Professional Documents

Culture Documents

Data Table For Grades Stainless Steels SUH 660

Uploaded by

Agy RandhikoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Table For Grades Stainless Steels SUH 660

Uploaded by

Agy RandhikoCopyright:

Available Formats

SUH 660 Chemical information,Mechanical properties

Physical properties, Mechanical properties, Heat treatment, and

Micro structure

This page is mainly introduced the SUH 660 chemical information,mechanical

properties, physical properties, mechanical properties, heat treatment, and Micro

structure, etc. It also contains the use of SUH 660,such as it is commonly used in bars,

sheet,plates, steel coils, steel pipes,forged and other materials application.

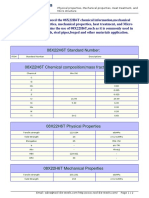

Data Table for Grades Stainless Steels SUH 660

SUH 660 Standard Number:

ITEM Standard Number Descriptions

1 G 4311 (2011) Heat-resisting steel bars and wire rods

SUH 660 Chemical composition(mass fraction)(wt.%)

Chemical Min.(%) Max.(%)

C 0.08

Si 1.00

Mn 2.00

P 0.04

S 0.03

Cr 13.50 16.00

Ni 24.00 27.00

Mo 1.00 1.50

V 0.10 0.50

Ti 1.90 2.35

Al 0.35

B 0.001 0.010

SUH 660 Physical Properties

Tensile strength 115-234 σb/MPa

Yield Strength 23 σ 0.2 ≥/MPa

Elongation 65 δ5≥ (%)

ψ - ψ≥ (%)

Akv - Akv≥/J

HBS 123-321 -

HRC 30 -

Email: sales@tool-die-steels.com http://www.tool-die-steels.com/ Page 1 / 2

SUH 660 Chemical information,Mechanical properties

Physical properties, Mechanical properties, Heat treatment, and

Micro structure

SUH 660 Mechanical Properties

Tensile strength 231-231 σb/MPa

Yield Strength 154 σ 0.2 ≥/MPa

Elongation 56 δ5≥(%)

ψ - ψ≥(%)

Akv - Akv≥/J

HBS 235-268 -

HRC 30 -

SUH 660 Heat Treatment Regime

Annealing Quenching Tempering Normalizing Q&T

√ √ √ √ √

SUH 660 Range of products

Product type Products Dimension Processes Deliver Status

Plates / Sheets Plates / Sheets 0.08-200mm(T)*W*L Forging, hot rolling and Annealed, Solution and

cold rolling Aging, Q+T, ACID-

WASHED, Shot Blasting

Steel Bar Round Bar, Flat Bar, Φ8-1200mm*L Forging, hot rolling and Black, Rough Turning,

Square Bar cold rolling, Cast Shot Blasting,

Coil / Strip Steel Coil /Steel Strip 0.03-16.0x1200mm Cold-Rolled & Hot- Annealed, Solution and

Rolled Aging, Q+T, ACID-

WASHED, Shot Blasting

Pipes / Tubes Seamless Pipes/Tubes, OD:6-219mm x Hot extrusion, Cold Annealed, Solution and

Welded Pipes/Tubes WT:0.5-20.0mm Drawn, Welded Aging, Q+T, ACID-

WASHED

We can produce Stainless Steels the specifications follows:

Email: sales@tool-die-steels.com http://www.tool-die-steels.com/ Page 2 / 2

Powered by TCPDF (www.tcpdf.org)

You might also like

- Datasheet For Steel Grades Specialsteel EN30BDocument2 pagesDatasheet For Steel Grades Specialsteel EN30BIzhar MehdiNo ratings yet

- Data Table For Grades Stainless Steels & Special Steels 301S21Document2 pagesData Table For Grades Stainless Steels & Special Steels 301S21earth metallurgical services pvt.ltd.No ratings yet

- S30601 DatasheetDocument3 pagesS30601 DatasheetLokman SirajNo ratings yet

- E26 4 DatasheetDocument2 pagesE26 4 DatasheetIdan FriedbergNo ratings yet

- Datasheet For Steel Grades Specialsteel SUS 301 CSPDocument3 pagesDatasheet For Steel Grades Specialsteel SUS 301 CSPAdzan RamadhanNo ratings yet

- Sus420f PDFDocument2 pagesSus420f PDFarnettoNo ratings yet

- SUS420FDocument2 pagesSUS420FarnettoNo ratings yet

- CSP Informações Material MolaDocument2 pagesCSP Informações Material MolasidneyNo ratings yet

- 12Cr12Mo 1Cr12MoDocument2 pages12Cr12Mo 1Cr12MoKashif MohiuddinNo ratings yet

- Datasheet For Steel Grades Carbon Steel SUP11ADocument2 pagesDatasheet For Steel Grades Carbon Steel SUP11AswatkoolNo ratings yet

- Sae 1006Document2 pagesSae 1006Nguyễn Tiến TùngNo ratings yet

- 1.3532 16NiCrMo16-5Document3 pages1.3532 16NiCrMo16-5RedNo ratings yet

- SAE 1541 DatasheetDocument2 pagesSAE 1541 DatasheetabhayuietNo ratings yet

- SSW-Q1R Class 2Document2 pagesSSW-Q1R Class 2mohsen_267No ratings yet

- Datasheet For Steel Grades Carbon Steel AISI 302Document2 pagesDatasheet For Steel Grades Carbon Steel AISI 302s_omeone4usNo ratings yet

- Zar 400Document2 pagesZar 400WILLIAN PATRICK DA SILVA RODRIGUESNo ratings yet

- Datasheet For Steel Grades Special Alloy GH3128Document2 pagesDatasheet For Steel Grades Special Alloy GH3128Ishaq Khan IKNo ratings yet

- Data Table For Grades Stainless Steels 0Cr17Ni4Cu4NbDocument3 pagesData Table For Grades Stainless Steels 0Cr17Ni4Cu4Nbkurniuawan6723No ratings yet

- 1 4848-DatasheetDocument2 pages1 4848-DatasheetAshish KumarNo ratings yet

- Data Table For Grades Stainless Steels SUS 410 J1Document3 pagesData Table For Grades Stainless Steels SUS 410 J1retrogradesNo ratings yet

- Datasheet For Steel Grades Specialsteel X6Crnimob17-12-2Document3 pagesDatasheet For Steel Grades Specialsteel X6Crnimob17-12-2axis inspection solutionsNo ratings yet

- Data Table For Grades Tool Steels & Die Steels 1.2327: 1.2327 Standard NumberDocument3 pagesData Table For Grades Tool Steels & Die Steels 1.2327: 1.2327 Standard Numbersmith willNo ratings yet

- SUJ2 DatasheetDocument2 pagesSUJ2 DatasheetGyurmoooNo ratings yet

- X12CrNiMoV12 3Document3 pagesX12CrNiMoV12 3manjunath k sNo ratings yet

- 1 5511Document3 pages1 5511arunv19No ratings yet

- Steel P235TR2Document2 pagesSteel P235TR2Moulham ShahinNo ratings yet

- Data Table For Grades Stainless Steels - Special Steels STS304Document3 pagesData Table For Grades Stainless Steels - Special Steels STS304NathanNo ratings yet

- 1 2743-DatasheetDocument2 pages1 2743-DatasheetsrinivasaNo ratings yet

- Datasheet For Steel Grades Carbon Steel SAE 1090Document2 pagesDatasheet For Steel Grades Carbon Steel SAE 1090Todd FlowNo ratings yet

- Q460 DatasheetDocument2 pagesQ460 DatasheetarabsniperNo ratings yet

- Datasheet For Steel Grades Structure Steel 30crmnsiaDocument2 pagesDatasheet For Steel Grades Structure Steel 30crmnsiaMohammed Elmodathir AliNo ratings yet

- 125Cr1 DatasheetDocument3 pages125Cr1 DatasheetshamrajjNo ratings yet

- SWRCH18ADocument2 pagesSWRCH18AHari SuthanNo ratings yet

- 35CD4Document2 pages35CD4Tarun Kumar V MNo ratings yet

- Datasheet For Steel Grades Structure Steel 15MnvDocument2 pagesDatasheet For Steel Grades Structure Steel 15MnvoomoomNo ratings yet

- Data Table For Grades Stainless Steels - Special Steels SA-815 WPS41500Document3 pagesData Table For Grades Stainless Steels - Special Steels SA-815 WPS41500AndresInforBJNo ratings yet

- Datasheet For Steel Grades Structure Steel 35Mn16Document2 pagesDatasheet For Steel Grades Structure Steel 35Mn16Artur LucaNo ratings yet

- 08X22H6T PDFDocument2 pages08X22H6T PDFnikhiljith o uNo ratings yet

- DatasheetDocument3 pagesDatasheetzaranrajputNo ratings yet

- SWCH 10aDocument2 pagesSWCH 10asujiyopptsrNo ratings yet

- Datasheet For Steel Grades Special Alloy STS304Document2 pagesDatasheet For Steel Grades Special Alloy STS304Thanakit Srisaeng100% (1)

- SS41Document3 pagesSS41Danifarrel NurhafizNo ratings yet

- M2 DatasheetDocument2 pagesM2 Datasheet025Syaro Fudin HusniNo ratings yet

- 50CrMo4 PDFDocument3 pages50CrMo4 PDFsaptotoNo ratings yet

- 3 CR 13Document3 pages3 CR 13Ali HashemiNo ratings yet

- Datasheet For Steel Grades Structure Steel 45HDocument2 pagesDatasheet For Steel Grades Structure Steel 45HZvonimir OpicNo ratings yet

- Datasheet For Steel Grades Specialsteel 06Cr25Ni20Document3 pagesDatasheet For Steel Grades Specialsteel 06Cr25Ni20nagmech07No ratings yet

- Datasheet For Steel Grades Carbon Steel Swrch6ADocument3 pagesDatasheet For Steel Grades Carbon Steel Swrch6AzaxaxazNo ratings yet

- 9SMnPb28 DatasheetDocument3 pages9SMnPb28 DatasheetVipul SharmaNo ratings yet

- Astm 4140 PDFDocument3 pagesAstm 4140 PDFRameshNo ratings yet

- Astm 4140Document3 pagesAstm 4140Ramiz KhanNo ratings yet

- 60CrMnMoA DatasheetDocument2 pages60CrMnMoA DatasheetKashif MohiuddinNo ratings yet

- Datasheet For Steel Grades Structure Steel 30crmntiDocument2 pagesDatasheet For Steel Grades Structure Steel 30crmntiAchmad MiftahNo ratings yet

- Datasheet For Steel Grades Tool Steel and Hard Alloy SKD11Document2 pagesDatasheet For Steel Grades Tool Steel and Hard Alloy SKD11Adhi candra irawan100% (1)

- Datasheet For Steel Grades Carbon Steel S70C-CSPDocument3 pagesDatasheet For Steel Grades Carbon Steel S70C-CSPMuhamad Syaiful AnwarNo ratings yet

- Aisi 1045 PDFDocument3 pagesAisi 1045 PDFvendi supendiNo ratings yet

- 26MoCr11 Datasheet PDFDocument3 pages26MoCr11 Datasheet PDFEugen PosticaNo ratings yet

- m3 C-Pillar ReinforcementDocument29 pagesm3 C-Pillar ReinforcementWilliam SouzaNo ratings yet

- Interior Painting WoodworksDocument7 pagesInterior Painting WoodworksanaNo ratings yet

- GrindingDocument50 pagesGrindinggillawatNo ratings yet

- Hulp Statistiek ThesisDocument8 pagesHulp Statistiek ThesiszxtccvgldNo ratings yet

- Piping Defects MynoteDocument4 pagesPiping Defects MynoteMuhammad ZariqNo ratings yet

- S.No Process Description Fixture Requirement Instruments and Gauges Inspection Criteria RecordsDocument5 pagesS.No Process Description Fixture Requirement Instruments and Gauges Inspection Criteria RecordsRavi BabaladiNo ratings yet

- SurTec Industrial Parts CleaningDocument2 pagesSurTec Industrial Parts CleaningHNo ratings yet

- 3d Printing ProcessDocument24 pages3d Printing ProcessvarunNo ratings yet

- SRM Nagar, Kattankulathur - 603 203: Prepared byDocument13 pagesSRM Nagar, Kattankulathur - 603 203: Prepared byrgopi_83No ratings yet

- Welding QuizDocument5 pagesWelding QuizHamza NoumanNo ratings yet

- Steel Data Ocr12Vm: IdentificationDocument4 pagesSteel Data Ocr12Vm: IdentificationzglogovNo ratings yet

- PTG 402 Litho 5Document7 pagesPTG 402 Litho 5Ahmad OlaiyaNo ratings yet

- Machine Mall - All PagesDocument6 pagesMachine Mall - All PagesGM Business DevelopmentNo ratings yet

- Centrifugal CastingDocument21 pagesCentrifugal CastingVishal VsNo ratings yet

- Lecture-6: Heat Treatment of Metals and Alloys - Importance Heat Treatment Processes NormalisingDocument47 pagesLecture-6: Heat Treatment of Metals and Alloys - Importance Heat Treatment Processes NormalisingSarojKumarSinghNo ratings yet

- 2.5 Chapter 5 - Processing - PlantDocument58 pages2.5 Chapter 5 - Processing - Plantperezbernaolaronaldodanielb201No ratings yet

- 2a1 Physics Spot WeldDocument25 pages2a1 Physics Spot WeldVikas SinghalNo ratings yet

- API 5L Pipe SpecDocument7 pagesAPI 5L Pipe SpecZainudinNo ratings yet

- Genral Arrangment of Pellet PlantDocument1 pageGenral Arrangment of Pellet PlantashiyNo ratings yet

- Opss-Prov 908 - 1998 - Construction Specification For Metal Railings For StructuresDocument9 pagesOpss-Prov 908 - 1998 - Construction Specification For Metal Railings For StructuresPubcrawlNo ratings yet

- An 15 Days Training in Casting IndustrialDocument27 pagesAn 15 Days Training in Casting IndustrialAmar Shete100% (1)

- Raw Materials For Steel MakingDocument10 pagesRaw Materials For Steel MakingsaileshNo ratings yet

- Wfbschools Middle School Homework HotlineDocument5 pagesWfbschools Middle School Homework Hotlineafmtbyuao100% (1)

- Diff Between Soldring and BrazingDocument2 pagesDiff Between Soldring and BrazingEr Gurdeep SinghNo ratings yet

- Jadwal Tentative INDOCOR 2019Document1 pageJadwal Tentative INDOCOR 2019Aswin Lorenzo GultomNo ratings yet

- M50-NF High Speed Steel Metaux-SolutionsDocument2 pagesM50-NF High Speed Steel Metaux-SolutionsLaurent MorgeNo ratings yet

- Steel MillDocument6 pagesSteel MillRenato Gigliotti MPhNo ratings yet

- Shaping & Grinding and Realated OperationsDocument26 pagesShaping & Grinding and Realated OperationsIzi86% (7)

- JNK Heaters Co - LTD: Ferrite Test ReportDocument1 pageJNK Heaters Co - LTD: Ferrite Test ReportUzorNo ratings yet

- U W CNC Lathe CNC Program ExamplesDocument30 pagesU W CNC Lathe CNC Program ExamplesTrần Xuân Thanh100% (1)