Professional Documents

Culture Documents

Article PDF

Article PDF

Uploaded by

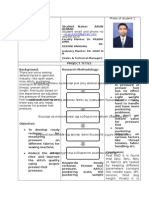

Hatem AbdelnabiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Article PDF

Article PDF

Uploaded by

Hatem AbdelnabiCopyright:

Available Formats

Factors Controlling Biofloc

Characteristics

Vikas Phulia1*, Babita Mandal, Aritra Bera, Soibam Khogen Singh, Rakesh Das and Ankur Jamwal

Biofloc Technology Flocs can reach more than 1000 µm in diameter. Typical

Biofloc technology combines the removal of nutrients from flocs are irregular in shape, have a broad distribution of particle

water with the production of microbial biota, which can be used sizes, are fine and easily compressible, with more than 99 percent

by some fish and shrimp as food. Bioflocs are macroaggregates porosity, and are permeable to fluids (Chu and Lee 2004). The

of diatoms, macroalgae, fecal pellets, exoskeletons and the density of floc material is low, just slightly greater than that

remains of dead organisms, bacteria, and invertebrates. Biofloc of water. As a consequence, flocs sink rather slowly (1-3 m/h,

technology systems in aquaculture are based on activated-sludge Sears et al. 2006). Good-settling flocs are not necessarily lost

wastewater treatment systems. by sedimentation because

Biofloc technology is Biofloc technology combines the removal aeration devices keep them in

based on intensive growth of of nutrients from water with the suspension.

heterotrophic bacteria, which production of microbial biota, which can Extracellular polymeric

consume organic carbon and be used by some fish and shrimp as food. substances (EPS) form a

immobilize inorganic nitrogen, Bioflocs are macroaggregates of diatoms, matrix that encapsulate

depending on the C/N ratio. macroalgae, fecal pellets, exoskeletons and microbial calls and play a

Removal of nitrogen from the remains of dead organisms, bacteria, and major role in binding floc

culture water by means of invertebrates. Biofloc technology systems in components. The presence

biofloc technology (BFT) is aquaculture are based on activated-sludge of EPS in activated sludge

regulated by the balanced wastewater treatment systems. wastewater systems can be

addition of carbon. This substantial, up to 80 percent

transformation is achieved by adding different types of organic of the total mass (Hantula and Bamford 1991, Liu and Fang

carbon and results in the production of microbial protein that can 2003). EPS typically consist of polysaccharides, protein, humic

be used as fish food. compounds, nucleic acids and lipids (Zita and Hermansson

One striking feature of biofloc systems is very low retention 1994). They are produced as slime or capsule layers under

of nutrients by microbes. About 7 percent of the nitrogen and 6 various nutritional conditions, particularly nutrient limitation

percent of the phosphorus in feed are retained by conversion to (Steiner et al. 1976).

microbial biomass (Schneider et al. 2005). However, when carbon

and nitrogen are balanced in the water and microbial assimilation Critical Control Factors

of the ammonia is engineered efficiently, complete retention can The nutritional value and morphological characteristics of

be obtained. Avnimelech (1999) demonstrated that 10 mg NH4- bioflocs are dependent on a number of operational parameters.

N/L could be almost completely removed within 5 hours after the Inasmuch as floc is an aggregate of several components,

addition of glucose at a C/N ratio of 10, without the accumulation prevailing conditions in culture units strongly affect biofloc

of nitrite and nitrate. composition and characteristics.

Bioflocs have the potential to be used as fish food with good

nutritional quality. Biofloc technology can stimulate microbial Mixing Intensity

development in BFT ponds that will lead to improved nutrient In biofloc systems, one of the main functions of paddlewheel

efficiency and reduced need for dietary fishmeal and fish oil. aerators is to keep bioflocs in suspension. In aquaculture systems,

Biofloc technology can improve the efficiency in the use of a wide range of aeration devices are used, ranging from 0.1

nutrients from feed. Dried biofloc can be used as a protein source to 10 (up to 100) W/m3 (Boyd 1998). The correct number and

in aquafeeds. This article describes the factors that regulate the position of paddlewheel aerators used in ponds are critical. The

nutritional quality of bioflocs. steady-state floc particle size mainly depends on the number

and mixing intensity of aeration devices. The steady-state floc

Biofloc Constituents and Characteristics particle size distribution reflects an equilibrium between the

Microbial flocs consist of a heterogeneous mixture of rate of aggregation and the rate of breakage and dispersion as

microorganisms, particles, colloids, organic polymers, cations affected by turbulent mixing (Chaignon et al. 2002, Spicer and

and dead cells (Jorand et al. 1995). Living microbial cells are Pratsinis 1996). At greater mixing intensities, shear rates will be

only 2-20 percent of the organic fraction of sludge flocs. The high and the average floc size will decrease because of increased

total organic content of flocs may be 60-70 percent (Wilen et al. floc breakage. For BFT systems, the steady-state floc size is an

2003). (CONTINUED ON PAGE 58)

W W W.WA S .O R G • W O R L D AQ UACU LT U R E • D E C E M B E R 2 012 59

important feature because food quality for different aquaculture by-product of biodiesel production (Dube et al. 2007).

species is partially dependent on particle size (Garatun-

Tjeldsto et al. 2006, Knights 1983). In the case of cod and Organic Loading Rate

Macrobrachium rosenbergii larvae, floc particle size should The rate of organic carbon loading is a major technical

range from 250 to 1200 µm (de Barros and Valenti 2003). process factor. Filamentous bacteria have an advantage over

non-filamentous bacteria at low substrate concentration because

Dissolved Oxygen Concentration of their greater surface-to-volume ratio. Moreover, filaments

Dissolved oxygen (DO) is essential for the metabolic can extend from the floc core into the bulk water and are

activity of cells within aerobic flocs. Flocs tend to be larger thus exposed to greater substrate concentrations than non-

and more compact at higher DO concentrations (Wilen and filamentous bacteria that grow mainly within flocs (Martins et

Balmer 1999), although there is no clear relation between DO al. 2003).

concentration and average floc diameter. At low DO levels (0.5- Organic carbon can be added in small amounts, almost

2.0 mg/L), flocs have poor settling properties, with a sludge continuously, or in larger doses at regular time intervals. The

volume index (SVI) of 250 mL/g. At higher DO levels (2.0-5.0 second approach is known as a “feast or famine” regime

mg/L), the SVI is about 100 (Salehizadeh and Van

mL/g. Bioflocs have the potential to be used as Loosdrecht 2004) and

More filamentous bacteria fish food with good nutritional quality. results in transient

than zoogloeal bacteria occur Biofloc technology can stimulate microbial conditions of substrate

at DO concentration less than development in BFT ponds that will lead to limitation. Microbial

or equal to 1.1 mg/L (Martins improved nutrient efficiency and reduced biomass stores cellular

et al. 2003). Filamentous need for dietary fishmeal and fish oil. Biofloc energy reserves, such as

bacteria have a greater affinity technology can improve the efficiency in the poly-β-hydroxybutyrate,

for oxygen than zoogleal use of nutrients from feed. Dried biofloc can under conditions of excess

bacteria and thus dominate the be used as a protein source in aquafeeds. nutrient availability,

floc during periods of low DO allowing microorganisms to

concentration (Martins et al. 2003). Bioflocs with a greater bridge periods of nutrient shortage.

SVI can be produced at lower DO levels in biofloc ponds. This Energy storage products may be of importance to the

gives the aquaculture organisms opportunity to filter flocs from added value that bioflocs bring to aquaculture. As such, it may

suspension before they fall to the sediment and are lost as food. not be advisable to apply organic carbon sources continuously if

However, floc with a higher SVI can cause clogging of fish the goal is to produce reserve materials.

gills.

Any organic carbon source added to biofloc ponds causes Temperature

a decrease in dissolved oxygen levels from aerobic microbial The parameters described above can be controlled

metabolism. To produce biofloc as food, it is advisable to grow in aquaculture systems. Temperature influences floc

the heterotrophic biomass in an external reactor rather than characteristics but is more difficult to control. Temperature is

within the culture unit itself. Externally grown flocs can be of major importance for microbial metabolism. The influence

redirected to the pond as food without inducing stress through of temperature on biofloc characteristics is complex. More

depressed DO levels. deflocculation of activated sludge flocs occurs in cold water (4

°C) than cool water (18-20 °C), probably related to decreased

Organic Carbon Source microbial activity within flocs (Wilen et al. 2000). At high

Organic carbon can be supplied 1) as an additional organic water temperature (30-35 °C), bulking of sludge (SVI ≥ 500

carbon source (e.g., glucose, acetate or glycerol) with high- mL/g) occurs from excessive production of EPS (Krishna and

protein feed, or 2) by reducing the protein content of feed, Van Loosdrecht 1999). At intermediate water temperature (20-

thereby increasing its organic carbon content (Avnimelech 25 °C), flocs are stable and have an an intermediate SVI (200

1999). The quantity of organic matter needed for an intensive mL/g).

pond can be calculated on the basis of the amount of nitrogen The water temperature in BFT ponds is not a factor that

excreted by the aquaculture species. can be easily adjusted without imposing considerable additional

The organic carbon source of choice will, to a large operating costs, especially in outdoor ponds. In most cases,

degree, determine the composition of flocs produced, mainly prevailing climatic conditions determine the operational

the type and amount of energy storage polymers (Hollender temperature.

et al. 2002, Oehmen et al. 2004). Considerations for carbon

source selection include local availability, cost, biodegradability Ecofriendly Approach of BFT

and efficiency of bacteria assimilation. The cost of different in Limited Water Aquaculture

organic carbon sources will be the main determining factor in Biofloc technology is step towards a more environmentally

making a choice (Salehizadeh and Van Loosdrecht 2004). With friendly aquaculture production system. The technology was

BFT systems, it is best to use organic carbon sources that are developed to create economic and environmental benefits by

considered low-value by-products, such as glycerol, which is a reducing water use, effluent discharges, artificial feed supply

60 D E C E M B E R 2 012 • W O R L D AQ UACU LT U R E • W W W.WA S .O R G

and improved biosecurity. Biofloc technology systems have high Liu, Y. and H. H. P. Fang. 2003. Influences of extracellular

efficiency, productivity, sustainability and lower FCR. By using polymeric substances (EPS) on flocculation, settling,

this novel technology, the blue revolution in aquatic systems and dewatering of activated sludge. Critical Reviews in

can be achieved in a sustainable manner. Biofloc technology Environmental Science and Technology 33:237-273.

increases pond productivity. A global effort is needed to Martins, A.M.P., J. J. Heijnen and M.C.M. van Loosdrecht.

optimize, integrate and disseminate this appropriate, emerging 2003. Effect of dissolved oxygen concentration on sludge

technology. settleability. Applied Microbiology and Biotechnology

62:586-593.

Mikkelsen, L.H., A. K. Gotfredsen, M. L. Agerbaek, P. H.

Notes Nielsen and K. Keiding. 1996. Effects of colloidal stability

1

Ph.D. Scholars, Central Institute of Fisheries Education, on clarification and dewatering of activated sludge. Water

Mumbai- 400 061. Science and Technology 34:449-457.

* Corresponding Author: vikas.phulia@gmail.com Mishra, J. K., T. M. Samocha, S. Patnaik, M. Speed, R. L.

Gandy and A. Ali. 2008. Performance of an intensive

nursery system for the Pacific white shrimp, Litopenaeus

References vannamei, under limited discharge condition. Aquacultural

Avnimelech, Y. 1999. Carbon/nitrogen ratio as a control element Engineering 38:2-15.

in aquaculture systems. Aquaculture 176:227-235. Oehmen, A., Z.Yuan, L.L. Blackall and J. Keller. 2004.

Boyd, C. E. 1998. Pond water aeration systems. Aquacultural Short-term effects of carbon source on the competition

Engineering 18:9-40. of polyphosphate accumulating organisms and glycogen

Chaignon, V., B. S. Lartiges, A. El Samrani and C. Mustin. accumulating organisms. Water Science and Technology

2002. Evolution of size distribution and transfer of mineral 50:139-144.

particles between flocs in activated sludges: an insight into Salehizadeh, H. and M. C. M. Van Loosdrecht. 2004.

floc exchange dynamics. Water Research 36:676-684. Production of polyhydroxyalkanoates by mixed culture:

Chu, C. P. and D. J. Lee. 2004. Multiscale structures of recent trends and biotechnological importance. Biotechnology

biological flocs. Chemical Engineering Science 59:1875-1883. Advances 22:261-279.

Colt, J., 2006. Water quality requirements for reuse systems. Schneider, O., V. Sereti, E. H. Eding and J. A. J. Verreth. 2005.

Aquacultural Engineering 34:143-156. Analysis of nutrient flows in integrated intensive aquaculture

de Barros, H.P. and W.C. Valenti. 2003. Food intake of systems. Aquacultural Engineering 32:379-401.

Macrobrachium rosenbergii during larval development. Sears, K., Alleman, J.E., Barnard, J.L. and J.A. Oleszkiewicz,

Aquaculture 216:165-176. J.A., 2006. Density and activity characterization of activated

Dube, M.A., A.Y. Tremblay and J. Liu. 2007. Biodiesel sludge flocs. Journal of Environment Engineering.-ASCE

production using a membrane reactor. Bioresource 132:1235-1242.

Technology 98:639-647. Spicer, P. T. and S. E. Pratsinis. 1996. Shear-induced

Garatun-Tjeldsto, O., H. Ottera, K. Julshamn and E. Austreng. flocculation: the evolution of floc structure and the shape of

2006. Food ingestion in juvenile cod estimated by inert the size distribution at steady state. Water Research 30:1049-

lanthanide markers — effects of food particle size. ICES 1056.

Journal of Marine Science 63:311-319. Steiner, A. E., D. A. McLaren and , C. F. Forster. 1976. Nature

Hantula, J. and D.H. Bamford. 1991. The efficiency of the of activated-sludge flocs. Water Research 10:25-30.

protein-dependent flocculation of Flavobacterium sp. is Subasinghe, R. P. 2005. Epidemiological approach to aquatic

sensitive to the composition of growth-medium. Applied animal health management: opportunities and challenges for

Microbiology and Biotechnology 36:100-104. developing countries to increase aquatic production through

Hollender, J., D. van der Krol, L. Kornberger, E. Gierden and W. aquaculture. Preventive Veterinary Medicine 67:117-124.

Dott. 2002. Effect of different carbon sources on the enhanced Wilen, B. M. and P. Balmer. 1999. The effect of dissolved

biological phosphorus removal in a sequencing batch reactor. oxygen concentration on the structure, size and size

World Journal of Microbiology and Biotechnology 18:355- distribution of activated sludge flocs. Water Research 33:391-

360. 400.

Jorand, F., F. Zartarian, F. Thomas, J. C. Block, J. Y.Bottero, Wilen, B. M., B. Jin and P. Lant. 2003. The influence of key

G. Villemin, V. Urbain and J. Manem.1995. Chemical and chemical constituents in activated sludge on surface and

structural (2d) linkage between bacteria within activated- flocculating properties. Water Research 37:2127-2139.

sludge flocs. Water Research 29:1639-1647. Wilen, B. M., J. L. Nielsen, K. Keiding and P. H. Nielsen. 2000.

Knights, B. 1983. Food particle-size preferences and feeding– Influence of microbial activity on the stability of activated

behavior in warmwater aquaculture of European eel, Anguilla sludge flocs. Colloids and Surfaces B: 18:145-156.

anguilla (L). Aquaculture 30:173-190. Zita, A. and , M. Hermansson. 1994. Effects of ionic-

Krishna, C., M.C.M. van Loosdrecht. 1999. Effect of strength on bacterial adhesion and stability of flocs in a

temperature on storage polymers and settleability of activated wastewater activated-sludge system. Applied Environmental

sludge. Water Research 33:2374-2382. Microbiology 60:3041-3048.

W W W.WA S .O R G • W O R L D AQ UACU LT U R E • D E C E M B E R 2 012 61

You might also like

- Handbook of Technology Management - GaynorDocument355 pagesHandbook of Technology Management - GaynorParth100% (6)

- OSA - Century of OpticsDocument365 pagesOSA - Century of Opticsluisacp5343No ratings yet

- Biofloc - A Technical Alternative For Culturing Malaysian PrawnDocument18 pagesBiofloc - A Technical Alternative For Culturing Malaysian PrawnclaudiousdecastroNo ratings yet

- No. M.1642/COLREG 1: The Merchant Shipping (Distress Signals and Prevention of Collisions) Regulations 1996Document32 pagesNo. M.1642/COLREG 1: The Merchant Shipping (Distress Signals and Prevention of Collisions) Regulations 1996Polaris BridgemanNo ratings yet

- Scenario (Business Area) : Business Process: : Functional SpecificationDocument21 pagesScenario (Business Area) : Business Process: : Functional SpecificationsapeinsNo ratings yet

- BIO FLOC TECHNOLOGY For Sustainable AquacultureDocument19 pagesBIO FLOC TECHNOLOGY For Sustainable AquacultureRabia HaiderNo ratings yet

- Presentation1 BioflocDocument9 pagesPresentation1 BioflocsjahrierNo ratings yet

- Nutritional Importance For Aquaculture A PDFDocument9 pagesNutritional Importance For Aquaculture A PDFM RajasekaranNo ratings yet

- Biofloc Technology For Sustainable Aquaculture ProductionDocument4 pagesBiofloc Technology For Sustainable Aquaculture ProductionMayar HatemNo ratings yet

- Bio Oc Systems in Aquaculture Bio Oc Systems: A Technological Breakthrough in AquacultureDocument6 pagesBio Oc Systems in Aquaculture Bio Oc Systems: A Technological Breakthrough in AquacultureVipinNo ratings yet

- Biofloc Technology (BFT) and Its ApplicationDocument5 pagesBiofloc Technology (BFT) and Its ApplicationrobiyullahNo ratings yet

- The Effect of Biofloc With The Additon of Different Commercial Probiotics in CathfishocxDocument9 pagesThe Effect of Biofloc With The Additon of Different Commercial Probiotics in CathfishocxADRY GHULAM DARMAWANNo ratings yet

- Bio Oc Systems in Aquaculture Bio Oc Systems: A Technological Breakthrough in AquacultureDocument6 pagesBio Oc Systems in Aquaculture Bio Oc Systems: A Technological Breakthrough in Aquaculturejamal sanadNo ratings yet

- Articulo1bioflocvol 12012inglesDocument6 pagesArticulo1bioflocvol 12012ingleselbahhatiNo ratings yet

- Biofloc Production Systems For Aquaculture: S R A CDocument12 pagesBiofloc Production Systems For Aquaculture: S R A CAnoman Obong100% (1)

- Biofloc-Good SRAC Publication 4503Document12 pagesBiofloc-Good SRAC Publication 4503Dr-Raju Ahmed100% (1)

- Biofloc Technology For Sustainable Aquaculture ProductionDocument4 pagesBiofloc Technology For Sustainable Aquaculture ProductionMuhammad ImamNo ratings yet

- Sistemas Biofloc Un Avance Tecnologico eDocument5 pagesSistemas Biofloc Un Avance Tecnologico eJuan José Bonilla ReinosoNo ratings yet

- Aquaculture Fish Fisheries - 2023 - McCuskerDocument22 pagesAquaculture Fish Fisheries - 2023 - McCuskerIbnu MustofaNo ratings yet

- Biofloc Technology An Emerging Tool For Aquacultur PDFDocument5 pagesBiofloc Technology An Emerging Tool For Aquacultur PDFMd SattarNo ratings yet

- Biofloc SystemDocument12 pagesBiofloc SystemPeter YoungNo ratings yet

- Biofloc TechnologyDocument53 pagesBiofloc Technologyjact_1100% (8)

- Bioremediation: Eco Technology of Cultured Water Using Efficient Microbes (ECO Microbes)Document6 pagesBioremediation: Eco Technology of Cultured Water Using Efficient Microbes (ECO Microbes)NehaNo ratings yet

- Flocharvesting AquacultureDocument10 pagesFlocharvesting AquacultureLizbeth Zuta PinedoNo ratings yet

- Microorganisms 10 02069 v2Document20 pagesMicroorganisms 10 02069 v2Austeridad LopezNo ratings yet

- Ray Etal 2010 Microbes and Solids Management FINALDocument10 pagesRay Etal 2010 Microbes and Solids Management FINALBenjamin BarcelóNo ratings yet

- 2006 Bioremediation - in - Shrimp - Culture - SystemsDocument6 pages2006 Bioremediation - in - Shrimp - Culture - SystemsChristian LeonNo ratings yet

- Aquaculture: SciencedirectDocument11 pagesAquaculture: SciencedirectJeisson OmarNo ratings yet

- Use of Bioflocs in Shrimp Farming: July 2014Document6 pagesUse of Bioflocs in Shrimp Farming: July 2014Kresimir Sedak-BencicNo ratings yet

- De Godos Et Al.. 2011. Coagulationflocculation-Based Removal of Algal-Bacterial Biomass From Piggery Wastewater TreatmentDocument5 pagesDe Godos Et Al.. 2011. Coagulationflocculation-Based Removal of Algal-Bacterial Biomass From Piggery Wastewater TreatmentAzb 711No ratings yet

- Kultur FitoplanktonDocument9 pagesKultur FitoplanktoniqyuwidyaNo ratings yet

- Pathogens 11 00932Document13 pagesPathogens 11 00932Daniel ImanuelNo ratings yet

- Fishes 08 00163 v2Document16 pagesFishes 08 00163 v2sissokoabdoulkarim11No ratings yet

- Biofloc Technology A Review On The Microbial Interactions, Operational Parameters and Implications To Disease and Health Management of Cultured Aquatic AnimalsDocument18 pagesBiofloc Technology A Review On The Microbial Interactions, Operational Parameters and Implications To Disease and Health Management of Cultured Aquatic AnimalsMarylene PaivaNo ratings yet

- Culture of Rotifer With CommentsDocument20 pagesCulture of Rotifer With CommentsJerick Christian P Dagdagan0% (1)

- Ghonimy 2023-3Document12 pagesGhonimy 2023-3AbdallahNo ratings yet

- Grupo 6. Enrichen RotifersDocument5 pagesGrupo 6. Enrichen RotifersJordan IsmaelNo ratings yet

- DSDSDSDDocument20 pagesDSDSDSDecobuckNo ratings yet

- Microorganisms in Biofloc Aquaculture SystemDocument17 pagesMicroorganisms in Biofloc Aquaculture SystemMarylene PaivaNo ratings yet

- BosevikatugunegofepalDocument3 pagesBosevikatugunegofepalFaisal RehmanNo ratings yet

- Meiobenthos PDFDocument13 pagesMeiobenthos PDFMilagritos Gianelly Sanchez ZarateNo ratings yet

- Biofloc Technology - An Overview and Its Application in Animal Food IndustryDocument20 pagesBiofloc Technology - An Overview and Its Application in Animal Food IndustryrobiyullahNo ratings yet

- Microalge For AquacultureDocument10 pagesMicroalge For AquacultureJosue GarciaNo ratings yet

- Ajarat New ProjectDocument40 pagesAjarat New ProjectTemidayoNo ratings yet

- Microalgae - A Sustainable Feed Source For AquacultureDocument11 pagesMicroalgae - A Sustainable Feed Source For AquacultureFaisal SetiawanNo ratings yet

- Biofloc Farming Technology Agriculture - Lyst3582Document8 pagesBiofloc Farming Technology Agriculture - Lyst3582venshmasuslaNo ratings yet

- Aquaculture: Penaeus Vannamei NurseryDocument10 pagesAquaculture: Penaeus Vannamei NurseryAldy KiatNo ratings yet

- Aquaculture 524 (2020) 735277Document11 pagesAquaculture 524 (2020) 735277Jeisson OmarNo ratings yet

- A Practical Experience at A Shrimp Nursery System in Vietnam - Aqua Culture AsiaDocument6 pagesA Practical Experience at A Shrimp Nursery System in Vietnam - Aqua Culture AsiaSandeep SinghNo ratings yet

- Effect of Different Total Suspended Solids Levels On A Litopenaeus Vannamei (Boone, 1931) BFT Culture System During Biofloc FormationDocument10 pagesEffect of Different Total Suspended Solids Levels On A Litopenaeus Vannamei (Boone, 1931) BFT Culture System During Biofloc FormationRogerioportelaNo ratings yet

- Muller 2014Document8 pagesMuller 2014Maria MaghdalenaNo ratings yet

- 14.Applied-BioPlastic A Better-Mukti GilDocument6 pages14.Applied-BioPlastic A Better-Mukti GilImpact JournalsNo ratings yet

- Microalgal Drying and Cell Disruption - Recent AdvancesDocument9 pagesMicroalgal Drying and Cell Disruption - Recent AdvancesJuan Diego CárdenasNo ratings yet

- BFT An Emerging Avenue in Aquatic Animal Healthcare and NutritionDocument12 pagesBFT An Emerging Avenue in Aquatic Animal Healthcare and NutritionMarylene PaivaNo ratings yet

- 2021Document20 pages2021Yousaf JamalNo ratings yet

- Treated Effluent DisposalDocument5 pagesTreated Effluent DisposalvipinNo ratings yet

- Tilapia Production Using Biofloc Technology (BFT) : Agyoram@Technion - Ac.IlDocument4 pagesTilapia Production Using Biofloc Technology (BFT) : Agyoram@Technion - Ac.IlqaiserNo ratings yet

- Tz-Mass CultivationDocument11 pagesTz-Mass CultivationLuis EspinozaNo ratings yet

- 321 Bio Preservation of FishDocument8 pages321 Bio Preservation of Fisholy mishraNo ratings yet

- Vertical Substrates in BioflocDocument6 pagesVertical Substrates in Bioflocanonymous manNo ratings yet

- J Ecoleng 2017 03 009Document8 pagesJ Ecoleng 2017 03 009laraib fatimaNo ratings yet

- A Compilation of Ligno-Cellulose Feedstock and Related Research for Feed, Food and EnergyFrom EverandA Compilation of Ligno-Cellulose Feedstock and Related Research for Feed, Food and EnergyNo ratings yet

- Biogas Production: Pretreatment Methods in Anaerobic DigestionFrom EverandBiogas Production: Pretreatment Methods in Anaerobic DigestionNo ratings yet

- Aquaponics system, fish. Volume 1: Sistemas de acuaponíaFrom EverandAquaponics system, fish. Volume 1: Sistemas de acuaponíaNo ratings yet

- Municipality of Paniqui Term PaperDocument23 pagesMunicipality of Paniqui Term PaperNhevia de GuzmanNo ratings yet

- Tiger Barbs PDFDocument14 pagesTiger Barbs PDFamitdesai1508No ratings yet

- Basic 2 Workbook Unit 6Document6 pagesBasic 2 Workbook Unit 6Libnim GarciaNo ratings yet

- Action Plan in Science Jaja VersionDocument4 pagesAction Plan in Science Jaja VersionJaja Carlina100% (1)

- Catalogo Bulldog Jgo Empacaduras Maquinas+Motores Todo en UnoDocument78 pagesCatalogo Bulldog Jgo Empacaduras Maquinas+Motores Todo en UnoAlexis SanchezNo ratings yet

- Is A Term Which Means Computer Aided Design Computer Aided ManufacturingDocument50 pagesIs A Term Which Means Computer Aided Design Computer Aided ManufacturingDarbhalaPavanKumarNo ratings yet

- Block and Bleed 2-Valve Manifolds - V02 Series: Data SheetDocument2 pagesBlock and Bleed 2-Valve Manifolds - V02 Series: Data SheetedwinsazzzNo ratings yet

- Mini Flow Channel ExperimentDocument9 pagesMini Flow Channel Experimentpotato92No ratings yet

- ZvsDocument22 pagesZvsgopalchandramahatoNo ratings yet

- TaskList 1stclassDocument18 pagesTaskList 1stclassMob KingsNo ratings yet

- Action Plan For Science Month CelebrationDocument3 pagesAction Plan For Science Month CelebrationRoilan Marlang100% (2)

- Faculty Mentor: Dr. PRABIR Jana Mr. Deepak Panghal Industry Mentor: Mr. UDAY N B (Sales & Technical Manager)Document2 pagesFaculty Mentor: Dr. PRABIR Jana Mr. Deepak Panghal Industry Mentor: Mr. UDAY N B (Sales & Technical Manager)Varun MehrotraNo ratings yet

- Shivam 5555@yahoo Dotco DotinDocument3 pagesShivam 5555@yahoo Dotco DotinsupriyaNo ratings yet

- Difference Between OSI and TCPIP ModelsDocument2 pagesDifference Between OSI and TCPIP ModelsSami khan orakzai83% (6)

- Handbook of Spectrum Monitoring 2011Document678 pagesHandbook of Spectrum Monitoring 2011haripost100% (1)

- Electric Charges and Fields MCQ Class 12 Physics Chapter 1Document8 pagesElectric Charges and Fields MCQ Class 12 Physics Chapter 1suousNo ratings yet

- Trafo Oil Testing TypesDocument10 pagesTrafo Oil Testing TypesShrikanth SolaNo ratings yet

- Mucoadhesive DDS - 1749098145Document14 pagesMucoadhesive DDS - 1749098145Vaibhav ThoratNo ratings yet

- FullPaperPublishedine Book OnlineLearningDocument13 pagesFullPaperPublishedine Book OnlineLearningALIF FITRI BIN MOHD JASMINo ratings yet

- I Had A Farm in Africa PDFDocument4 pagesI Had A Farm in Africa PDFAlberto de la FuenteNo ratings yet

- Results For Sai Teja Traders - Rajahmundry - ZonalinfoDocument4 pagesResults For Sai Teja Traders - Rajahmundry - ZonalinfoManoj Digi LoansNo ratings yet

- Alcohol, Phenols and Ether NotesDocument23 pagesAlcohol, Phenols and Ether NotesArshad KhanNo ratings yet

- Written Digests105 124Document845 pagesWritten Digests105 124Hoven MacasinagNo ratings yet

- Public Health ResearchDocument124 pagesPublic Health ResearchAsmitNo ratings yet

- Physician-Induced Demand: EM Johnson, Massachusetts Institute of Technology, Cambridge, MA, USADocument6 pagesPhysician-Induced Demand: EM Johnson, Massachusetts Institute of Technology, Cambridge, MA, USAAnonymous mDkBoIyhjlNo ratings yet

- Dari SiniDocument7 pagesDari SinidindasaviraNo ratings yet