Professional Documents

Culture Documents

m3 C-Pillar Reinforcement

Uploaded by

William SouzaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

m3 C-Pillar Reinforcement

Uploaded by

William SouzaCopyright:

Available Formats

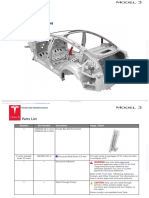

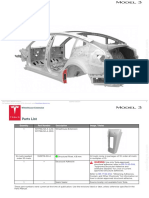

C-Pillar Reinforcement

TESLA BODY REPAIR MANUAL Updated: 28JUL17 1

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Parts List

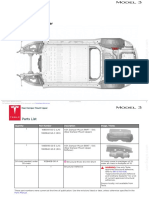

Quantity Part Number Description Image / Notes

1 1095027-S0-A (LH) C-Pillar Reinforcement

1095028-S0-A (RH)

The C-Pillar Reinforcement is listed in the Parts

Manual as the "C-Pillar Extension".

13 rivets needed; 1028719-00-A Structural Rivet, 4.8 mm All rivets come in packages of 10; order all rivets

order 20 rivets. in multiples of 10.

6 rivets needed; 1063943-00-A Structural Bulb Rivet, 6.5 mm All rivets come in packages of 10; order all rivets

order 10 rivets. in multiples of 10.

1 — Urethane Sealant WARNING: Use only Tesla-approved

urethane sealant; refer to BR-15-92-008,

"Approved Structural Adhesive and

Urethane Sealants" for a list of current

approved urethane sealants.

Refer to BR-17-92-002, "Obtaining Adhesives,

Coolant, and Other Chemicals" for information on

how to obtain approved urethane sealant.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 2

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

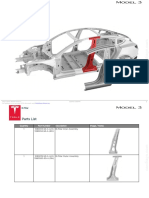

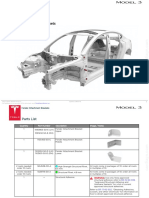

C-Pillar Reinforcement

Parts List

Quantity Part Number Description Image / Notes

1 — Structural Adhesive WARNING: Use only Tesla-approved

structural adhesive; refer to BR-15-92-008,

"Approved Structural Adhesive and

Urethane Sealants" for a list of current

approved structural adhesives.

Refer to BR-17-92-002, "Obtaining Adhesives,

Coolant, and Other Chemicals" for information on

how to obtain approved structural adhesive.

These part numbers were current at the time of publication. Use the revisions listed or later, unless otherwise specified in the

Parts Manual.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 3

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

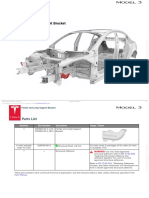

C-Pillar Reinforcement

Repair Information

Repair Information Warnings and Cautions Special Tools

This procedure is for the left-hand WARNING: Wear the appropriate The special tools listed below are

component; the procedure is identical for personal protective equipment required to perform this procedure:

the right-hand component. (PPE) when performing this • SPR removal tool

procedure. • Frame bench

CAUTION: This procedure involves The vehicle must be properly mounted

both steel and aluminum on an approved frame bench to

components. Use the appropriate replace this component. Refer to

tools at each step to avoid cross- BR-16-92-006, "Approved Frame

contamination. Bench Systems" for a list of current

approved bench repair systems.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 4

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Prerequisites

Remove the Quarter Outer Skin.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 5

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

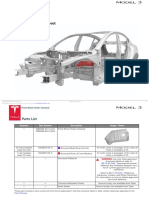

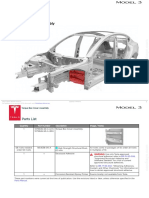

C-Pillar Reinforcement

Removal

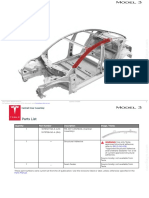

1

Identify the steel components and the aluminum components on the

vehicle.

Aluminum

Steel

CAUTION: Take the appropriate steps to minimize the cross-

contamination of steel and aluminum components during the repair.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 6

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Removal

2

Remove the original component.

A

Remove the foam dams from the original C-Pillar Reinforcement and

set them aside for use during installation.

NOTE: Keep the foam dams for reinstallation in a later step.

B

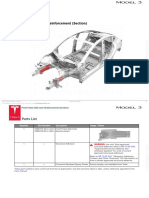

Identify the fasteners.

Factory Spot Weld (x15)

Factory SPR (x19)

NOTE: Factory spot weld locations shown are approximate. Exact

spot weld locations and number vary from vehicle to vehicle.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 7

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

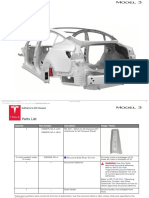

C-Pillar Reinforcement

Removal

2

Remove the original component (continued).

C

Use an SPR removal tool or a drill with a high-strength steel bit to

remove the factory self-piercing rivets. Use a belt sander for any

factory self-piercing rivets that cannot be removed with an SPR

removal tool or a drill.

Factory SPR (x19)

TESLA BODY REPAIR MANUAL Updated: 28JUL17 8

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Removal

2

Remove the original component (continued).

D

Use a drill with a spot weld bit to drill out the factory spot welds.

Factory Spot Weld (x15)

NOTE: Factory spot weld locations shown are approximate. Exact

spot weld locations and number vary from vehicle to vehicle.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 9

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Removal

2

Remove the original component (continued).

E

Use a heat gun to heat the adhesive joints, and then use a hammer

and chisel to remove the original component.

WARNING: Do not heat the adhesive joints above 100°C (212°F).

Heating the adhesive joints above 100°C (212°F) can weaken the

aluminum and compromise vehicle crash integrity.

WARNING: Do not heat any adhesive joints of components that are

not being removed. Heating adhesive joints weakens the adhesive

bond and could compromise vehicle crash integrity.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 10

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Removal

3

Use a disc sander with a medium-abrasive surface conditioning disc to

remove any remaining materials from the bond paths. Use a belt sander

with a medium-abrasive belt for any areas that cannot be reached with

a disc sander. Vacuum any adhesive dust.

WARNING: Remove the epoxy adhesive in a well-ventilated area. Wear

suitable personal protective equipment.

WARNING: Use only sanding wheels and belts that are 80 grit or finer

on aluminum components. Using sanding wheels or belts that are

coarser than 80 grit can cause fractures in the aluminum.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 11

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

1

Prepare for installation.

A

Put the new component into position and align it to the frame bench

jig points.

NOTE: If necessary, use a shim to account for the thickness of the

Quarter Outer Skin.

B

Clamp all areas where fasteners will not be installed.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 12

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

1

Prepare for installation (continued).

C

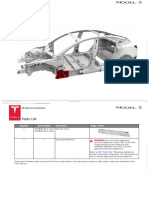

Mark the fastener locations on the new component.

Structural Rivet, 4.8 mm (x13)

Structural Bulb Rivet, 6.5 mm (x6)

TESLA BODY REPAIR MANUAL Updated: 28JUL17 13

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

1

Prepare for installation (continued).

D

Use a drill with a 4.8 mm (3/16 in) bit to drill holes for structural

rivets.

Structural Rivet, 4.8 mm (x13)

NOTE: If a location has remaining pieces of a factory SPR, drill the

hole from the back side of the panel to avoid drilling through the

remaining pieces of the factory SPR.

NOTE: Install a grip screw after drilling each hole to keep the panel

aligned while drilling the remaining holes.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 14

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

1

Prepare for installation (continued).

D

Use a drill with a 4.8 mm (3/16 in) bit to drill holes for structural

rivets (continued).

E

Use a drill with a 6.8 mm (17/64 in) bit to drill holes for structural

bulb rivets.

Structural Bulb Rivet, 6.5 mm (x6)

NOTE: If necessary, temporarily remove the gantry to drill any holes

that are not accessible with the gantry in place.

NOTE: Install a grip screw after drilling each hole to keep the panel

aligned while drilling the remaining holes.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 15

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

1

Prepare for installation (continued).

E

Use a drill with a 6.8 mm (17/64 in) bit to drill holes for structural

bulb rivets (continued).

F

Mark the steel-to-aluminum bond path areas on the new component.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 16

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

1

Prepare for installation (continued).

G

Mark the boundary path areas on the new component to indicate

where the new component does not contact the vehicle.

NOTE: Do not remove the e-coat from these areas.

H

Remove the new component.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 17

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

1

Prepare for installation (continued).

I

Mark the bond path areas on the new component. These areas will

be prepared for bonding in a later step.

TIP: Mark the panels in a way that delineates between the different

types of areas to be prepared.

2

Prepare the surfaces.

A

Use a red Scotch-Brite pad or equivalent to scuff the new

component in the steel-to-aluminum bond path areas.

Steel-to-Aluminum Bond Path

TESLA BODY REPAIR MANUAL Updated: 28JUL17 18

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

2

Prepare the surfaces (continued).

A

Use a red Scotch-Brite pad or equivalent to scuff the new

component in the steel-to-aluminum bond path areas (continued).

TESLA BODY REPAIR MANUAL Updated: 28JUL17 19

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

2

Prepare the surfaces (continued).

B

Use a disc sander with a medium-abrasive surface conditioning disc

to remove the e-coat on the new component in the bond path areas.

Use a belt sander with a medium-abrasive belt for any areas that

cannot be reached with a disc sander.

Aluminum-to-Aluminum Bond Path

WARNING: Remove the e-coat in a well-ventilated area. Wear

suitable personal protective equipment.

WARNING: Use only sanding wheels and belts that are 80 grit or

finer on aluminum components. Using sanding wheels or belts that

are coarser than 80 grit can cause fractures in the aluminum.

CAUTION: Within two hours of removing the e-coat or paint, cover

the abraded areas in the bond path with a thin primer layer of

structural adhesive. If the abraded areas are not primed within two

hours, they must be abraded again to remove any oxidation.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 20

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

2

Prepare the surfaces (continued).

B

Use a disc sander with a medium-abrasive surface conditioning disc

to remove the e-coat on the new component in the bond path areas.

Use a belt sander with a medium-abrasive belt for any areas that

cannot be reached with a disc sander (continued).

TESLA BODY REPAIR MANUAL Updated: 28JUL17 21

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

2

Prepare the surfaces (continued).

C

Clean all the bond paths on the new component or components and

on the vehicle with isopropyl alcohol (IPA).

WARNING: Wipe off the remaining isopropyl alcohol with a clean, dry

towel immediately after application. Do not let the remaining

isopropyl alcohol air dry. Allowing the remaining isopropyl alcohol to

air dry can compromise the adhesive bond.

3

Apply structural adhesive.

A

Spread a thin coating of structural adhesive as a primer layer on the

bond paths on the vehicle and the new component.

NOTE: Assembly must be performed while the primer layer is still

wet. The drying time of the adhesive varies depending on

temperature and humidity.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 22

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

3

Apply structural adhesive (continued).

B

While the primer layer is still wet, apply a bead of structural adhesive

on top of the primer layer on the new component.

4

Install the new component.

A

Put the new component into position and align it to the frame bench

jig points.

NOTE: If necessary, use a shim to account for the thickness of the

Quarter Outer Skin.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 23

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

4

Install the new component (continued).

A

Put the new component into position and align it to the frame bench

jig points (continued).

B

Insert the structural rivets and structural bulb rivets.

Structural Rivet, 4.8 mm (x8)

Structural Bulb Rivet, 6.5 mm (x6)

NOTE: The rivets can be inserted from outside the vehicle so that

they stay in place during alignment, but all rivets are installed from

inside the vehicle or from underneath the wheel well, as appropriate.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 24

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

4

Install the new component (continued).

B

Insert the structural rivets and structural bulb rivets (continued).

C

Clamp any area that is not secured with a fastener.

NOTE: Additional fasteners are installed in these areas when

installing the new Quarter Outer Skin.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 25

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

4

Install the new component (continued).

C

Clamp any area that is not secured with a fastener (continued).

D

Install the structural rivets and structural bulb rivets.

CAUTION: All rivets are installed from inside the vehicle or from

underneath the wheel well, as appropriate.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 26

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

4

Install the new component (continued).

E

Wipe off any excess adhesive.

F

Bake the structural adhesive so that the bonded panels reach a

temperature of 60°C–80°C (140°F–176°F) for at least 30 minutes to

achieve full strength.

WARNING: Do not allow the High Voltage Battery to reach a

temperature above 74°C (165°F). Heating the High Voltage Battery

above 74°C (165°F) for an extended period could result in injury to

personnel and/or damage to the battery.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 27

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

5

Reinstall the foam dams.

A

Apply urethane adhesive to the edge of the foam dams that were

removed in an earlier step.

B

Install the foam dams in the original locations.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 28

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

C-Pillar Reinforcement

Replacement

6

Install the new Quarter Outer Skin.

TESLA BODY REPAIR MANUAL Updated: 28JUL17 29

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

You might also like

- M3 Divider Bar ReinforcementDocument35 pagesM3 Divider Bar ReinforcementĐông NguyễnNo ratings yet

- B-Pillar: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 26SEP18 1Document64 pagesB-Pillar: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 26SEP18 1DongTaNo ratings yet

- Dash Crossmember: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 08FEB19 1Document13 pagesDash Crossmember: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 08FEB19 1Đông NguyễnNo ratings yet

- A-Pillar Outer Reinforcement (Complete)Document24 pagesA-Pillar Outer Reinforcement (Complete)DongTaNo ratings yet

- Shotgun Inner: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 30AUG18 1Document21 pagesShotgun Inner: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 30AUG18 1Đông NguyễnNo ratings yet

- Front Frame Rail Inner Reinforcement (Complete)Document29 pagesFront Frame Rail Inner Reinforcement (Complete)Dong NguyenNo ratings yet

- M3 Cantrail Extension InnerDocument22 pagesM3 Cantrail Extension InnerDongTaNo ratings yet

- M3 Fender and Lamp Support BracketDocument17 pagesM3 Fender and Lamp Support BracketĐông NguyễnNo ratings yet

- 02-M3 Shock Tower CloseoutDocument21 pages02-M3 Shock Tower CloseoutLinh VoNo ratings yet

- Wheelhouse Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 28JUL17Document28 pagesWheelhouse Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 28JUL17Hieu DvNo ratings yet

- M3 Fender Attachment BracketsDocument14 pagesM3 Fender Attachment BracketsĐông NguyễnNo ratings yet

- Fender Support BracketDocument13 pagesFender Support BracketDong NguyenNo ratings yet

- Shotgun Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 27JUL17Document26 pagesShotgun Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 27JUL17Đông Nguyễn100% (1)

- Sill Inner (Complete) : Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 13APR18Document40 pagesSill Inner (Complete) : Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 13APR18Đông NguyễnNo ratings yet

- Trunk Floor Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 01AUG17Document20 pagesTrunk Floor Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 01AUG17Hieu DvNo ratings yet

- M3 Torque Box Cover AssemblyDocument20 pagesM3 Torque Box Cover AssemblyHieu DvNo ratings yet

- m3 Subframe To Sill CloseoutDocument16 pagesm3 Subframe To Sill CloseoutWilliam SouzaNo ratings yet

- M3 - Rear Wheelhouse Rear StiffenerDocument17 pagesM3 - Rear Wheelhouse Rear StiffenerDongTaNo ratings yet

- 02-M3 Shotgun Tower PDFDocument35 pages02-M3 Shotgun Tower PDFLinh VoNo ratings yet

- 02-M3 Shotgun Outer PDFDocument26 pages02-M3 Shotgun Outer PDFLinh VoNo ratings yet

- M3 Fender Front Inner BracketDocument19 pagesM3 Fender Front Inner BracketĐông NguyễnNo ratings yet

- Front Frame Rail Inner (Large Front Section)Document38 pagesFront Frame Rail Inner (Large Front Section)Dong NguyenNo ratings yet

- Shotgun Shear Wall: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 15JAN18Document25 pagesShotgun Shear Wall: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 15JAN18Đông NguyễnNo ratings yet

- 02-M3 Shotgun Shear Wall PDFDocument25 pages02-M3 Shotgun Shear Wall PDFLinh VoNo ratings yet

- Shotgun Tower: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 25JAN18Document35 pagesShotgun Tower: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 25JAN18Đông NguyễnNo ratings yet

- M3 - Rear Wheelhouse Front StiffenerDocument17 pagesM3 - Rear Wheelhouse Front StiffenerDongTaNo ratings yet

- Subframe To Sill CloseoutDocument16 pagesSubframe To Sill CloseoutĐông NguyễnNo ratings yet

- 02-M3 Frunk BracketDocument15 pages02-M3 Frunk BracketLinh VoNo ratings yet

- M3 Cantrail Inner AssemblyDocument16 pagesM3 Cantrail Inner AssemblyDongTaNo ratings yet

- Toeboard Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 18APR19 1Document16 pagesToeboard Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 18APR19 1Hieu DvNo ratings yet

- M3 - Rear Damper Mount UpperDocument29 pagesM3 - Rear Damper Mount UpperDongTaNo ratings yet

- M3 Front Frame Rail Inner Reinforcement (Section)Document24 pagesM3 Front Frame Rail Inner Reinforcement (Section)Hieu DvNo ratings yet

- Sill Inner (Front Section)Document20 pagesSill Inner (Front Section)Đông NguyễnNo ratings yet

- Front Frame Rail Inner (Small Front Section)Document40 pagesFront Frame Rail Inner (Small Front Section)Dong NguyenNo ratings yet

- Sill Insert (Front Section)Document39 pagesSill Insert (Front Section)Đông NguyễnNo ratings yet

- Trunk Floor Assembly (Side Panel)Document23 pagesTrunk Floor Assembly (Side Panel)Hieu DvNo ratings yet

- m3 Charge Port Housing AssemblyDocument20 pagesm3 Charge Port Housing AssemblyWilliam SouzaNo ratings yet

- M3 Sill Outer (Front Section)Document120 pagesM3 Sill Outer (Front Section)Đông NguyễnNo ratings yet

- RT-135 Piston RingsDocument10 pagesRT-135 Piston Rings郑开元No ratings yet

- RT-137 - A1 Onboard Repair Kits and Order NumbersDocument6 pagesRT-137 - A1 Onboard Repair Kits and Order Numbers郑开元No ratings yet

- Body-M3 Symbols Used in The Body Repair ManualDocument8 pagesBody-M3 Symbols Used in The Body Repair ManualLinh VoNo ratings yet

- 05 Tyco TJRDocument6 pages05 Tyco TJRsamNo ratings yet

- RT 149 PDFDocument10 pagesRT 149 PDFRaul Diaz100% (1)

- Data & Specifications: 3299N030 4-Stroke EnginesDocument9 pagesData & Specifications: 3299N030 4-Stroke EnginesShadi MuhammedNo ratings yet

- Ipc1998-2028 - Repairing Pipe Defects Without Operational Outages With PetrosleeveDocument9 pagesIpc1998-2028 - Repairing Pipe Defects Without Operational Outages With PetrosleeveDietmar WengerNo ratings yet

- T-41/T-43 and ST-41/ST-43: Ptfe-Lined ValvesDocument12 pagesT-41/T-43 and ST-41/ST-43: Ptfe-Lined ValvesMauricioMoralesNo ratings yet

- Service Instructions PDFDocument13 pagesService Instructions PDFBrett GottliebNo ratings yet

- TDS 04 04 PIB 背钳扶正环Document6 pagesTDS 04 04 PIB 背钳扶正环xlzyydf2015No ratings yet

- Assembly Fluid 1 TDSDocument1 pageAssembly Fluid 1 TDSpokleNo ratings yet

- ManualDocument3 pagesManualRodrigo AbbaNo ratings yet

- RT-96 - Exhaust Valve Spindle LubricationDocument6 pagesRT-96 - Exhaust Valve Spindle LubricationGeorgios MariolisNo ratings yet

- 2RZ 3RZ SC PDFDocument21 pages2RZ 3RZ SC PDFUliAlejandroRodriguezCoriangaNo ratings yet

- ER-63 Fastener Torques For Reciprocating CompressorsDocument8 pagesER-63 Fastener Torques For Reciprocating CompressorsCarlos A. Mantilla J.No ratings yet

- A Size 10 × 4-5 Smooth-Tread Friction Test Tire: Standard Specification ForDocument5 pagesA Size 10 × 4-5 Smooth-Tread Friction Test Tire: Standard Specification ForEric GozzerNo ratings yet

- Service Letter: Hartzell Propeller Inc. HC-SL-61-239 Propeller - Slip Ring Split Mounting Plate Inspection and RepairDocument4 pagesService Letter: Hartzell Propeller Inc. HC-SL-61-239 Propeller - Slip Ring Split Mounting Plate Inspection and RepairQuezia PereiraNo ratings yet

- BHT - Technical Publications1Document13 pagesBHT - Technical Publications1Abner Colín QuijanoNo ratings yet

- Bettis CBA 300 Series Service ManualDocument15 pagesBettis CBA 300 Series Service ManualKenny BNo ratings yet

- E501 1113239-1Document4 pagesE501 1113239-1Sum BeautyNo ratings yet

- RT-258 - A1 - Inspection and Overhaul in - CleanedDocument13 pagesRT-258 - A1 - Inspection and Overhaul in - CleanedFaye BachtisNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Manual T400X4i R1Document4 pagesManual T400X4i R1William SouzaNo ratings yet

- Manual T35 - 0KWDocument8 pagesManual T35 - 0KWWilliam SouzaNo ratings yet

- m3 Subframe To Sill CloseoutDocument16 pagesm3 Subframe To Sill CloseoutWilliam SouzaNo ratings yet

- Manual Taramps T200x2 e T400x4 - A4Document8 pagesManual Taramps T200x2 e T400x4 - A4William SouzaNo ratings yet

- m3 Charge Port Housing AssemblyDocument20 pagesm3 Charge Port Housing AssemblyWilliam SouzaNo ratings yet

- Paccar 12-Speed Transmission Spec Sheet 2020Document2 pagesPaccar 12-Speed Transmission Spec Sheet 2020William SouzaNo ratings yet

- Smartlinq Remote Diagnostics Subscription Renewals 2019Document3 pagesSmartlinq Remote Diagnostics Subscription Renewals 2019William SouzaNo ratings yet

- Paccar Axle Operators ManualDocument20 pagesPaccar Axle Operators ManualWilliam SouzaNo ratings yet

- Smartnav Operator Manual 2016Document58 pagesSmartnav Operator Manual 2016William SouzaNo ratings yet

- Paccar Auto Start Stop Operators ManualDocument71 pagesPaccar Auto Start Stop Operators ManualWilliam SouzaNo ratings yet

- 004 - Enhanced Oil Recovery Willhite Capitulo 1Document12 pages004 - Enhanced Oil Recovery Willhite Capitulo 1Vanesa LunaNo ratings yet

- Energy and Mass Balance in The Pyrolysis Process oDocument8 pagesEnergy and Mass Balance in The Pyrolysis Process oAlvin IpNo ratings yet

- First Monography Operation in The AlchemDocument4 pagesFirst Monography Operation in The AlchemahmNo ratings yet

- Electric CircuitsDocument14 pagesElectric CircuitsPreet BassiNo ratings yet

- THE ION-Electron Method of BalancingDocument3 pagesTHE ION-Electron Method of BalancingDanluidQMalintadNo ratings yet

- Full Download Heat and Mass Transfer Si Edition 2nd Edition Rolle Solutions ManualDocument22 pagesFull Download Heat and Mass Transfer Si Edition 2nd Edition Rolle Solutions Manualretainalgrainascjy100% (39)

- How A Photon Is Created or AbsorbedDocument5 pagesHow A Photon Is Created or AbsorbedLucia LopezNo ratings yet

- Borates PresentationDocument20 pagesBorates Presentationpoly6icsNo ratings yet

- Calculating Relief Load For Liquids Near Critical TemperatureDocument3 pagesCalculating Relief Load For Liquids Near Critical TemperatureMoca PhoenixNo ratings yet

- Chemistry and Electricity:: ElectrochemistryDocument5 pagesChemistry and Electricity:: ElectrochemistrySuleman TariqNo ratings yet

- Force Law of MotionDocument2 pagesForce Law of MotionPrabodh GuptNo ratings yet

- Ashby Deformation Mechanism MapsDocument232 pagesAshby Deformation Mechanism MapsDaniel Eduardo Lescano100% (1)

- Chapter 37 PDFDocument48 pagesChapter 37 PDFZmarkz ZmarkzNo ratings yet

- SS1 Chemistry 2nd Term Lesson Note PDFDocument58 pagesSS1 Chemistry 2nd Term Lesson Note PDFKelly Isaac100% (3)

- Name-Avinash Upadhyay Class - M.SC. 3RD SEM. Roll No. - 04 Sub. - Ore Geology Session - 2019-2021 Year - 2021Document10 pagesName-Avinash Upadhyay Class - M.SC. 3RD SEM. Roll No. - 04 Sub. - Ore Geology Session - 2019-2021 Year - 2021Avinash UpadhyayNo ratings yet

- Studies On Bound Water in PvaDocument4 pagesStudies On Bound Water in PvasggdgdNo ratings yet

- A New Synthetic Method For The Preparation of 5-Deazaflavins and 5-Deaza-10-OxaflavinsDocument2 pagesA New Synthetic Method For The Preparation of 5-Deazaflavins and 5-Deaza-10-OxaflavinsThéoNo ratings yet

- Electric Bell AnsDocument4 pagesElectric Bell AnsManishaNo ratings yet

- Wastewater - Types, Characteristics & RegulationDocument50 pagesWastewater - Types, Characteristics & Regulationsam samNo ratings yet

- Clean Soil and Dirty SoilDocument4 pagesClean Soil and Dirty SoilRamces Soliman100% (2)

- Zonyl FSO PDFDocument2 pagesZonyl FSO PDFarguijNo ratings yet

- Act 3 ConclusionDocument13 pagesAct 3 ConclusionVon A. DamirezNo ratings yet

- CHE 176 Complete SlideDocument606 pagesCHE 176 Complete Slideolawandeilo123No ratings yet

- NEET Some Basic Concepts of Chemistry Important QuestionsDocument27 pagesNEET Some Basic Concepts of Chemistry Important QuestionsJiya KhanNo ratings yet

- Testing The Hardness of WaterDocument3 pagesTesting The Hardness of Wateralexduart01No ratings yet

- Trico Bond EpDocument2 pagesTrico Bond EpBrandon TrocNo ratings yet

- BiocoagulantDocument15 pagesBiocoagulantNed CarterNo ratings yet

- Types of MeteoritesDocument2 pagesTypes of MeteoritesJoel SamsonNo ratings yet

- STP Presentation by JeffconDocument45 pagesSTP Presentation by JeffconCHIN FelleNo ratings yet

- 6323 12101 1 SMDocument7 pages6323 12101 1 SMElna PurwantiNo ratings yet