Professional Documents

Culture Documents

Fire Water Storage Tank PDF

Fire Water Storage Tank PDF

Uploaded by

sky7Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Water Storage Tank PDF

Fire Water Storage Tank PDF

Uploaded by

sky7Copyright:

Available Formats

16'-613

16", TYP.

TO

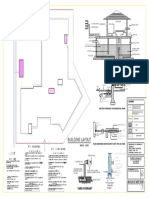

FOUNDATION ELEVATION & LOCATION SCHEDULE

T O /1 6

TO P/

P/ " B

SL

-2

-2

SL E L

P/ AB

3/1

SL HIGH POINT ELEVATION NORTHING EASTING

AB O

-2

6"

AB

"B

BE

(CTR.OF TANK / CTR. OF SLAB) (CTR.OF TANK / CTR. OF SLAB) (CTR.OF TANK / CTR. OF SLAB)

EL

LO

OW

W

W

SL

PAYNE & DOLAN

SL

SL

KUESTER 1284' - 6 15/16" N1302'-4 3/16" E2284'-4"

AB

AB

AB

HI

HI

HI

INCORPORATED

GH

GH

GH

MIHM 709' - 3 15/16" N1169'-10 15/16" E1675'-8 3/4"

PO

PO

PO

A WALBEC GROUP COMPANY

IN

IN

INT

T

T

W6380 Design Drive | Greenville, Wisconsin 54942

TEL 920.757.7550 | FAX 920.757.2906

www.payneanddolan.com

PLAN NOTES

TO " BE

1. FINISH SLAB CONTOUR TO MATCH CONTOUR OF CONICAL TANK BOTTOM.

P/ LO

-2

SL W

2. SLAB LOCATION AND ORIENTATION PER UMERC PLANS K-SF148 AND M-SF148.

AB S

3. SLAB ELEVATIONS PER WITHERUP FABRICATION DRAWING 17586, SHEET 1, REV.

A, 02/01/2018 WITH BMCD# 97179-5.2970-08496 COMMENTS, AND PAYNE & DOLAN WITHERUP

LA

B

EMAIL CORRESPONDENCE TO WITHERUP FABRICATION ON 3/15/2018.

FABRICATION AND

HI

GH

PO

TOP/SLAB ERECTION, INC.

IN

T

-2" BELOW SLAB HIGH POINT

CLIENT

TO 3/16

P/ " B

-2

SL EL

AB O

W

SL

NOT FOR

AB

#5 REBAR @ 12" O.C., EA. WAY

HI

GH

SLAB REINFORCING CONSTRUCTION

PO

REF. 1/F101, TYP.

IN

T

TO

-2

P/

3/1

SL

6"

AB

35'-0" DIA. FIRE WATER

UMERC F.D. KUESTER GENERATING STATION

BE

STORAGE TANK LO

UMERC A.J. MIHM GENERATING STATION

W

SL

AB

EQUAL, TYP.

STORAGE TANK

HI

G H

SLOPE 1" V : 10'-0" H

PO

REF. PLAN NOTE 1

FIRE WATER

CTR. OF TANK / CTR. FOUNDATION IN

HIGH POINT OF SLAB T

REF. FOUNDATION ELEVATION

& LOCATION SCHEDULE

1 1

TYP. F101 F101

TOP/SLAB TOP/SLAB

40'-0"

SLOPE 1" V : 10'-0" H SLOPE 1" V : 10'-0" H

-2" BELOW SLAB HIGH POINT REF. PLAN NOTE 1 REF. PLAN NOTE 1 -2" BELOW SLAB HIGH POINT

SLOPE 1" V : 10'-0" H

REF. PLAN NOTE 1

STAGGER LAP SPLICES

@ ADJACENT BARS, TYP.

EQUAL, TYP.

BOTTOM BARS

135

REF. 1/F101, TYP.

°, TY

P.

TO

P/

SL

-2

3-16-2018 UPDATED PER BMCD COMMENTS

NT

AB

3 /16

I

PO

"B

GH

DESCRIPTION

EL

OW

HI

AB

SL

1-24-2018 ISSUED FOR APPROVAL

REVISION SCHEDULE

SL

AB

W

6" B

HI

LO

3/1 /SLA

GH

BE

P

PO

TO

IN

2'-4" LAP @ BOTTOM BARS, TYP.

T

-2

TO

-2

"B

P/

SL

EL

AB

OW

T

IN

SL

PO

AB

GH

HI

GH

HI

DATE

AB

PO

EL LAB

SL

IN

T

OW

S

P/

TO

"B

NO.

PERIMETER BARS

-2

A

B

REF. 1/F101, TYP.

TO 3/16

STATE OF MICHIGAN

-2" BELOW SLAB HIGH POINT

P/ " B

-2

DATE: 1/24/2018

SL E

PROFESSIONAL ENGINEER

AB LO

T

IN

ENGINEER: DAN KLEIN

PO

DRAWN BY: DAN KLEIN

GH

W

HI

CHECKED BY: JARED MARUGG

SL

AB

AB

SL

SCALE: AS NOTED

HI

W

B

GH

LO

3/1 /SLA

PROJECT NUMBER:

TOP/SLAB

BE

PO

P

6"

IN

TO

T

-2

40'-0" REF. SHT. F101 FOR FOUNDATION

DESIGN AND

CONSTRUCTION PLAN

FOUNDATION PLAN 1 SPECIFICATIONS

FIRE WATER STORAGE TANK F100 DANIEL M. KLEIN

SCALE: 3/8" = 1'-0" LICENSE # 6201056325 F100

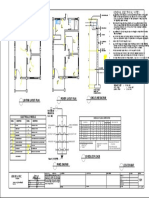

FOUNDATION DESIGN CRITERIA CONCRETE - GENERAL

1. DESIGN BASIS - BMCD SPECIFICATION 2970 FOR PROJECT 97179, AUGUST 29, 2017 AND REVISED REFERENCE DRAWINGS RECEIVED 1. CONCRETE CONSTRUCTION SHALL CONFORM TO THE LATEST EDITION OF ACI 301, ACI 318, 302.1, AND THESE PLANS, DETAILS AND

VIA EMAIL ON JANUARY 23, 2018. ALL MATERIALS AND CONSTRUCTION SHALL MEET THE REQUIREMENTS OF THESE DOCUMENTS, SPECIFICATIONS.

AND THE REFERENCE DOCUMENTS AND SPECIFICATIONS. 2. COLD WEATHER CONCRETING SHALL MEET THE REQUIREMENTS OF “STANDARD SPECIFICATION FOR COLD WEATHER

2. FOUNDATION LOADS - WITHERUP FABRICATION AND ERECTION, INC. TANK DESIGN DRAWING S1, REV. 0, 1/4/2018. CONCRETING”, ACI 306.1, LATEST EDITION.

3. FOUNDATION ELEVATIONS - WITHERUP FABRICATION DRAWING 17586, REV. A, SHEET 1, 02/01/18 WITH BMCD# 3. HOT WEATHER CONCRETING SHALL MEET THE REQUIREMENTS OF “SPECIFICATION FOR HOT WEATHER

CONCRETING”, ACI 305.1, LATEST EDITION.

PAYNE & DOLAN

97179-5.2970-08496 COMMENTS. PAYNE & DOLAN EMAIL CORRESPONDENCE TO WITHERUP FABRICATION ON 3/15/2018. INCORPORATED

4. FOUNDATION LOCATIONS AND ORIENTATION - BMCD DRAWINGS K-SF148, REV 0 AND M-SF148, REV 0. A WALBEC GROUP COMPANY

5. GEOTECHNICAL DESIGN - COLEMAN ENGINEERING REPORT OF GEOTECHNICAL INVESTIGATION FOR KUESTER GENERATING STATION, BASE SLAB

W6380 Design Drive | Greenville, Wisconsin 54942

JULY, 2017 AND COLEMAN ENGINEERING REPORT OF GEOTECHNICAL INVESTIGATION FOR MIHM GENERATING STATION, ADDENDUM TEL 920.757.7550 | FAX 920.757.2906

#1, SEPTEMBER 12, 2017. 1. TANK BOTTOM CUSHION SHALL BE PROVIDED BY TANK MANUFACTURER IN ACCORDANCE WITH AWWA D100, SECTION 12.6. www.payneanddolan.com

6. TANK GENERAL ARRANGEMENT - WITHERUP FABRICATION AND ERECTION, INC. TANK DESIGN DRAWING S1, REV. 0, 1/4/2018. 2. TOLERANCES ON SLAB FINISH SHALL BE IN ACCARDANCE WITH AWWA D100, SECTION 12.6.2.

7. SLAB EMBEDDED ITEMS - NONE. 3. BASE SLAB SHALL BE POURED MONOLITHICALLY

8. TANK BASE INSTALLATION DETAILS BY OTHERS. 4. REBAR BENDING SHALL BE PERFORMED IN ACCORDANCE WITH THE LATEST EDITIONS OF ACI 315, ACI 318, AND CRSI “MANUAL OF

9. MECHANICAL ANCHORAGE OF TANK IS NOT REQUIRED PER THE APPROVED TANK DESIGN. CONCRETE PRACTICE”.

10.DESIGN AND INSTALLATION OF TANK GROUNDING BY OTHERS. FOUNDATION CONTRACTOR TO COORDINATE GROUNDING SYSTEM 5. VIBRATE CONCRETE AS NECESSARY TO CONSOLIDATE CONCRETE AROUND REBAR AND PREVENT VOIDS.

6. REBAR SPLICES SHALL BE CLASS B LAP SPLICES.

INSTALLATION WITH OWNER PRIOR TO COMMENCING FOUNDATION CONSTRUCTION.

7. LAP SPLICES OF ADJACENT BARS SHALL BE STAGGERED SO THAT ADJACENT BAR SPLICES DO NOT OVERLAP. STAGGER LENGTH SHALL WITHERUP

GENERAL SPECIFICATIONS BE NOT LESS THAN THE LAP LENGTH SPECIFIED BELOW. FABRICATION AND

8. MINIMUM REBAR LAP SPLICE LENGTHS: #5 REBAR - 2'-0”.

1. THE SCOPE OF THIS PLAN AND SPECIFICATION IS FOR THE GEOSTRUCTURAL AND STRUCTURAL DESIGN AND CONSTRUCTION OF THE #6 REBAR - SEE PLAN. ERECTION, INC.

TANK FOUNDATION ONLY. 9. SLAB SHALL BE FINISHED FLAT AND LEVEL UNLESS OTHERWISE NOTED ON THE PLANS.

2. OBTAIN ALL REQUIRED PERMITS AND APPROVALS PRIOR TO MATERIAL PROCUREMENT AND CONSTRUCTION. 10.SLAB SHALL BE MAGNESIUM TROWEL FINISHED. CLIENT

3. THE CONTRACTOR SHALL FIELD VERIFY ALL ELEVATIONS AND DIMENSIONS PRIOR TO CONSTRUCTION. 11.CHAMFER EXPOSED CONCRETE EDGES ¾” X 45 DEGREES.

4. THE CONTRACTOR SHALL COMPLY WITH ALL FEDERAL AND STATE REQUIREMENTS FOR CONSTRUCTION SAFETY, CONSTRUCTION 12.DO NOT LOAD SLAB UNTIL THE SPECIFIED DESIGN COMPRESSIVE STRENGTH OF THE CONCRETE IS ACHIEVED.

PERSONNEL SAFETY, MAINTENANCE PERSONNEL SAFETY AND GENERAL PUBLIC SAFETY.

5. COORDINATE RELOCATION OF EXISTING UTILITIES AS REQUIRED WITH OWNER PRIOR TO CONSTRUCTION. USE OF DOCUMENTS

6. THE CONTRACTOR SHALL PROTECT ALL STRUCTURES, EQUIPMENT, PIPING AND ELECTRICAL SYSTEMS AND SITE IMPROVEMENTS

DURING CONSTRUCTION. 1. THE USE OF THESE PLANS, DETAILS OR SPECIFICATIONS FOR OTHER LOADING CONDITIONS OR OTHER PROJECTS IS PROHIBITED NOT FOR

WITHOUT THE WRITTEN CONSENT OF PAYNE & DOLAN, INC.

7. THE OWNER SHALL IDENTIFY TO THE CONTRACTOR THE LOCATION OF ALL UNDERGROUND UTILITIES AND UNDERGROUND

STRUCTURES IN THE VICINITY OF AND BELOW THE PROPOSED BASE SLABS, EXCAVATIONS AND GRADING PRIOR TO CONSTRUCTION.

CONSTRUCTION

8. THE OWNER IS RESPONSIBLE FOR IDENTIFICATION OF POTENTIAL ENVIRONMENTAL AND PERSONNEL SAFETY HAZARDS TO THE

CONTRACTOR PRIOR TO CONSTRUCTION.

9. HANDLING AND DISPOSAL OF POTENTIAL ENVIRONMENTAL HAZARDS SHALL BE IN ACCORDANCE WITH ALL STATE AND FEDERAL

UMERC F.D. KUESTER GENERATING STATION

REQUIREMENTS.

10.THE FOUNDATION SHALL BE PLACED USING METHODS THAT WILL NOT DAMAGE EXISTING FACILITIES.

UMERC A.J. MIHM GENERATING STATION

11.CONTACT THE ENGINEER FOR DIRECTION IF FIELD CONDITIONS DO NOT AGREE WITH THE PLANS AND SPECIFICATIONS.

STORAGE TANK

REFERENCE SPECIFICATIONS 10'-0" MIN.

VARIES, SEE PLAN

FIRE WATER

3

4"x45° CHAMFER

SEE PLAN

1. MICHIGAN BUILDING CODE, 2015 EDITION.

VARIES

2. AWWA D100-11 - “WELDED CARBON STEEL TANKS FOR WATER STORAGE”. #5 REBAR @ 12" O.C. EA. WAY

3. ASCE 7-10 - “MINIMUM DESIGN LOADS FOR BUILDINGS AND OTHER STRUCTURES”. (3) - #6 PERIMETER BARS

@ EQ. SPACING SLOPE 1" V : 10'-0" H

4. ACI 318-14 - “BUILDING CODE REQUIREMENTS FOR STRUCTURAL CONCRETE”

41 2" CLR.

TOP/SLAB

SEE PLAN

SUBMITTALS

FIN. GRADE

1. SUBMIT REBAR SHOP DETAIL AND PLACEMENT DRAWINGS TO THE DESIGN ENGINEER FOR REVIEW AND APPROVAL PRIOR TO SLOPE 8% REF. SECTION NOTE 1

FABRICATING REBAR.

PER

1'-10"

FINISH GRADE

1'-8"

4" CLR.

INSPECTIONS AND TESTING ICATIONS 4" 1

UMERC SPECIF

1. INSPECTIONS AND MATERIAL TESTING SHALL BE IN ACCORDANCE WITH THE REQUIREMENTS OF THE CONTRACT. 1.5

2. SUBGRADE AND FOUNDATION FILL COMPACTION TESTING SHALL BE AS SPECIFIED IN THE COLEMAN GEOTECHNICAL REPORTS.

3. ALL INSPECTION REPORTS AND TEST RESULTS SHALL BE SUBMITTED TO THE OWNER FOR REVIEW AND APPROVAL.

MATERIALS 4" CLR.

(5) - #6 REBAR @ EQ. SPACING

1. STRUCTURAL FILL BELOW THE BASE SLAB SHALL BE A NON FROST SUSCEPTIBLE MATERIAL CONFORMING TO MDOT CLASS IIA SAND CONTINUOUS, BOTTOM

3'-2" MIN.

OR EQUAL. 2" MUD SLAB

2. MINIMUM REQUIRED BEARING CAPACITY FOR STRUCTURAL FILL IS 2,500 PSF. NON FROST SUSCEPTIBLE

3. REBAR - ASTM A615 GR. 60. STRUCTURAL FILL

4. CONCRETE FOR BASE SLAB: MDOT CLASS IIA SAND

A. f'c=4,500 PSI MIN. COMPRESSIVE STRENGTH AT 28 DAYS. (OR EQUAL)

B. CONCRETE MIX SHALL BE PROPORTIONED BASED ON THE FOLLOWING EXPOSURE CATEGORIES AND CLASSES REFERENCING ACI

3-16-2018 UPDATED PER BMCD COMMENTS

318-14, SECTION 19.3.1:

I. FREEZING AND THAWING - F1 SECTION NOTES

DESCRIPTION

II. SULFATE - S0 3'-6" 5'-4"

III. IN CONTACT WITH WATER - W0 1. REF. BURNS & MCDONNELL PLANS FOR FINISH GRADE ELEVATION.

1-24-2018 ISSUED FOR APPROVAL

REVISION SCHEDULE

IV. CORROSION - C1 2. FIRE WATER STORAGE TANK NOT SHOWN.

C. CONCRETE SLUMP - MAXIMUM CONCRETE SLUMP IS 4” AT TIME OF PLACEMENT.

D. CONCRETE MIXTURES SHALL COMPLY WITH THE REQUIREMENTS OF ACI 318-14, SECTION 19.3.2.

E. CAST IN PLACE CONCRETE SHALL BE IN CONFORMANCE WITH BMCD SPECIFICATION 2970 FOR PROJECT 97179, AUGUST 29, 2017, TYP. FOUNDATION SECTION 1

SECTION 03 30 00.

FIRE WATER STORAGE TANK F100

EARTHWORK SCALE: 3/4" = 1'-0"

1. EROSION CONTROL MEASURES SHALL BE PROVIDED IN ACCORDANCE WITH STATE OF MICHIGAN REQUIREMENTS AND BEST

PRACTICE RECOMMENDATIONS.

2. OWNER TO LOCATE AND MARK ALL UNDERGROUND UTILITIES AND STRUCTURES WITHIN THE CONSTRUCTION BOUNDARY PRIOR TO

DATE

CONSTRUCTION.

3. THE CONTRACTOR SHALL CONTACT DIGGERS HOTLINE TO MARK UNDERGROUND UTILITIES PRIOR TO CONSTRUCTION.

4. CONTACT THE ENGINEER FOR DIRECTION IF GROUNDWATER IS ENCOUNTERED IN THE EXCAVATIONS.

5. THE CONTRACTOR SHALL KEEP EXCAVATIONS DRY DURING CONSTRUCTION.

NO.

6. STOCKPILED FILL MATERIALS SHALL BE KEPT DRY DURING CONSTRUCTION.

A

B

7. NO HOLES, TRENCHES, OR DISTURBANCES OF THE SOIL SHALL BE ALLOWED WITHIN THE VOLUME

DESCRIBED BY 45 DEGREE LINES SLOPING FROM THE BOTTOM EDGE OF THE EXISTING FOUNDATIONS. STATE OF MICHIGAN

DATE: 1/24/2018

DO NOT UNDERMINE EXISTING SLABS OR FOUNDATIONS. PROFESSIONAL ENGINEER

8. REMOVE ALL TOPSOIL, UNSUITABLE SOILS, ORGANIC MATERIALS, DEBRIS, ETC. BELOW THE OPEN GRADED STRUCTURAL FILL. ENGINEER: DAN KLEIN

9. COMPACT THE SUB-GRADE PRIOR TO PLACEMENT OF STRUCTURAL FILL. DRAWN BY: DAN KLEIN

10.MINIMUM REQUIRED SUBGRADE BEARING CAPACITY FOR SLAB CONSTRUCTION IS 2,500 PSF. VERIFY THE SUB-GRADE BEARING CHECKED BY: JARED MARUGG

CAPACITY PRIOR TO PLACEMENT OF STRUCTURAL FILL. IF THE SUB-GRADE BEARING CAPACITY BELOW THE STRUCTURAL SLAB IS LESS SCALE: AS NOTED

THAN 2,500 PSF, NOTIFY THE ENGINEER FOR DIRECTION BEFORE PROCEEDING WITH FOUNDATION CONSTRUCTION.

PROJECT NUMBER:

11.DO NOT PLACE FILL MATERIALS OR CONCRETE ON FROZEN GROUND, ICE OR SNOW.

12.ALL BEDDING AND FILL MATERIALS SHALL BE CLEAN, INORGANIC GRANULAR MATERIAL, FREE OF ICE, SNOW, DEBRIS AND LARGE

ROCKS. REF. SHT. F100 FOR SPECIFICATIONS

13.STRUCTURAL FILL SHALL BE PLACED IN LIFTS NOT EXCEEDING 12" IN LOOSE THICKNESS. EACH LIFT SHALL BE COMPACTED TO A FOUNDATION PLAN FOR FOUNDATION

MINIMUM OF 98% OF STANDARD PROCTOR (ASTM D-698) MAXIMUM DRY DENSITY.

14.PLACE MUD SLAB IMMEDIATELY AFTER PLACEMENT OF STRUCTURAL FILL. DESIGN &

15.CONCRETE FOR MUD SLAB SHALL BE f'c = 2000 PSI.

CONSTRUCTION

DANIEL M. KLEIN

LICENSE # 6201056325 F101

You might also like

- Kuenz TRCMDocument9 pagesKuenz TRCMklcy1987No ratings yet

- Sercel 428XL Manuals - En428user1Document388 pagesSercel 428XL Manuals - En428user1Vlad Mitin100% (1)

- SgTank Sectional Water Storage TankDocument33 pagesSgTank Sectional Water Storage TankRichard LeongNo ratings yet

- Vertical In-Line Pump: Technical FeaturesDocument22 pagesVertical In-Line Pump: Technical FeaturesHicham HrslNo ratings yet

- Pneumatic Conveyor: I. Introduction of Pneumatics and Its ApplicationsDocument11 pagesPneumatic Conveyor: I. Introduction of Pneumatics and Its ApplicationsAbas S. AcmadNo ratings yet

- Water Storage Tank Design CriteriaDocument34 pagesWater Storage Tank Design Criterialance boxNo ratings yet

- Manual SMLDocument76 pagesManual SMLsulebebNo ratings yet

- Storage Volume of TanksDocument90 pagesStorage Volume of TanksRamachandran VenkateshNo ratings yet

- ERICO Seismic Sway Bracing SeminarDocument129 pagesERICO Seismic Sway Bracing Seminarmas zak danielNo ratings yet

- 03 WSC 13Document36 pages03 WSC 13Madan YadavNo ratings yet

- Type AB Air Gaps - Practical ExamplesDocument3 pagesType AB Air Gaps - Practical ExamplesZack ZakariaNo ratings yet

- Roto Pump VLCA-571 General ArrangeDocument1 pageRoto Pump VLCA-571 General ArrangeEdinsonUribeTorresNo ratings yet

- 3.a13a PMSDocument5 pages3.a13a PMSS.selvakumarNo ratings yet

- Papers - Pipe Conveyors - Development and AdvantagesDocument8 pagesPapers - Pipe Conveyors - Development and AdvantagesJulie WillisNo ratings yet

- 1 Air Quality 1.8 National Air Quality Status Report 2008 2015 PDFDocument52 pages1 Air Quality 1.8 National Air Quality Status Report 2008 2015 PDFPaolo Q. Sangalang100% (1)

- Pump TemplateDocument2 pagesPump TemplateamitkrayNo ratings yet

- 2 1 PDFDocument162 pages2 1 PDFyvanmmuNo ratings yet

- Solar Resource Lecture NotesDocument57 pagesSolar Resource Lecture NotesmdmarufurNo ratings yet

- Pipe Thread SizeDocument1 pagePipe Thread SizeJeffrey WalkerNo ratings yet

- Water Meter Design Criteria ManualDocument21 pagesWater Meter Design Criteria ManualAnonymous M0tjyWNo ratings yet

- Standard Specification For Hot Insulation Piping EquipmentDocument62 pagesStandard Specification For Hot Insulation Piping EquipmentAri SupramonoNo ratings yet

- 25hp 4p 284tpa Wpi Bf37 AuDocument15 pages25hp 4p 284tpa Wpi Bf37 Aurhusseinpos4765No ratings yet

- Foam Proportioning Equipment: DescriptionDocument32 pagesFoam Proportioning Equipment: Descriptionkiara nasutionNo ratings yet

- (For SHI-UNA RFQ) MTO For Non-Pressure Parts (Excluding PlateDocument14 pages(For SHI-UNA RFQ) MTO For Non-Pressure Parts (Excluding PlategerrydimayugaNo ratings yet

- Horizontal Split CasingDocument6 pagesHorizontal Split Casingvivekpec100% (1)

- Pumping Stations Design Lecture 6Document45 pagesPumping Stations Design Lecture 6njvargascNo ratings yet

- FGD ADS Power Flame Gas Oil Mist Detection TurbinesDocument4 pagesFGD ADS Power Flame Gas Oil Mist Detection Turbinesaugur886No ratings yet

- Vessel Conveyor SystemDocument4 pagesVessel Conveyor SystemleekiangyenNo ratings yet

- Outgoing Drawing RegisterDocument12 pagesOutgoing Drawing RegisteradnanNo ratings yet

- ASME FlangeDocument5 pagesASME FlangeKuldeep SinghNo ratings yet

- Haestad All ProductsDocument22 pagesHaestad All ProductsopetcoNo ratings yet

- Bomba SihiDocument24 pagesBomba SihiCristian PovedaNo ratings yet

- Dryer Output CalculationDocument1 pageDryer Output CalculationSatish DaveNo ratings yet

- OxfordFiltration SelfCleaningFiltersDocument2 pagesOxfordFiltration SelfCleaningFiltersgui51comlimaoNo ratings yet

- Project Standard Specification: Potable-Water Storage Tanks 15450 - Page 1/12Document12 pagesProject Standard Specification: Potable-Water Storage Tanks 15450 - Page 1/12adel rihanaNo ratings yet

- R-102 Restaurant Fire Suppression Systems: FeaturesDocument4 pagesR-102 Restaurant Fire Suppression Systems: FeaturesAdil SyedNo ratings yet

- Mechanical Properties of Poly (Ether-Etherketone)Document9 pagesMechanical Properties of Poly (Ether-Etherketone)Uriel PeñaNo ratings yet

- Pad Eye Lifting PDFDocument1 pagePad Eye Lifting PDFnaval_05No ratings yet

- Abstract Deccan Hvac ProjectDocument2 pagesAbstract Deccan Hvac ProjectMajeed aliNo ratings yet

- MU Literature SLIDE GATEDocument15 pagesMU Literature SLIDE GATEJulio PCNo ratings yet

- Application For Registration and Licensing Without ExaminationDocument2 pagesApplication For Registration and Licensing Without ExaminationSphinx DinopolNo ratings yet

- Series 500 Mk3 General Arrangement Rev 3 RNE PUMP PARTSDocument1 pageSeries 500 Mk3 General Arrangement Rev 3 RNE PUMP PARTSZaen SalimNo ratings yet

- Leak Detection SystemsDocument13 pagesLeak Detection SystemsHouyemeZouariNo ratings yet

- Belt Speed in M/sec (V) Elevator CalculationsDocument1 pageBelt Speed in M/sec (V) Elevator CalculationsKendra TerryNo ratings yet

- DUST CONTROL HANDBOOK FOR MINERALS PROCESSING by Martin Marietta Laboratories 1987Document176 pagesDUST CONTROL HANDBOOK FOR MINERALS PROCESSING by Martin Marietta Laboratories 1987Ferudun AkyolNo ratings yet

- Portable Fire Pump PDFDocument8 pagesPortable Fire Pump PDFNajib NdutNo ratings yet

- Finding The Difficult' Leaks: Mfarley@alvescot - Demon.co - UkDocument4 pagesFinding The Difficult' Leaks: Mfarley@alvescot - Demon.co - UkYoussefNo ratings yet

- Pickup and Saltation Velocitiesin Pneumatic ConveyingDocument12 pagesPickup and Saltation Velocitiesin Pneumatic ConveyingMichael J. BaneNo ratings yet

- WL130 PE4710 FM Approved Pipe: IPS & DIPS Pipe Sizes - Class 150, 200 & 267Document3 pagesWL130 PE4710 FM Approved Pipe: IPS & DIPS Pipe Sizes - Class 150, 200 & 267Tanwir AhmadNo ratings yet

- Standard Belt Feeders HF Series LRDocument2 pagesStandard Belt Feeders HF Series LREduardoNo ratings yet

- Rescue and Ventilation Plan Template (Vent Plan)Document1 pageRescue and Ventilation Plan Template (Vent Plan)Denn HairlyNo ratings yet

- Aero Belt ConveyorDocument8 pagesAero Belt ConveyorsrinivasakumarNo ratings yet

- Building Layout: Yard HydrantDocument1 pageBuilding Layout: Yard HydrantPrashant JadhavNo ratings yet

- OSHA Long Term Care Worker Protection ProgramDocument50 pagesOSHA Long Term Care Worker Protection ProgramKaiser Angelo G. LadoresNo ratings yet

- Waste Water Piping and Vent System Sir FhaDocument40 pagesWaste Water Piping and Vent System Sir Fhabradley100% (1)

- IBC2015 Egress CalculatorDocument53 pagesIBC2015 Egress CalculatorAnonymous C2Scx5nkdK0% (1)

- Water Line Lay-Out and DetailsDocument1 pageWater Line Lay-Out and DetailsWilbert ReuyanNo ratings yet

- Power Inlet Assy: 13NO 14NODocument1 pagePower Inlet Assy: 13NO 14NOananth bhuvanaNo ratings yet

- Electrical Layout and Dyanmic Block Copy PAPER 20 X 30Document1 pageElectrical Layout and Dyanmic Block Copy PAPER 20 X 30Danczar JuanNo ratings yet

- Test Pile For Flyover 16+250Document1 pageTest Pile For Flyover 16+250vivekNo ratings yet

- E PlanDocument1 pageE PlanSheila Mary CamuloNo ratings yet

- SAP SRM Course CurriculumDocument1 pageSAP SRM Course CurriculumSantoshReddyNo ratings yet

- Adpatch BasicsDocument37 pagesAdpatch BasicsArindam DebrayNo ratings yet

- Dear Sir/Madam, Thanks For Being Our Awesome Customer! Naina Realty Offers You This Navratri Buy Your Dream Home in Smart City Ulwe Navi MumbaiDocument2 pagesDear Sir/Madam, Thanks For Being Our Awesome Customer! Naina Realty Offers You This Navratri Buy Your Dream Home in Smart City Ulwe Navi MumbaiManoj MulikNo ratings yet

- Satellite InternetDocument4 pagesSatellite Internetuzair awanNo ratings yet

- BIST-Based Test and Diagnosis of FPGA Logic Blocks: Miron AbramoviciDocument23 pagesBIST-Based Test and Diagnosis of FPGA Logic Blocks: Miron AbramoviciPrasanth VarasalaNo ratings yet

- Huawei Product and Knowledge Enterprise Customer Training Manual PDFDocument644 pagesHuawei Product and Knowledge Enterprise Customer Training Manual PDFDemarco Dayanghirang FormalejoNo ratings yet

- Progress OpenEdge 10.1A02 Service Pack Release NotesDocument55 pagesProgress OpenEdge 10.1A02 Service Pack Release NoteselmofoNo ratings yet

- Cat 03 15 NPP 02Document1 pageCat 03 15 NPP 02Markus MatikNo ratings yet

- Sentry Multi 10-40 Ita-En PDFDocument87 pagesSentry Multi 10-40 Ita-En PDFpudescioriNo ratings yet

- Serpentine Pavilion Press PackDocument21 pagesSerpentine Pavilion Press PackAlvaro RosaDayerNo ratings yet

- VDP Technical Drawings RealDocument12 pagesVDP Technical Drawings Realapi-331456896No ratings yet

- Pic 32 MXDocument646 pagesPic 32 MXagatheludaNo ratings yet

- FPGA Architecture SulochanaDocument38 pagesFPGA Architecture SulochanaGagandeep Singh DhingraNo ratings yet

- Synopsis PDF FinalDocument7 pagesSynopsis PDF FinalVIGNESH A100% (1)

- Toshiba - Rekuperatori - Katalog (Staro)Document11 pagesToshiba - Rekuperatori - Katalog (Staro)Matija PolićNo ratings yet

- 3 Jet GroutingDocument5 pages3 Jet GroutingshubhamNo ratings yet

- Case Amazon AwsDocument9 pagesCase Amazon AwsrobertoazulNo ratings yet

- File 959Document8 pagesFile 959kaushal kumarNo ratings yet

- GUIDELINES FOR Certificate of Approval Lamp Latest PDFDocument4 pagesGUIDELINES FOR Certificate of Approval Lamp Latest PDFevonchayNo ratings yet

- MARS Release History and NotesDocument12 pagesMARS Release History and NotesNabil AlzeqriNo ratings yet

- Sap Jam Collaboration Advanced Plus Edition English v12 2018 (1341)Document7 pagesSap Jam Collaboration Advanced Plus Edition English v12 2018 (1341)dipeshNo ratings yet

- ExpressionismDocument14 pagesExpressionismDinsha DineshNo ratings yet

- v6.3.2b Releasenotes v1.0-1Document115 pagesv6.3.2b Releasenotes v1.0-1Thirunavukkarasu ThangavelNo ratings yet

- 5to E - B3 Y B1 - Guía N°2 y TP San MartinDocument4 pages5to E - B3 Y B1 - Guía N°2 y TP San MartinFerNo ratings yet

- LibuestionsDocument25 pagesLibuestionsnasrinNo ratings yet

- Lesson 7 - Laying Out and StakingDocument13 pagesLesson 7 - Laying Out and StakingROMNICK HANDAYANNo ratings yet

- Acer Aspire V7-481 (Quanta ZQK)Document46 pagesAcer Aspire V7-481 (Quanta ZQK)maoh80No ratings yet

- ArQoS PROBE-PON - EN v10.1 PDFDocument13 pagesArQoS PROBE-PON - EN v10.1 PDFNelson R. Vicente AndréNo ratings yet

- MonitorDocument16 pagesMonitorchristianpascuaNo ratings yet