Professional Documents

Culture Documents

02-M3 Frunk Bracket

02-M3 Frunk Bracket

Uploaded by

Linh VoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02-M3 Frunk Bracket

02-M3 Frunk Bracket

Uploaded by

Linh VoCopyright:

Available Formats

Frunk Bracket

TESLA BODY REPAIR MANUAL Updated: 10OCT17 1

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Frunk Bracket

Parts List

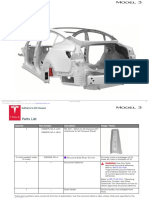

Quantity Part Number Description Image / Notes

1 1105305-S0-A Frunk Bracket

2 rivets needed; 1028719-00-A Structural Rivet, 4.8 mm All rivets come in packages of 10; order all rivets

order 10 rivets in multiples of 10.

1 — Structural Adhesive WARNING: Use only Tesla-approved

structural adhesive; refer to BR-15-92-008,

"Approved Structural Adhesive and

Urethane Sealants" for a list of current

approved structural adhesives.

Refer to BR-17-92-002, "Obtaining Adhesives,

Coolant, and Other Chemicals" for information on

how to obtain approved structural adhesive.

1 — Corrosion-Resistant Primer Source locally; not available from Tesla.

These part numbers were current at the time of publication. Use the revisions listed or later, unless otherwise specified in the

Parts Manual.

TESLA BODY REPAIR MANUAL Updated: 10OCT17 2

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Frunk Bracket

Repair Information

Repair Information Warnings and Cautions Special Tools

This procedure is for the left-hand WARNING: Wear the appropriate No special tools are required to perform

component; the procedure is identical for personal protective equipment this procedure.

the right-hand component. (PPE) when performing this

procedure.

CAUTION: This procedure involves

only steel components. Use the

appropriate tools to avoid cross-

contamination.

TESLA BODY REPAIR MANUAL Updated: 10OCT17 3

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Frunk Bracket

Prerequisites

No welded, riveted, or bonded panels need to be removed prior to

performing this procedure.

TESLA BODY REPAIR MANUAL Updated: 10OCT17 4

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Frunk Bracket

Removal

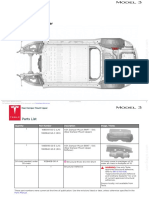

1

Remove the original component.

A

Trace the outline of the original component to aid in installation in a

later step.

B

Use a belt sander to sand down the factory spot welds, or use a drill

with a spot weld bit to drill them out.

Factory Spot Weld (x2)

NOTE: Factory spot weld locations shown are approximate. Exact

spot weld locations and number vary from vehicle to vehicle.

TESLA BODY REPAIR MANUAL Updated: 10OCT17 5

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Frunk Bracket

Removal

1

Remove the original component (continued).

B

Use a belt sander to sand down the factory spot welds, or use a drill

with a spot weld bit to drill them out (continued).

C

Remove the original component.

TESLA BODY REPAIR MANUAL Updated: 10OCT17 6

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Frunk Bracket

Removal

2

Use a disc sander with a medium-abrasive surface conditioning disc to

remove any remaining materials from the bond paths. Use a belt sander

with a medium-abrasive belt for any areas that cannot be reached with

a disc sander. Vacuum any adhesive dust.

TESLA BODY REPAIR MANUAL Updated: 10OCT17 7

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Frunk Bracket

Replacement

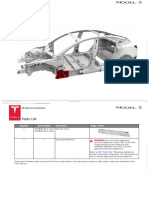

1

Prepare for installation.

A

Put the new component into position and clamp it into place.

NOTE: Use the outline traced in an earlier step to aid in installation.

B

Use a drill with a 4.8 mm (3/16 in) bit to drill holes for structural

rivets.

Structural Rivet, 4.8 mm (x2)

TESLA BODY REPAIR MANUAL Updated: 10OCT17 8

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Frunk Bracket

Replacement

1

Prepare for installation (continued).

B

Use a drill with a 4.8 mm (3/16 in) bit to drill holes for structural

rivets (continued).

C

Remove the new component.

TESLA BODY REPAIR MANUAL Updated: 10OCT17 9

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Frunk Bracket

Replacement

2

Prepare the surfaces.

A

Use a disc sander with a medium-abrasive surface conditioning disc

to remove the e-coat on the new component and on the vehicle in

the bond path areas. Use a belt sander with a medium-abrasive belt

for any areas that cannot be reached with a disc sander.

WARNING: Remove the e-coat in a well-ventilated area. Wear

suitable personal protective equipment.

TESLA BODY REPAIR MANUAL Updated: 10OCT17 10

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Frunk Bracket

Replacement

2

Prepare the surfaces (continued).

B

Clean all the bond paths on the new component or components and

on the vehicle with isopropyl alcohol (IPA).

WARNING: Wipe off the remaining isopropyl alcohol with a clean, dry

towel immediately after application. Do not let the remaining

isopropyl alcohol air dry. Allowing the remaining isopropyl alcohol to

air dry can compromise the adhesive bond.

3

Apply structural adhesive.

A

Spread a thin coating of structural adhesive as a primer layer on the

bond paths on the vehicle and the new component.

NOTE: Assembly must be performed while the primer layer is still

wet. The drying time of the adhesive varies depending on

temperature and humidity.

TESLA BODY REPAIR MANUAL Updated: 10OCT17 11

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Frunk Bracket

Replacement

3

Apply structural adhesive (continued).

B

While the primer layer is still wet, apply a bead of structural adhesive

on top of the primer layer on the new component.

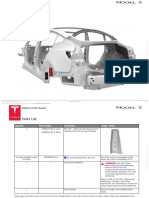

4

Install the new component.

A

Put the new component into position and insert the structural rivets

to align the new component.

Structural Rivet, 4.8 mm (x2)

TESLA BODY REPAIR MANUAL Updated: 10OCT17 12

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Frunk Bracket

Replacement

4

Install the new component (continued).

A

Put the new component into position and insert the structural rivets

to align the new component (continued).

B

Install the structural rivets.

TESLA BODY REPAIR MANUAL Updated: 10OCT17 13

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Frunk Bracket

Replacement

4

Install the new component (continued).

C

Wipe off any excess adhesive.

D

Bake the structural adhesive so that the bonded panels reach a

temperature of 60°C–80°C (140°F–176°F) for at least 30 minutes to

achieve full strength.

WARNING: Do not allow the High Voltage Battery to reach a

temperature above 74°C (165°F). Heating the High Voltage Battery

above 74°C (165°F) for an extended period could result in injury to

personnel and/or damage to the battery.

TESLA BODY REPAIR MANUAL Updated: 10OCT17 14

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Frunk Bracket

Replacement

5

Prime any bare metal with a suitable corrosion-resistant primer.

TESLA BODY REPAIR MANUAL Updated: 10OCT17 15

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

You might also like

- Hall Ticket IgnouDocument1 pageHall Ticket IgnouPranjalGoelNo ratings yet

- Router 6000 R17 Operation and Maintenance: Solution To ExercisesDocument84 pagesRouter 6000 R17 Operation and Maintenance: Solution To ExercisesAhsanSaleemNo ratings yet

- 2007 - Isuzu - NPR - W3500, NPR HD - W4500, NQR - W5500 Diesel Electric - 46 PDFDocument24 pages2007 - Isuzu - NPR - W3500, NPR HD - W4500, NQR - W5500 Diesel Electric - 46 PDFPhil B.100% (2)

- Astm D3139Document3 pagesAstm D3139Hernando Andrés Ramírez GilNo ratings yet

- M3 Front Frame Rail Inner Reinforcement (Section)Document24 pagesM3 Front Frame Rail Inner Reinforcement (Section)Hieu DvNo ratings yet

- Shotgun Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 27JUL17Document26 pagesShotgun Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 27JUL17Đông Nguyễn100% (1)

- ASME PCC-1 - 2013 Guidelines For Pressure Boundary Bolted Flange Joint AssemblyDocument4 pagesASME PCC-1 - 2013 Guidelines For Pressure Boundary Bolted Flange Joint AssemblyIrshad AhmadNo ratings yet

- Chilled Water PipingDocument34 pagesChilled Water Pipingapi-2599951798% (50)

- M3 Fender and Lamp Support BracketDocument17 pagesM3 Fender and Lamp Support BracketĐông NguyễnNo ratings yet

- M3 Torque Box Cover AssemblyDocument20 pagesM3 Torque Box Cover AssemblyHieu DvNo ratings yet

- M3 Fender Front Inner BracketDocument19 pagesM3 Fender Front Inner BracketĐông NguyễnNo ratings yet

- 02-M3 Shock Tower CloseoutDocument21 pages02-M3 Shock Tower CloseoutLinh VoNo ratings yet

- M3 Divider Bar ReinforcementDocument35 pagesM3 Divider Bar ReinforcementĐông NguyễnNo ratings yet

- Wheelhouse Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 28JUL17Document28 pagesWheelhouse Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 28JUL17Hieu DvNo ratings yet

- M3 Fender Attachment BracketsDocument14 pagesM3 Fender Attachment BracketsĐông NguyễnNo ratings yet

- 02-M3 Shotgun Shear Wall PDFDocument25 pages02-M3 Shotgun Shear Wall PDFLinh VoNo ratings yet

- Trunk Floor Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 01AUG17Document20 pagesTrunk Floor Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 01AUG17Hieu DvNo ratings yet

- 02-M3 Shotgun Outer PDFDocument26 pages02-M3 Shotgun Outer PDFLinh VoNo ratings yet

- m3 C-Pillar ReinforcementDocument29 pagesm3 C-Pillar ReinforcementWilliam SouzaNo ratings yet

- Shotgun Shear Wall: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 15JAN18Document25 pagesShotgun Shear Wall: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 15JAN18Đông NguyễnNo ratings yet

- A-Pillar Outer Reinforcement (Complete)Document24 pagesA-Pillar Outer Reinforcement (Complete)DongTaNo ratings yet

- M3 - Rear Wheelhouse Front StiffenerDocument17 pagesM3 - Rear Wheelhouse Front StiffenerDongTaNo ratings yet

- Front Frame Rail Inner Reinforcement (Complete)Document29 pagesFront Frame Rail Inner Reinforcement (Complete)Dong NguyenNo ratings yet

- Shotgun Inner: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 30AUG18 1Document21 pagesShotgun Inner: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 30AUG18 1Đông NguyễnNo ratings yet

- M3 - Rear Wheelhouse Rear StiffenerDocument17 pagesM3 - Rear Wheelhouse Rear StiffenerDongTaNo ratings yet

- Trunk Floor Assembly (Side Panel)Document23 pagesTrunk Floor Assembly (Side Panel)Hieu DvNo ratings yet

- Dash Crossmember: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 08FEB19 1Document13 pagesDash Crossmember: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 08FEB19 1Đông NguyễnNo ratings yet

- Sill Inner (Complete) : Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 13APR18Document40 pagesSill Inner (Complete) : Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 13APR18Đông NguyễnNo ratings yet

- B-Pillar: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 26SEP18 1Document64 pagesB-Pillar: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 26SEP18 1DongTaNo ratings yet

- Front Frame Rail Inner (Large Front Section)Document38 pagesFront Frame Rail Inner (Large Front Section)Dong NguyenNo ratings yet

- M3 Cantrail Inner AssemblyDocument16 pagesM3 Cantrail Inner AssemblyDongTaNo ratings yet

- 02-M3 Shotgun Tower PDFDocument35 pages02-M3 Shotgun Tower PDFLinh VoNo ratings yet

- M3 Cantrail Extension InnerDocument22 pagesM3 Cantrail Extension InnerDongTaNo ratings yet

- Front Frame Rail Inner (Small Front Section)Document40 pagesFront Frame Rail Inner (Small Front Section)Dong NguyenNo ratings yet

- Shotgun Tower: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 25JAN18Document35 pagesShotgun Tower: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 25JAN18Đông NguyễnNo ratings yet

- m3 Subframe To Sill CloseoutDocument16 pagesm3 Subframe To Sill CloseoutWilliam SouzaNo ratings yet

- M3 - Rear Damper Mount UpperDocument29 pagesM3 - Rear Damper Mount UpperDongTaNo ratings yet

- Sill Inner (Front Section)Document20 pagesSill Inner (Front Section)Đông NguyễnNo ratings yet

- m3 Charge Port Housing AssemblyDocument20 pagesm3 Charge Port Housing AssemblyWilliam SouzaNo ratings yet

- Sill Insert (Front Section)Document39 pagesSill Insert (Front Section)Đông NguyễnNo ratings yet

- Toeboard Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 18APR19 1Document16 pagesToeboard Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 18APR19 1Hieu DvNo ratings yet

- M3 Sill Outer (Front Section)Document120 pagesM3 Sill Outer (Front Section)Đông NguyễnNo ratings yet

- Subframe To Sill CloseoutDocument16 pagesSubframe To Sill CloseoutĐông NguyễnNo ratings yet

- Body-M3 Symbols Used in The Body Repair ManualDocument8 pagesBody-M3 Symbols Used in The Body Repair ManualLinh VoNo ratings yet

- Fender Support BracketDocument13 pagesFender Support BracketDong NguyenNo ratings yet

- A325-Twist of BoltDocument6 pagesA325-Twist of BoltPham NhatNo ratings yet

- F3096-14 (Edition 2014.10.01)Document2 pagesF3096-14 (Edition 2014.10.01)Nguyen PhatNo ratings yet

- Blowout Resistance of Room-Temperature Vulcanized ElastomersDocument5 pagesBlowout Resistance of Room-Temperature Vulcanized ElastomersAMUL VEKARIANo ratings yet

- CP3-001 ManualDocument13 pagesCP3-001 ManualJoao Carlos PereiraNo ratings yet

- Torque Values and Appendix O Calculations VWADocument2 pagesTorque Values and Appendix O Calculations VWARicNo ratings yet

- Astm D5417-16Document3 pagesAstm D5417-16Sandra LopesNo ratings yet

- MM - 5P Tandem AxleDocument65 pagesMM - 5P Tandem AxleFredy VelazquezNo ratings yet

- Blowout Resistance of Room-Temperature Vulcanized ElastomersDocument7 pagesBlowout Resistance of Room-Temperature Vulcanized ElastomersAhmad Zubair RasulyNo ratings yet

- AUTOMATIC TRANSMISSION 6T70 (M7W) - REPAIR INSTRUCTION - OFF VEHICLE-unlockedDocument109 pagesAUTOMATIC TRANSMISSION 6T70 (M7W) - REPAIR INSTRUCTION - OFF VEHICLE-unlockedMarco MeloncelliNo ratings yet

- 15 - DTA Guidelines For Repairs and AltertaionsDocument55 pages15 - DTA Guidelines For Repairs and AltertaionsskullmacNo ratings yet

- Technical Data Sheet Medium Strength Threadlocker BlueDocument3 pagesTechnical Data Sheet Medium Strength Threadlocker BlueVictorNo ratings yet

- Technical Data Sheet Medium Strength Threadlocker Blue: Toll Free: 87 PERMATEX (877-376-2839)Document3 pagesTechnical Data Sheet Medium Strength Threadlocker Blue: Toll Free: 87 PERMATEX (877-376-2839)VictorNo ratings yet

- TM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)Document5 pagesTM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)方綵樺100% (1)

- Iom TSKSDocument12 pagesIom TSKSTakbir2011No ratings yet

- Astm C 907-2008Document3 pagesAstm C 907-2008zeqs9No ratings yet

- Liquid Silicone Rubber: Description ApplicationDocument3 pagesLiquid Silicone Rubber: Description ApplicationMaximiliano TaubeNo ratings yet

- JC-364-TSKS IOM EN Final HiRes NoCropsDocument12 pagesJC-364-TSKS IOM EN Final HiRes NoCropsFabio StuiNo ratings yet

- D4317 4434Document6 pagesD4317 4434JEISON ESTEBAN YUCUMA MARTINEZNo ratings yet

- M3 Sill Outer (Complete)Document182 pagesM3 Sill Outer (Complete)Linh VoNo ratings yet

- 02-M3 Shotgun Tower PDFDocument35 pages02-M3 Shotgun Tower PDFLinh VoNo ratings yet

- 02-M3 Shotgun Shear Wall PDFDocument25 pages02-M3 Shotgun Shear Wall PDFLinh VoNo ratings yet

- 02-M3 Fender Front Inner BracketDocument19 pages02-M3 Fender Front Inner BracketLinh VoNo ratings yet

- 02-M3 Shotgun Outer PDFDocument26 pages02-M3 Shotgun Outer PDFLinh VoNo ratings yet

- Home Decor & Furniture Catalog by SlidesgoDocument11 pagesHome Decor & Furniture Catalog by Slidesgopejuang ITNo ratings yet

- NextGen Bus Study UpdateDocument16 pagesNextGen Bus Study UpdateMetro Los AngelesNo ratings yet

- Mitsubishi SL Series ServicemanualDocument10 pagesMitsubishi SL Series ServicemanualKaren100% (54)

- Gas Lift OperationsDocument4 pagesGas Lift OperationsAbdelrahman AliNo ratings yet

- Guia Red Team v2Document321 pagesGuia Red Team v2vakafaj889No ratings yet

- Sem 6Document19 pagesSem 6Toku SharmaNo ratings yet

- Mayor's Speech: Valuing DiversityDocument20 pagesMayor's Speech: Valuing Diversityian rex desolocNo ratings yet

- Brochure Solar Module - Znshine Solar - ZXM6-NH156 166 - 460-485W - 40 35 - 20200311 - E - 1200mmcable20Document2 pagesBrochure Solar Module - Znshine Solar - ZXM6-NH156 166 - 460-485W - 40 35 - 20200311 - E - 1200mmcable20Yudha Trias Rusmana100% (1)

- Background MRP ProcedureDocument8 pagesBackground MRP Procedureranedivakar100% (2)

- Rhoda Sanyangore ProposalDocument7 pagesRhoda Sanyangore ProposalTanniya Denniz GurureNo ratings yet

- X Brief Review of NanocompositeDocument9 pagesX Brief Review of NanocompositeNUR KHOLISH ALI FAHMINo ratings yet

- CHL Unit 3 Task 1 ResponseDocument2 pagesCHL Unit 3 Task 1 Responsekenneth chaunoda50% (2)

- Production Methods of Aluminium Foam A Brief ReviewDocument4 pagesProduction Methods of Aluminium Foam A Brief ReviewJuan SarmientoNo ratings yet

- 59 Cambridge LJ 85Document49 pages59 Cambridge LJ 85helllooNo ratings yet

- BILL GATES TEDROS On Twitter PDFDocument304 pagesBILL GATES TEDROS On Twitter PDFCOVID 19 CORONA VIRUSNo ratings yet

- 2537 VD4G-50 Vacuum Circuit-Breaker GBDocument4 pages2537 VD4G-50 Vacuum Circuit-Breaker GBburvanov0% (1)

- Via Facsimile and First Class MailDocument8 pagesVia Facsimile and First Class Mailmoveonorg100% (1)

- Introduction of New Bharat Fiber Unlimited Broadband Combo 33GB CUL' PlanDocument1 pageIntroduction of New Bharat Fiber Unlimited Broadband Combo 33GB CUL' PlanrcpawarNo ratings yet

- Service Valves Manifolds: 5H CompressorsDocument12 pagesService Valves Manifolds: 5H CompressorsJeser EgañaNo ratings yet

- Health Care PassportDocument9 pagesHealth Care PassportArnav RaiNo ratings yet

- Ozkan 2004 Using NVivo To Analyze Qualitative Classroom Data On Constructivist Learning EnvironmentsDocument15 pagesOzkan 2004 Using NVivo To Analyze Qualitative Classroom Data On Constructivist Learning EnvironmentsBahrouniNo ratings yet

- 3c Report On VodaDocument13 pages3c Report On Vodapunitha_june2553No ratings yet

- Court of Appeal Handout On Writs Mandate Etc 9 Pages 8-13-13Document9 pagesCourt of Appeal Handout On Writs Mandate Etc 9 Pages 8-13-13traderash1020No ratings yet

- Chapter 5 Additional Self TestDocument5 pagesChapter 5 Additional Self TestMichelleNo ratings yet

- German Pharmacies (Figures, Data, Facts) 2012Document31 pagesGerman Pharmacies (Figures, Data, Facts) 2012Vladimir ArguirovNo ratings yet

- Epson Aculaser Cx16nfDocument26 pagesEpson Aculaser Cx16nffefotroncitoNo ratings yet