Professional Documents

Culture Documents

Determining Fiber Loss in Biofinishing of Cotton and Cotton Wool Blends

Uploaded by

hawOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Determining Fiber Loss in Biofinishing of Cotton and Cotton Wool Blends

Uploaded by

hawCopyright:

Available Formats

Determining Fiber Loss in Biofinishing

of Cotton and CottonNvool Blended Fabrics

~~~

By Shridhar V. Chikkodi, International Textile Center, Texas Tech University, Lubbock

Cellulase Digestion

B iofinishing is a relatively new con-

cept of treating the fabrics with en-

zymes. Recent advances in biofin-

In the p r e s e k study, cotton and

cottonlwool blended fabrics were

treated with cellulase and cellulase or

The experimental fabric, three meters

in length, was weighed, loaded on a

ishing of cellulosic fabrics have led to protease enzymes, respectively. Cellu- laboratory jig, and run dry four times

multiple improvements of surface lases degrade cellulose by breaking the around doctor blades to raise the loose

properties. The main objective of 1,4 D-glucosidic bonds, whereas pro- fibers to the surface. The doctor blades

biofinishing is to upgrade the fabric by teases hydrolyze the peptide bonds of also assured a thorough mechanical

removing the protruding fibers. The rotei ins.^^^ The hydrolysis of gluco- action throughout the enzyme applica-

conventional methods of removing the sidic or peptide bonds leads to the tion. The aqueous bath had a liquor

protruding fibers employ a burning-off degradation of the molecules into ratio of 1:10, pH of 4.5 (using sodium

process (singeing) or a chemical treat- smaller units, which are amenable to acetate buffer), temperature of 60C and

ment. The conventional methods are further degradation into glucose and cellulase enzyme added at 3 or 5% on

temporary, potentially toxic, and fibers amino acids, respectively. An effective the weight of fabric (owf), equivalent

return to the surface after a few enzymatic treatment results in suc- to cellulase activity of 3 or 5 CCU/gram

washings and form fuzz. The fuzz on cessful removal of protruding fibers, of fabric. The pH was periodically

the surface of the fabrics constitutes the hence a certain weight loss is ex- checked during the one-hour enzy-

major reason for customer dissatisfac- pected. The main objective of this matic treatment and adjusted with ace-

tion. However, by using enzymes in the study was to determine the relation- tic acid when necessary. After the treat-

finishing process, the protruding fibers ship between fabric weight loss and ment, the fabric was washed in hot

can be permanently removed from the free glucose and amino acids found in deionized water at 9OC to terminate the

fabric thus eliminating the fuzz. The enzyme solutions after biofinishing enzyme action, and then dried using a

enzyme treatment not only keeps the cotton and cottonlwool blended fab- drum dryer.4

fabric looking new after repeated rics. In the process, the assay meth-

washings, but enhances feel, color, ods were also optimized to measure Protease Digestion

softness and drapeability which trans- the free glucose and amino acids re- Proteases were applied in a second in-

lates into a higher quality textile or leased from the enzymatic action. dependent treatment to the cottonlwool

apparel product.*P2 blend using the same conditions as in

Material and Methods

cellulase digestion changing only the

Plain woven fabrics of 37 tex ring-spun bath pH to 8.5 using boric acid buffer

ABSTRACT yarn were used. The fiber contents of and sodium hydroxide. Enzyme activ-

the fabrics included 100% cotton and ity of 12,000 or 20,000 Delf Units/gram

In recent years, biofinishing, an 80120 and 60140 cottonlwool blends.

application technique using enzymes of fabric were equivalent to 3 or 5% owf.

Prior to enzymatic treatment, fabrics

such as cellulases and proteases to Analysis of Enzymatic Digestion

digest the protruding fibers, has

were desized in a jig using 1:10 liquor

gained considerable attention. ratio, 1% nonionic detergent, 0.5% At the same time the fabric was re-

Several studies have reported that a hydrogen peroxide and 0.25% acetic moved, ten liquid samples of 10 mL

certain weight loss is desirable as a acid at 9OC for 30 minutes, followed each were collected from the well-

result of an effective enzyme by a hot rinse (9oC) for 20 minutes and mixed bath liquor and frozen imme-

treatment. In this study the a final cold rinse to thoroughly remove diately (-20C) for the glucose and

relationship between weight loss and the PVA added to the warp during amino acid assay. To determine

the amount of glucose and amino slashing. Cellulase and protease en- whether the effect of treatment was

acids released was examined. It zymes used in this study came from truly due to enzymatic action, samples

appeared that weight loss conformed Royal Gist-Brocades (Charlotte, N.C.). of fabrics treated in the same manner

with the glucose and amino acids Cellulase enzymes used were of indus- but without the addition of enzymes

released, thus confirming the trial grade with an activity of 100 CCUI were collected.

existence of a relation between gram and the protease enzymes had the

weight loss and the activity of proteolytic activity of 400,000 Delft Glucose Assay

specific enzymes. Unitslgram. In order to quantify glucose, it was nec-

KEY TERMS

Cellulase was applied on 100% essary to digest all the remaining cel-

cotton and on cotton/wool blends to lulose fragments. After thawing the fro-

Biofinishing digest the protruding cotton fibers. zen samples with hot water, four 2 mL

Cellulases Protease was used on cottonlwool aliquots were drawn from each 10 mL

Enzymes blends to digest the protruding wool liquid sample. To each of these test

Proteases fibers. samples, 0.158 mL of 1M sodium ac-

28 Textile Chemist and Colorist Vol. 28, No. 3

etate buffer (pH 4.5) and 1 mL of cel- zine methosulfate). To 6.7 pL of each 1. Visual examination was performed

lulase enzyme (100 CCU) were added. aliquot, 0.33 mL of assay reagent was with an Olympus BH-2 microscope

To aid complete digestion the samples added and the sample was mixed by after staining with 0.1% Aniline

were incubated in a sealed condition gentle inversion and allowed to stand Blue to detect protein.

at 60C for 24 to 96 hours with constant for 10 minutes. Then 3.33 mL of 0.1N 2. Amino acid assay was performed at

stirring in a Reactitherm (Pierce Chem HC1 was added and the optical density 24, 48, 72 and 96 hours of protease

Co., Rockford, Ill.). Complete digestion was measured at 520 nm using a treatment.

was ensured by two methods: Bausch & Lomb Spectronic 2 1 Spectro- Once the time required for conrplete

1. Visual examination was performed photometer against a reagent blank of digestion was established, triplicate

with an Olympus BH-2 microscope 6.7 pL of nanopure water and 0.33 mL aliquots of each experimental sample

equipped for polarization analysis to of assay agent. To quantify the glucose were assayed as follows. The amino

detect cellulose birefringence and for concentration in the test samples, a acid assay was carried out using the

fluorescence analysis to detect cel- standard curve was prepared using 1:1, Ninhydrin reaction. Ninhydrin reagent

lulose after staining with the fluores- 1 2 , 1:4 and 1:9 dilutions of stock so- was obtained from Sigma Diagnostics.

cent brightener Tinopal LPW (Ciba lution consisting of 5.56 mmoles/L glu- The 10 mmoles/L amino acid standard

Geigy, Greensboro, N.C.). cose in saturated benzoic acid. was prepared by combining 17.12 g of

2. Glucose assay was performed at 24, aspartic acid,-13.12 g of leucine and

48,72 and 96 hours of cellulase treat- Protein Assay 17.42 g of arginine per 100 mL of wa-

ment. To quantify amino acids, it was neces- . ~ 2 mL of each

ter as per P l ~ m m e rTo

Once the time required for complete sary to digest any remaining wool frag- sample, 2 mL of Ninhydrin reagent was

digestion was established, triplicate ments. After thawing the frozen added. The samples were heated for 15

aliquots of each experimental sample samples with hot water, four 2 mL minutes in boiling water and cooled to ’

were assayed as described below. aliquots were taken from each 10 mL room temperature. Then 3 mL of 50%

Glucose was analyzed using a diag- liquid samples for the assay. To each ethanol was added and the optical den-

nostic kit based on hexokinase (Sigma of these test samples, 0.158 mL of 1M sity was measured at 570 nm using a

Chemical Co., Catalog #115-A). The Boric Acid buffer (pH 8.5) and 1mL of Bausch & Lomb Spectronic 2 1 Spectro-

glucose assay reagent was prepared by protease enzyme equivalent to 400,000 photometer against a reagent blank of

mixing one vial of glucose enzyme re- Delf Units were added. The samples 2 mL of nanopure water, 2 mL Ninhy-

agent with 17.0 mL of deionized water were incubated at 60C for 24 to 96 drin reagent and 3 mL of 50% ethanol.

and 4 mL of glucose color reagent (3.95 hours with constant stirring to ensure In order to quantify the amino acid

mmoles/L of iodonitrotetrazolium complete digestion. Complete diges- concentration in the test samples, a

chloride and 1.63 mmoles/L of phena- tion was ensured by two methods: standard curve was prepared using i:i,

1:2, 1:4 and 1:9 dilutions of 0.1

mmoles/L amino acid solution.

Table 1. Effects of Cellula and Protease Treatment Results and Discussion

on Weight Loss ( Merent Fabrics

In the presence of buffer, 24 hours of

Weight Before Weight After Weight Weight Loss Due cellulase or protease treatment brought

Treatment Treatment Loss to Enzymes about complete digestion. Aftor this

Test Sample Enzyme (grams) (grams) (“N (“4 amount of time, there was no further

100% Cotton decrease in the number and sizo of fi-

Control 207.9 205.1 1.35

3% Cellulase 212.0 203.9 3.82 2.47 bers and no further increase in glucose

5% Cellulase 218.3 205.4 5.91 4.56 or amino acids. It should be noted that

00120 cottomooi these results indicate that the addition

Control 232.0 229.2 1.21 of buffer greatly enhances rate of ac-

3% Cellulase 230.4 222.8 3.25 2.04

5% Cellulase 234.1 221.1 5.55 4.34 tion of these enzymes, an observation

3% Protease 206.2 201.1 2.47 1.26 which has bearing on design of Fabric

5% Protease 209.0 201.3 3.68 2.47 enzymatic treatment processes.

60140 c o t t o m o o i The weights of the experimental

Control 189.3 187.4 1.01

3% Cellulase 196.5 191.1 2.75 1.74 fabrics were measured before and af-

5% Cellulase 190.8 182.8 4.19 3.18 ter enzyme treatments and reported to

3% Protease 193.0 185.4 3.94 2.93 the nearest gram. Table I shows the

5% Protease 190.0 179.7 5.42 4.41 weight loss after enzyme treatments for

all experimental fabrics at both enzyme

concentrations. As indicated, fabrics

Table 11. Released Glucose treated with 5% enzymes lost about 4-

Adjusted

6% weight, whereas those with 3%

Cellulase Glucose Released Glucose Released Standard treatment lost 2-4%. Effective removal

Test Sample (%I (mmoles/L) (mmoledL) Error of protruding loose fibers contributed

100% Cotton to most of the weight loss.6 However,

Control 6.45 f 0.25 a small weight loss of about 1-2% was

3% Cellulase 13.12 6.67 f 0.25 observed for control fabrics, which

5% Cellulase 14.84 8.39 f 0.00 may be due to the mechanical action

~mo cottomooi

that took place during the treatment.

Control 5.20 t 0.00

3% Cellulase 11.12 6.00 f 0.00 In the case of 100% cotton fabrics

5% Cellulase 11.36 6.16 f 0.25 treated with 5% cellulase, the weight

60140 Cotton/Wool

Control 4.96 _+ 0.23

loss was found to be more than that of

3% Cellulase 9.12 4.16 f 0.25 blended fabrics, probably because

5% Cellulase 10.36 5.40 f 0.00 more protruding cellulose fibers were

March 1996 Textile Chemist and Colorist 29

Table 111. Released Amino Acids Table I11 shows the amount of amino

acid released and the corresponding

Amino Adjusted standard error. Fabric containing

Protease Acids Released Amino Acids Standard

Test Sample (“A) (mmoledL) Released (mmoles/L) Error higher wool content and fabric treated

with 5% protease enzymes released

80/20 ColtonMlool more amino acids as compared to those

Control 0.023 ? 0.002

3% Protease 0.059 0.036 * 0.002 treated with 3% protease enzymes. Fig.

5% Protease 0.068 0.045 i 0.000 2 illustrates the amount of amino ac-

60/40 CottonMlool ids released in mmoles.

Control 0.038 *f.0.005 The relationship between weight

3% Protease 0.077 0.039 0.002

5% Protease 0.085 0.047 f.0.000 loss and the amount of glucose released

for the fabrics treated with cellulase

enzymes is shown in Figs. 3-5. Linear

regression was used to examine this

16

14.84 3% relationship. The R2 values (0.919 and

Control

0.924) indicate the significant relation-

14 ta 3% cellulase treatment ships between the fabric weight loss

I5% cellulase treatmenl

and the amount of glucose molecules

12

released for 100% cotton and 60140

cottonlwool blend. However, the 801

10.36

20 cottonlwool blend exhibited a mod-

-E

E

U

10

erate R2 value (0.747). Similarly the

% data in Figs. 6 and 7 shows the corre-

-

m

a

E a lation between the weight loss and the

8 amount of amino acids released for the

8 fabrics treated with protease enzymes.

2 6

(3 High R2 (0.88 and 0.94) values were

observed for blended fabrics. In sum-

4 mary, there is a high correlation be-

tween weight loss and glucose and

2 amino acid concentrations.

Conclusions

0

100% cotton 80/20 cotton/wool j0/40 cotton/wool A method to indirectly assess the

amount of fiber loss in biofinishing of

Fig. 1. Effect of cellulase on the amount of glucose released. cotton and cottonlwool blended fabrics

was examined. Effective enzyme treat-

ment, which depended on fiber content

available for the cellulase enzyme to standard error. With the decrease in the and treatment level, resulted in pro-

attack. Similarly more weight loss was amount of cellulose content in the test gressive weight loss. Assays were used

observed in the case of 60140 cotton/ fabrics, a decrease in the amount of glu- to determine the amount of cellulose

wool blended fabrics treated with 5% cose released was observed. The glu- and protein fiber loss. This study

protease than in blends with lower cose released also depended upon the showed that the reported weight loss

percent wool, because more protrud- treatment level. Five percent cellulase- was proportional to the release of glu-

ing wool fibers were available for the treated fabrics released more glucose cose and amino acids. It confirmed a

protease enzyme to attack. than three percent treated fabrics. Fig. relation between weight loss and the

Table I1 shows the amount of glu- 1illustrates the amount of glucose re- amount of glucose and amino acid re-

cose released and the corresponding leased in mmoles. leased by specific enzymes.

-H

0.09

0.08

0.07

0.085

Control

3% Drotease treatment

5% brotease treatment

0.068 -

P

16 7

A /!

E

v E

1

0.06 V

ul

a,

m

0.05 -

a,

a,

8

=m

0 0.04 0

L

6

0

.-C 0.03 4 A 100% Cotton

E -Linear (100% Cotton: j

a 0.02 2

0.01 0 ............................................................................................................. j

0

60140 80/20

cottonlwool cottonlwool

Fig. 2. Effect of protease on the amount of amino acid released.

30 Textile Chemist and Colorist COi, Vol. 28, No. 3

14 :

A

A a0120 cottonlwool

-Linear (80120

cottonlwool)

0 1 2 3 4 5 6

Weight loss in %

Fig. 4. Relationship between weight loss and glucose released for cel- Fig. 5. Relationship between

lulase-treated fabrics. cellulase-treated fabrics.

0.08 0.09

0.08

-$ 0.07

0.06

sE 0.07

v Y

U p 0.06

2 0.05 In

-2mal 0.04 -$ 0.05

E

0 0.04

0

2 0.03 A

m

2 0.03 A

0

.-K A A 80120 cottonlwool .- A 60140 cotton wool

E 0.02 E 0.02

<

< -Linear (80120 -Linear (60140 cotton

0.01 cottonlwool) 0.01

wool)

0 0

0 1 2 3 4 0 1 2 3 4 5 6

Weight loss in % Weight loss in %

Fig. 6. Relationship between weight loss and amino acid released for Fig. 7.Relationship between weight loss and amino acid released for

protease-treated fabric. protease-treated fabric.

Plans for future research include the the course of this work and technicaI 2. Schubel, P.. Textile Industries Dyegest-SA,

use of other commercially available Vol. 9, No. 11. November 1990, p4.

guidance during the preparation of this 3. Enzymes in Industry: Production and Appli-

cellulase and protease preparations of manuscript. Appreciation is extended cations, Edited by W. Gerhartz, Weinheim

various activities from different manu- to B. G. Wyatt, International Textile (FRG): VCH Verlagsgesellschaft. 1990.

facturers to examine the effectiveness of Center at Texas Tech University, for his 4. Chikkodi. S., Thesis:EffecfsofBiofinishingon

other enzyme preparations. It should be Cotton and Catton/Wool Blended Fabrics,

comments in reviewing this paper. The Texas Tech University, Lubbock, 1994.

noted that names of commercial prod- Department of Biology and Interna- 5 . Plummer, D. T., An Introduction to Practical

ucts used in this study are solely pro- tional Textile Center at Texas Tech Biochemistry, McGraw-Hill Book Co., London,

vided for the purpose of providing University, is also acknowledged for 1989.

6. Tyndall, R. M.. Textile Chemist and Colorist,

specific information and their mention providing resources to undertake this Vol. 24, No. 6, June 1992, p23.

does not imply recommendation. work.

Author's Address

Acknowledgements References

Shridhar V. Chikkodi, International

The author thanks Candace Haigler, 1. Hemmpel, W. H., International Textile Bulle-

tin Dyeing /Printing/Finishing, Vol. 3 7 , No. 3, Textile Center, Texas Tech University,

Department of Biology at Texas Tech March 1991, p5. Lubbock, Texas 79408.

University, for her supervision during

March 1996 033 Textile Chemist and Colorist 31

You might also like

- Cellulase Production by Thermophilic Bacillus Sp. SMIA-2 and Its Detergent CompatibilityDocument10 pagesCellulase Production by Thermophilic Bacillus Sp. SMIA-2 and Its Detergent CompatibilitydadjNo ratings yet

- Chapter 3Document13 pagesChapter 3Patrick LenguajeNo ratings yet

- Thermostable β-Galactosidase from Bacillus coagulansDocument6 pagesThermostable β-Galactosidase from Bacillus coagulansguiervicalNo ratings yet

- β-galactosidase from Bacillus coagulans RCS3: Production and characterization of a thermostableDocument6 pagesβ-galactosidase from Bacillus coagulans RCS3: Production and characterization of a thermostablemoogambigai smNo ratings yet

- Isolation and Purification of CellulaseDocument6 pagesIsolation and Purification of CellulaseMeshal NoorNo ratings yet

- Enzymatic Polishing and Reactive Dyeing of Cotton Fabric in One BathDocument5 pagesEnzymatic Polishing and Reactive Dyeing of Cotton Fabric in One Bathdanibgg823No ratings yet

- Invertase Lab 1 and 2Document8 pagesInvertase Lab 1 and 2Tiyah TimothyNo ratings yet

- Invertase Lab 1 or 2Document8 pagesInvertase Lab 1 or 2Tiyah TimothyNo ratings yet

- Physico-Mechanical Properties of Chemically-Treated Bacterial Cellulose Membrane - George Et Al., 2005Document5 pagesPhysico-Mechanical Properties of Chemically-Treated Bacterial Cellulose Membrane - George Et Al., 2005Carinna SaldanaNo ratings yet

- Heine 2008Document14 pagesHeine 2008Mia EruNo ratings yet

- Isolation and Characterization of A Thermostable - Amylase FromDocument5 pagesIsolation and Characterization of A Thermostable - Amylase FromDương Nguyễn Thùy DungNo ratings yet

- Nelson and SomogyiDocument3 pagesNelson and Somogyisurrender003No ratings yet

- Cheng (2013) - XylDocument10 pagesCheng (2013) - XylAlly BNo ratings yet

- Enzymatic Hydrolysis of Rice Straw in a Membrane BioreactorDocument5 pagesEnzymatic Hydrolysis of Rice Straw in a Membrane BioreactorYi Wen YapNo ratings yet

- HydrolyseDocument10 pagesHydrolyseBenyoucef AmelNo ratings yet

- LactosacarosaDocument8 pagesLactosacarosaAriel plutarco cardoso herreraNo ratings yet

- Fractionation of Glycomacropeptide From Whey Using Positively Charged Ultrafiltration MembranesDocument9 pagesFractionation of Glycomacropeptide From Whey Using Positively Charged Ultrafiltration MembranesTULLIMILLI CHANIKYA VENKAT KRISHNA SAI 2200268No ratings yet

- Cellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateDocument5 pagesCellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateHamka NurkayaNo ratings yet

- °c/15psi) - Under This Condition, The Cellulose Content of Wheat Straw Was Increased byDocument9 pages°c/15psi) - Under This Condition, The Cellulose Content of Wheat Straw Was Increased byHet ThankiNo ratings yet

- Assessment of A Thermostable Xylanase From Paenibacillus Sp. ASCF@ For Application in Prebleaching of Eucalyptus Kraft PulpDocument6 pagesAssessment of A Thermostable Xylanase From Paenibacillus Sp. ASCF@ For Application in Prebleaching of Eucalyptus Kraft PulpAlonsoNo ratings yet

- New Environmentally Benign Leather Technology: Combination Tanning Using Vegetable Tannin, Naphthol and OxazolidineDocument6 pagesNew Environmentally Benign Leather Technology: Combination Tanning Using Vegetable Tannin, Naphthol and OxazolidinechandraNo ratings yet

- Low Temperature Acidic Pectinase Scouring For Enhancing Textile QualityDocument5 pagesLow Temperature Acidic Pectinase Scouring For Enhancing Textile QualityAzizNo ratings yet

- The Action of An Amyloglucosidase of Aspergillus Niger On Starch and MaltooligosaccharidesDocument5 pagesThe Action of An Amyloglucosidase of Aspergillus Niger On Starch and MaltooligosaccharidesKukymovNo ratings yet

- Skin Uptake and Release of BilirubinDocument9 pagesSkin Uptake and Release of BilirubinhozedrNo ratings yet

- Denim FadingDocument8 pagesDenim FadingDelwar HossainNo ratings yet

- Linjianqiang 6Document8 pagesLinjianqiang 6Med Ramy Gaddem EssefiNo ratings yet

- Pretreatment and Saccharification of Rice HuksDocument7 pagesPretreatment and Saccharification of Rice HuksHimpunan Mahasiswa Teknik KimiaNo ratings yet

- Amylolytic Enzymes Produced by B. Amyloliquefaciens MIR41Document6 pagesAmylolytic Enzymes Produced by B. Amyloliquefaciens MIR41Guillermo Raul CastroNo ratings yet

- Cristalización CuajoDocument9 pagesCristalización CuajoPablo GarcíaNo ratings yet

- Enzymatic Hydrolysis of Pretreated Sugarcane BagasseDocument7 pagesEnzymatic Hydrolysis of Pretreated Sugarcane BagassebryanNo ratings yet

- Ethanol Extraction Membrane During Supported Liquid Ferment at IonDocument8 pagesEthanol Extraction Membrane During Supported Liquid Ferment at Ionapi-26678889No ratings yet

- BiomassDocument15 pagesBiomassJESUS ALBERTO GUERRERO DE LA ROSA ESTUDIANTE ACTIVONo ratings yet

- Experimental Techniques For BioDocument6 pagesExperimental Techniques For BioMariam AsgharNo ratings yet

- Sheng 2014Document9 pagesSheng 2014Rara IqromNo ratings yet

- Extraction and Characterization of ProteinsDocument4 pagesExtraction and Characterization of ProteinsDozdi100% (2)

- LAboratory ProceduresDocument29 pagesLAboratory ProceduresNaji MajoudiNo ratings yet

- Role of Plasmid in Production of Acetobacter Xylinum BiofilmsDocument4 pagesRole of Plasmid in Production of Acetobacter Xylinum BiofilmsShofiaNo ratings yet

- Pengaruh Variasi Kecepatan Agitasi Pada 29910e55Document6 pagesPengaruh Variasi Kecepatan Agitasi Pada 29910e55RyuNo ratings yet

- AND Renin by The CatDocument7 pagesAND Renin by The CatSianipar RomulussNo ratings yet

- Gelatina 1.2Document6 pagesGelatina 1.2Santiago ZapataNo ratings yet

- 2011 Article 160Document6 pages2011 Article 160jwalantkbhattNo ratings yet

- NAOH Alkali Treatment For Banana FiberDocument5 pagesNAOH Alkali Treatment For Banana FiberJayendrasingh RawalNo ratings yet

- Laboratory Analytical Procedure: Chemical Analysis and Testing TaskDocument8 pagesLaboratory Analytical Procedure: Chemical Analysis and Testing TaskJuan Alzate JaramilloNo ratings yet

- Formal Report BiochemDocument6 pagesFormal Report Biochemjoshua_naruto100% (1)

- Tilley & Terry (1963)Document9 pagesTilley & Terry (1963)RatuAnggistaAprilinaNo ratings yet

- Acta, 104 (1980) 161-167: To Whom Correspondence Should Be AddressedDocument7 pagesActa, 104 (1980) 161-167: To Whom Correspondence Should Be AddressediulianaNo ratings yet

- Ahmad 2001Document9 pagesAhmad 2001Himew BraidNo ratings yet

- Rice Hull To Kojic AcidDocument17 pagesRice Hull To Kojic AcidArrianne Jaye MataNo ratings yet

- TMP 633 EDocument5 pagesTMP 633 EFrontiersNo ratings yet

- A New Method To Obtain B-Glucan From Saccharomyces Cerevisiae CellsDocument4 pagesA New Method To Obtain B-Glucan From Saccharomyces Cerevisiae Cellshuynhtanvu2011No ratings yet

- PredictDocument8 pagesPredictMia EruNo ratings yet

- The Kinetics of Glucose Production From Rice Straw By: Aspergillus NigerDocument8 pagesThe Kinetics of Glucose Production From Rice Straw By: Aspergillus NigerUttam KolekarNo ratings yet

- ElectroelutionDocument5 pagesElectroelutionPaulaSaPereiraNo ratings yet

- Proposal Project f4 DrafDocument6 pagesProposal Project f4 Drafaiman farhanaNo ratings yet

- Removal Protein With EnzymeDocument9 pagesRemoval Protein With EnzymeThu Trang LêNo ratings yet

- Characterization of Industrially-Valuable Xylanopectinolytic Enzymes Produced Concurrently by A Novel Isolate of Bacillus PumilusDocument9 pagesCharacterization of Industrially-Valuable Xylanopectinolytic Enzymes Produced Concurrently by A Novel Isolate of Bacillus PumilusLiyin WongNo ratings yet

- LAboratory ProceduresDocument29 pagesLAboratory ProceduresFer CasNo ratings yet

- Updegraff 1969Document5 pagesUpdegraff 1969neeraj bishtNo ratings yet

- ResearchDocument13 pagesResearchLucyana Can D VithNo ratings yet

- 1 s2.0 S2238785421001617 MainDocument13 pages1 s2.0 S2238785421001617 MainhawNo ratings yet

- Sol-Gel Process For Synthesis of Nanoparticles and Applications ThereofDocument5 pagesSol-Gel Process For Synthesis of Nanoparticles and Applications ThereofhawNo ratings yet

- Loop LengthDocument1 pageLoop LengthhawNo ratings yet

- Measurement of Comfort UPF and Structural ParametersDocument1 pageMeasurement of Comfort UPF and Structural ParametershawNo ratings yet

- أسئلة وأجوبة فى النسيجDocument17 pagesأسئلة وأجوبة فى النسيجhawNo ratings yet

- Measuring Sewability DeviceDocument121 pagesMeasuring Sewability DevicehawNo ratings yet

- 1 s2.0 S0144861719300876 MainDocument13 pages1 s2.0 S0144861719300876 MainhawNo ratings yet

- 1 s2.0 S246802302100688X MainDocument9 pages1 s2.0 S246802302100688X MainhawNo ratings yet

- Synthesis and Characterization of Sol-Gel Alumina NanofibersDocument10 pagesSynthesis and Characterization of Sol-Gel Alumina NanofibershawNo ratings yet

- 1 s2.0 S0254058422009646 MainDocument8 pages1 s2.0 S0254058422009646 MainhawNo ratings yet

- 1 s2.0 S0141813021000076 MainDocument8 pages1 s2.0 S0141813021000076 MainhawNo ratings yet

- 1 s2.0 S0300944022003034 MainDocument10 pages1 s2.0 S0300944022003034 MainhawNo ratings yet

- مهم1Document33 pagesمهم1hawNo ratings yet

- 1 s2.0 S0144861714003877 MainDocument10 pages1 s2.0 S0144861714003877 MainhawNo ratings yet

- 1 s2.0 S0959652621027104 MainDocument9 pages1 s2.0 S0959652621027104 MainhawNo ratings yet

- Moisture Vapor Permeability and Thermal Wear ComfortDocument24 pagesMoisture Vapor Permeability and Thermal Wear ComforthawNo ratings yet

- Innovative Management in Protective Clothing RentalDocument5 pagesInnovative Management in Protective Clothing RentalhawNo ratings yet

- 1 s2.0 S0014305722000441 MainDocument11 pages1 s2.0 S0014305722000441 MainhawNo ratings yet

- Fundamentals of The Fibrous MaterialsDocument36 pagesFundamentals of The Fibrous MaterialshawNo ratings yet

- Effect of Yarn Twist On Young's Modulus of Fully-Green Composites Reinforced With Ramie Woven FabricsDocument8 pagesEffect of Yarn Twist On Young's Modulus of Fully-Green Composites Reinforced With Ramie Woven FabricshawNo ratings yet

- Smart Breathable Fabric: N S. S, M J A K. ADocument17 pagesSmart Breathable Fabric: N S. S, M J A K. AhawNo ratings yet

- تقييم القلق- الاكتئاب والتور لدى الأفراد المصابيين بكورونا وأسرهمDocument6 pagesتقييم القلق- الاكتئاب والتور لدى الأفراد المصابيين بكورونا وأسرهمhawNo ratings yet

- Dimensional StabilityDocument10 pagesDimensional StabilityhawNo ratings yet

- Effect of comber noil percentage on yarn qualityDocument12 pagesEffect of comber noil percentage on yarn qualityhawNo ratings yet

- Archives of Psychiatric Nursing: Gulay Tasdemir Yigitoglu, Atakan Yilmaz, Halis YilmazDocument7 pagesArchives of Psychiatric Nursing: Gulay Tasdemir Yigitoglu, Atakan Yilmaz, Halis YilmazhawNo ratings yet

- Development of A Multifunctional Intelligent Elbow Brace (MIEB) Using A Knitted Textile Strain SensorDocument9 pagesDevelopment of A Multifunctional Intelligent Elbow Brace (MIEB) Using A Knitted Textile Strain SensorhawNo ratings yet

- Prediction of Dimensional Change in Finished Fabric Through Artificial Neural Networks (#411631) - 451256Document9 pagesPrediction of Dimensional Change in Finished Fabric Through Artificial Neural Networks (#411631) - 451256hawNo ratings yet

- العلاج السلوكى المعرفى لعلاج الاكتئاب والقلق الناتج من كوروناDocument7 pagesالعلاج السلوكى المعرفى لعلاج الاكتئاب والقلق الناتج من كوروناhawNo ratings yet

- Anxiety and Depression in Medical Staff During COVIDDocument4 pagesAnxiety and Depression in Medical Staff During COVIDhawNo ratings yet

- LS CHEMISTRY CO.,LTD, Basic Organic Chemicals, EgyptDocument2 pagesLS CHEMISTRY CO.,LTD, Basic Organic Chemicals, EgypthawNo ratings yet

- Masai School Code of Conduct - Prefinal 11.10.2019Document3 pagesMasai School Code of Conduct - Prefinal 11.10.2019xavigatorNo ratings yet

- What Is The Time Value of MoneyDocument6 pagesWhat Is The Time Value of MoneySadia JuiNo ratings yet

- Motor-Catalog English 2013 PDFDocument80 pagesMotor-Catalog English 2013 PDFILham Dwi PutraNo ratings yet

- Make Money OnlineDocument9 pagesMake Money OnlineTimiNo ratings yet

- NBCC Green ViewDocument12 pagesNBCC Green Views_baishyaNo ratings yet

- Down Syndrome Research PaperDocument11 pagesDown Syndrome Research Paperapi-299871292100% (1)

- Sponsor A Child With E-Tuition 2022Document19 pagesSponsor A Child With E-Tuition 2022nuur xiemaNo ratings yet

- Smith Bell v. Sotello MattiDocument3 pagesSmith Bell v. Sotello MattijrvyeeNo ratings yet

- Architecture Floor Plan Abbreviations AnDocument11 pagesArchitecture Floor Plan Abbreviations AnGraphitti Koncepts and DesignsNo ratings yet

- USA V Brandon Hunt - April 2021 Jury VerdictDocument3 pagesUSA V Brandon Hunt - April 2021 Jury VerdictFile 411No ratings yet

- A Case of Haemochromatosis and Diabetes A Missed OpportunityDocument111 pagesA Case of Haemochromatosis and Diabetes A Missed Opportunitymimran1974No ratings yet

- List of Registered Non Govt and Govt Secondary SchoolDocument200 pagesList of Registered Non Govt and Govt Secondary SchoolDennisEudes78% (9)

- GES1003 AY1819 CLS Tutorial 1Document4 pagesGES1003 AY1819 CLS Tutorial 1AshwinNo ratings yet

- UTH homework template for English exercisesDocument8 pagesUTH homework template for English exercisesCinthya Peña de MezaNo ratings yet

- Beaba Babycook Recipe BookDocument10 pagesBeaba Babycook Recipe BookFlorina Ciorba50% (2)

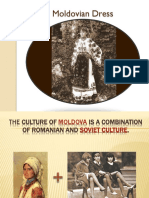

- Moldavian DressDocument16 pagesMoldavian DressAnastasia GavrilitaNo ratings yet

- On Healing Powers: Asclepius, Caduceus and AntibodiesDocument4 pagesOn Healing Powers: Asclepius, Caduceus and AntibodiesasclepiuspdfsNo ratings yet

- BATCH Bat Matrix OriginalDocument5 pagesBATCH Bat Matrix OriginalBarangay NandacanNo ratings yet

- Tax 1Document351 pagesTax 1AbbyNo ratings yet

- Emotion-WPS OfficeDocument2 pagesEmotion-WPS OfficemikaNo ratings yet

- Lab Report 4 - Group 6Document15 pagesLab Report 4 - Group 6ClarisshaNo ratings yet

- Use VCDS with PC lacking InternetDocument1 pageUse VCDS with PC lacking Internetvali_nedeleaNo ratings yet

- CLASS 7B Result Software 2023-24Document266 pagesCLASS 7B Result Software 2023-24JNVG XIB BOYSNo ratings yet

- Surveying 2 Practical 3Document15 pagesSurveying 2 Practical 3Huzefa AliNo ratings yet

- Balint Training System 1948Document16 pagesBalint Training System 1948Laura Acosta100% (2)

- India-An Underdeveloped Economy: (Contd )Document6 pagesIndia-An Underdeveloped Economy: (Contd )Amrita Prashant IyerNo ratings yet

- PCC 3300 PDFDocument6 pagesPCC 3300 PDFdelangenico4No ratings yet

- Chimdesa J. Functional FoodsDocument201 pagesChimdesa J. Functional FoodsChimdesa100% (1)

- Terms of Engagement - TMCS - GoldDocument14 pagesTerms of Engagement - TMCS - GoldPriyank KulshreshthaNo ratings yet

- Registration Form Proficiency Testing Program: Name Designation Mob. / Tel. NoDocument4 pagesRegistration Form Proficiency Testing Program: Name Designation Mob. / Tel. NoOwais Manzoor MalikNo ratings yet