Professional Documents

Culture Documents

002 Cement Plant The Manufacturing Process

Uploaded by

jimmygerman333Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

002 Cement Plant The Manufacturing Process

Uploaded by

jimmygerman333Copyright:

Available Formats

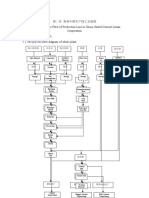

Cement Plant:

The Manufacturing Process

4 The kiln feed is blasted in a

cement kiln at a temperature

5 The clinker is mixed

with additives, such

of 1450oC, causing clinkering as gypsum, and then

2 The limestone is

fed into a crusher

and then stored

to occur (small balls of up to

25mm diameter)

ground in a cement

mill, which creates

cement

until needed

Coal Storage Additives

Silos

Coal mill

Cement mill Cement

Crusher storage silos

Rotary Kiln

Limestone storage Pre-heated tower

and pre-blending unit Packing

warehouse

Raw material silos

1 Raw mill

6

Limestone (CaCO3) is

taken from a quarry The cement is then

packed and distributed

to consumers

3 The crushed limestone and aggregates such

as sand, clay and ironstone are blended

together in a raw mill to a particle size of 90

micrometres, producing “kiln feed”

worldcementassociation.org

You might also like

- Cement ABCDocument100 pagesCement ABCSriram Ramanujam100% (1)

- Methods, Processes, and Equipment Involved in Manufacturing CementDocument22 pagesMethods, Processes, and Equipment Involved in Manufacturing Cementanon_497391427No ratings yet

- Raw Material Handling Plant: Download The Original AttachmentDocument36 pagesRaw Material Handling Plant: Download The Original AttachmentJaved AlamNo ratings yet

- What Is Cement?Document17 pagesWhat Is Cement?markdanielgolisaoNo ratings yet

- Cement SlideshareDocument37 pagesCement SlideshareMuhammad Haseeb Alam100% (2)

- The Cement Manufacturing ProcessDocument24 pagesThe Cement Manufacturing ProcessdennisNo ratings yet

- Unit 1 Cement and ConcreteDocument130 pagesUnit 1 Cement and Concretehamshini100% (1)

- Cement PlantDocument4 pagesCement PlantVishnu VenugopalNo ratings yet

- Supply Chain of Cement Manufacturing IndustryDocument16 pagesSupply Chain of Cement Manufacturing IndustryVarun SinhaNo ratings yet

- 8manufacturing of CementDocument14 pages8manufacturing of CementGaurav KandelNo ratings yet

- 8manufacturing of CementDocument14 pages8manufacturing of CementGaurav KandelNo ratings yet

- GR Chapter - 19 Cement 78, 12Document14 pagesGR Chapter - 19 Cement 78, 12Chemistry have a solutionNo ratings yet

- 2 Process Flow of Production Line in China United Cement Lunan Corporation - Íð - + ÑêiDocument5 pages2 Process Flow of Production Line in China United Cement Lunan Corporation - Íð - + ÑêiNova HeriNo ratings yet

- Lecture Notes On CementDocument58 pagesLecture Notes On CementPoonam ModiNo ratings yet

- Cement Manufacturing ProcessDocument4 pagesCement Manufacturing ProcessChloe MercadoNo ratings yet

- Cement Production ProcessDocument1 pageCement Production ProcessVivi OktaviantiNo ratings yet

- The Cement Manufacturing Process: Quarry Raw Grinding and Burning Grinding, Storage, Packing, DispatchDocument4 pagesThe Cement Manufacturing Process: Quarry Raw Grinding and Burning Grinding, Storage, Packing, Dispatchdudhmogre23No ratings yet

- Cement Cement - Manufacturing - Process UkDocument4 pagesCement Cement - Manufacturing - Process UkJayasriNo ratings yet

- The Cement Manufacturing Process: Quarry Raw Grinding and Burning Grinding, Storage, Packing, DispatchDocument4 pagesThe Cement Manufacturing Process: Quarry Raw Grinding and Burning Grinding, Storage, Packing, DispatchShailesh RautNo ratings yet

- The Cement Manufacturing Process: Quarry Raw Grinding and Burning Grinding, Storage, Packing, DispatchDocument4 pagesThe Cement Manufacturing Process: Quarry Raw Grinding and Burning Grinding, Storage, Packing, DispatchKirubaKaran SNo ratings yet

- Industry Sectors - CementDocument16 pagesIndustry Sectors - CementCrestian Nebreja MortaNo ratings yet

- 2 CementDocument114 pages2 CementAbdisamed AhmedNo ratings yet

- Module 2 CementDocument20 pagesModule 2 CementKamil ShairNo ratings yet

- Cement Process in PT Holcim Indonesia Cilacap PlantDocument21 pagesCement Process in PT Holcim Indonesia Cilacap Plantrasmohan100% (1)

- Cement Industry Mikiyas awekeID 0712Document23 pagesCement Industry Mikiyas awekeID 0712abrhshNo ratings yet

- Binani Cement PDFDocument24 pagesBinani Cement PDFZahir KhiraNo ratings yet

- Debre Brhan Unversity College of Engineering Department of Chemical EngineeringDocument11 pagesDebre Brhan Unversity College of Engineering Department of Chemical EngineeringabrhshNo ratings yet

- CementDocument59 pagesCementLealyn Pagsinuhin BobadillaNo ratings yet

- Cement 12Document24 pagesCement 12prashannapandit832No ratings yet

- CEMENTDocument2 pagesCEMENTChannis ExoNo ratings yet

- Best 1Document72 pagesBest 1tesfayregs gebretsadikNo ratings yet

- Presentation of Heat Recovery Energy AuditDocument19 pagesPresentation of Heat Recovery Energy AuditIhsan MohamedNo ratings yet

- Production Process of CementDocument2 pagesProduction Process of CementMarwaNo ratings yet

- Module 4 - Dryers and Drying ProcessesDocument18 pagesModule 4 - Dryers and Drying ProcessesGold BlandoNo ratings yet

- Cement Industry: Map - KeyDocument4 pagesCement Industry: Map - KeyMohamed Hamdallah100% (1)

- Overall Increase in Efficiency in Raw MeDocument6 pagesOverall Increase in Efficiency in Raw MeMadanKarkiNo ratings yet

- Cement Manufacturing ProcessDocument2 pagesCement Manufacturing ProcessVenkata Ramana Murty GandiNo ratings yet

- Building Materials and Construction 4Document59 pagesBuilding Materials and Construction 4IswaryaNo ratings yet

- Lec. 2 CementDocument31 pagesLec. 2 CementCarvajal015No ratings yet

- CementDocument82 pagesCementzohaib ul hassanNo ratings yet

- INDEX: Contents of The ReportDocument34 pagesINDEX: Contents of The Reportrahul rayNo ratings yet

- Ma Seminar On Jaypee CementDocument23 pagesMa Seminar On Jaypee CementShashank GuptaNo ratings yet

- Cementing OverviewDocument23 pagesCementing OverviewAhmed Ali Alsubaih100% (1)

- CementDocument17 pagesCementIndigo CupcakeNo ratings yet

- Cleaner Production Assessment in CementDocument5 pagesCleaner Production Assessment in CementMadanKarkiNo ratings yet

- Cement Manufacturing at A GlanceDocument2 pagesCement Manufacturing at A GlancelokeshkrjainNo ratings yet

- Cement Manufacturing ProcessDocument2 pagesCement Manufacturing ProcessMorning Kalal0% (1)

- Cement ManufacturingDocument4 pagesCement Manufacturinghijzain100% (1)

- Report in Technical Analysis CEMENTDocument26 pagesReport in Technical Analysis CEMENTNatrium KirchhoffNo ratings yet

- Cement Industry - MRUDocument50 pagesCement Industry - MRUeasyway187139No ratings yet

- Heidelbergcement at A GlanceDocument19 pagesHeidelbergcement at A GlancefasfasfasNo ratings yet

- 143 LOESCHE Mills For Cement and Granulated Blast Furnace Slag E 2016Document28 pages143 LOESCHE Mills For Cement and Granulated Blast Furnace Slag E 2016rsekumar1980No ratings yet

- Cement: Chemical Composition of Cement Is: Lime 63% Silica 22% Alumina 06% Iron Oxide 03% Gypsum 01 To 04%Document6 pagesCement: Chemical Composition of Cement Is: Lime 63% Silica 22% Alumina 06% Iron Oxide 03% Gypsum 01 To 04%Ch. Muhammad UsamaNo ratings yet

- Muhammadhaikal - AA212622 - Cement Mind MapDocument3 pagesMuhammadhaikal - AA212622 - Cement Mind Maphaikal.ab31No ratings yet

- Homo Silo VRM Crusher Quarry Prehe - AterDocument1 pageHomo Silo VRM Crusher Quarry Prehe - AterMark Angelo UyNo ratings yet

- Kepy - Cement - Case Study Report 2Document16 pagesKepy - Cement - Case Study Report 2XpreneursHub EventsNo ratings yet

- PosterDocument1 pagePosterSivani KrishnaNo ratings yet

- Part B GBDDocument15 pagesPart B GBDP.Prithivi RajNo ratings yet

- Fildzah Yulianingrum - 1707621020 - PB-A - BIB - Writing Task 1Document1 pageFildzah Yulianingrum - 1707621020 - PB-A - BIB - Writing Task 1Fildzah YulianingrumNo ratings yet

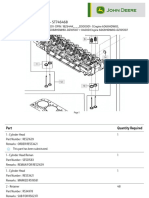

- 5120 CabezalDocument3 pages5120 Cabezaljimmygerman333No ratings yet

- 9901 Block EnsambleDocument5 pages9901 Block Ensamblejimmygerman333No ratings yet

- 9901 Kit PistonDocument2 pages9901 Kit Pistonjimmygerman333No ratings yet

- 9901 Metales CiguenalDocument2 pages9901 Metales Ciguenaljimmygerman333No ratings yet

- 9901 Kit PistonDocument2 pages9901 Kit Pistonjimmygerman333No ratings yet

- 9901 Camiseta y SellosDocument2 pages9901 Camiseta y Sellosjimmygerman333No ratings yet

- Starwalk2 Manual enDocument24 pagesStarwalk2 Manual enErick LopezNo ratings yet

- Lefg Articles4Document2 pagesLefg Articles4MilenaMiseljicNo ratings yet

- Rating Action - Moodys-downgrades-Perus-rating-to-Baa1-changes-outlook-to-stable - 01sep21Document6 pagesRating Action - Moodys-downgrades-Perus-rating-to-Baa1-changes-outlook-to-stable - 01sep21jimmygerman333No ratings yet

- Ball-Mills en PDFDocument6 pagesBall-Mills en PDFAndres CarmonaNo ratings yet

- CL Articles5Document2 pagesCL Articles5Kamolpan JammapatNo ratings yet

- Article or No Article4Document2 pagesArticle or No Article4jimmygerman333No ratings yet

- Articles Mixed3 PDFDocument2 pagesArticles Mixed3 PDFjimmygerman333No ratings yet

- Articles A or An2Document2 pagesArticles A or An2Ainul Husna Abdul HamidNo ratings yet

- Articles Mixed5Document2 pagesArticles Mixed5FabioGomesNo ratings yet

- CL Articles3Document2 pagesCL Articles3Kamolpan JammapatNo ratings yet

- Lefg Mixedarticles4Document2 pagesLefg Mixedarticles4kamolpan@gmail.comNo ratings yet

- Lefg Mixedarticles4Document2 pagesLefg Mixedarticles4kamolpan@gmail.comNo ratings yet

- Aplicación Industria Del CementoDocument3 pagesAplicación Industria Del Cementojimmygerman333No ratings yet

- Articles Mixed7Document2 pagesArticles Mixed7Ale AlexaNo ratings yet

- Articles The A An1heDocument2 pagesArticles The A An1heMohamad Hasri MajdiNo ratings yet

- Article or No Article2 PDFDocument2 pagesArticle or No Article2 PDFSidney WeedyNo ratings yet

- Articles Mixed2Document2 pagesArticles Mixed2polamrajuNo ratings yet

- CL Articles4Document2 pagesCL Articles4Kamolpan JammapatNo ratings yet

- Articles Mixed6 PDFDocument2 pagesArticles Mixed6 PDFSidney WeedyNo ratings yet

- Our Dangerous Universe': Friday, October 5 7:30 P.M. Nebraska Union AuditoriumDocument1 pageOur Dangerous Universe': Friday, October 5 7:30 P.M. Nebraska Union AuditoriumWahyu Dipa PratamaNo ratings yet

- OpenMind 1 Unit 1 CEFR ChecklistDocument1 pageOpenMind 1 Unit 1 CEFR ChecklistEdgarElHippieOrozcoNo ratings yet

- 203 - 207 Double Reduction Helical-Worm Max RatingsDocument5 pages203 - 207 Double Reduction Helical-Worm Max Ratingsjimmygerman333No ratings yet

- OMAM Level-1 Word List Unit1Document7 pagesOMAM Level-1 Word List Unit1seseg2No ratings yet