0% found this document useful (0 votes)

1K views10 pagesRT-135 Piston Rings

This technical bulletin provides an update on piston ring specifications for Wärtsilä RTA, RT-flex, and W-X engines. It introduces the latest chrome-ceramic coated piston ring technology, which has shown better wear resistance and increased time between overhauls compared to previous designs. The bulletin standardizes piston ring nomenclature, lists current and alternative piston ring versions, and provides ordering information for replacement tools and parts.

Uploaded by

郑开元Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views10 pagesRT-135 Piston Rings

This technical bulletin provides an update on piston ring specifications for Wärtsilä RTA, RT-flex, and W-X engines. It introduces the latest chrome-ceramic coated piston ring technology, which has shown better wear resistance and increased time between overhauls compared to previous designs. The bulletin standardizes piston ring nomenclature, lists current and alternative piston ring versions, and provides ordering information for replacement tools and parts.

Uploaded by

郑开元Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Piston Ring Technology

- Introduction

- SIPWA Parts

- Piston Ring Designation

- Gas Tight Piston Rings

- KOP Piston Rings

- Piston Ring Standard

- General Recommendations

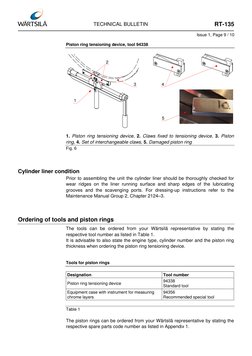

- Ordering of Tools and Piston Rings

- Appendix

- Contacts