Professional Documents

Culture Documents

Optimal Spring Design Using Genetic Algorithm

Uploaded by

Habtamu GeremewOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimal Spring Design Using Genetic Algorithm

Uploaded by

Habtamu GeremewCopyright:

Available Formats

[Dighewar, 3(2): February, 2014] ISSN: 2277-9655

Impact Factor: 1.852

IJESRT

INTERNATIONAL JOURNAL OF ENGINEERING SCIENCES & RESEARCH

TECHNOLOGY

Optimizing Design of Spring Using Genetic Algorithm

Atish B. Dighewar

Department of Mechanical Engineering, Babasaheb Naik College of Engineering, Pusad (MS), India

dighewar_atish@rediffmail.com

Abstract

This paper deals with the elaborate design optimization technique of coil spring sets with genetic algorithm.

Attention is focused on reducing the weight and stresses keeping into considerations the various critical points. The

spring is designed to operate with tension load, so the spring stretches as the load is applied to it. The aim of the

present work is to design the extension spring for various material like steel, stainless steel, music wire (High carbon

steel), oil Tempered (High carbon steel) for same loading condition, since each material has different compositions

and properties. Optimization of spring helps in selecting most appropriate and cost effective material for spring. On

applying the GA, the optimum parameter of spring have been obtained, which contribute towards achieving the

minimum weight. A reduction of 7% weight is achieved when stainless steel spring is replaced with other spring

stated here, under identical condition of design parameters and optimization. Paper also discuss about the application

and problem formulation using genetic algorithm which is one of nontraditional methods.

Keywords: Spring, Genetic Algorithm (GA).

Introduction

Over a few years, a number of search and stretched, the force it exerts is proportional to its

optimization techniques, drastically different on change in length. The rate or spring constant of a

principle from classical methods, are getting spring is the change in the force it exerts, divided by

increasing more alternation. These methods mimic a the change in deflection of the spring. That is, it is the

particular natural phenomenon to solve as gradient of the force versus deflection curve.

optimization problem with the development of Depending on the design and required operating

mathematical programming techniques for environment, any material can be used to construct a

optimization and rapid advances made in computer spring, so long as the material has the required

hardware and software technologies; it is now combination of rigidity and elasticity.

possible to formulate engineering design problems as The spring is design to introduce controlled

an optimization problem, with the objective of flexibility by deflecting under applied loads. The

minimizing the cost or weight subject to satisfaction current design aims is to minimize weight of spring

of all the conditions of design [1,2]. as well as reduction of stresses for various materials.

The evolution strategies like Genetic

algorithm, simulated annealing, fuzzy sets, and neural

networks are major techniques of which genetic

algorithms are the present topic of discussion. GA is

a population based search and optimization

technique. It is an interactive optimization procedure,

instead of working with a single solution, in each

iteration, a GA works with a number of solutions.

A spring is an elastic object used to store

mechanical energy. Springs are usually made out of

spring steel. Small springs can be wound form pre-

hardened stock, while larger ones are made from

annealed steel and hardened after fabrication. Some

non-ferrous metals are also used including phosphor

bronze and titanium for parts requiring corrosion

resistance and beryllium copper for springs carrying

electrical current (because of its low electrical Fig a: Coil Spring

resistance). When a spring is compressed or

http: // www.ijesrt.com(C)International Journal of Engineering Sciences & Research Technology

[929-931]

[Dighewar, 3(2): February, 2014] ISSN: 2277-9655

Impact Factor: 1.852

Brief Details of GA which can be solved by optimization algorithm.

A Genetic Algorithm applies the principles Optimization problem must be formulated as per the

of evolutions found in nature, to the problem of format of the algorithm. The problem formulate for,

finding an optimal solution to a solver problem. In a optimal design of extension spring is proposed here.

GA the problem is encoded in a series of bit strings The various steps in the GA procedure are explained

that are manipulated by the algorithm; also it uses the below:

decision variables and problem functions directly. A. Objective Function: The objective is to arrive at

Most commercial solver problems are based on the minimum weight of the spring.

genetic algorithms [5]. A genetic algorithm for The objective function, f (w) identified for the study

optimization is different from “classical” is given below:

optimization methods in several ways: f (w) = ρ(π/4) d2nπD

Random Versus Deterministic Operation Where, ρ is the Density of material, d is the Diameter

Population versus Single Best Solution of coil spring; D is Mean Diameter and n is the

Creating New Solutions through Mutation Number of active coils.

Combining Solutions through Crossover B. Design Variables: The design problem usually

Selecting Solutions via “Survival of the Fittest”, involves many design parameters, of which, some are

GA is search algorithms that simulate highly sensitive. This parameter is called design

Darwinian evolutionary generating a population of variables in optimization process. Design variables

potential solutions to the problem and then chosen for the present problem are: Load, Weight,

manipulating those solutions using genetic Deflection, Coil Diameter, Material etc.

operations. The solutions are typically represented as Design Load (W), Pmin, 300N & Pmax, 700

finite sequences drawn from a finite alphabet of N

characters. Through selection, crossover and Maximum Deflection (∂), 30mm

mutation operations, better solutions are generated Diameter of coil spring (d), 7mm

out of current population of potential solutions. This Mean diameter of coil spring (D), 43mm

process continues until an acceptable solution is Number of active coils (N), 10

found. C. Design Parameters: The design parameters are

usually remain fixed in relation to design variable or

Design of Spring it is independent of the design variables. The design

A spring is a resilient member capable of parameters chosen for the design are, load W,

providing large elastic deformation. A spring is material properties – (1) Density, ρ (2) Modulus of

basically defined as an elastic body whose function is Rigidity, G (3) Maximum allowable stress, ta (4)

to distort when loaded and to recover its original Yield Stress, ty.

shape when the load is removed. Mechanical springs

are used in machines and other applications mainly Design Constraints

• To exert force, The constraints represents some functional

• To provide flexibility relationships amongst the design variable and other

• To store or absorb energy. design parameters satisfying certain physical

Among the various springs helical or coil phenomenon and certain resource limitation in this

compression / extension springs are the widely used problem the following are the design constraints.

ones and hence discussions will be confined to the Maximum endurance shear stress in a coil

helical (coil) extension springs. The basic formulize 2 ∗ ta

≤ ten

for design of this spring are given below. (1/n − ((tm − ta)/ty)

Inner diameter is, Di=D -d Outside diameter D+d <=Do

Outer diameter is, Do=D + d Inside diameter D-d<=di

Stress factor, K= ((4*D-d)/4*(D-d)) + (0.615*d/D) Bounds limits

Shear stress factor, Ks= (1+ (d/2*D)) Dmin <= d<= dmax

Mean shear stress, tm = (ks*8*pmax*D)/ (3.14*d3) Dmin <= D <= dmax

Variable shear stress, ta = (k*8*pm*D)/(3.14*d^3) Nmin <= N <= Nmax

Endurance shear stress, ten= (2*ta)/ ((1/n)-((tm- ∗

Maximum deflection allowable <=0

ta)/ty) ∗ ^

Stress factor K= ((4*D-d)/4*(D-d)) + (0.615*d/D)

Mean shear stress tm= (Ks*8*D*pmax)/ (3.14*d^3)

Optimal Problem Formulation

The purpose of formulation is to create

mathematical model of optimum design problem,

http: // www.ijesrt.com(C)International Journal of Engineering Sciences & Research Technology

[929-931]

[Dighewar, 3(2): February, 2014] ISSN: 2277-9655

Impact Factor: 1.852

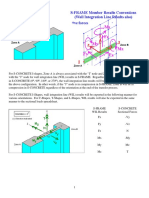

Table 1: Comparison of Stresses and Weight realistic designs often encountered in engineering

Design Stress Weight application.

Materials ks

parameters (N/mm2) (N)

Steel 1.24 275.86 5.205 References

[1] Rajendran, S. Vijayarangan, (July 2000)

D=43mm, Music

1.24 272.41 5.205 “Optimal Design of Composite Leaf Spring

d=7mm, wire

Using Genetic Algorithms”, Elsevier,

∂=30mm, Oil Computer and Structures 79(2001), pp.

P max Tempered 1.24 275.86 5.211 1121-1129.

=700 mm wire [2] K. Mahadevan, K. Balaveera Reddy,

Stainless “Design Data Hand Book”, Third Edition,

1.24 241.38 4.847

steel pp. 138-140.

[3] R.S. Khurmi, J. K. Gupta, (2005), “A Text

Weight Book of Machine Design”, pp. 80,824,855.

5.3 [4] G. Brassard, P. Bratley, “Fundamentals of

5.2 Algorithms” (PHI).

5.1

5

4.9

4.8

4.7

4.6

Steel Music Oil Stainless

wire tempered steel

wire

Fig b: Weight Vs Material

Stress

280

270

260

250

240

230 Stress

220

Fig c: Stress Vs Material

Conclusion

In the present work, the design parameters

(Material, Weight) of Steel, Stainless steel, Music

wire, oil tempered wire are optimized by making use

of GA; a non-traditional optimization methods. So, it

is advisable that application of GA in optimization of

various design parameters can be used. When

compared with other traditional method, it is

observed that optimization using GA leads to time

reduction as well as weight due to its search for

global optimum as against the local optimum in

traditional search method. These results are

encouraging and suggest that GA can be used

effectively and efficiently in other complex and

http: // www.ijesrt.com(C)International Journal of Engineering Sciences & Research Technology

[929-931]

You might also like

- Size and Topological Optimization of Cantilever BeamDocument6 pagesSize and Topological Optimization of Cantilever BeamseventhsensegroupNo ratings yet

- Paper On Optimisational Design of Pressure VesselDocument12 pagesPaper On Optimisational Design of Pressure VesselEr Pravin V TembeNo ratings yet

- Design Optimization of Power Screw JackDocument7 pagesDesign Optimization of Power Screw JackTd DammikaNo ratings yet

- Discrete Optimum Design of Cable-Stayed BridgesDocument9 pagesDiscrete Optimum Design of Cable-Stayed BridgesspoorthissNo ratings yet

- Weight Optimization of Girderbeam For 70t E.O.T Crane Through Fe Analysis IJERTV2IS50534Document7 pagesWeight Optimization of Girderbeam For 70t E.O.T Crane Through Fe Analysis IJERTV2IS50534resendez.oscar100No ratings yet

- International Conference On Modeling, Optimization and Computing (ICMOC 2012)Document22 pagesInternational Conference On Modeling, Optimization and Computing (ICMOC 2012)Zain Ul AbideenNo ratings yet

- .Design and Analysis of A Shock Absorber by Varying Spring Materials - Analysis Using Fea TechniqueDocument9 pages.Design and Analysis of A Shock Absorber by Varying Spring Materials - Analysis Using Fea TechniqueManjunath ReddyNo ratings yet

- ProjectDocument50 pagesProjectAhmed AlrashidNo ratings yet

- Robust Optimization With Simulated AnnealingDocument13 pagesRobust Optimization With Simulated Annealingjihanemanar72No ratings yet

- Global Optimization For Some Engineering Problems: Difficulties and ProspectsDocument9 pagesGlobal Optimization For Some Engineering Problems: Difficulties and ProspectsTheRFCBlueBearNo ratings yet

- Increasing Load Capacity of Spline Connections Through DesignDocument6 pagesIncreasing Load Capacity of Spline Connections Through DesignBala LakshmanNo ratings yet

- 080Document9 pages080Stefano Del TedescoNo ratings yet

- Optimisation of Three - Phase Separators: A Mathematical Model DesignDocument9 pagesOptimisation of Three - Phase Separators: A Mathematical Model DesignAbubakarNo ratings yet

- Design Analysis of Industrial Gear Box Casing.: International Research Journal of Engineering and Technology (IRJET)Document5 pagesDesign Analysis of Industrial Gear Box Casing.: International Research Journal of Engineering and Technology (IRJET)Akash NandargiNo ratings yet

- Parametric Design: EngineeringdesignDocument11 pagesParametric Design: EngineeringdesignJhon Leyder Rodriguez OrtizNo ratings yet

- A Solution Method For Optimal Weight Design ProblemDocument4 pagesA Solution Method For Optimal Weight Design ProblemAbdelmajid AittalebNo ratings yet

- Effect of Material Properties On DesignDocument32 pagesEffect of Material Properties On DesignKumaravel SivamNo ratings yet

- Ijasrm V3S6 606 130 132Document3 pagesIjasrm V3S6 606 130 132Atharva SalunkheNo ratings yet

- 0192 Design Optimization of Eot Crane BridgeDocument9 pages0192 Design Optimization of Eot Crane BridgeJignesh Tala100% (1)

- Timber Beam Design Per The 2018 NDS Standard: Technical ArticleDocument1 pageTimber Beam Design Per The 2018 NDS Standard: Technical ArticleDoğan ArslanNo ratings yet

- Design Analysis of Industrial Gear Box C 221013 042656Document5 pagesDesign Analysis of Industrial Gear Box C 221013 042656Trung ThanhNo ratings yet

- S.T. Selvamani, K. Umanath, K. Palanikumar, K. Vigneswar: Key WordsDocument4 pagesS.T. Selvamani, K. Umanath, K. Palanikumar, K. Vigneswar: Key WordsSundaraPandiyanNo ratings yet

- Analysis of Stress Square Thread Power Screws Using AnsysDocument6 pagesAnalysis of Stress Square Thread Power Screws Using AnsysmahsaNo ratings yet

- 2 Study On Diff Truss Structures Ware House DesignDocument4 pages2 Study On Diff Truss Structures Ware House DesigndhanarajNo ratings yet

- Cascade Structural Sizing Optimization With Large Numbers of Design VariablesDocument17 pagesCascade Structural Sizing Optimization With Large Numbers of Design Variablespraveen kumarNo ratings yet

- MECH410/520 Pro/E WF2Motion Animation TutorialDocument6 pagesMECH410/520 Pro/E WF2Motion Animation TutorialAmit RoyNo ratings yet

- Ijsetr Vol 2 Issue 3 676 683Document8 pagesIjsetr Vol 2 Issue 3 676 683kinfegetaNo ratings yet

- CFD Modeling and Multi-Objective Optimization of Cyclone GeometryDocument25 pagesCFD Modeling and Multi-Objective Optimization of Cyclone GeometryArunNo ratings yet

- Engineering Journal Optimal Design of Steel and Composite Vessels With Tube Branch JointDocument12 pagesEngineering Journal Optimal Design of Steel and Composite Vessels With Tube Branch JointEngineering JournalNo ratings yet

- Introduction To Ship Structural DesignDocument34 pagesIntroduction To Ship Structural DesignRahul SunilNo ratings yet

- Optimization of Mechanical Design Problems Using ADocument6 pagesOptimization of Mechanical Design Problems Using AKARTIK ZALAKINo ratings yet

- Unit 1 Steady & Variable Stresses in Machine Members: Design of Machine ElementsDocument30 pagesUnit 1 Steady & Variable Stresses in Machine Members: Design of Machine ElementsPrasanth YuviNo ratings yet

- Career Episode 1 Analysis of A Disc BrakeDocument8 pagesCareer Episode 1 Analysis of A Disc BrakeNishar Alam Khan 19MCD0042No ratings yet

- Irjet V5i5220Document4 pagesIrjet V5i5220afaq AhmadNo ratings yet

- FEM Analysis of Connecting Rod of Different Materials Using AnsysDocument20 pagesFEM Analysis of Connecting Rod of Different Materials Using AnsysjeffNo ratings yet

- Cost Effective Design of RC ColumnDocument5 pagesCost Effective Design of RC ColumnIbrahim PashaNo ratings yet

- KISSsoft, Shaft Analysis - Introduction To DIN 743, October 2000Document8 pagesKISSsoft, Shaft Analysis - Introduction To DIN 743, October 2000Tomas PinheiroNo ratings yet

- FEM&BestpracticesDocument293 pagesFEM&BestpracticesHem ANo ratings yet

- Dynamic Algorithms in Computational GeometryDocument49 pagesDynamic Algorithms in Computational Geometrysolrak_07No ratings yet

- Constructive Factors Optimization of The Heat ExchDocument6 pagesConstructive Factors Optimization of The Heat ExchAlina Paula OpreaNo ratings yet

- Analysis and Validation of Eicher 11.10 ChassisDocument4 pagesAnalysis and Validation of Eicher 11.10 ChassisdessaivipulNo ratings yet

- Optimization MethodsDocument62 pagesOptimization MethodsDiego Isla-LópezNo ratings yet

- Asabe Pe Review Machine DesignDocument80 pagesAsabe Pe Review Machine DesignvijaybuxNo ratings yet

- Analysis of Piston, Connecting Rod and Crank Shaft Assembly: SciencedirectDocument10 pagesAnalysis of Piston, Connecting Rod and Crank Shaft Assembly: Sciencedirectvikek vikumarNo ratings yet

- Chapter 02 - Past Present FutureDocument12 pagesChapter 02 - Past Present FuturedeepakNo ratings yet

- Finite Element Method: A Brief History and Look at its Past, Present and FutureDocument12 pagesFinite Element Method: A Brief History and Look at its Past, Present and FuturedeepakNo ratings yet

- An Optimization Procedure For Truss Structures With Discrete Design Variables and Dynamic ConstraintsDocument8 pagesAn Optimization Procedure For Truss Structures With Discrete Design Variables and Dynamic ConstraintsXuân Thắng LêNo ratings yet

- Land 3D Design OptimizationDocument12 pagesLand 3D Design OptimizationNamwangala Rashid NatinduNo ratings yet

- Optimum Design of Geodesic Steel Domes Using MetaheuristicsDocument16 pagesOptimum Design of Geodesic Steel Domes Using MetaheuristicsVinayak PotdarNo ratings yet

- Optimization of Steel ChimneyDocument4 pagesOptimization of Steel ChimneyIJRASETPublicationsNo ratings yet

- Shaft analysis calculation of load capacity according to DIN 743Document8 pagesShaft analysis calculation of load capacity according to DIN 743droessaert_stijnNo ratings yet

- Knuckle Joints DesignDocument10 pagesKnuckle Joints DesignKvrd Prasad100% (1)

- Design Optimization of Spur Gear Using SA and RCGADocument8 pagesDesign Optimization of Spur Gear Using SA and RCGAs d pavan kumarNo ratings yet

- Saka 1991Document13 pagesSaka 1991fahmi aballiNo ratings yet

- Prestressing of Compression Springs-Part1Document9 pagesPrestressing of Compression Springs-Part1Prihastya WishnutamaNo ratings yet

- SolidWorks OptimisationDocument9 pagesSolidWorks OptimisationBobi PitropNo ratings yet

- Din743 Intro EnglishDocument9 pagesDin743 Intro EnglishUber_Konstruktor100% (1)

- Design and analysis of a connecting rod using ANSYSDocument7 pagesDesign and analysis of a connecting rod using ANSYSD MasthanNo ratings yet

- 3d-Objects and Mathematical EquationsDocument69 pages3d-Objects and Mathematical EquationsGomathi SankarNo ratings yet

- Mathematics of 3D PrintingDocument41 pagesMathematics of 3D PrintingHabtamu GeremewNo ratings yet

- CURVES Basics: Prof. Janakarajan Ramkumar Professor Department of Mechanical & Design Program IIT Kanpur, IndiaDocument61 pagesCURVES Basics: Prof. Janakarajan Ramkumar Professor Department of Mechanical & Design Program IIT Kanpur, IndiaHabtamu GeremewNo ratings yet

- Algebraic geometry for geometric modelingDocument46 pagesAlgebraic geometry for geometric modelingHabtamu GeremewNo ratings yet

- Algebraic Methods For Geometric Modeling: To Cite This VersionDocument170 pagesAlgebraic Methods For Geometric Modeling: To Cite This VersionHabtamu GeremewNo ratings yet

- Y, Z AB Is PerpendicularDocument28 pagesY, Z AB Is PerpendicularHabtamu GeremewNo ratings yet

- Thickning OperationDocument10 pagesThickning OperationHabtamu GeremewNo ratings yet

- Lattice Structure Modeling and OptimizationDocument58 pagesLattice Structure Modeling and OptimizationHabtamu GeremewNo ratings yet

- 12 CM0268 Geometric Computing2Document50 pages12 CM0268 Geometric Computing2Babu Kaala PandianNo ratings yet

- ELG5124-3D ObjectModelling-TR-01-2003-Cretu PDFDocument27 pagesELG5124-3D ObjectModelling-TR-01-2003-Cretu PDFHabtamu GeremewNo ratings yet

- 10-1 and 13-1 Overheads (Landscape) PDFDocument10 pages10-1 and 13-1 Overheads (Landscape) PDFHabtamu GeremewNo ratings yet

- CMR A 21470 PDFDocument6 pagesCMR A 21470 PDFHabtamu GeremewNo ratings yet

- 3D Printing For Math Professors and Their StudentsDocument18 pages3D Printing For Math Professors and Their StudentsHabtamu GeremewNo ratings yet

- Y, Z AB Is PerpendicularDocument28 pagesY, Z AB Is PerpendicularHabtamu GeremewNo ratings yet

- Lattice Structures ModelingDocument8 pagesLattice Structures ModelingHabtamu GeremewNo ratings yet

- ABCD Clicking AppDocument1 pageABCD Clicking AppHabtamu GeremewNo ratings yet

- Analysis and Optimization of A Helical Compression Coil Spring Used For TWV Ijariie1624Document6 pagesAnalysis and Optimization of A Helical Compression Coil Spring Used For TWV Ijariie1624Anonymous uQONItHwRNo ratings yet

- CMR A 21470 PDFDocument6 pagesCMR A 21470 PDFHabtamu GeremewNo ratings yet

- Fliping Coin GuseDocument1 pageFliping Coin GuseHabtamu GeremewNo ratings yet

- File Opening AppDocument1 pageFile Opening AppHabtamu GeremewNo ratings yet

- Hangout GameDocument3 pagesHangout GameHabtamu GeremewNo ratings yet

- Optimization of Spring Weight Using Genetic Algorithm IJERTV1IS9507 PDFDocument12 pagesOptimization of Spring Weight Using Genetic Algorithm IJERTV1IS9507 PDFHabtamu GeremewNo ratings yet

- Classical & Advanced Optimization Techniques PDFDocument12 pagesClassical & Advanced Optimization Techniques PDFBarathNo ratings yet

- Fracture Mechanics Project IDocument1 pageFracture Mechanics Project IHabtamu GeremewNo ratings yet

- Optimization of Spring Weight Using Genetic Algorithm IJERTV1IS9507 PDFDocument12 pagesOptimization of Spring Weight Using Genetic Algorithm IJERTV1IS9507 PDFHabtamu GeremewNo ratings yet

- Optimal Spring Design Using Genetic AlgorithmDocument3 pagesOptimal Spring Design Using Genetic AlgorithmHabtamu GeremewNo ratings yet

- Guess the Number GameDocument1 pageGuess the Number GameHabtamu GeremewNo ratings yet

- Optimizing The Design of A Helical SpringDocument4 pagesOptimizing The Design of A Helical SpringHabtamu GeremewNo ratings yet

- Optimizing The Design of A Helical SpringDocument4 pagesOptimizing The Design of A Helical SpringHabtamu GeremewNo ratings yet

- OS ABB Comem BR EN 16-05-2018Document12 pagesOS ABB Comem BR EN 16-05-2018RosaFNo ratings yet

- Design and Analysis of Reinforced Concrete StructuresDocument16 pagesDesign and Analysis of Reinforced Concrete StructuresFaizalhizam NoordinNo ratings yet

- Model Predictive Control Thesesgood PDFDocument267 pagesModel Predictive Control Thesesgood PDFyalllikNo ratings yet

- RR 105Document130 pagesRR 105Dr R Panneer SelvamNo ratings yet

- Maythuykhi Tracnghiem CodapanDocument18 pagesMaythuykhi Tracnghiem CodapanLuan BuiNo ratings yet

- Model Number Significance ChartDocument15 pagesModel Number Significance ChartSHAKEEL ISMAIL LAMBAYNo ratings yet

- Yaskawa Inverter Basic Control Training in Vietnam (Saigon)Document112 pagesYaskawa Inverter Basic Control Training in Vietnam (Saigon)NguyễnVănThiện100% (3)

- Ducati Panigale Superbike 959 MY16 enDocument152 pagesDucati Panigale Superbike 959 MY16 enAdrian ChippendaleNo ratings yet

- Advanced Molecular Quantum MechanicsDocument312 pagesAdvanced Molecular Quantum MechanicsSamantha Loredo RamirezNo ratings yet

- Civil Engineering Systems AnalysisDocument10 pagesCivil Engineering Systems AnalysisNikhil JohnNo ratings yet

- Service and Maintenance of Engine TAD1355GEDocument90 pagesService and Maintenance of Engine TAD1355GEЕвгений АрабаджиNo ratings yet

- Worksheet 8 (Thermodynamics) With AnswersDocument2 pagesWorksheet 8 (Thermodynamics) With AnswersChristopher Latta100% (1)

- CFF 2nd Series QP - Nov 2019Document1 pageCFF 2nd Series QP - Nov 2019Venkitaraj K PNo ratings yet

- Engine Monitors For General Aviation Piston Engines Condition MonitoringDocument6 pagesEngine Monitors For General Aviation Piston Engines Condition MonitoringShanker PandeyNo ratings yet

- Fisher 2500 249 Pneumatic Controllers Transmitters en 127050Document16 pagesFisher 2500 249 Pneumatic Controllers Transmitters en 127050GOKUL PRASADNo ratings yet

- Air Cooler Piping Design Questionaries With AnswerDocument1 pageAir Cooler Piping Design Questionaries With AnswerVikash TiwariNo ratings yet

- Wall Integration Conventions S-CONCRETE R11 S-FRAMEDocument3 pagesWall Integration Conventions S-CONCRETE R11 S-FRAMESyed RaziuddinNo ratings yet

- KEYSDocument21 pagesKEYSAndrea Douglas100% (1)

- ST.TERESA SCHOOL PPT ON ENERGY FORMSDocument21 pagesST.TERESA SCHOOL PPT ON ENERGY FORMSYash SharmaNo ratings yet

- Resistencia de Materiales - N. M. Belyaev - Strength of Materials - MirDocument650 pagesResistencia de Materiales - N. M. Belyaev - Strength of Materials - MirSandoval Rivas RafaelNo ratings yet

- Comments On Io List & P&I Diagram: Motor Feeder SignalsDocument4 pagesComments On Io List & P&I Diagram: Motor Feeder SignalsNaveen NagisettiNo ratings yet

- Step N. Start Sequence Step Steps DetailsDocument4 pagesStep N. Start Sequence Step Steps DetailsAndrea CupelloNo ratings yet

- Walking-Type Agricultural Tractor Specifications Rotary Tilling TypeDocument6 pagesWalking-Type Agricultural Tractor Specifications Rotary Tilling TypeEdsel Jay RaperNo ratings yet

- Specification Sheet: Pour Point of Crude Oils - Procedure BDocument3 pagesSpecification Sheet: Pour Point of Crude Oils - Procedure BMiguelNo ratings yet

- Roster Sheet TE LabDocument2 pagesRoster Sheet TE LabakshaysinghNo ratings yet

- What Is An RTJ Flange - Ring Type Joint Flanges (PDF) - What Is PipingDocument12 pagesWhat Is An RTJ Flange - Ring Type Joint Flanges (PDF) - What Is Pipinghervé louisNo ratings yet

- AbsDocument26 pagesAbsEngine Tuning UPNo ratings yet

- Updated Checklist of JCB (1), MINI BATCHING PLANT, Concrete PumpDocument6 pagesUpdated Checklist of JCB (1), MINI BATCHING PLANT, Concrete Pumppartha100% (2)