I, Division 1 or Class I

$44 When clasifying buildings, careful evaluation of prior

experience with the same or similar installations should be

made. Is not enough to merely dentifya potential source of

the combustible material within the building and proceed im-

‘mediately to defining the extent of either the Clas, Division

Vor Division 2; or Clast I, Zone 1 or Zone 2 classified areas,

Where experience indicates that particular design conceptis,

sound, a more hazardous classification for similar installations

‘may not be justified. Furthermore, itis conceivable that an

area might be reclassified from either Class, Division 1 10

vision 2, or from Glass I, Division 2 10 unclassified or from

1967 Eaton

497-58

combustible material. This testing produced more variability

‘when the results of specific combustible materials were com-

pared. Howeves, it was found that the minimum igniting cur-

Fenis of one test could be favorably compared with those of

‘other tests ifa ratio value based on methane was applied. This

testing has resulted in the generation of MIC ratio daca

Other testing has been performed when it was incorrectly

assumed that a factor called “Minimum Ignition Energy”

(MIE) and “Autoignition Temperature” (AIT) were related.

and could be used to place materials imo groups. The fact tat

‘these were independent factors resulted in deletion of AITs as

aabasis for group determination in the 1971 NEC,

-MIEs have been found to exhibit theoretical results that do

‘not translate into practical designs that can be applied to ac-

wal electrical devices with their associated energy levels.

Since the primary concern js to have electrical devices that

can safely operate when used in locations clastified by clas,

group, and division, the definitions for the four gas groups

Ihave been defined on the basis of the parameters providing

‘he most significant basis for that design, which are MESG and

MIC ratio. Lacking these values, expericace-based data indi-

cating equivalency to atmospheres providing similar hazards

may be used.

ALL, Table Note 5. Selecting clectrical oquipment based

fn the lowest AT showin Tab 21 may be unncsrriy e-

Stricdre. As an example, in an area handling a commercial

trade of hexane, Table 31 tabulate Sve diferent isomers of

fRexane solvent (GH) with the AIT ranging from alow of

225'C 10.4 high of H8°C. The AIT of the sohent mixta

‘should be determined either experimentally or fom the sp

Plier. Itwould be expected thatthe commercial grade of hex

ne would have an AIT ranging fom 268°C to 200°.

A21.2. Electrical installations for classified areas may be de-

‘Signed in various manners. No single manner is best in all e-

specis for all types of equipment used in a chemical plant

Explosionproof enclosures, pressurized equipment, and ia-

insicaly safe circuits are applicable to both Division 1 and

Division 2 areas. Nonincendive equi

Vision 2 areas. No ‘equipment and other

“less restrictive equipment, as specified in NFPA70, National

Ei ited in Division areas,

Factors such as corrosion, weather, maintenance, equip:

‘ment standardization and interchangeabiliy, and possible

process changes or expansion frequently dictate the use of

Special enclosures or installations for electrical systems. How

ver, such Factors are outside the scope of this recommended

practice, which is concerned entirely with the proper applica

tion of electrical equipment to avoid ignition of combustible

materials,

424.2 Combustible materials shown in Table 2 have been

‘classified in groups. Some of these combustible materials are

indicated in groups that may not seem to agree with defined

-MESG or MIC ratio values, but have been continued within

groups due to historical experiences and specific properties

that are not reflected in MESG or MIC ratio testing, For

‘example, one source for group classifications was Matix of

Combustion-Relevani Properties and Classification of Gases, Vapors,

‘and Secied Solids, NMAB 353-1, published by the National

‘Academy of Sciences. Those materials whose group classifica

tions are marked with asterisks were previously assigned

group classifications based on tests conducted in the Wester-

1097 Eon

GLASSINCATION OF FLAMMABLE LIQUIDS

berg Apparatus at Underwriters Laboratories Inc. (See An

Investigation of Flammable Gases oF Vapors with Respot to Explo-

sion Poof Electrical Equipment, UL Bulletin of Research No. 58,

‘and subsequent Bulletins Nos. 58A and 58B, reissued July 23, 1993,

‘as UL Technical Report No. 38.) All other materials were a.

signed group classifications based on analogy with tested ma-

terials and on chemical stracture, or on reputable published

data reflecting MESG or MIC ratio values. (Se for example, IEC

7920.) While the classifications of these latter materials rep.

reseot the best judgment of three groups of experts, itis con-

ceivable that the group classification of any particular

untested material may be incorrect. Users of these data

should be aware that the data are the result of experimental

determination, and 28 such are influenced by variation in ex:

perimental apparatus and procedures and in the accuracy of

tation. Additionally, some of the datz have

at an above-ambient temperature in order

‘that the vapor is within the flammable region. Variation in the

temperature for the determination would be expected to i

fluence the result of the determination. Also, values shown

generally represent the lowest reported in reputable, docu-

imented studies, In certain instances, therefore, it may be 2

visable to submit an untested material to a qualified testing

laboratory for verification of the assigned group classifice

tion, Autoignition temperatures fisted in Table 21 are the

lowest value for each material as listed in NFPA 325, Guide to

‘Fire Hezard Properties of Fanmable Liquids, Gass, and Volatile

‘Slids, or as reported in an article by C.J. Hilado and 8. W.

(Clark in Chenseal Enginaering, September 4, 1972,

S42 The degree to which air movement and material vol

aly combine to affect the extent of the clasifid area can be

iiustrated by two experiences monitored by combustible gas

detectors. Gasoline spilled in a sizable open manifold pit gave

ro Indieation of igatabie mixtares beyond 8 fo 4f (0.9 m

10 L2m) from the pit when the breeze was 8 0 10 mph (130

16m he) slighty smaller pool of more volatile materia,

blocked on one side, was monitored during agente breeze. At

rade, vapors could be detected for approximately 100 fe

{G0:m) downwind; however, at 18 in. (4 cn) above grade

there was no indication of vapor as close as 30 ft (9 m) from

he poo!

"These examples show the great variability that may be

resent in situations of this ype, and pointout again thateare-

Ex'consideration must be gien toa lage numberof factors

when classifying areas.

‘A37.2.5 When fire hazard properties of a combustible ma-

terial are not avalabe, the appropriate group may be es

tated using the following information:

(2) Minimum igniting current (MIC) ratio

(b) Ratio of upper flammable li

limit

(©) Molar heat of combustion mult

fammable limit

(€) Ratio of the lower flammable limit to the stoichiomet-

rie concentration

(©) Maximum experimental safe gap (MESG)

(© Minimum ignition energy (MIE)

(@) Stoichiometse Name temperature

(8) Knowledge ofthe chemical structure

to lower flammable

by the lower

You might also like

- VKM-706 Dimensional Drawing TextsDocument34 pagesVKM-706 Dimensional Drawing TextsAV Shrinivas100% (1)

- EU2 Bus LabelDocument4 pagesEU2 Bus LabelAV ShrinivasNo ratings yet

- EBSM Danger Label-BusDocument2 pagesEBSM Danger Label-BusAV ShrinivasNo ratings yet

- EBSM - Incident EnergyDocument1 pageEBSM - Incident EnergyAV ShrinivasNo ratings yet

- EU2-Arc Flash SummaryDocument1 pageEU2-Arc Flash SummaryAV ShrinivasNo ratings yet

- EBSM - Incident EnergyDocument1 pageEBSM - Incident EnergyAV ShrinivasNo ratings yet

- Iec 60079Document1 pageIec 60079AV ShrinivasNo ratings yet

- EBSM - Arc Flash Summary PDFDocument1 pageEBSM - Arc Flash Summary PDFAV ShrinivasNo ratings yet

- EBSM - Incident EnergyDocument1 pageEBSM - Incident EnergyAV ShrinivasNo ratings yet

- TEP0089U Terminator ZT SpecDocument1 pageTEP0089U Terminator ZT SpecAV ShrinivasNo ratings yet

- TEP0010U Heat Tracing Accessories SpecDocument2 pagesTEP0010U Heat Tracing Accessories SpecAV ShrinivasNo ratings yet

- 41161E-B 706 Load Torque PDFDocument2 pages41161E-B 706 Load Torque PDFAV ShrinivasNo ratings yet

- Tep0072u KSX SpecDocument2 pagesTep0072u KSX SpecYlm PtanaNo ratings yet

- 0411114E 706 Torsonal Analysis PDFDocument71 pages0411114E 706 Torsonal Analysis PDFAV ShrinivasNo ratings yet

- 0 /0 Fi/':Io: Ftvp'I No Ldj01Document3 pages0 /0 Fi/':Io: Ftvp'I No Ldj01AV ShrinivasNo ratings yet

- 731 Motor Data Sheet PDFDocument2 pages731 Motor Data Sheet PDFAV ShrinivasNo ratings yet

- 0 /0 Fi/':Io: Ftvp'I No Ldj01Document3 pages0 /0 Fi/':Io: Ftvp'I No Ldj01AV ShrinivasNo ratings yet

- 41161E-B 706 Load Torque PDFDocument2 pages41161E-B 706 Load Torque PDFAV ShrinivasNo ratings yet

- POWER SYSTENM ANALYSIS & FAULT Lecture - 18Document35 pagesPOWER SYSTENM ANALYSIS & FAULT Lecture - 18AV ShrinivasNo ratings yet

- 731 Motor Data Sheet PDFDocument2 pages731 Motor Data Sheet PDFAV ShrinivasNo ratings yet

- 731 Motor Data Sheet PDFDocument2 pages731 Motor Data Sheet PDFAV ShrinivasNo ratings yet

- 0411114E 706 Torsonal Analysis PDFDocument71 pages0411114E 706 Torsonal Analysis PDFAV ShrinivasNo ratings yet

- 731 Motor Data Sheet PDFDocument2 pages731 Motor Data Sheet PDFAV ShrinivasNo ratings yet

- Hazardous Areas ClassificationsDocument6 pagesHazardous Areas ClassificationsAV ShrinivasNo ratings yet

- WIRE Conversion TablesDocument16 pagesWIRE Conversion TablesEmdad YusufNo ratings yet

- Symmetrical FaultsDocument45 pagesSymmetrical FaultsTesfahun GirmaNo ratings yet

- LED Technology Presentation (Rev Kuwait)Document63 pagesLED Technology Presentation (Rev Kuwait)AV Shrinivas100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)