Professional Documents

Culture Documents

02-M3 Shotgun Shear Wall PDF

Uploaded by

Linh VoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02-M3 Shotgun Shear Wall PDF

Uploaded by

Linh VoCopyright:

Available Formats

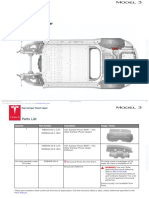

Shotgun Shear Wall

TESLA BODY REPAIR MANUAL Updated: 15JAN18 1

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Parts List

Quantity Part Number Description Image / Notes

1 1103456-S0-A (LH) Shotgun Shear Wall

1103457-S0-A (RH)

16 rivets needed; 1062559-00-A Structural Rivet, 6.5 mm All rivets come in packages of 10; order all rivets

order 20 rivets Medium in multiples of 10.

1 — Structural Adhesive WARNING: Use only Tesla-approved

structural adhesive; refer to BR-15-92-008,

"Approved Structural Adhesive and

Urethane Sealants" for a list of current

approved structural adhesives.

Refer to BR-17-92-002, "Obtaining Adhesives,

Coolant, and Other Chemicals" for information on

how to obtain approved structural adhesive.

1 — Corrosion-Resistant Epoxy Primer Source locally; not available from Tesla.

These part numbers were current at the time of publication. Use the revisions listed or later, unless otherwise specified in the

Parts Manual.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 2

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Repair Information

Repair Information Warnings and Cautions Special Tools

This procedure is for the left-hand WARNING: Wear the appropriate The special tool listed below is required

component; the procedure is identical for personal protective equipment to perform this procedure:

the right-hand component. (PPE) when performing this

procedure. • Resistance Spot Welder

The photos show a repair where the

Shotgun Inner has been removed, but CAUTION: This procedure involves Use only an approved resistance spot

this procedure can be performed with only steel components. Use the welder. Refer to BR-16-92-007,

the Shotgun Inner in place. appropriate tools to avoid cross- "Approved Welders" for a list of

contamination. current approved resistance spot

welders.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 3

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Prerequisites

1

Disconnect 12V and high voltage power (refer to the appropriate

section in BR-17-17-004, "Disconnecting 12V and High Voltage Power on

Model 3").

WARNING: Before disconnecting the 12V power supply, make sure that

all windows are at least slightly open. Attempting to open a door with a

fully-closed window when the 12V power supply is disconnected could

result in door glass shatter.

NOTE: Before disconnecting the 12V power supply, make sure that the

driver’s door window is fully open. Failure to lower the driver's door

window before disconnecting the 12V power supply could result in

vehicle lockout.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 4

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Prerequisites

2

Remove the Shotgun Tower.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 5

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Removal

1

Remove the original component.

A

Cut away the bulk of the original component.

Cut Line

B

Use a drill with a 6.7 mm (17/64 in) bit to drill completely through

the factory spot welds shown.

Factory Spot Weld (x2)

NOTE: Structural bulb rivets will be installed in these locations in a

later step.

NOTE: Factory spot weld locations shown are approximate. Exact

spot weld locations and number vary from vehicle to vehicle.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 6

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Removal

1

Remove the original component (continued).

C

Use a drill with a spot weld bit to drill out the remaining factory

spot welds.

Factory Spot Weld

NOTE: Factory spot weld locations shown are approximate. Exact

spot weld locations and number vary from vehicle to vehicle.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 7

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Removal

1

Remove the original component (continued).

C

Use a drill with a spot weld bit to drill out the remaining factory

spot welds (continued).

TESLA BODY REPAIR MANUAL Updated: 15JAN18 8

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Removal

1

Remove the original component (continued).

D

Use a heat gun to heat the adhesive joints, and then use a hammer

and chisel to remove the remaining pieces of the original

component.

WARNING: Do not heat any adhesive joints of components that are

not being removed. Heating adhesive joints weakens the adhesive

bond and could compromise vehicle crash integrity.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 9

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Removal

2

Use a disc sander with a medium-abrasive surface conditioning disc to

remove any remaining materials from the bond paths. Use a belt sander

with a medium-abrasive belt for any areas that cannot be reached with

a disc sander. Vacuum any adhesive dust.

WARNING: Remove the epoxy adhesive in a well-ventilated area. Wear

suitable personal protective equipment.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 10

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

1

Prepare for installation.

A

Put the new component into position and clamp it into place.

B

Mark the locations for structural rivets.

Structural Rivet, 6.5 mm Medium (x16)

NOTE: Make sure to mark the rivet location circled in green so that it

does not interfere with the installation of the Shotgun Tower.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 11

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

1

Prepare for installation (continued).

B

Mark the locations for structural rivets (continued).

C

Use a drill with a 6.7 mm (17/64 in) bit to drill holes for structural

rivets.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 12

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

1

Prepare for installation (continued).

D

Mark the bond path areas and weld areas on the new component

and the vehicle. These areas will be prepared for bonding and

welding in the next step.

E

Remove the new component.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 13

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

1

Prepare for installation (continued).

F

Mark the bond path areas on the new component and the vehicle.

These areas will be prepared for bonding in the next step.

Steel-to-Steel Bond Path

TESLA BODY REPAIR MANUAL Updated: 15JAN18 14

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

1

Prepare for installation (continued).

F

Mark the bond path areas on the new component and the vehicle.

These areas will be prepared for bonding in the next step

(continued).

TESLA BODY REPAIR MANUAL Updated: 15JAN18 15

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

1

Prepare for installation (continued).

F

Mark the bond path areas on the new component and the vehicle.

These areas will be prepared for bonding in the next step

(continued).

TESLA BODY REPAIR MANUAL Updated: 15JAN18 16

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

2

Prepare the surfaces.

A

Use a red Scotch-Brite pad or equivalent to scuff the e-coat on the

inside surfaces of the Shotgun Inner and the Front Shock Tower in

the bond path area.

Steel-to-Steel Bond Path

B

Use a red Scotch-Brite pad or equivalent to scuff the e-coat on the

new component and on the vehicle in the bond path areas.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 17

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

2

Prepare the surfaces (continued).

C

Mark the locations for resistance spot welds.

Installation Spot Weld (x2)

TESLA BODY REPAIR MANUAL Updated: 15JAN18 18

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

2

Prepare the surfaces (continued).

C

Mark the locations for resistance spot welds (continued).

D

Use a disc sander with a medium-abrasive surface conditioning disc

to remove the e-coat on the new component and on the vehicle in

the weld areas. Use a belt sander with a medium-abrasive belt for

any areas that cannot be reached with a disc sander.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 19

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

2

Prepare the surfaces (continued).

E

Clean all the bond paths and weld areas on the new component or

components and on the vehicle with isopropyl alcohol (IPA).

WARNING: Wipe off the remaining isopropyl alcohol with a clean,

dry towel immediately after application. Do not let the remaining

isopropyl alcohol air dry. Allowing the remaining isopropyl alcohol to

air dry can compromise the adhesive bond.

3

Apply structural adhesive.

A

Spread a thin coating of structural adhesive as a primer layer on the

bond paths on the vehicle and the new component.

NOTE: Assembly must be performed while the primer layer is still

wet. The drying time of the adhesive varies depending on

temperature and humidity.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 20

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

3

Apply structural adhesive (continued).

B

While the primer layer is still wet, apply a bead of structural

adhesive on top of the primer layer on the new component.

4

Install the new component.

A

Put the new component into position and clamp it into place.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 21

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

4

Install the new component (continued).

B

Insert the structural rivets, and then install them.

Structural Rivet, 6.5 mm Medium (x16)

TESLA BODY REPAIR MANUAL Updated: 15JAN18 22

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

4

Install the new component (continued).

C

Perform resistance spot welding.

Installation Spot Weld (x2)

WARNING: Failure to follow all welding safety precautions, including

the use of personal protective equipment, could result in serious

injury or property damage. Only technicians who have successfully

met Tesla’s requirements for welding training are authorized to weld

structural components on Tesla vehicles.

CAUTION: Do not weld on a Tesla vehicle with an energized high

voltage or 12V system. Welding on a Tesla vehicle with an energized

high voltage or 12V system might damage vehicle components.

CAUTION: Use only insulated clamps within 200 mm (8 in) of

resistance spot weld locations. Do not perform resistance spot

welding when there is an uninsulated clamp within 200 mm (8 in) of

the spot weld location.

D

Prime any bare metal with a suitable corrosion-resistant epoxy

primer.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 23

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

4

Install the new component (continued).

E

Clamp the areas that are not secured with fasteners.

F

Bake the structural adhesive so that the bonded panels reach a

temperature of 60°C–80°C (140°F–176°F) for at least 30 minutes to

achieve full strength.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 24

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Shotgun Shear Wall

Replacement

5

Remove the clamps.

6

Install the new Shotgun Tower.

TESLA BODY REPAIR MANUAL Updated: 15JAN18 25

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

You might also like

- DTA Guidelines For Repairs and AlterationsDocument55 pagesDTA Guidelines For Repairs and Alterationsskullmac100% (1)

- E2751 Design Laminated Glass WalkwaysDocument3 pagesE2751 Design Laminated Glass WalkwaysDon ZNo ratings yet

- Foundation PilesDocument123 pagesFoundation PilesPravindNo ratings yet

- 15 - DTA Guidelines For Repairs and AltertaionsDocument55 pages15 - DTA Guidelines For Repairs and AltertaionsskullmacNo ratings yet

- Shotgun Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 27JUL17Document26 pagesShotgun Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 27JUL17Đông Nguyễn100% (1)

- Astm F959-09Document5 pagesAstm F959-09Nhật NguyễnNo ratings yet

- Sill Inner (Complete) : Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 13APR18Document40 pagesSill Inner (Complete) : Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 13APR18Đông NguyễnNo ratings yet

- M3 Front Frame Rail Inner Reinforcement (Section)Document24 pagesM3 Front Frame Rail Inner Reinforcement (Section)Hieu DvNo ratings yet

- Bolt Torque & Bolt Tap TestDocument20 pagesBolt Torque & Bolt Tap Testbudymood100% (3)

- Section 1600: © 2003 AWI/AWMAC - 8th Edition Quality StandardsDocument16 pagesSection 1600: © 2003 AWI/AWMAC - 8th Edition Quality StandardsAnthony Thaddeus AntonioNo ratings yet

- Astm A325-2014 PDFDocument8 pagesAstm A325-2014 PDFMuhammad Reza SeptyansyahNo ratings yet

- Steelwise PDFDocument3 pagesSteelwise PDFrohalestatNo ratings yet

- Compressible-Washer-Type Direct Tension Indicators For Use With Structural FastenersDocument5 pagesCompressible-Washer-Type Direct Tension Indicators For Use With Structural FastenersDarwin DarmawanNo ratings yet

- Chapter 23. Concrete Building Systems 21.11.08Document94 pagesChapter 23. Concrete Building Systems 21.11.08Hasanain GaltanNo ratings yet

- Shotgun Shear Wall: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 15JAN18Document25 pagesShotgun Shear Wall: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 15JAN18Đông NguyễnNo ratings yet

- 02-M3 Shotgun Outer PDFDocument26 pages02-M3 Shotgun Outer PDFLinh VoNo ratings yet

- 02-M3 Shock Tower CloseoutDocument21 pages02-M3 Shock Tower CloseoutLinh VoNo ratings yet

- Shotgun Inner: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 30AUG18 1Document21 pagesShotgun Inner: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 30AUG18 1Đông NguyễnNo ratings yet

- 02-M3 Shotgun Tower PDFDocument35 pages02-M3 Shotgun Tower PDFLinh VoNo ratings yet

- Shotgun Tower: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 25JAN18Document35 pagesShotgun Tower: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 25JAN18Đông NguyễnNo ratings yet

- A-Pillar Outer Reinforcement (Complete)Document24 pagesA-Pillar Outer Reinforcement (Complete)DongTaNo ratings yet

- M3 Divider Bar ReinforcementDocument35 pagesM3 Divider Bar ReinforcementĐông NguyễnNo ratings yet

- M3 Torque Box Cover AssemblyDocument20 pagesM3 Torque Box Cover AssemblyHieu DvNo ratings yet

- M3 Fender and Lamp Support BracketDocument17 pagesM3 Fender and Lamp Support BracketĐông NguyễnNo ratings yet

- Sill Inner (Front Section)Document20 pagesSill Inner (Front Section)Đông NguyễnNo ratings yet

- m3 Subframe To Sill CloseoutDocument16 pagesm3 Subframe To Sill CloseoutWilliam SouzaNo ratings yet

- 02-M3 Frunk BracketDocument15 pages02-M3 Frunk BracketLinh VoNo ratings yet

- B-Pillar: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 26SEP18 1Document64 pagesB-Pillar: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 26SEP18 1DongTaNo ratings yet

- Front Frame Rail Inner (Small Front Section)Document40 pagesFront Frame Rail Inner (Small Front Section)Dong NguyenNo ratings yet

- Front Frame Rail Inner Reinforcement (Complete)Document29 pagesFront Frame Rail Inner Reinforcement (Complete)Dong NguyenNo ratings yet

- Front Frame Rail Inner (Large Front Section)Document38 pagesFront Frame Rail Inner (Large Front Section)Dong NguyenNo ratings yet

- M3 Fender Front Inner BracketDocument19 pagesM3 Fender Front Inner BracketĐông NguyễnNo ratings yet

- m3 C-Pillar ReinforcementDocument29 pagesm3 C-Pillar ReinforcementWilliam SouzaNo ratings yet

- M3 Fender Attachment BracketsDocument14 pagesM3 Fender Attachment BracketsĐông NguyễnNo ratings yet

- M3 Cantrail Inner AssemblyDocument16 pagesM3 Cantrail Inner AssemblyDongTaNo ratings yet

- Wheelhouse Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 28JUL17Document28 pagesWheelhouse Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 28JUL17Hieu DvNo ratings yet

- Trunk Floor Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 01AUG17Document20 pagesTrunk Floor Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 01AUG17Hieu DvNo ratings yet

- Dash Crossmember: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 08FEB19 1Document13 pagesDash Crossmember: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 08FEB19 1Đông NguyễnNo ratings yet

- M3 - Rear Wheelhouse Rear StiffenerDocument17 pagesM3 - Rear Wheelhouse Rear StiffenerDongTaNo ratings yet

- M3 - Rear Wheelhouse Front StiffenerDocument17 pagesM3 - Rear Wheelhouse Front StiffenerDongTaNo ratings yet

- M3 Cantrail Extension InnerDocument22 pagesM3 Cantrail Extension InnerDongTaNo ratings yet

- Toeboard Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 18APR19 1Document16 pagesToeboard Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 18APR19 1Hieu DvNo ratings yet

- Subframe To Sill CloseoutDocument16 pagesSubframe To Sill CloseoutĐông NguyễnNo ratings yet

- Trunk Floor Assembly (Side Panel)Document23 pagesTrunk Floor Assembly (Side Panel)Hieu DvNo ratings yet

- M3 - Rear Damper Mount UpperDocument29 pagesM3 - Rear Damper Mount UpperDongTaNo ratings yet

- Fender Support BracketDocument13 pagesFender Support BracketDong NguyenNo ratings yet

- M3 Sill Outer (Front Section)Document120 pagesM3 Sill Outer (Front Section)Đông NguyễnNo ratings yet

- Sill Insert (Front Section)Document39 pagesSill Insert (Front Section)Đông NguyễnNo ratings yet

- m3 Charge Port Housing AssemblyDocument20 pagesm3 Charge Port Housing AssemblyWilliam SouzaNo ratings yet

- 05 Tyco TJRDocument6 pages05 Tyco TJRsamNo ratings yet

- Body-M3 Symbols Used in The Body Repair ManualDocument8 pagesBody-M3 Symbols Used in The Body Repair ManualLinh VoNo ratings yet

- ASTM F 959 Standard Specification For Compressible-Washer-Type Direct Tension Indicators For Use With Structural FastenersDocument4 pagesASTM F 959 Standard Specification For Compressible-Washer-Type Direct Tension Indicators For Use With Structural FastenersILSEN N. DAETNo ratings yet

- Printed in GermanyDocument222 pagesPrinted in GermanyGilberto GonzalezNo ratings yet

- A325-Twist of BoltDocument6 pagesA325-Twist of BoltPham NhatNo ratings yet

- Fastener Torques For Reciprocating Compressors: Engineering ReferenceDocument8 pagesFastener Torques For Reciprocating Compressors: Engineering ReferenceTomy lee youngNo ratings yet

- ER-63 Fastener Torques For Reciprocating CompressorsDocument8 pagesER-63 Fastener Torques For Reciprocating CompressorsCarlos A. Mantilla J.No ratings yet

- Structural Bolts, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthDocument8 pagesStructural Bolts, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthPlinio LavinasNo ratings yet

- GSB 450-2-1-0-3-0Document10 pagesGSB 450-2-1-0-3-0Łukasz OlszewskiNo ratings yet

- Technical Data Sheet Medium Strength Threadlocker Blue: Toll Free: 87 PERMATEX (877-376-2839)Document3 pagesTechnical Data Sheet Medium Strength Threadlocker Blue: Toll Free: 87 PERMATEX (877-376-2839)VictorNo ratings yet

- Calibrated Wrench DownloadDocument7 pagesCalibrated Wrench DownloadAnonyNo ratings yet

- C 1461 - 00 - Qze0njetukveDocument4 pagesC 1461 - 00 - Qze0njetukveSamuel EduardoNo ratings yet

- Planta Dosificadora ODISA Modelo 5000 de 50-75m3.hDocument3 pagesPlanta Dosificadora ODISA Modelo 5000 de 50-75m3.hVictor A. RamosNo ratings yet

- Earth Quake Resistant StructureDocument21 pagesEarth Quake Resistant StructureMinsha SalimNo ratings yet

- Asa S12.51Document22 pagesAsa S12.51ozgurNo ratings yet

- File 1441Document5 pagesFile 1441ContractsNo ratings yet

- Mason E0010Document24 pagesMason E0010SandeepNo ratings yet

- Calcium Bare - CPDocument3 pagesCalcium Bare - CPa73806780No ratings yet

- CEMFOAMDocument2 pagesCEMFOAMOsama Abu ShalthamNo ratings yet

- Quality of Installation Manual: WWW - Yahsat.aeDocument59 pagesQuality of Installation Manual: WWW - Yahsat.aeDavidNo ratings yet

- Literature Review Lathe MachineDocument5 pagesLiterature Review Lathe Machinecmppcmwgf100% (1)

- Zodiac Milpro - SRR 420Document2 pagesZodiac Milpro - SRR 420Sebastian RentschNo ratings yet

- Site Development Plan/ Roof Plan A 1-2 Exterior Perspective A 2-2Document1 pageSite Development Plan/ Roof Plan A 1-2 Exterior Perspective A 2-2Angelica MendozaNo ratings yet

- Installation Instructions SimoprimeDocument41 pagesInstallation Instructions SimoprimeJohn PalacioNo ratings yet

- S2214785323044796 MainDocument10 pagesS2214785323044796 MainVincent P. PilienNo ratings yet

- Pol of AhmedabadDocument18 pagesPol of Ahmedabadhudco kaamNo ratings yet

- BoqDocument18 pagesBoqkunal humane0% (1)

- Architecture Ppt.1Document53 pagesArchitecture Ppt.1centNo ratings yet

- Steel I-Girder Composite Bridge PDFDocument48 pagesSteel I-Girder Composite Bridge PDFShamaNo ratings yet

- Elevation..retail StoreDocument1 pageElevation..retail Storesri vidhya AmbikaNo ratings yet

- LONG Wo EXAM-Q3-TLE 10Document4 pagesLONG Wo EXAM-Q3-TLE 10Hajie RosarioNo ratings yet

- SYNTRAN MT241 Technical Data SheetDocument1 pageSYNTRAN MT241 Technical Data SheetEdgardo VillaNo ratings yet

- Camd Lab ManualDocument95 pagesCamd Lab ManualK.S.HARIHARANNo ratings yet

- Interior Design: Interior of A Living Room-Classicism Bachelor of Architecture Barch-Ii Sem-IvDocument11 pagesInterior Design: Interior of A Living Room-Classicism Bachelor of Architecture Barch-Ii Sem-IvA-16 RUSHALINo ratings yet

- Method Statement For Mineral Fiber Tiles: Sandvik PVT LTD, Dapodi, PuneDocument3 pagesMethod Statement For Mineral Fiber Tiles: Sandvik PVT LTD, Dapodi, PuneParasNo ratings yet

- Bill of QuantitiesDocument64 pagesBill of QuantitiesshahidNo ratings yet

- Satish Paint PDFDocument26 pagesSatish Paint PDFCRAZY ARCHINo ratings yet

- Types of Grilling Materials: Submitted by - DigangganaDocument18 pagesTypes of Grilling Materials: Submitted by - DigangganaDiganggana BharadwajNo ratings yet

- Table Loom 16 ShaftDocument15 pagesTable Loom 16 ShaftCK RichardNo ratings yet