Professional Documents

Culture Documents

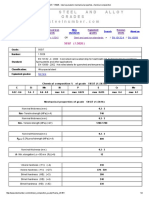

Data Table For Grades Stainless Steels - Special Steels SA-815 WPS41500

Uploaded by

AndresInforBJOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Table For Grades Stainless Steels - Special Steels SA-815 WPS41500

Uploaded by

AndresInforBJCopyright:

Available Formats

SA-815 WPS41500 Chemical information,Mechanical prope

Physical properties, Mechanical properties, Heat treatment, and

Micro structure

This page is mainly introduced the SA-815 WPS41500 chemical

information,mechanical properties, physical properties, mechanical properties, heat

treatment, and Micro structure, etc. It also contains the use of SA-815

WPS41500,such as it is commonly used in bars, sheet,plates, steel coils, steel

pipes,forged and other materials application.

Data Table for Grades Stainless Steels - Special

Steels SA-815 WPS41500

SA-815 WPS41500 Standard Number:

ITEM Standard Number Descriptions

1 SA-815/SA-815M Specification for Wrought Ferritic, Ferritic /Austenitic, and Martensitic Stainless

Steel Piping Fittings

SA-815 WPS41500 Chemical composition(mass fraction)(wt.%)

Chemical Min.(%) Max.(%)

C 0.05

Mn 0.50 1.00

Si 0.60

P 0.03

S 0.03

Cr 11.50 14.00

Ni 3.50 5.50

Mo 0.50 1.00

SA-815 WPS41500 Physical Properties

Tensile strength 115-234 σb/MPa

Yield Strength 23 σ 0.2 ≥/MPa

Elongation 65 δ5≥ (%)

ψ - ψ≥ (%)

Akv - Akv≥/J

HBS 123-321 -

HRC 30 -

SA-815 WPS41500 Mechanical Properties

Email: sales@tool-die-steels.com http://www.tool-die-steels.com/ Page 1 / 3

SA-815 WPS41500 Chemical information,Mechanical prope

Physical properties, Mechanical properties, Heat treatment, and

Micro structure

Tensile strength 231-231 σb/MPa

Yield Strength 154 σ 0.2 ≥/MPa

Elongation 56 δ5≥(%)

ψ - ψ≥(%)

Akv - Akv≥/J

HBS 235-268 -

HRC 30 -

SA-815 WPS41500 Heat Treatment Regime

Annealing Quenching Tempering Normalizing Q&T

√ √ √ √ √

SA-815 WPS41500 Range of products

Product type Products Dimension Processes Deliver Status

Plates / Sheets Plates / Sheets 0.08-200mm(T)*W*L Forging, hot rolling and Annealed, Solution and

cold rolling Aging, Q+T, ACID-

WASHED, Shot Blasting

Steel Bar Round Bar, Flat Bar, Φ8-1200mm*L Forging, hot rolling and Black, Rough Turning,

Square Bar cold rolling, Cast Shot Blasting,

Coil / Strip Steel Coil /Steel Strip 0.03-16.0x1200mm Cold-Rolled & Hot- Annealed, Solution and

Rolled Aging, Q+T, ACID-

WASHED, Shot Blasting

Pipes / Tubes Seamless Pipes/Tubes, OD:6-219mm x Hot extrusion, Cold Annealed, Solution and

Welded Pipes/Tubes WT:0.5-20.0mm Drawn, Welded Aging, Q+T, ACID-

WASHED

We can produce Stainless Steels - Special Steels the specifications follows:

Note:

(1) listed in the table apex diameter (d), to steel thickness (a) multiples said.

(2) in the ASTM A6 standard specified scope can meet any additional conditions.

(3) from the standard for 50 mm (2 in).

Mechanical properties

Mechanische Eigenschaften

Caracteristiques mecaniques

ReH Minimum yield strength / Mindestwert der oberen Streckgrenze / Limite d’elasticite minimale

Rm Tensile strength / Zugfestigkeit / Resistance a la traction

A Minimum elongation / Mindestwert der Bruchdehnung / Allongement minimal

J Notch impact test / Kerbschlagbiegeversuch / Essai de flexion par choc

Round bar:

Diameter : 1mm-2000mm

Email: sales@tool-die-steels.com http://www.tool-die-steels.com/ Page 2 / 3

SA-815 WPS41500 Chemical information,Mechanical prope

Physical properties, Mechanical properties, Heat treatment, and

Micro structure

Square bar:

Size: 50mm * 50mm-600mm *600mm

Plate steel/flat bar:

Size: Thickness: 0.1mm-800mm Width: 10mm to 1500mm

Tube/pipe:

Size: OD: 6-219mm WT: 1-35 mm.

Cold-rolled sheet: Thickness: 2-5mm Width:1000mm Length: 2000mm

Hot-rolled sheet: Thickness:6-80mm Width: 210-610mm

Length: We can supply any length based on the customer's requirement.

Forging/hot rolling/ extrusion of steel.

Forging: Shafts with flanks/pipes/tubes/slugs/donuts/cubes/other shapes

Finished goods condition: hot forging/hot rolling + annealing/normalizing + tempering/quenching + tempering/any

conditions based on the customer's requirement

Surface conditions: scaled (hot working finish)/ground/rough machining/fine machining/based on the customer's requirement

Furnaces for metallurgical processing: electrode arc + LF/VD/VOD/ESR/Vacuum consumable electrode.

Ultrasonic inspection: 100% ultrasonic inspection for any inperfections or based on the customer's requirement.

UTS according to SEP 1921 C/c,D/d,E/e;A388 or GB/T 6402

Excellent service for all kinds of industries, with advantages of technologies, equipment and price.

We serve you with our honesty, integrity, and professionality.

Email: sales@tool-die-steels.com http://www.tool-die-steels.com/ Page 3 / 3

Powered by TCPDF (www.tcpdf.org)

You might also like

- Astm 4140Document3 pagesAstm 4140Ramiz KhanNo ratings yet

- Astm 4140 PDFDocument3 pagesAstm 4140 PDFRameshNo ratings yet

- Data Table For Grades Stainless Steels SUS 410 J1Document3 pagesData Table For Grades Stainless Steels SUS 410 J1retrogradesNo ratings yet

- 125Cr1 DatasheetDocument3 pages125Cr1 DatasheetshamrajjNo ratings yet

- Data Table For Grades Stainless Steels - Special Steels STS304Document3 pagesData Table For Grades Stainless Steels - Special Steels STS304NathanNo ratings yet

- SAE 1060 Ficha TecnicaDocument2 pagesSAE 1060 Ficha TecnicaDECRO EIRLNo ratings yet

- SWCH 10aDocument2 pagesSWCH 10asujiyopptsrNo ratings yet

- Datasheet For Steel Grades Specialsteel SUS 301 CSPDocument3 pagesDatasheet For Steel Grades Specialsteel SUS 301 CSPAdzan RamadhanNo ratings yet

- 1.7734-DatasheetDocument4 pages1.7734-DatasheetMax PrzybyllaNo ratings yet

- Datasheet For Steel Grades Carbon Steel 1.1141: 1.1141 Standard NumberDocument2 pagesDatasheet For Steel Grades Carbon Steel 1.1141: 1.1141 Standard NumberCricri CriNo ratings yet

- 50CrMo4 PDFDocument3 pages50CrMo4 PDFsaptotoNo ratings yet

- Datasheet For Steel Grades Special Alloy STS304Document2 pagesDatasheet For Steel Grades Special Alloy STS304Thanakit Srisaeng100% (1)

- Sus420f PDFDocument2 pagesSus420f PDFarnettoNo ratings yet

- SUS420FDocument2 pagesSUS420FarnettoNo ratings yet

- S30601 DatasheetDocument3 pagesS30601 DatasheetLokman SirajNo ratings yet

- Datasheet For Steel Grades Carbon Steel Swrch6ADocument3 pagesDatasheet For Steel Grades Carbon Steel Swrch6AzaxaxazNo ratings yet

- 1 5511Document3 pages1 5511arunv19No ratings yet

- E26 4 DatasheetDocument2 pagesE26 4 DatasheetIdan FriedbergNo ratings yet

- 3 CR 13Document3 pages3 CR 13Ali HashemiNo ratings yet

- SS41Document3 pagesSS41Danifarrel NurhafizNo ratings yet

- Data Table For Grades Stainless Steels SUH 660Document2 pagesData Table For Grades Stainless Steels SUH 660Agy RandhikoNo ratings yet

- Zar 400Document2 pagesZar 400WILLIAN PATRICK DA SILVA RODRIGUESNo ratings yet

- Datasheet For Steel Grades Mould Steel 1.4869: 1.4869 Standard NumberDocument2 pagesDatasheet For Steel Grades Mould Steel 1.4869: 1.4869 Standard NumberManoj SNo ratings yet

- SSW-Q1R Class 2Document2 pagesSSW-Q1R Class 2mohsen_267No ratings yet

- Aisi 1045 PDFDocument3 pagesAisi 1045 PDFvendi supendiNo ratings yet

- 1 2743-DatasheetDocument2 pages1 2743-DatasheetsrinivasaNo ratings yet

- 12Cr12Mo 1Cr12MoDocument2 pages12Cr12Mo 1Cr12MoKashif MohiuddinNo ratings yet

- FCD 450-10Document2 pagesFCD 450-10MohammedFaisalGirachNo ratings yet

- Datasheet For Steel Grades Specialsteel X6Crnimob17-12-2Document3 pagesDatasheet For Steel Grades Specialsteel X6Crnimob17-12-2axis inspection solutionsNo ratings yet

- X12CrNiMoV12 3Document3 pagesX12CrNiMoV12 3manjunath k sNo ratings yet

- CSP Informações Material MolaDocument2 pagesCSP Informações Material MolasidneyNo ratings yet

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDocument2 pagesSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- Data Table For Grades Tool Die Steels SKD-11Document3 pagesData Table For Grades Tool Die Steels SKD-11Adhi candra irawanNo ratings yet

- Datasheet For Metals ST 90 PCDocument2 pagesDatasheet For Metals ST 90 PCGalNo ratings yet

- Datasheet For Steel Grades High Alloy Thermax 115Document3 pagesDatasheet For Steel Grades High Alloy Thermax 115alirezaNo ratings yet

- Data Table For Grades Stainless Steels 0Cr17Ni4Cu4NbDocument3 pagesData Table For Grades Stainless Steels 0Cr17Ni4Cu4Nbkurniuawan6723No ratings yet

- CCTTC - SUP9 Datasheet, Chemical Composition: Item Standard Number DescriptionsDocument3 pagesCCTTC - SUP9 Datasheet, Chemical Composition: Item Standard Number DescriptionsAjeeth KumarNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- 14CrMoV6 9 DatasheetDocument3 pages14CrMoV6 9 DatasheetDhurusha GovenderNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10207Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10207farshid KarpasandNo ratings yet

- Data Table For Grades Special Alloy 50MnDocument3 pagesData Table For Grades Special Alloy 50MnHoLinhNo ratings yet

- CCTTC - Cr12Mov Datasheet, Chemical CompositionDocument3 pagesCCTTC - Cr12Mov Datasheet, Chemical CompositiontalalNo ratings yet

- 4140 Electrode PDFDocument1 page4140 Electrode PDFweerasinghekNo ratings yet

- Q460 DatasheetDocument2 pagesQ460 DatasheetarabsniperNo ratings yet

- IS 513 Grade EDDDocument2 pagesIS 513 Grade EDDRamji GautamNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- 1.3532 16NiCrMo16-5Document3 pages1.3532 16NiCrMo16-5RedNo ratings yet

- 9SMnPb28 DatasheetDocument3 pages9SMnPb28 DatasheetVipul SharmaNo ratings yet

- Datasheet For Steel Grades Carbon Steel S70C-CSPDocument3 pagesDatasheet For Steel Grades Carbon Steel S70C-CSPMuhamad Syaiful AnwarNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10132-4 EN 10089Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10132-4 EN 10089farshid KarpasandNo ratings yet

- Datasheet For Steel Grades Structure Steel 16MnDocument2 pagesDatasheet For Steel Grades Structure Steel 16MnPond KampeeraNo ratings yet

- SWRCH18ADocument2 pagesSWRCH18AHari SuthanNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10225Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10225farshid KarpasandNo ratings yet

- European Steel and Alloy Grades: 24crmo13-6 (1.8516)Document2 pagesEuropean Steel and Alloy Grades: 24crmo13-6 (1.8516)farshid KarpasandNo ratings yet

- Datasheet For Steel Grades Specialsteel 06Cr25Ni20Document3 pagesDatasheet For Steel Grades Specialsteel 06Cr25Ni20nagmech07No ratings yet

- Data Table For Grades Stainless Steels & Special Steels 301S21Document2 pagesData Table For Grades Stainless Steels & Special Steels 301S21earth metallurgical services pvt.ltd.No ratings yet

- 60CrMnMoA DatasheetDocument2 pages60CrMnMoA DatasheetKashif MohiuddinNo ratings yet

- SK95, Such As It Is Commonly Used in Bars, Sheet, Plates, Steel Coils, Steel Pipes, Forged and OtherDocument3 pagesSK95, Such As It Is Commonly Used in Bars, Sheet, Plates, Steel Coils, Steel Pipes, Forged and OtherFortune FireNo ratings yet

- Datasheet For Steel Grades Tool Steel and Hard Alloy Stellite 6Document2 pagesDatasheet For Steel Grades Tool Steel and Hard Alloy Stellite 6kdalavadi3905No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Condensadro EspiralDocument13 pagesCondensadro EspiralAndresInforBJNo ratings yet

- Ventilador 3Document7 pagesVentilador 3AndresInforBJNo ratings yet

- Visual-Environment 10.0 ReleaseNotesDocument156 pagesVisual-Environment 10.0 ReleaseNotesAndresInforBJNo ratings yet

- VisualEnvironment 10.7 ReleaseNotesDocument196 pagesVisualEnvironment 10.7 ReleaseNotesAndresInforBJNo ratings yet

- Fan Pressure-Based Testing, Adjusting, and Balancing of A Ventilation SystemDocument9 pagesFan Pressure-Based Testing, Adjusting, and Balancing of A Ventilation SystemAndresInforBJNo ratings yet

- Astm A356 PDFDocument6 pagesAstm A356 PDFAndresInforBJNo ratings yet

- A32Document2 pagesA32Ivan GarzonNo ratings yet

- Modci EhDocument2 pagesModci EhAndresInforBJNo ratings yet

- Model FHDocument2 pagesModel FHAndresInforBJNo ratings yet

- Gunjo - 2017 - ANSYS - Col en ZDocument15 pagesGunjo - 2017 - ANSYS - Col en ZAndresInforBJNo ratings yet

- An Experimental Study On Condensation Heat Transfer Characteristics of R600a in Tubes With Coiled Wire InsertsDocument9 pagesAn Experimental Study On Condensation Heat Transfer Characteristics of R600a in Tubes With Coiled Wire InsertsAndresInforBJNo ratings yet

- Practical Verification of Bernoulli'S Theorem: StructureDocument3 pagesPractical Verification of Bernoulli'S Theorem: StructureVívék SâíNo ratings yet

- Module5 NanotechnologyDocument17 pagesModule5 NanotechnologyMidas Troy VictorNo ratings yet

- Convert Chest Freezer Into A FridgeDocument6 pagesConvert Chest Freezer Into A FridgeelurrakkeroNo ratings yet

- Rationale Number of Personnel in Clean Rooms CM 20131023Document6 pagesRationale Number of Personnel in Clean Rooms CM 20131023Brian Williams67% (3)

- CSDJ Plus User's Manual V1.4Document279 pagesCSDJ Plus User's Manual V1.4domenico_leuzziNo ratings yet

- Piping GuidDocument261 pagesPiping GuidSimon Louise100% (2)

- Gascalc 5.0: Calculation ReferenceDocument15 pagesGascalc 5.0: Calculation ReferenceApril TrevinoNo ratings yet

- 25th Secondary Aluminium Conference 2017 Salt SlagDocument48 pages25th Secondary Aluminium Conference 2017 Salt SlagСтанислав ПодольскийNo ratings yet

- BS 6319-2-1983 Testing of Resin Compositions For Use in Construction - Part 2 Method For Measurement of Compressive StrengthDocument8 pagesBS 6319-2-1983 Testing of Resin Compositions For Use in Construction - Part 2 Method For Measurement of Compressive Strengthsgondosch100% (1)

- Feed Mechanism of Single Needle MachineDocument9 pagesFeed Mechanism of Single Needle MachineSWAPNIL KRISHNANo ratings yet

- Dani - An156 - RgaDocument6 pagesDani - An156 - RgaandreililioanceaNo ratings yet

- Miele Tumble Dryer T5206 Operating Instructions enDocument36 pagesMiele Tumble Dryer T5206 Operating Instructions enAlberto AriasNo ratings yet

- Biomass Torrefaction in Indonesia - March, 2016Document17 pagesBiomass Torrefaction in Indonesia - March, 2016Herman Eenk HidayatNo ratings yet

- Ad 301 303 BH enDocument8 pagesAd 301 303 BH enLeed ENNo ratings yet

- Engine Testing TechniqueDocument8 pagesEngine Testing TechniqueNur YakhinNo ratings yet

- Duplex Ss Welding PDF FreeDocument8 pagesDuplex Ss Welding PDF Freeel_sharkawy2011No ratings yet

- C5Document43 pagesC5Romany AllamNo ratings yet

- Sanitary Fixtures Fittings Appliances & Appurtenances 21 NovDocument61 pagesSanitary Fixtures Fittings Appliances & Appurtenances 21 NovTesfa GetachewNo ratings yet

- ABS & Royalex Canoe Maintenance GuideDocument1 pageABS & Royalex Canoe Maintenance GuideSwift Canoe And KayakNo ratings yet

- Machinery Lubrication May - June 2010Document74 pagesMachinery Lubrication May - June 2010daniel adamNo ratings yet

- Goetze Faceseals FTL Seal TechnologyDocument13 pagesGoetze Faceseals FTL Seal Technologycristobal_tl2277No ratings yet

- GRP - GRE - GRV Pipes and FittingDocument6 pagesGRP - GRE - GRV Pipes and FittingrajaNo ratings yet

- Astm A20Document34 pagesAstm A20Pedro Diaz UzcateguiNo ratings yet

- Test Stand Technical ManualDocument51 pagesTest Stand Technical Manualewhf weGJO100% (1)

- 1.6.5 Preliminary Hazard Analysis - Rev0Document22 pages1.6.5 Preliminary Hazard Analysis - Rev0singla.nishant1245No ratings yet

- Paper 6 FRF-lube - Oil - MixingDocument34 pagesPaper 6 FRF-lube - Oil - MixingsoorajssNo ratings yet

- KNIPEX Popular Pliers For The USA Catalog (AA12)Document12 pagesKNIPEX Popular Pliers For The USA Catalog (AA12)Paul HopkinsonNo ratings yet

- Simmons Reference GuideDocument12 pagesSimmons Reference GuideLja CsaNo ratings yet

- Purification of Al (OH) 3 Synthesized by Bayer Process For Preparation of High Purity Alumina As Sapphire Raw MaterialDocument4 pagesPurification of Al (OH) 3 Synthesized by Bayer Process For Preparation of High Purity Alumina As Sapphire Raw Materialhaisamdo100% (1)

- Glass ManufacturingDocument23 pagesGlass ManufacturingPiyush VermaNo ratings yet